Parametric Object

138. Fahz (2015), by Brooklyn design studio Des Des Res, is a fabrication system for producing unique custom vases. The negative space around each vase is generated from silhouettes of the customer's face.

Brief

Create a program that generates 3D objects. More specifically, your program should generate a family of 3D objects that are all parameterized in the same way, but that differ when their parameters are set to different values. The output from your program should be suitable, at least in principle, for prototyping in the real world.

Give consideration to the way in which your parametric object operates as a cultural artifact. How might your software attain special relevance by generating things that address a real human need or interest? Can it make a dataset tangible or wearable? Is it possible for a generated object to be critical or tactical? Is it a tool? Garment? Decoration? Can it be funny, surprising, or unexpected? If you are hunting for a concept, it may be helpful to think of things in the world around us that are mass-produced but that could be (or ought to be) personalized. Document your object so that it can be shared with relevant audiences.

Learning Objectives

- Apply generative design principles to the design of 3D form

- Control solid geometry operations with algorithmic techniques

- Discuss form in relation to the contexts of the body, society, or the environment

Variations

- For introductory students: Write software to define a surface of revolution that produces a series of vases, cups, candlesticks, spinning tops, etc.

- Working “unplugged” (without a computer), devise a set of rules for creating a class of objects from everyday materials. Your rules should incorporate an element of chance (such as a coin flip) or a dependency on real-world data (by collecting a measurement). Make at least two objects according to your rules.

- Write software that generates a tactile, 3D-printable map from cartographic data.

Making It Meaningful

Generative design is the activity of authoring a system of rules for automating design decisions. In the case of the parametric object, a form is produced with properties articulated by certain variables. Changing the values of these variables changes the form in response, and incorporating elements of contingency or randomness can produce unique objects in every iteration. Among other approaches, parametric forms can be assembled from different arrangements of modular components, lofted from mathematical curves and surfaces, or produced through the actions of simulated physics.

3D parametric objects can be rendered in physical materials with the help of a wide range of fabrication technologies. These include additive technologies like 3D printers, which accrete or accumulate material, and subtractive technologies such as mills, which remove material from a piece of stock. The earliest of these, the CNC (computer-numeric controlled) milling machine, was developed in the 1950s through a military-funded, Cold War initiative to create mathematically precise propellers for aircraft. The early 1960s saw the parallel development of CAD (computer-aided design) tools to simplify the process of specifying geometries for CNC manufacture, and it wasn't long before artists finagled access to these technologies. In 1965, around the same time as the first exhibition of computer-generated plotter art, pioneer Charles “Chuck” Csuri became the first artist to employ CNC tooling for expressive ends, in his abstract Numeric Milling sculptures.

The creation of generative forms does not necessarily require computer programming. Traditions of process-based, open-ended and rule-based conceptual art create meaning in the tension between algorithmic logics and the material or social contingencies of the real world. Highly systematic thinking underpins works like SCUMAK by Roxy Paine (a metasculptural machine that extrudes randomly-shaped plastic blobs); Nathalie Miebach's handmade sculptures, structured according to weather data; and Laura Devendorf's Being the Machine project, an “alternative 3D printer” in which instructions typically provided to fabrication machines are instead given to human makers.

Manufactured objects gain a role in our lives through their utility as furniture, housewares, tools, toys, and ornaments. At times, however, the “one size fits all” approach in industrial design means “no size fits any.” Parametric design counters this by enabling “mass customization”—offering personalization akin to handcrafted and homemade forms, but at a heretofore impossible scale. Eyeglasses, prosthetics, and other wearables, for example, can be customized using measurements or scans taken from an individual's body. Maps, histograms, and time series can be generated from data and rendered into tactile media; this “physical visualization” approach can be useful in widening the accessibility of data for the visually impaired, or in producing mementos or souvenirs that encode information from highly personal experiences. In situations where uniqueness is prized, algorithmic design techniques can guarantee that no two items are alike. Parametric design also holds the alluring promise of creating “optimal” forms for a given situation (e.g., solving for the greatest strength per unit of material). While this is important for reducing the material impact of design processes, we must also recognize that over-optimization risks producing unduly specific outcomes in a dynamic world.

139. Jessica Rosenkrantz and Jesse Louis-Rosenberg, also known as the design studio Nervous System, are pioneers of simulating natural phenomena to produce 3D forms. Their Kinematic Dress (2014) is made up of over 2000 unique, interlocking triangular facets that are capable of accommodating the curves of the body. The entire dress is 3D printed as a single folded piece of material.

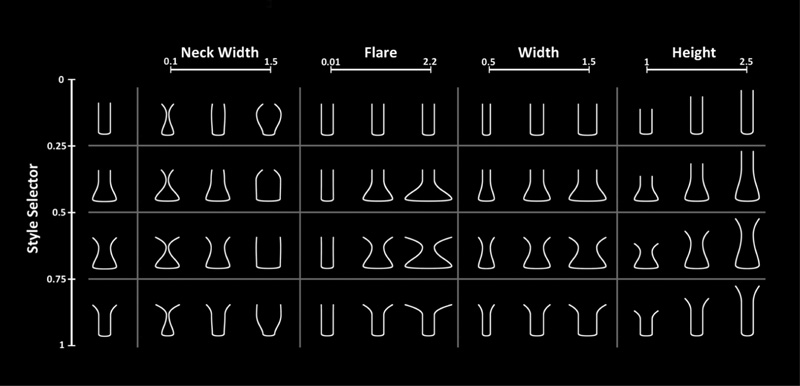

140. Jonathan Eisenman's Vase Parametric Model (2014) illustrates how a simple vase form may be parameterized.

141. Grand Old Party (2013) by Matthew Epler is a set of computationally generated butt plugs. Each form is a “physical visualization” whose diameter represents the voter approval rating, over time, of select presidential candidates.

142. Filament Sculptures (2014), by the mononymous Austrian artist Lia, are computationally generated forms in which a 3D printer's hot filament has been allowed to droop in unpredictable ways. Each sculpture arises through a negotiation between virtual and physical parameters, articulated by the CAD model, 3D printer settings, and natural forces in the physical world.

143. Charles Csuri's Numeric Milling (1968) sculpture is one of the earliest artworks produced with a computer-controlled milling machine. Csuri wrote: “While the device was capable of making a smooth surface, I decided it was best to leave the tool's marks for the paths.”

144. For his interactive installation Wage Islands (2015), Ekene Ijeoma generated a new topography for New York City, in which elevation represents the inverse of median wages. As the lasercut sculpture is submerged into ink-dyed water, it visualizes the “wage islands” where low-wage workers can afford to rent.

145. Adrien Segal's Cedar Fire Progression (2017) is a data-driven sculpture that depicts (from bottom to top) the evolving geographic contour of a wildfire front over time.

146. Amanda Ghassaei's 3D Printed Record (2012) is a playable, 12-inch, 33rpm phonograph disc whose spiral groove geometry is computationally derived from audio data. The fidelity of its sound reveals the limits and artifacts of digital fabrication.

147. Meshu (2012) by Rachel Binx and Sha Huang exemplifies the use of 3D fabrication pipelines to produce personalized jewelry pieces, on demand, that are derived from a customer's geospatial information.

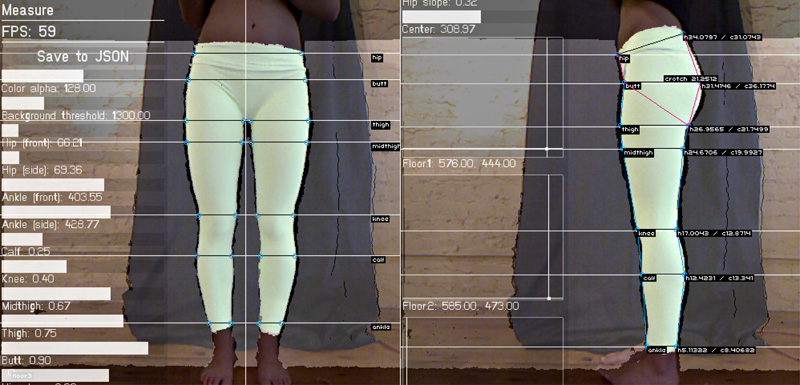

148. Open Fit Lab (2013) by Lisa Kori Chung and Kyle McDonald is a performance in which 3D scans of the audience's bodies are used to generate garment patterns for on-the-spot assembly of custom-tailored pants.

149. The objects in Morehshin Allahyari's Material Speculation: ISIS series (2015–2016) are procedural reconstructions of ancient artifacts destroyed by ISIS militants—systematically recreated from dozens of publicly available photographs. Shown here is Allahyari's reconstruction of a Roman-period figure of King Uthal of Hatra, smashed at the Mosul Museum in 2015.

Additional Projects

- Alisa Andrasek et al., Li-Quid, 2016, generated chair design.

- Ingrid Burrington, Alchemy Studies, 2018, iPhone 5 cast in resin sphere.

- Mat Collishaw, The Centrifugal Soul, 2017, mixed media three-dimensional zoetrope.

- David Dameron, in Paul Freiberger, “Sculptor Waxes Creative with Computer,” InfoWorld, July 6, 1981.

- Laura Devendorf, Being the Machine, 2014–2017, videos, instructable, and app for generating human-executable g-code fabrication instructions.

- Erwin Driessens & Maria Verstappen, Tuboid, 2000, computationally generated wooden sculptures and virtual environments.

- John Edmark, Blooms, 2015, 3D-printed stroboscopic sculptures.

- Madeline Gannon, Reverberating across the Divide, 2014, context-aware modeling tool.

- Gelitin, Tantamounter 24/7, 2005, copy machine performance.

- Nadeem Haidary, In-Formed, 2009, fork as data visualization.

- Mike Kneupfel, Keyboard Frequency Sculpture, 2011, 3D-printed information visualization.

- Golan Levin and Shawn Sims, Free Universal Construction Kit, 2012, software and SLS nylon 3D prints.

- Nathalie Miebach, To Hear an Ocean in a Whisper, 2013, data sculpture.

- Neri Oxman et al., Silk Pavilion, 2013, structure made by silkworms.

- Roxy Paine, SCUMAK (Auto Sculpture Maker), 1998–2001, sculpture-making machine.

- Matthew Plummer-Fernández and Julien Deswaef, Shiv Integer, 2016, Thingiverse mashup bot and SLS nylon 3D prints.

- Stephanie Rothenberg, Reversal of Fortune: The Garden of Virtual Kinship, 2013, telematic garden visualizing philanthropic data.

- Jenny Sabin, PolyMorph, 2014, modular ceramic sculpture.

- Jason Salavon, Form Study #1, 2004, video of generated objects.

- Keith Tyson, Geno Pheno Sculpture “Fractal Dice No. 1”, 2005, algorithmically generated sculpture.

- Wen Wang and Lining Yao et al., Transformative Appetite, 2017, computationally shaped pasta.

- Mitchell Whitelaw, Measuring Cup, 2010, generated cup visualizing 150 years of Sydney temperature data.

- Maria Yablonina, Mobile Robotic Fabrication System for Filament Structures, 2015, fabrication system.

Readings

- Christopher Alexander, “Introduction” and “Goodness of Fit,” Notes on the Synthesis of Form (Cambridge, MA: Harvard University Press, 1964), 1–27.

- Morehshin Allahyari and Daniel Rourke, The 3D Additivist Cookbook (Amsterdam: The Institute of Network Cultures, 2017).

- Nathalie Bredella and Carolin Höfler, eds., “Computational Tools in Architecture, Cybernetic Theory, Rationalization, and Objectivity,” special issue, arq: Architectural Research Quarterly 21, no. 1 (March 2017).

- Joseph Choma, Morphing: A Guide to Mathematical Transformations for Architects and Designers (London: Laurence King Publishing, 2013).

- Pierre Dragicevic and Yvonne Jansen, List of Physical Visualizations and Related Artifacts, dataphys.org, accessed April 13, 2020.

- Marc Fornes, Scripted by Purpose: Explicit and Encoded Processes within Design, 2007, exhibition.

- Wassim Jabi, Parametric Design for Architecture (London: Laurence King Publishing, 2013).

- Vassilis Kourkoutas, Parametric Form Finding in Contemporary Architecture: The Simplicity within the Complexity of Modern Architectural Form (Riga, Latvia: Lambert Academic Publishing, 2012).

- Golan Levin, “Parametric 3D Form” (lecture, Interactive Art & Computational Design, Carnegie Mellon University, Pittsburgh, Spring 2015).

- D’Arcy Wentworth Thompson, On Growth and Form, 2nd ed. (Cambridge, UK: Cambridge University Press, 1942).

- Claire Warnier et al., eds., Printing Things: Visions and Essentials for 3D Printing (New York: Gestalten, 2014).

- Liss Werner, ed., (En)Coding Architecture: The Book (Pittsburgh: Carnegie Mellon University School of Architecture, 2013).