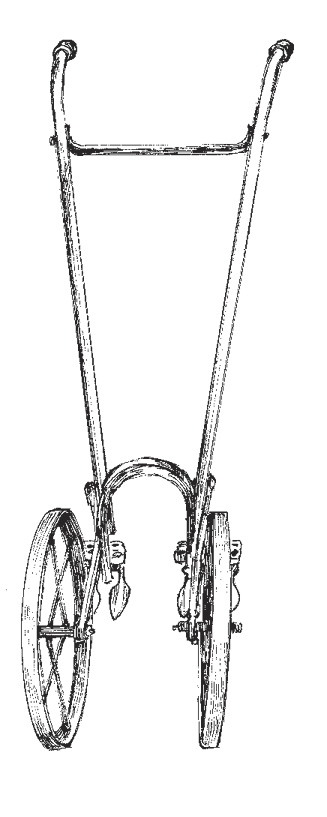

Two-wheel tine hoe

Unless you have an unlimited supply of willing workers, it’s hard to grow more than a couple of acres of vegetables without the aid of a tractor (or possibly a horse) and a few basic implements. This is especially true when it comes to field preparations such as chisel plowing and rototilling. But it doesn’t mean that hand tools have no place on a small diversified farm — far from it. Many organic growers, including this one, rely on an assortment of wheel hoes, hand hoes, rakes, forks, shovels, wheelbarrows, and other miscellaneous tools on a daily basis.

Crop diversity and numerous sequential plantings of the same crop are the norm on small organic farms. Under these conditions, the use of hand tools — especially for weed control — often makes the most sense. Let’s use Swiss chard as an example.

In a typical year, we seed Swiss chard in our greenhouse on seven separate occasions — once in early March, once in April, once in May, three times in June, and one last time in the first half of July. We aim for anywhere between 300 and 1,200 seedlings per sowing, depending on the month, with the larger numbers occurring in June so we have a good supply of chard to take us through fall. The total for the season is usually about 4,500. In aggregate, this is a fair number of seedlings, but the amount of land required for each individual planting is quite small. Let’s take a closer look at the numbers.

In the field, we plant Swiss chard three rows to a bed, with 18 inches between rows and 12 inches between plants within each row; therefore, a 200-foot row would contain two hundred plants, and a 200-foot bed would contain six hundred. Remember, our beds are 76 inches (6.33 feet) on center, so a 200-foot bed will require 1,266 square feet (200 × 6.33), which is only 0.03 acre (1,266 ÷ 43,560). Not a lot of land.

In my view, at this scale, tractor cultivation would be overkill — both unnecessary and impractical. Moreover, it would increase the likelihood of soil compaction. Instead, we rely on workers who are proficient with wheel hoes and hand hoes to keep weeds at bay during the few weeks that the plants are most vulnerable to competition. One or two persons weeding for a half hour, every other week, is usually enough to take care of business, as long as we don’t let the weeds get too far ahead of us.

Of course, one might argue that if there were numerous plantings of similar crops at the same row spacing, a small cultivating tractor might do the work more expeditiously. And this is probably true.

Near the corner of our closest field, we have a small (12' × 12') shed sitting on a concrete pad. This shed is stocked with hand tools that are brought into service almost every day. Let’s take a look at some of the standbys and what they are used for:

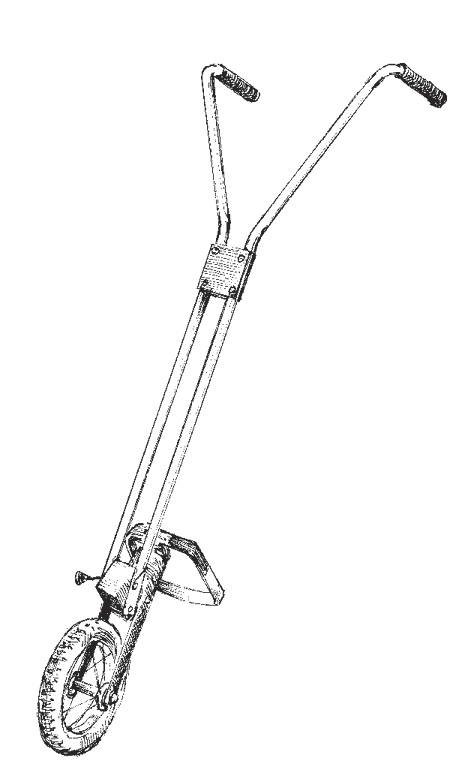

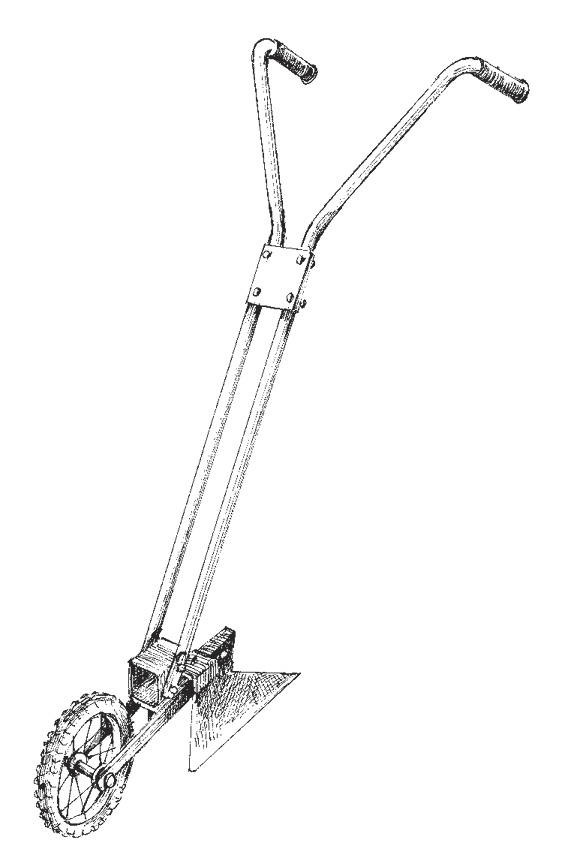

A wheel hoe is a human-powered, walk-behind cultivator with either one or two wheels or, in some rare instances, four. They are used primarily for controlling weeds between parallel rows of vegetables. The one-wheeled models work between rows. The two-wheeled models can straddle a single row of vegetables and take out weeds on either side — while the vegetables are still small. As the crop grows larger, they can be used between rows, just as the one-wheeled models.

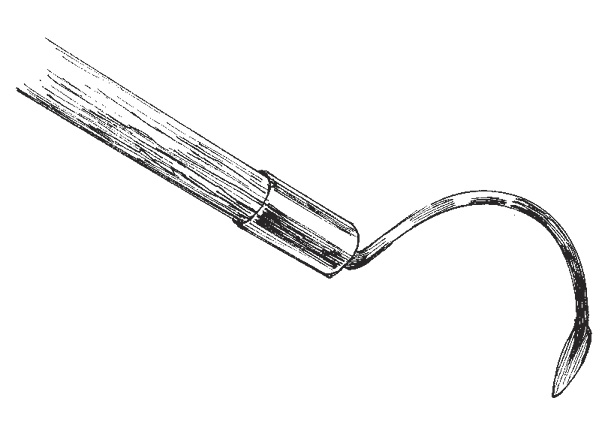

Some wheel hoes use small cultivating tines or teeth to scratch their way through the soil up to a few inches deep. These tines do a fair job of uprooting both small and larger weeds but, because of their hooked shape and the depth to which they penetrate, they cause significant soil disturbance. This often brings dormant weed seeds closer to the surface, where they are likely to take advantage of newfound light and promptly germinate. In other words, the tine-type hoes can solve your immediate weed problem but, in the process, create a future one.

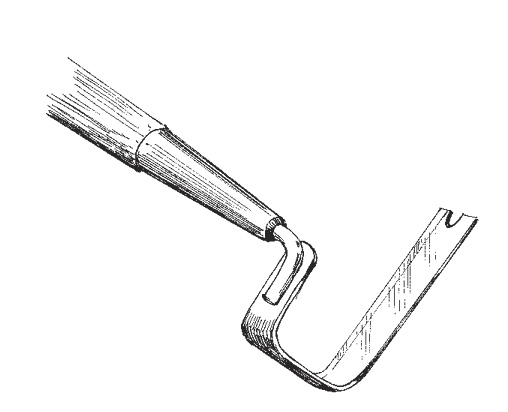

Other wheel hoes use blades, sweeps, or oscillating stirrups to undercut weeds, rather than uproot them. These hoes are used for shallow cultivation and work best when weeds are small — less than a few inches high. They disturb the soil surface less than the tine hoes and are therefore less likely to bring on another flush of weeds. They also require less physical effort. Most growers prefer this type of hoe. We have at least half a dozen wheel hoes in our shed, and a few different models. The ones we reach for most often are the oscillating stirrup type. Depending on the spacing between our rows, we use interchangeable stirrups that are 4, 6, or 8 inches wide.

Height adjustment. If you’re in the market for a wheel hoe, look for one that has a height adjustment feature that allows the handles to be set easily to match the height of the user. Taller people will want the handles set higher, and shorter folks will want them set lower. Most people lean forward slightly when using a wheel hoe. The idea is to let the legs do most of the pushing, rather than the arms and upper body. A reasonably fit individual, with a correctly adjusted wheel hoe, should have no trouble working for a couple of hours at a stretch.

Offset adjustment. This is another good feature in a wheel hoe. The offset adjustment enables you to cultivate off to one side and avoid walking on the area the hoe has just passed over and loosened.

Attachments. Some wheel hoe manufacturers offer a few different attachments. A good one to get is a V-shaped furrower. This can come in handy when you need a planting furrow and don’t want to use a tractor to make one. It can also be used for hilling plants such as carrots and leeks.

Prices. The better-known wheel hoes on the market are made by three different companies — Valley Oak, Glaser, and Hoss. You can buy them online or through various seed and garden supply catalogs. Prices range from $250 to $400.

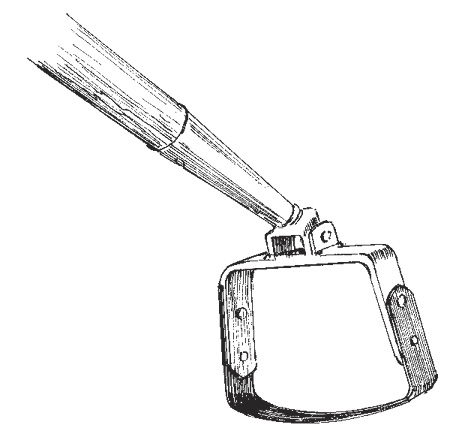

Two-wheel tine hoe

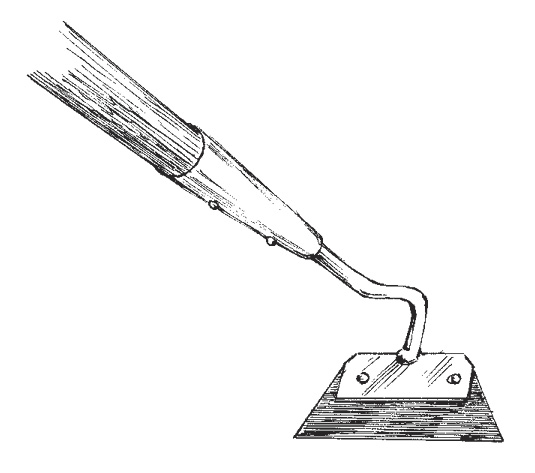

One-wheel oscillating stirrup hoe

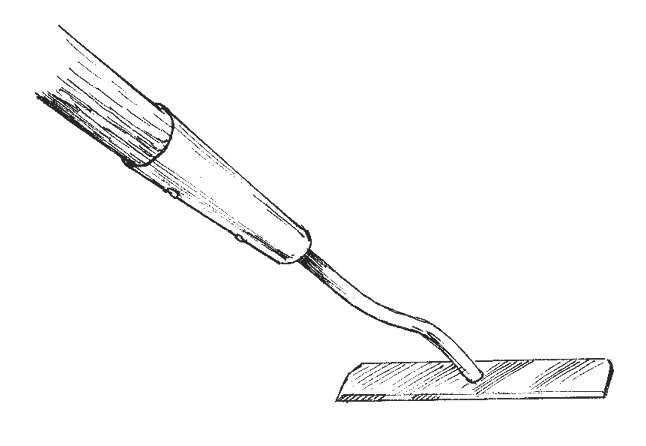

One-wheel hoe with furrowing attachment

Wheel hoes control weeds between rows of vegetables. Hand hoes can do this, too, but they are especially good for working between plants within a row, which is something that a wheel hoe is not designed to do. There are plenty of different hand hoes to choose from — they come in a variety of shapes and designs, both long- and short-handled, each touting its own virtues and applications.

Some long-handled hoes are suited to shallow cultivation and small weeds; others, especially the tine-style hoes, tackle weeds both large and small, but like tine-style wheel hoes, these more versatile tools tend to rough up the soil surface and expose weed seeds to light. Some hoes have small blades and more precise action — they are ideal for getting between closely spaced plants, such as onions or mesclun salad greens; other hoes are heavier and sport broader blades that can dispatch a larger number of weeds in one pass.

If you’re anything like us, you’ll end up owning several different hoes and will take some satisfaction in selecting the most suitable one for the job at hand. Here’s a rundown on some of the better hoes that are available today.

Stirrup hoe. Popular and easy to use, most stirrup hoes have oscillating stirrups with thin blades that cut through small weeds just below the soil surface. They are used with a back-and-forth or push-and-pull motion. The user has full visibility of the two sides of the hoe at all times, which reduces the chance of nicking crop plants. The stirrups come in different widths, from 3 to 8 inches. Blades are replaceable, which is a good thing, because they wear down after substantial use in rocky soil.

Stirrup hoe

Trapezoid hoe. This sturdy hoe has a cutting blade with sharp corners and a beveled shape. It is good for larger weeds, especially those with taproots. The blades are replaceable.

Trapezoid hoe

Collinear hoe. Designed by Eliot Coleman, the collinear hoe slices through the soil just below the surface. It works well in tight spaces and when handled skillfully can get under the leaves of heading crops such as cabbages, escarole, and lettuces without causing damage.

Collinear hoe

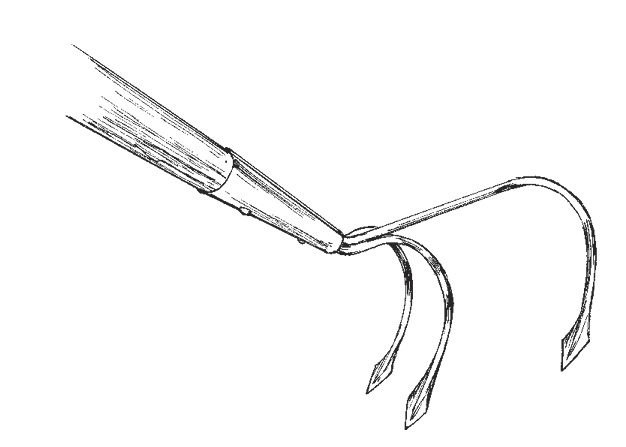

Toothed cultivator hoe. This hoe is designed to penetrate more deeply into the soil. It is used to uproot larger weeds and loosen a crusty soil surface. It can also be used to incorporate compost or organic fertilizer.

Toothed cultivator hoe

The CobraHead hoe. This is a versatile, all-purpose hoe that can work the soil surface or dig more deeply to uproot larger weeds. The manufacturer compares it to a “steel fingernail,” and with some justification. The CobraHead can also be used to cut shallow furrows for planting. Its sturdy but small blade allows for precision weeding.

CobraHead hoe

The Hooke ’n Crooke hoe. This extremely sturdy undercutting hoe has become one of our favorites. The flat, rigid blade is used in a back-and-forth motion to slice through weeds both large and small, with minimal disturbance to the soil surface. The grooved tip can be used to isolate and uproot individual weeds. If flipped over, the Hooke ’n Crooke can be used like a small rake to remove cut weeds or smooth out the soil surface. This hoe is available in two sizes: the larger Heron model with a 6-inch blade and the smaller, somewhat lighter Honey Bee, which has a 4-inch blade.

Hooke ’n Crooke hoe

Prices. Well-designed and well-made hand hoes are not inexpensive. You can purchase replacement blades for most of them, and the best ones will last for many years. Over the course of a farming career, you’re likely to spend countless hours working with hoes. Quality tools are a pleasure to use; they prove their worth in the long run, and often in the short run, as well. If a friend or family member is having a hard time deciding what to give you for your birthday, tell them you’d be happy with a good hand hoe.

These hoes are held in one hand and are normally used when kneeling or sitting. They are good for very delicate weeding around direct-seeded crops such as carrots or onions soon after germination, when a long-handled hoe might be too blunt an instrument. There are several models on the market, and as is the case with long-handled hoes, it makes sense to try at least a few of them to find out which ones work the best for you.

Both Cobra and Hooke ’n Crooke have one-handed versions of their larger hoes. Both are well made and good for their intended purposes: The Cobra is more of a precision scalping and digging tool, while the Hooke ’n Crooke Hummingbird model does a nice job of undercutting small- and medium-size weeds. Check out garden supply and seed catalogs to view the different hand hoes available.

Shovels. Every farm needs a few good shovels. You’ll use them for planting trees, turning over small patches of ground, cleaning out a manure spreader, burying the edges of plastic mulch or row cover, and just plain shoveling. Go for quality.

Forks. A good digging fork is hard to find but worth looking for. We use forks for digging up carrots, turnips, potatoes, celeriac, and sometimes garlic. The problem with cheap forks is that they tend to break under heavy use. After they are sunk all the way into the ground, many forks cannot withstand the full weight of a human body bearing down on them — at least not repeatedly.

Even with a high-quality, high-priced fork, it is better to ease off a little and withdraw the tines a few inches when the soil is dry and offering a lot of resistance. Don’t test the tool’s limits. Hay and manure forks, or pitchforks, have longer handles and thinner tines. These are no good for digging but work well for pitching around straw, hay, manure, or piles of weeds.

Right-angle trowel. This is a useful tool for setting plants in the ground. With an easy motion, it enables you to create a wedge-shaped hole big enough to accommodate the plug or root-ball of your transplant. It is good for herbs and other limited plantings.

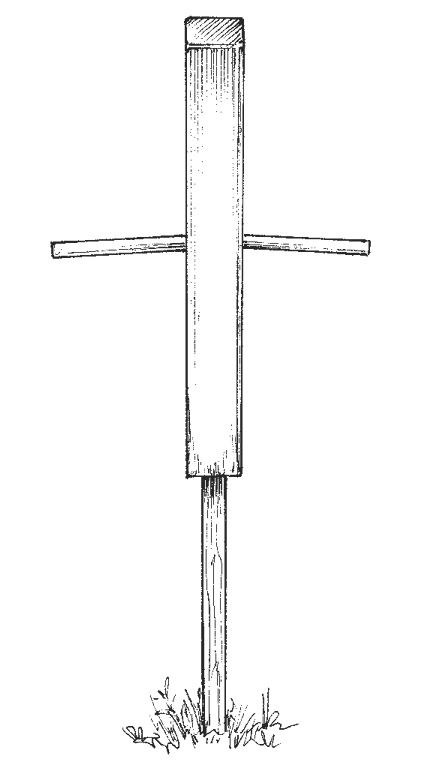

Stake pounders. If you grow tomatoes, peas, or other crops that will benefit from staking or some form of trellising, a stake pounder is a useful tool to have. It will work better than a sledgehammer, which is likely to chip, split, or mushroom your stakes. It will also make it easier to set your stakes vertically, rather than at different angles. A good stake pounder should be heavy enough to drive a stake into the ground without your having to exert too much downward pressure. Instead, focus your energy on the lifting. But even then, stake pounding can be vigorous work, especially in dry or rocky soil. Wait for some moisture, if you can.

Stake pounder and stake

To my mind, a good workshop will be spacious and have good lighting, a concrete floor, a large and very solid bench with a vise grip on it, plenty of electrical outlets (including at least one 220 outlet), ample shelving, and a heavy-duty pegboard. Finally, it would be nice to have a large sliding door that would permit you to bring in a vehicle or tractor. But these are things to aspire to. A lesser workshop will take you a long way.

Here are some of the tools I’ve used to stock my workshop. The list is by no means exhaustive.

Depending on your needs and do-it-yourself skills, this can be a long list. We started out with a few hammers, screwdrivers, pliers, wrenches, socket sets, and the like, many of them picked up for pennies on the dollar at auctions or yard sales. Next came a number of power tools: A drill, skill saw, chop saw, table saw, grinder, and sander. Within a few years, we had acquired an air compressor and a battery charger. Later, an arc welder and then an oxyacetylene welder found their way onto the farm, but I have to admit that I’m far from proficient with either of these — they are generally used by others on the farm who have proper training. In New York State, the Boards of Cooperative Educational Services (BOCES) offers adult education courses in practical subjects ranging from welding to small engine repair. Many other states offer similar training and adult education programs.

The longer you farm, the more you’ll understand which tools will make your life a little easier and enable you to get work done more expeditiously. You don’t need a fully equipped workshop on day one. A few simple items are enough to get started. In good time, your supply of tools will increase. Each new addition will come because you have a need for it.

Most farmers will keep acquiring tools and equipment for a long time, perhaps right up to retirement and even beyond. In a way, it’s part of the job description, part of the learning process. There are a lot of useful tools out there, many of them not specifically designed for farmers and gardeners; nonetheless, it’s good to have them on a farmstead and become familiar with them.

Landon Jefferies has worked around farms since he was 14 years old. He started out working summers at a farm stand near his hometown of Westford, Massachusetts. A few years later, while attending Vassar College, he signed on for summer work at Butterbrook Farm — a diversified organic farm not far from his home. Then, when he was just 20 and still a little shy, he came to work at our place in 2005. He put in two seasons with us, the second in the role of crew manager — our youngest ever. He helped assign tasks, worked alongside the rest of the crew, and took charge of our Wednesday farmers’ market in New York City.

After graduating with a degree in political science (the major, he informed me, with the fewest requirements), Landon moved to Philadelphia to be with his girlfriend, Lindsey Shapiro. For a few years, he managed farmers’ markets around Philadelphia, worked at farm stands, and managed a small urban farm on a historical property. But what he really wanted to do was start a farm of his own. The problem was finding land to do it.

In 2010, Landon found what he was looking for in the rural town of Oley, Pennsylvania, an hour northwest of Philadelphia. A large family with farming aspirations, some idle land, and plenty of mouths to feed, agreed to lease a few acres and a small house to him and Lindsey, in exchange for a regular supply of organically grown vegetables.

In summer 2010, Landon and Lindsey set about creating Root Mass Farm. They were able to use the landowner’s tractor and moldboard plow to work up an acre of clay loam soil that had been in pasture for several years. They seeded buckwheat as a smother crop at the end of June and followed it with a cover of alfalfa in early September. The following spring, they planted some 30 different vegetables (including two thousand heads of garlic — most of it from our Italian ‘Rocambole’ stock but also some of a sharper hardneck variety called ‘Georgian Fire’), along with assorted herbs, melons, and berries. They signed up with two farmers’ markets in Philadelphia and established what they call a “stakeholder account” — their term for a debit-style, farmers’ market CSA — to bring in some cash up front.

When I spoke with Landon, he told me he was satisfied with Root Mass Farm’s first season and was planning to bring another acre into production in 2012 and, in all likelihood, a third acre in 2013. And there are possibilities for expanding beyond that. Landon and Lindsey have the use of the landowners’ equipment, which, in addition to the tractor and plow, includes a set of discs, a bed shaper, and a brush hog mower. They have access to a steady supply of cow manure and a shallow well, which they use for drip irrigation. They use only organic methods but are not certified.

Except for when they got hit with torrential rains late in the season, the first-year crops at Root Mass Farm grew nicely. One of the farmers’ markets in Philadelphia worked out well, the other less so. They’ll probably drop the weaker market and look for a better one. Landon and Lindsey are excited about their prospects. They like being in business for themselves and making their own decisions. They are working hard, and both of them believe in and enjoy what they do. But Landon cautions: “We’ll see where it takes us.”