We begin this chapter where we finished chapter 2, with rifled muskets in the middle of the nineteenth century, and will progress from these strange hybrid shoulder-fired weapons to their modern equivalent: assault rifles. In parallel, we will look at the development of ordnance over the same period. The reason for pausing at this particular time in history (around 1850) is because the succeeding half century saw the greatest changes and the most rapid advances in firearms technology—more rapid than any period before or since. You can readily appreciate this surge in weapons construction and capability (which ultimately was due to the Industrial Revolution) by considering the state of firearms at the beginning of the nineteenth century, and the beginning of the twentieth. In 1800 small arms and ordnance consisted mostly of smoothbore muzzle loaders firing spherical ball projectiles propelled by black powder. By 1900 we had automatic weapons firing metal-jacketed cartridges propelled by smokeless powder.

Since then, developments have been significant but more incremental, less revolutionary. Metallurgy and propellant chemistry have led to improvements in the muzzle velocities and ranges of firearms. Twentieth-century refinements in design have led to increased calibers and rates of fire—important improvements, but nothing like the unprecedented leap forward that occurred during the five decades between 1850 and 1900. The twenty-first century may well produce another surge in firearm development, though one that is less closely related to our subject of ballistics: computer processing and remote sensing technology will revolutionize (are already revolutionizing) the long-range accuracy of missiles.

The internal ballistics of firearms changed apace with the technological advances. We can see why, and how, by going back to the mid-nineteenth century and tracing the main developments.

In 1853 the Enfield rifled musket was introduced in Britain; two years later the Springfield rifled musket appeared in America. Both these weapons would be produced in massive numbers, and both would evolve over the course of their distinguished careers. They existed because in 1849 Claude Minié in France made the crucial breakthrough in bullet design that spelled the end for smoothbore muskets. Yet rifled muskets were stopgap, transitional weapons. The writing on the wall, pointing to the future, occurred at exactly the same time. In 1853 Christian Sharps, in America, produced his famous breech-loading rifle (actually a percussion carbine).1

The Enfield rifled musket was used by the British during the Crimean War (1854–56), where it is said to have given British soldiers a great advantage over their Russian opponents, and again in the massive Indian Mutiny of 1857. The Springfield was the standard weapon of the American Civil War: over 1½ million were used (and half a million imported En-fields; they were almost the same caliber and so could use the same ammunition). Rifled muskets had a slower rate of fire than smoothbore muskets but were much more accurate and were effective out to a much greater range (over 250 yards in the case of an 1855 Springfield, compared with about 75 yards against an individual target for a late-model smoothbore musket). There are two reasons for the difference in performance: rifled barrels and Minié bullets.2

Rifling refers to the helical grooves cut along the inside surface of the barrel. (Some technical aspects of rifling are discussed in technical note 9.) Known in Europe from the sixteenth century but little used for 400 years, for reasons that will soon become clear, rifled small arms were probably developed as a response to the fouling of barrels that resulted from burning black powder. Recall that half the chemical products of black powder deflagration are solid; some of this solid material would, after a number of firings, gum up the barrel. Rifling provided a place for the gunk to accumulate, so that muzzle loading and projectile speed would not be compromised too badly. That was the theory. Why do we think this is the original motivation for rifled gun barrels? Several early small arm weapons have been found with straight rifling—no twist. It was soon discovered that twisted rifling made the firearm more accurate; we now know that this is due to gyroscopic stabilization (which I will discuss in chapter 5). Beginning in the eighteenth century, some rifled muskets were produced and used in warfare,3 but there were always fewer of these than of smoothbore muskets until the 1850s.

To work properly, so that it develops a spin as it accelerates down the barrel, a musket ball must grab the rifling grooves—and so the ball must fit snugly. This made muzzle-loading a pain because the ball had to be rammed down the barrel. (Ramming also tended to compromise the improved accuracy somewhat by distorting the soft lead ball, making it fly erratically.) So, as I have already noted, the rate of fire of rifled muskets was less than that of smoothbore muskets even though their effective range was greater because of the tight seal—no windage. On an eighteenth-century battlefield with ranks of closely packed infantry, the inaccuracy of smoothbore guns was not so important; similarly, the vast amount of smoke generated by musket volleys meant that the rifled musket’s longer range was not much of an advantage. Thus, in the eighteenth and early nineteenth centuries rifled muskets were relegated to use by hunters and skirmishers.4 The main business of battle was conducted with smoothbore weapons.

All that changed with the Minié bullet. The end result of a series of developments from about 1825, mostly in France, the Minié bullet was shaped like a modern bullet (called at the time a “cylindro-conoidal ball”) not like the spherical musket ball. The bullet’s diameter was less than the caliber of the rifled musket for which it was designed, and yet there was no loss of power due to windage. This was because the back end of the Minié bullet was hollowed out, so that the gas pressure produced by deflagrating powder would cause the end of the bullet to expand, grabbing the rifling and sealing the barrel. This new bullet design solved all the problems of muzzle-loaded rifled small arms: easy loading because the bullet diameter was less than the caliber and no compromising of accuracy from distorted bullet shape because the bullet did not need to be rammed into the barrel. Furthermore, the bullet shape is more aerodynamic than that of a musket ball; for this reason, as well as the elimination of windage, rifled musket ranges improved.

Add to the improved range and accuracy an improved ignition system—caplock instead of flintlock—and you have the difference between a Napoleonic musket such as the Brown Bess and a Civil War rifled musket such as the 1855 Springfield.5 The increased range and accuracy of these small arms changed warfare. Thus, to give one small example, colorful uniforms disappeared, to be replaced by cryptically colored gear that rendered a distant soldier less visible.6

Artillery development lagged behind small arms development by several decades, for reasons we will soon see, and so the American Civil War was dominated by the rifled musket. This new weapon changed the tactics that were required for victory on the field of battle: no longer could massed ranks of infantry advance in formation over open ground. Civil War commanders were slow to realize that the new technology was changing the face of war, and so casualties were high. This factor—that tactical developments lagged technological ones—would culminate in the slaughter of World War I, fought at a time when artillery (but not military thinking) had absorbed the new developments.

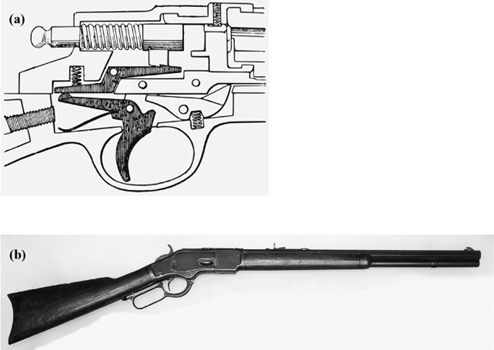

Just a few years separated the American Civil War from the Franco-Prussian War (1870–71). This war was also dominated by small arms and was also very bloody. The small arms, however, were no longer rifled muskets but were instead breech-loading rifles. Better manufacturing techniques (in which quality-controlled factory production replaced older craft traditions) and new rotating bolt action breechblocks (fig. 3.1a) produced an effective seal that eliminated the old problem of propellant gas leaking from breeches. The Sharps rifle, appearing at the end of the U.S. Civil War, was a single-shot breech loading rifle, but the French Chasse-pots and the less robust Prussian “needle guns” were repeating rifles, and these cut swathes through enemy infantry. The new technology that led to repeaters took the form of metal cartridges and a spring-loaded magazine to hold them.

Figure 3.1. Rifle action. (a) Schematic of a bolt-action weapon. Taken from an illustration in Encyclopédie Larousse Illustré of 1897. (b) Winchester model 1873 lever-action short rifle. In this repeater rifle with a tube magazine in the stock, the trigger guard pulls down and forward to eject a spent cartridge case and load a new round. Photo by Bob Adams (www.adamsguns.com).

Earlier cartridges consisted of a paper wad containing powder and ball—the cap was separate. A soldier loading his rifled musket would bite the end off the cartridge; pour the black powder down the barrel, followed by paper and ball or Minié bullet (the paper wadding acted as a seal, reducing ball windage somewhat); place a percussion cap under the cocked hammer (later replaced by paper tape caps); and then aim and fire, achieving perhaps three shots per minute. The new metal cartridges contained powder, bullet, and primer. A lever action (see fig. 3.1b) loaded a cartridge into the chamber; releasing the trigger caused a firing pin to strike the cartridge base, thus igniting the primer, which, in turn, set off the powder. The highly successful American Spencer repeating rifle of this period, and the Henry, could fire 20 rounds a minute. Pulling the lever down and forward ejected the spent case; pulling it back into place injected a fresh cartridge into the chamber—and no need to take your eye off the target. The British Martini-Henry rifle of 1871 had a similar lever action and was accurate up to 600 yards.

Handguns also were revolutionized by metal cartridge rounds. A revolving magazine to store six of them gave rise to the revolver—the “six-shooter” beloved of Western fans. A Colt invention—the “crane” that is used to swing out an empty magazine cylinder—made these weapons quick to load. Adam and Beaumont in England developed the double action revolver; readily taken up by Colt and by Smith and Wesson, this development made revolvers quick to fire and to load. A double action mechanism provides the shooter with a choice. For rapid fire he can repeatedly pull the trigger, which cocks and fires the gun, ejects the spent cartridge and loads the next round, all from the same trigger pull. This pull was heavy, and so aiming was not easy, but if you need rapid fire at close range (say you are involved in a gunfight at the OK Corral), then this is the option you choose. For greater accuracy you pull back the hammer with your thumb to cock the weapon before pulling the trigger.

The 1880s brought another key development: after half a millennium, black powder was replaced by a new propellant that became known as smokeless powder. Guncotton (made by soaking cotton in concentrated nitric acid) had been invented in the 1840s but proved to be unsuitable as a propellant; however, improvements by Paul Vieille in France led in 1884 to his Poudre B, which was revolutionary.7 When ignited, each gram of this new powder rapidly produced about a liter of gas, making it three times as powerful as the old black powder. Furthermore, because it converted almost all of its mass into gas, there were fewer solid products of burning, which meant less fouling of the gun barrel and—importantly for military purposes—much less smoke. Hence the name.

Hard on the arrival of smokeless powder, the French army introduced the Lebel rifle (1886), the first to take advantage of the new propellant. This rifle was in service for three decades, and nearly three million were made. Its 8 mm bullet left the barrel at a muzzle speed of 2,300 ft/s (700 m/s) which yielded a maximum range of 4,500 yards (4.1 km). Note the small caliber: 8 mm is 0.315 inches—much less than the 0.577 inches typical of rifled muskets (which is, in turn, less than the 0.75 inch caliber of most smoothbore muskets). Stronger propellants meant less powder per charge, and so smaller calibers resulted. Two immediate consequences for the infantry soldier: his firearm was lighter, and he could carry more ammunition.

Within a couple of years of Vieille’s invention came two more smokeless powders—ballistite and cordite, both developed in Great Britain. These proved safer to handle than Poudre B (which became unstable when stored for long periods). A key component of smokeless powders is nitroglycerine, an explosive that forms up to 50% of smokeless powder. (Smokeless powder containing pure nitrocellulose, derived from guncotton, is called single-base powder; nitrocellulose plus nitroglycerin produces double-base powders.) Other additives ensured that smokeless powders were stable and were readily formed into granules of desired shape. The old idea of corned black powder still applies to these new gunpowder formulations: they burn from the surface, and so grain shape and size determine burn rate, which, as we have seen, greatly influences muzzle speed. In fact, because smokeless powder was a chemical rather than a physical mixture of different particles, it was more easily molded into granules of the desired shape and size, with reliable burning characteristics.

In technical note 10, I demonstrate how different granule shapes lead to different rates of generating propellant gas. These different rates are suitable for different gun barrel lengths. As for black powder, the finer, faster burning gunpowder formulations are more suitable for short-barreled firearms such as handguns. Weapons with longer barrels benefit from slower burning gunpowder. There is a limit, of course, to how slow a powder should burn: too slow and it won’t work at all; slower than optimum and the bullet leaves the barrel before all the powder is burned, reducing powder efficiency.

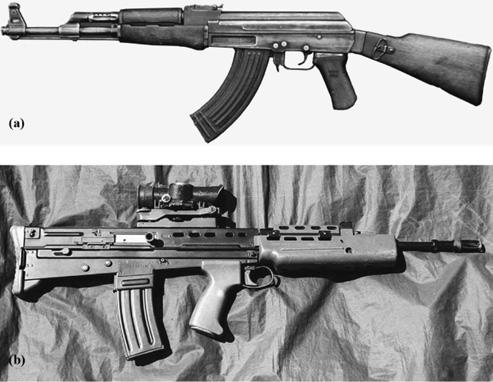

Two “fields”—the Springfield and the Enfield—are the subject of this section. In particular, we will see why they changed the nature of war by looking at how they influenced tactics during the American Civil War.

Figure 3.2. An Enfield (top) and a Springfield 63 caplock rifle (bottom). Springfields were the most common firerarm in the American Civil War, and Enfields were second most common. Image adapted from a photo by Mike Cumpston.

These two weapons (shown in fig. 3.2) had more similarities than differences even though they originated in different parts of the world. Their similarity is a technological example of what biologists call “convergent evolution,” in which species adapt to best suit their environments. For example, sharks and porpoises resemble one another because they share the same oceanic environment, though they evolved from very different ancestors. The arms needs of the Americans and the British in the mid-nineteenth century were different, their armies and soldiers were different, and their arms production facilities were quite independent of one another—yet, when both were presented with the Minié ball and had to produce a rifle to fire it, they came up with very similar weapons.

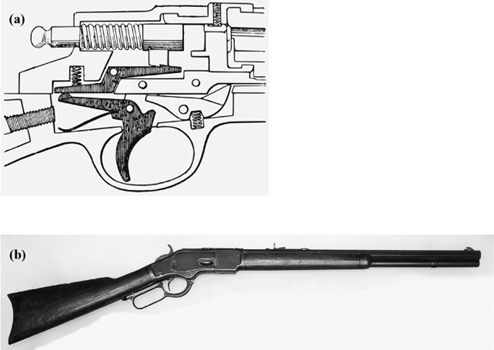

The Springfield Armory, in Massachusetts, made over 1.5 million rifled muskets of all types—about the same as the number of Enfields made. The most common weapon of the Civil War was the Springfield Model 1861 (about 700,000), followed by the Pattern 1853 Enfield (about 500,000). As you can see from table 3.1, the two weapons were quite similar, and they were also comparable in field performance, though some officers were biased against the Enfield. Each had an effective range of 200–300 yards; this range was determined more by the limited training of Civil War soldiers than by the weapons’ inherent capabilities.8 The rate of fire in both cases was about three shots per minute, and they could fix the same bayonet. The primer systems were a little different (varieties of caplock); the Enfield’s rear sight was more finely adjustable; the Springfield may have been a little more robust.

Table 3.1. Comparison of Springfield and Enfield rifles

How did the rifled musket—of either type—influence the Civil War? D. H. Mahan, a key military thinker in the United States before the war, suggested that tactics needed to change to address the improved accuracy and range of rifled muskets over the older smoothbore muskets—but standard military procedures were slow to change. An army manual at the time suggested that the only necessary infantry adaptation was faster deployment. It is generally argued that the old-fashioned tactics of frontal assault by close-packed infantry formations combined with the much-increased effectiveness of rifled muskets to produce the horrendous casualties of the Civil War.

This view has recently been challenged, at least in part, following a careful consideration of the poor training and lack of professionalism of the raw recruits who were swept into the armies of both combatants in large numbers. In this view, much of the superiority of the rifled muskets was wasted: most shots went over the heads of the intended targets because troops did not use the sights properly, and the long effective range was compromised by poor visibility much of the time. Only the more seasoned troops—which included many of the skirmishers—fully exploited the rifled muskets’ capabilities.9

The effectiveness of the new weapons was felt enough, however, to cause tactics to change over time. Infantry formations loosened up, with infantrymen going into battle more like skirmishers. Artillery pulled back behind the infantry (gun crews and horses made large targets that could be hit from half a mile away). Cavalry did not form into a dense mass and charge infantry across open ground, as they had during the Napoleonic Wars. Indeed, both artillery and cavalry were relegated to subordinate roles during the Civil War; infantry dominated the battlefields. The war became defensive, as frontal assaults were very costly and often failed.10

From repeating rifles and double-action revolvers, it is a short step to automatic weapons. Clever means of harnessing the recoil energy, or the energy remaining in propellant gas after a bullet had left the barrel, were adopted to mechanize the loading and firing process. A spent cartridge case could be ejected, and a new one loaded into the breech and fired, with increasing rapidity. The first attempt at such a “machine” gun was the Belgian Mitrailleuse, a heavy, multibarreled beast with an ammunition rack that loaded all the barrels together. The barrels were fired by the gunner rotating a lever—so this weapon was not really automatic, though a skilled gunner could get off 100 rounds a minute. Ten years later, in 1861, Richard Gatling invented a multibarreled gun that proved more successful. Gatling’s weapon also had a hand crank, but this was used to rotate the six barrels, not the firing mechanism. The Gatling gun, popular with the U.S. Army for decades, could fire 200 rounds per minute. Why did both these weapons have multiple barrels? Because of the rapid rate of fire a single barrel would overheat; multiple barrels would spread the heat and allow a given barrel time to cool down between shots.

Figure 3.3. A British Royal Navy Maxim gun in operation. Note the water jacket around the barrel, and the ammunition belt. Image from Wikipedia.

The first true self-actuated machine gun was the 1883 weapon of Hiram Maxim (fig. 3.3).11 Using recoil energy to reload, the Maxim gun could fire 600 rounds per minute, with the trigger held down. Its single barrel was cooled using a novel water-filled jacket (the water would boil unless replaced frequently). Machine guns developed rapidly between the 1880s and World War I, setting the stage for the carnage of that epochal event. Once again, weapons technology advanced faster than military thinking. The French, who quickly took up the Mitrailleuse for their war against Prussia in 1870–71, were slow to understand its potential and so did not benefit from their advantage. (The Prussians had no such weapon.) By World War I both sides appreciated the machine gun’s potential but were slow to develop tactics to counter these automatic weapons.

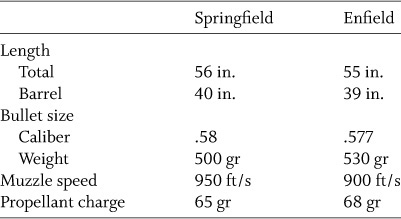

Figure 3.4. (a) Soviet 7.62×39 mm AK-47 assault rifle. U.S. Government image. Photographer: Cpl. D. A. Haynes. (b) A British SA-80 L85A bullpup rifle, with a 20-inch barrel and a SUSAT 4× optical sight. U.S. Army photo.

By the 1890s, all the key components of true automatic firing were understood. The new technology allowed European powers and America to expand the territory under their control, against preindustrialized peoples. As the Anglo-French writer Hilaire Belloc wrote at the end of the nineteenth century, “Whatever happens we have got / the Maxim gun and they have not.”

So-called semiautomatic pistols were invented by Hugo Schmeisser in Germany in 1916. The trigger was pulled for each round fired, but the hammer did not need to be cocked each time. Thus, semiautomatic pistols were functionally similar to double-action revolvers, with the big difference that the action was powered by recoil and gas pressure instead of by the trigger finger. The mechanism adopted—called blowback—was suitable for rapid firing of short-range weapons with pistol ammunition. Similar mechanisms were used for later machine pistols, such as the German MP38 and MP40 (iconic machine pistols of World War II), the Thompson (Tommy) gun, the Russian PPSH41 with its round magazine, and the mass-produced British Sten gun.

World War II saw the introduction of the StG machine gun, a fully automatic hand-held firearm notable as the ancestor of the modern assault rifle. Assault rifles have selective fire capability: the shooter can choose to fire a single shot or a burst. Sacrificing the range of a traditional rifle for the rapid fire of a machine gun, the early versions fired pistol rounds. The most famous assault rifle is the AK-47—the Automatic Kalashnikov first introduced in 1947 (fig. 3.4a). This is the world’s most popular firearm: somewhere between 30 million and 100 million have been produced. Another iconic assault rifle is Colt’s M16; perhaps always in the AK-47’s shadow, this American weapon has lasted over 40 years and exists in many versions. The most recent assault rifles, dating from the mid-1980s, adopt the bullpup configuration, with magazine and firing mechanism behind the trigger (see fig. 3.4b). Because bullpups have the same barrel lengths as ordinary assault rifles, they have the same accuracy (in principle), yet they are much shorter weapons and therefore easier to carry and use. This trick is achieved by pushing part of the barrel back into the stock.

Ammunition development did not cease with the arrival of metal cartridges; much tinkering has resulted in a wide variety of firearms munitions, often highly specialized. The earliest self-contained cartridges employed a pinfire ignition system; the primer was ignited by striking a metal pin that protruded from the cartridge. Pinfire cartridges were succeeded by rimfire cartridges, in which primer is located around the rim at the base of the cartridge. Today the rimfire system is common only in low-caliber ammunition such as .22 caliber rounds. Two centerfire cartridge ignition systems developed in 1866 account for most ammunition today. Named after their inventors, and differing only slightly, the Boxer system is more popular in the United States and the Berdan system in Europe. (A common irony in firearms development: Boxer was an Englishman and Berdan an American.) The Boxer system is more difficult to manufacture but easier to reload (that is, to reuse the brass cartridge case).

The material used to construct cartridges has also developed and specialized. Pistol bullets are now of lead-antimony alloy encased in a soft brass or copper-plated steel jacket, whereas rifle and machine gun bullets have a soft lead core that is encased in a harder steel or cupronickel jacket. Armor-piercing bullets have a hardened steel core. Expanding bullets (developed at the Dum Dum Arsenal in India in the nineteenth century, and banned in warfare) have a particularly soft core that deforms and expands upon impact. Much the same effect is attained by jacketed hollow-point bullets.

Modern high-explosive (HE) artillery shells consist of a shell casing, a propellant charge, and a bursting charge. As with small arms weapons, a primer at the base ignites the propellant charge; the bursting charge is ignited by a fuze in the nose. Fuzes vary with function: point detonation fuzes set off the bursting charge upon impact; delay fuzes wait a short time before detonation (so that, for example, an antitank round can get inside the tank before exploding); proximity fuzes explode in the air after a set time or at a set distance from the target. (The trench warfare of World War I was a spur to air-burst shell development and to the howitzers that fired them.) Heavy artillery rounds require a driving band (also known as a rotating band) and a bourrelet—two raised rings that are the only points of contact with the barrel. Without these bands the wear and tear upon the barrel would be excessive because of the hard casing of these munitions. The rotating band, near the cartridge base, is grooved to engage the barrel rifling. As well as reducing friction, these bands act as propellant gas seals.

Artillery developed more slowly than small arms for technical reasons: rifling was initially less successfully applied to artillery weapons, and advances in metallurgy were needed before artillery could benefit from smokeless powder.12 While rifling became standard for small arms during the course of the American Civil War, ordnance remained smoothbore.

These problems were overcome in several steps:

• Rifling of artillery barrels became standard in the 1870s.

• The introduction of the interrupted screw breech solved the gas leakage problem—a more severe problem for large-bore weapons—allowing the development of effective breech-loading artillery in the 1880s.

• Cased ammunition (analogous to metal-jacketed rifle cartridges) was developed.

• Improvements in barrel construction permitted powerful smokeless powder charges.

• Pneumatic recoil dampers solved the substantial recoil problems of artillery. With recoil dampers, the barrel slides back on damped rollers; this extends weapon lifetime and mitigates gun-laying problems.

• Self-contained firing mechanisms and modern aiming sights were introduced.

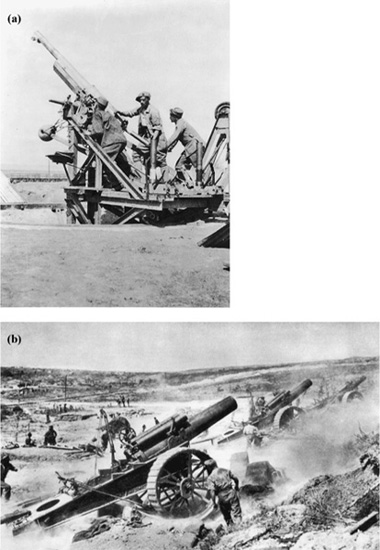

The first artillery weapon to benefit from these late-nineteenth-century developments was the famous French 75, which first rolled off the production lines in 1897. This weapon was a mainstay of the French army in World War I (fig. 3.5a): 75s fired over 200 million rounds during that conflict. The nickel-steel barrel was good for 6,000 rounds; the interrupted screw breech provided an effective seal; high-explosive shells packed a punch beyond the capabilities of old-fashioned solid shot or case shot; a trained crew could fire 30 aimed shots per minute.

By the time of World War I, the eclipse of artillery by small arms was a thing of the past. The deadlock of that conflict was due in large measure to the deadly new firepower: long-range artillery and machine guns combined (with a lack of mobility, a lack of communications, and a lack of leadership) to produce a static killing ground. As well as being far bloodier than any previous war, this conflict was fought continuously, at a furious pace, right from the start. Artillery was at the fore of any offensive (fig. 3.5b): enemy resolve and numbers were diminished by carefully coordinated rolling barrages that advanced just a few hundred yards in front of the infantry (in theory). Resembling a giant, prolonged siege, World War I has been called “the catastrophe of industrial war.”13

Figure 3.5. (a) The famous French 75. This gun, introduced in 1897, was the first modern artillery weapon. Here is an anti-aircraft variant, in use on the Salonika front in World War I. (b) A World War I photo of the British 39th Siege Battery in action during the Battle of the Somme, August 1916. The guns are 8-inch howitzers.

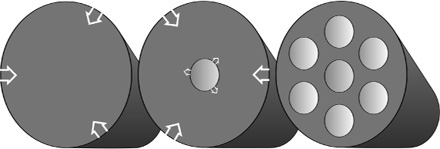

Figure 3.6. Propellant grain shape controls burn rate because gunpowder burns only on the surface. A solid cylindrical grain (left) burns degressively, which is to say it burns fast initially and then slows. A cylinder with one hole (center) burns out as well as in; the area burning does not change with time, and so the burn rate is constant—a neutral burn. A multiperforated cylinder (right) burns with increasing speed—a progressive burn. The timescale depends upon grain size.

Warfare in the twentieth century led to understanding of how internal ballistics works. Gun barrels are designed to withstand a fixed maximum gas pressure; carefully matching barrels with especially formulated double- and triple-base powders led to reliable, accurate, long-range, fast-firing artillery weapons. Recall that smokeless powder grains can readily be formed into desired shapes—important for deflagration rate because powder burns only at the surface. The traditional solid grain—for example, a solid cylindrical grain such as that shown in figure 3.6—produces a degressive burn: the burning surface (and thus the rate of gas generation) decreases with time. A cylinder with a single hole in it produces a neutral burn: the burn rate is constant. A cylinder with more than one hole produces a progressive burn: the area of burning surface increases with time. These grains are also shown in figure 3.6. If we plot the propellant gas pressure as a function of projectile position along the barrel, a degressive burn propellant produces a pressure peak early on, whereas the pressure peak for a progressive burn happens when the projectile is closer to the muzzle and that for a neutral burn is in between these two cases. With the careful formulation of grain composition and shape, a charge can be created that is close to optimum for a given gun (recall technical note 10).

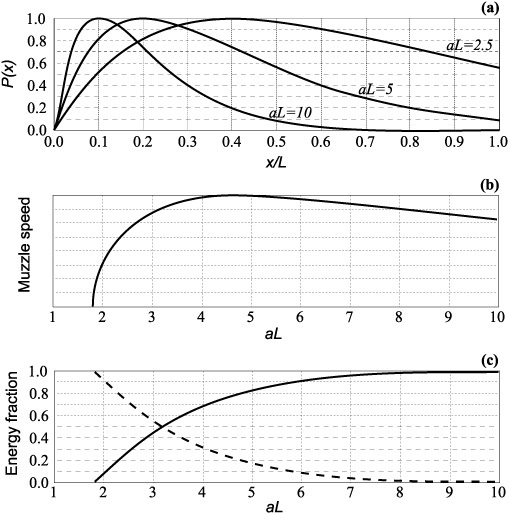

It is possible to investigate the effect of different burn rates mathematically. In technical note 11, our final look at the dynamics of bullets inside the gun barrel, I investigate the relationship between optimum burn rate and barrel length. A mathematical function representing propellant gas pressure is controlled by varying a parameter, leading to pressure curves that correspond to different burn rates, from degressive through progressive. Examples are shown in figure 3.7a. The muzzle speed produced by these different curves is plotted in figure 3.7b. Note that there is a best value, a maximum muzzle speed. This fact shows that we must be careful when choosing grain characteristics; they must be precisely matched with a particular gun caliber and barrel length in order to obtain optimum performance from the gun. (Fig. 3.7c shows the efficiency—solid line—and the fraction of energy used to overcome barrel friction, for the model of technical note 11.)

Figure 3.7. (a) Propellant gas pressure vs. projectile position along the barrel. The position of the pressure peak can be chosen, for a given caliber and weight of projectile, by careful choice of grain shape and size. (b) Muzzle speed vs. aL for a simple model of propellant gas pressure (with propellant parameter a; see technical note 11) inside a barrel of length L. There is an optimum choice (aL = 5), which shows that propellant burn rate and barrel length must be carefully matched for optimum performance. (c) For the simple model, efficiency (unbroken line) and the fraction of energy needed to overcome barrel friction (dashed line) vs. aL.

Artillery became more mobile between the two world wars.14 To emphasize the progress that has been made in artillery development during the past century or so, consider the artillery firing tactic known as MRSI (multiple round simultaneous impact). It was just about technically feasible in World War II to coordinate ordnance so that different long-range guns in a battery could be fired at slightly different times, in such a way that all their rounds landed in the target area at the same time. That is, guns at different ranges from the target could fire in a coordinated manner so that the target was hit simultaneously by all the guns. This ploy has an obvious tactical advantage: the enemy would have no time to get out of the way before the next round arrived. Today MRSI is more sophisticated: a single artillery piece operating at long range can fire several rounds, one after the other, so that these rounds can arrive at the target simultaneously. To achieve this trick, the gunner must load the round with different weights of powder, aim the gun with slightly different elevations, and fire with precise timing. Modern computer-controlled gun-laying can achieve this level of coordination; I show how it is done in technical note 12.

Newton’s third law: For every action there is an equal and opposite reaction. Does the bullet fly from the rifle or the rifle from the bullet? Both, of course, and in opposite directions. Rifle and bullet (and shooter) are initially at rest; pulling the trigger releases chemical energy into the system, resulting in the bullet exiting stage right, with momentum mν where m is bullet mass and ν is muzzle speed. Newton’s third tells us that the rest of the system (rifle and shooter) must acquire the same momentum in the opposite direction—stage left. For a high-caliber rifle with a high muzzle speed, this recoil, or “kick,” can be significant.15 For a low-powered rifle or handgun it is negligible; for ordnance it can be huge.

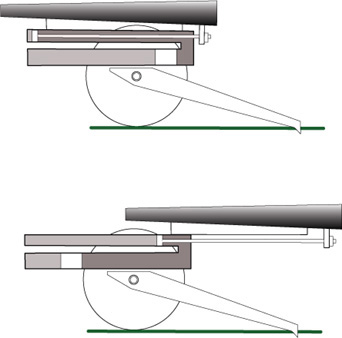

Figure 3.8. Artillery recoil is lessened by permitting the barrel to slide backwards during recoil (bottom), with the motion dampened by pneumatic or hydraulic pressure. In the system shown here, liquid (dark shading) compresses gas (light shading) during recoil; the gas then expands to return the barrel to its firing position (top).

Recoil was unavoidable until the 1860s, when various mechanisms to mitigate its effects were tried. One of the earliest ideas was to place the gun on a slope. Recoil would push the gun up the slope, but then gravity would return it “to battery”—that is, back to its original placement. Mobile artillery developed a pneumatic recoil mechanism that became commonplace by World War I; the idea is illustrated in figure 3.8.

In technical note 13, I discuss some technical aspects of recoil physics. Here, we can apply some of the derived equations to see how much of an effect recoil has for a given weapon type.

Age of Sail cannon. A long gun from a Napoleonic-era ship might weigh 3 tons and fire a 24-pound ball. Sir Isaac Newton tells us (see technical note 13) that if the muzzle speed is 1,000 ft/s, then the recoil speed of the gun is about 4 ft/s. These cannon were on wheels to facilitate aiming (recall fig. 2.5), and so it was vitally important to ensure that enough strong ropes were provided to prevent the gun breaking free when recoiling. (On a pitching deck, such a “loose cannon” could cause a great deal of damage.)

Heavy rifle. Some modern rifles generate muzzle energies exceeding 10,000 foot-pounds (13,560 J); technical note 13 shows that recoil typically absorbs about 1% of this value, corresponding to 100 foot-pounds of recoil energy—enough to knock a man over (20 ft-lb is considered uncomfortable). Powerful sniper rifles need to be heavy or tied to a frame or have the shooter in a prone position to avoid muzzle rise due to recoil; see figure 3.9. The effects of muzzle rise upon aim are estimated in technical note 13 for a handgun. An experienced shooter who is obliged to fire a large-caliber rifle from a standing position will lean into the shot. This braces him against recoil. (For example, if a 180-pound shooter leans forward enough to lower his height by 1 inch, then 15 foot-pounds of recoil energy will be absorbed just in raising him to his upright position.)

Muzzle brakes. For automatic weapons and large ordnance, recoil is significant, and muzzle brakes are common. A muzzle brake is a series of baffles or diagonal holes cut into the end of a barrel that redirects propellant gas sideways (to reduce recoil) or upward (to reduce muzzle rise). The calculations in technical note 13 show that a long-barrel, low-profile artillery piece that is, roughly speaking, four times as long as it is high would need to redirect about a quarter of the mass of propellant gas, to counter the muzzle rise.

Figure 3.9. The shooter must be careful to avoid muzzle rise when firing this .50 caliber Barrett sniper rifle. It is heavy, which helps, and the stock is in line with the barrel so that recoil induces no upward kick. U.S. Navy photo by J. Husman.

Figure 3.10. An M-198 155 mm howitzer live-fire exercise. The split-trail carriage (rear “legs” of the gun) bury into the ground to absorb recoil; a large muzzle brake redirects the blast. U.S. Army photo by Spc. Lucas T. Shihart.

The trend in artillery over recent decades toward greater mobility (requiring reduced weight and lighter construction) and increased muzzle speed have exacerbated recoil problems. Launcher design is greatly influenced by recoil considerations. Often, a gun design is such that muzzle rise is not a problem, but linear recoil (straight back) is a big problem. In figure 3.10, for example, a howitzer is fired at a sufficiently high elevation angle that there is no muzzle rise. Clearly, however, this gun has a muzzle brake that redirects propellant gas sideways, reducing recoil. The considerable recoil of heavy artillery can reduce the service life of the gun and makes re-aiming at a target more time-consuming, so anything that reduces recoil is beneficial. Note the symmetry of the redirected blast: because the sideways forces cancel, there is no torque acting to twist the barrel. Muzzle brakes can reduce recoil significantly.16 There is a cost to muzzle brakes, however, and one of these is evident in the figure. Sound pressure levels are higher behind the gun than would be the case without a muzzle brake, and artillery crew must take precautions to avoid hearing injury.

The last logical stage of recoil reduction was the recoilless rifle, developed in the United States in 1963 by William Kroeger and Walter Musser. Propellant gas boosts the projectile forward, and itself backwards out of the breech, so that there is very little gun recoil. Because the weapon is not subjected to large recoil forces, it can be of lighter construction than other ordnance of the same caliber. Two major disadvantages immediately leap to mind: first, the amount of propellant that is required for a given projectile weight is large (between 2½ and 3 times that normally needed); second, the back blast is considerable (for example, when firing a U.S. Army 57 mm rifle, personnel must steer clear of a cone 55 feet long and 45 feet wide in back of the breech).

In the late 1800s two inventions—smokeless powder and the Minié ball—led to a revolution in the design and effectiveness of firearms, first in small arms and then in ordnance. Improved manufacturing techniques were also crucial to these developments. Breech-loading rifled firearms took over from muzzle-loading smoothbore weapons. The accuracy, range, and rate of fire of gunpowder weapons all increased dramatically. Fully automatic weapons were developed during the first decade of the twentieth century.