CHAPTER 30

Broth on a Large Scale

Broth for Sale

Broth for Sale

We visited Jessica Prentice and Porsche Combash, two co-owners of Three Stone Hearth in Berkeley, California. This community kitchen prepares a wide variety of dishes, including broth-based soups and stews, pâté, breakfast cereals, lacto-fermented condiments and beverages, and broth-based gravies and sauces. They make thick, gelatinous chicken broth and beef broth and sell more than one hundred quarts of both types each week.

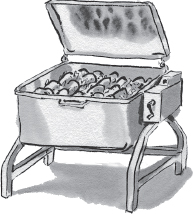

Broths (as well as soups and stews) are prepared in a 40-gallon rectangular stainless steel Cleveland tilt skillet. These are deemed easier to use and clean than the older steam-jacketed kettle, which was (and in many cases still is) standard restaurant equipment for making stocks and soups. The tilt skillet puts the broth at waist level so it is easy to stir and remove from the pan. New ones run about fifteen thousand dollars; they should be outfitted with a spigot on the front, which is another five hundred dollars to install.

At Three Stone Hearth, pastured chickens are roasted, then the meat is removed and used in soups and casseroles with the skin and bones reserved for stock. The fat from roasting is also reserved; this is used to seal the top of the broth when it is put into jars.

One batch of broth calls for about 30 chicken carcasses and skin, plus an additional 25 pounds of chicken heads and feet. These are put in the tilt skillet and covered with reverse osmosis water. The only addition is 1 cup apple cider vinegar to help pull the minerals from the bones. Prentice and Combash believe that the mineral-free water also helps pull minerals from the bones. No vegetables are added to this basic stock, and the stock is not skimmed.

The water is brought to a boil and then reduced to a simmer. The broth simmers at a setting of 200°F for 24 hours with the lid closed. A very important step comes at the end, after the long simmering, when a masher (like a potato masher) is used to press down the now-softened bones. This releases more minerals into the broth, as well as nutrients from the marrow.

The broth is removed through the spigot and strained through a strainer into pitchers. It is then poured into 1-quart wide-mouth mason jars, which have been sterilized in an industrial dishwasher using very hot water. About 1 ounce melted chicken fat is added to the top of every jar. New lids are used with every batch; the lids are immersed in boiling water and placed on top of each jar with tongs. Jars are then sealed with the rings (which are reused, but recycled if they have any rust). One batch yields about 110 quarts of broth.

The jars are immediately placed in sinks to which a block of ice and cold water has been added. The temperature reduces to 72 to 73 degrees within 40 minutes. The jars are then refrigerated, which brings the temperature down to below 40 degrees within 2 hours.

The chicken broth sells for $13 per quart, plus a $1.50 deposit for the jar.

At Three Stone Hearth, they also make a “second boil” using the same bones; this stock is used for making soup. The bones are again covered with water; often more heads and feet are added. This time the simmer is only 6 hours. The result is a stock that has less gelatin but is more flavorful than the “first boil.” The final mashing step, described above, is considered very important.

The second-boil broth is cooled in 6-inch hotel pans and then put into plastic “cambos” (large rectangular containers) for the freezer. Yield is about 90 quarts. The remaining cooked-down bones and skin are composted.

Beef broth is likewise made in the tilt skillet. One batch calls for 110 pounds of gelatinous bones (such as knuckles) and marrowbones, sawed so that the marrow is exposed. An additional 10 pounds of trim meat is also used.

The meat is browned in the tilt skillet and then the bones are added, along with 1 cup apple cider vinegar. The bones are then covered with water, which is brought to a boil and then reduced to a simmer. At this point it is necessary to redistribute the bones (using tongs) so that water is covering all the bones, as the heat causes the tendons to shrink. No vegetables are added and the stock is not skimmed.

The stock is simmered at a 200°F setting with the lid closed for 24 hours. There is no mashing at the end as with chicken broth.

The broth is put into mason jars and chilled, using the same process as chicken broth. One ounce of melted beef fat is added to the top of each jar. Yield is about 100 quarts. The beef broth sells for $12 per jar, with a $1.50 deposit for the jar.

The bones get a second boil, which yields broth that is used in soups and stews. As with the chicken broth, the second boil will not be quite as gelatinous, but still makes a flavorful and deeply nutritious soup base.

Broth at a Hotel

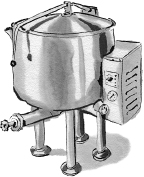

We visited Executive Chef Marc Suennemann at the Sheraton Atlanta Hotel. His well-equipped kitchen has three rectangular tilt skillets and one steam-jacketed kettle.

The hotel uses the tilt skillets for a variety of dishes, such as soups and stews, but Chef Suennemann prefers to use the steam-jacketed kettle for stock. While Three Stone Hearth aims for maximum gelatin content and produces an opaque broth, Suennemann aims for a clear, light broth, avoiding what he calls “muddiness.” He does not cover the broth when it is cooking, because this tends to make the broth muddy, he says. Also, in the tilt skillet, too much water evaporates, requiring more water to be added during cooking, thus diluting the broth. In the cylindrical kettle, the steam comes up around the edges and much of it curls back into the broth; there is less evaporation and less need to add additional water.

According to Suennemann, a light stock is best for clear reduction sauces, clear soups, and consommés; longer-cooked opaque sauces can be used for soups, gravies, and flour-based sauces.

For chicken broth, Chef Suennemann uses about 30 chickens. They are put into the steam kettle along with onion, carrots, celery, and herbs and simmered or gently boiled for only 45 minutes. The chickens are then taken out of the pot and the meat is removed from the carcasses. The carcasses are then returned to the kettle and simmered for another hour. Sometimes the carcasses are roasted before they are returned to the kettle; this results in a darker color to the broth. The second cooking is only 1 hour; then the broth is strained and cooled and used in soups or in small batches to create reduction sauces.

For beef broth, the staff roasts the bones and then simmers them along with vegetables and herbs in the steam kettle for 4 to 5 hours. The bones are then removed and the meat picked off. The bones are returned to the pot for another hour of cooking.

The stock is then strained and cooled. The congealed fat is reserved for roasting vegetables. This stock is used for consommé or reduction sauces and some of it is reserved and used as part of the liquid for the next batch of stock.

Broth in a Restaurant

We spoke to Nathanael Gregg, former chef de cuisine of Lincoln Restaurant in Washington, DC. He made chicken stock in a large stockpot. The recipe calls for 10 pounds of chicken backs and 5 pounds of chicken feet. The pot is filled with water, which is brought to a boil and then simmered for one day at the lowest heat with the cover off.

The cooked bones are then strained off and 10 pounds of roasted bones are added to the stock, along with 1 pound each of carrots, onions, and celery; 4 heads of garlic; bay leaves; peppercorns; thyme sprigs; and some pieces of kombu. This is brought to a boil and then simmered for 6 hours, or until reduced by half.

The resulting stock forms the basis for all sauces in the restaurant and for gravy in chicken pot pie.

The broth is enhanced with additional flavor by adding 5 pounds of hard cheese rinds (tied up in cheesecloth) to the finished stock. This is brought to a boil and then simmered for 4 hours. This savory stock is used in a sauce for meatballs.