Vessel Considerations and Services

Galvanic Corrosion and Stray Current

Galvanic Corrosion

All vessels are victim to galvanic corrosion (often called marine electrolysis), which is initiated by dissimilar metals that are in electrical contact with each other while immersed in seawater, an effective electrolytic solution. Galvanic corrosion also can be initiated from other nearby vessels, from large metal objects on the harbor bottom or from any metal pilings of the seawall at the head of the dock, if close to the vessel (say within 50 feet). Note that freshwater is a poor conductor of electricity therefore vessel corrosion from neighboring sources is much less of a concern than in saltwater. When seawater is warm, corrosion is accelerated as in Florida compared to New England.

To retard corrosion, zincs (sacrificial anodes) are attached to the vessel’s submerged metal components of exposed running gear and through-hull fittings. Additionally, heavy-gauge, green plastic-jacketed wire is attached to all metal components within the boat that have through-hull contact with the seawater. It is essential that the entire ‘bonding system’ has electrical continuity and is well maintained; otherwise, individual metal components will be ‘floating’ (i.e., electrically independent of the zinc anodes) and excessive, local corrosion will result from leaking current.

The rate of corrosion can be increased when a vessel connects to shore power unless the vessel is well bonded or isolated by a special type of marine-certified isolation transformer. Corrosion effects are typically worse at small marinas where the vessel is situated close to submerged metal shore structures (i.e., retaining walls) versus piers of large marinas that are considerably farther from metal shore structures.

Stray Current

If a marina is considered hot from an electrical standpoint, there are two possible sources: 1) the shore power cable is carrying stray current, or 2) the seawater is carrying stray current, possibly from an adjacent vessel. If you believe there is excessive stray current being released from an adjacent boat or any electrical equipment mounted on the pier, a simple source-identification test can be conducted at various locations around the dock using a basic voltmeter.

It is important to understand the differences between a safety issue for the vessel versus safety issues for humans. For example, galvanic corrosion (weak DC release) can slowly dissolve a propeller whereas stray AC current in the water can electrocute a swimmer. Keep in mind the difference between bonding for galvanic corrosion, stray current in the boat, stray current outside the boat and galvanic corrosion surrounding the boat. Causes of galvanic corrosion were discussed above.

Stray current in a vessel is common and easily tested by a marine electrician. A stray wire in the bilge originating from a submerged bilge pump causes one example. Stray current from outside a vessel is DC; AC does not cause stray current corrosion. On some facilities, DC current is dangerously carried through the AC ground (the green wire) to and from shore. Adding a galvanic isolator is a substantial expense but it would eliminate this type of stray current problem.

|

AUTHOR RECOMMENDATION |

|

If any problem is encountered with your shore power, contact an electrical technician, either from the marina or from a local, fully insured service company. Remember: Never disconnect the green ground wire from the shore power cable. This could put all persons aboard your vessel at risk of electrical shock or death. |

Biofouling – The Light Stuff

Vessels that are routinely berthed in marinas encounter biological growth on their submerged hulls. The majority of this growth is associated with local aquatic species but non-indigenous marine species also can make up part of the biological community, attaching themselves when the vessel visited other ports. In basic terms, biofouling is an accumulation of microorganisms, algae, marine plants and animals.

Problems Created by Biofouling

When fouling becomes significant, it has adverse effects on the hydrodynamics of the vessel, with increased drag and associated speed reduction for an underway vessel. It is not uncommon for a ‘fouled’ vessel to experience 10 percent loss of speed. If engine RPMs are increased to achieve normal speed, fuel consumption may increase by 20 to 40 percent.

In addition to hull fouling, biological growth on engine shafts, bearings and propellers can cause excess strain on the drive train of the propulsion system and loss of propeller efficiency. Fouling-induced friction and reduced mobility in rudder components can add significant stress to steering mechanisms and cause malfunction. These effects must be prevented by anti-fouling methods and postponement will only make the problem worse.

The Biological Process of Fouling

The first stage of fouling on a clean hull occurs during the first week it is immersed. Initially, a biofilm is developed from bacteria that adhere to the surface. This stage, called microfouling, does not significantly increase hull drag but it does create a surface upon which macrofouling can begin. During the second and third weeks, a wide variety of marine organisms eagerly attach to the film. Hard fouling organisms include barnacles, mollusks (including zebra mussels and others) and tube worms which have rigid casings. Soft fouling organisms also flourish on the surface, with growth of seaweed, algae and soft animals such as hydroids and slime. Within one month, an active biological community develops — ideal for analysis by the marine biologist but a significant problem for the boater.

Note that availability of a host surface is necessary for macrofouling. As soon as the hard organisms are able to settle in, they become an ideal surface for others to adhere to. This results in a rapid increase in population density and addition of more soft fouling organisms.

Prevalence of Biofouling

Marine biologists around the globe have conducted many studies of the incidence of biofouling on recreational vessels. Some of the key findings are given below:

- Warm waters accelerate biofouling.

- Berthing a vessel adjacent to piers, pilings or other structures with established biological communities fosters propagation of organisms to the vessel.

- Vessels with prolonged inactivity yield more biofouling development than an active vessel that is underway frequently.

- Vessels moored in a harbor tend to have more biofouling than vessels berthed at piers, primarily a result of moored vessels being used less frequently and having their hulls maintained seldom.

- Underway vessels prohibit initiation of marine growth and expel some of the established biofouling communities via the forces of water and waves which apply horizontal friction to the hull.

- Vessels that travel at high speeds shed biofouling organisms more effectively than slower vessels.

- Loss of speed and costs of wasted fuel from biofouling hull drag are strong incentives for owners to apply anti-fouling coatings to their vessel.

Brief History of Anti-Fouling Methodology

As far back as 1,500 B.C., mariners encountered biofouling and sought to alleviate the problem with hull applications of pitch, tar and wax. Around 400 B.C. the effectiveness of toxic chemicals for retarding biological growth was discovered and mixtures of oil, sulfur and arsenic were used to coat hulls as a deterrent for wood-boring shipworms.

In the 1700s, copper plating was applied over wood hulls with good anti-fouling success but with new construction of iron-hull vessels in the 1800s, copper plating became a major problem as it induced galvanic corrosion from the bonded dissimilar metals.

Not until the 1960s was there a major breakthrough for anti-fouling coatings, with development of organo-tin chemicals (i.e., tributyl-tin: TBT). As an anti-fouling coating is hydrolized in seawater, it slowly releases chemicals that are toxic to marine organisms. Hulls coated with TBT paints were mostly growth-free for periods up to 4 years in some regions. This was a major benefit for biofouling of recreational, commercial and naval vessels but TBT was later discovered to be highly toxic to mollusks and other marine organisms whose tissue could pass through the food chain to humans. Consequently, in the 1980s TBT was banned on vessels less than 25 meters in length. The use of organotin compounds as biocides in anti-fouling paint was completely banned in 2008 by the International Maritime Organization.

Present Day Types of Anti-Fouling

Biocides and non-toxic coatings are the two most widely used categories of anti-fouling chemicals in practice today. Biocides are added to anti-fouling surface coatings to attack film-producing aquatic bacteria. These copper-based (cuprous oxide) anti-fouling solutions are much less toxic than the earlier organotins but are generally effective with fewer adverse impacts on the marine environment.

Non-toxic coatings, primarily organic polymers, create a very smooth surface and thereby prevent attachment of marine organisms to the coated hulls. These fluoropolymers and silicone coatings are ecologically inert which is a major advantage over the organotins. However, they are still in early stages of perfection and have disadvantages of limited mechanical strength and long-term stability.

Hydrophilic coatings also are being developed for anti-fouling applications but they and other methods are still in Research and Development stages, and thus prohibitively expensive for recreational boaters.

Because the technology for anti-fouling coatings is advancing rapidly, boat owners should consult with major distributors of marine paints to determine best products and the associated terminology. Hard-coat paints are typically used on fast boats (i.e., greater than 20 knot speeds) because they are less prone to washing off by friction on the hull. Ablative (soft-coat) paints purposely shed their coating slowly but quicker under the action of water friction so they are not recommended on fast boats. Vessel characteristics, frequency of hauling and bottom cleaning, water temperature, local rates of fouling and other factors must be considered when selecting the best anti-fouling paint for your vessel.

Invasive Non-indigenous Mussels – The Worst Biofouling

Rapid reproduction and geographic spread of non-indigenous aquatic organisms is a major problem in fresh and saline environments of the U.S. In recent years, invasive lionfish have received broad public attention because of their decimation of reef fish in tropical waters (and their natural photographic appeal). They certainly are a major problem for co-located fisheries but infestations of nuisance mussels presently have far greater negative impact on native species and human health in the U.S. Additionally, they cause negative impacts to vessels, economically important fish and shellfish, and industrial facilities that rely on flow of natural waters for cooling.

This section provides an overview of major mussel species to familiarize the reader with the biological characteristics and potential impacts of each within U.S. waters. The majority of information provided herein came from Wikipedia.com, which proved to be a good source for general information on mussel species. Other more-specific, scientific articles on individual mussel species are given on that website.

|

Zebra Mussels |

|

|

|

|

Species: |

Dreissena Polymorpha (Dreissena is the name of an extinct zebra species) |

|

Native region: |

Rivers and lakes of Eastern Europe and western Asia |

|

History in U.S.A.: |

• Entered U.S.A. in ballast water of transoceanic ships. • First discovered in U.S.A. in the Great Lakes in 1988 |

|

Geographic range in U.S.A: |

• Throughout Great Lakes and down Mississippi River. • Also present in states south of Great Lakes • Atlantic coast is clear, from Florida to New York |

|

Problem level: |

Severe |

|

Known predators in U.S.A.: |

None |

|

Preferred environment: |

Attachment to hard surfaces and flow intake pipes |

|

Adverse impacts: |

• Depletion of dissolved oxygen in water • Suffocation of local shellfish by attachment. Densities up to 35,000 mussels per square meter • Clogging of water intake pipes and submerged pumps • Encrustation of vessels, buoys and coastal structures |

|

Positive impacts: |

Water clarity is improved by filtering of particulates |

|

Shell size: |

1 to 2 inches |

|

Preferred aquatic environment: |

• Freshwater only • Can withstand cold temperatures |

|

Reproduction cycle: |

• Growth, over-wintering and reproduction • Strong filter feeders (1 liter of water per day) |

|

Mussel’s food source: |

Algae (phytoplankton) |

|

Saltwater relative: |

Dark false mussel (native to Atlantic Coast) |

|

Food appeal in U.S.A.: |

• None – contaminated shellfish • Major accumulators of toxic chemicals in mussel tissue |

|

Quagga Mussels |

|

|

|

|

Species: |

Dreissena Bugenis |

|

Native region: |

Ukraine in western Asia |

|

History in U.S.A.: |

• Entered U.S. in ballast water via St. Lawrence seaway • First discovered in U.S.A. in the Great Lakes in 1989 |

|

Geographic range in U.S.A: |

• Throughout Great Lakes • In 2008, spread to Colorado River, southern California, western Arizona and Southern Nevada • Atlantic coast and Gulf of Mexico are quagga free |

|

Problem level: |

Severe |

|

Known predators in U.S.A.: |

None |

|

Preferred environment: |

Attachment to hard surfaces and flow intake pipes |

|

Adverse impacts: |

• Depletion of dissolved oxygen in water • Suffocation of local shellfish by attachment. Densities up to 35,000 mussels per square meter • Clogging of water intake pipes and submerged pumps • Encrustation of vessels, buoys and coastal structures |

|

Positive impacts: |

Water clarity is improved by filtering of particulates |

|

Shell size: |

Small (coin sized) |

|

Preferred aquatic environment: |

• Freshwater only • Can withstand cold temperatures |

|

Reproduction cycle: |

• Strong filter feeders (1 liter of water per day). • Prolific breeders: 1 million eggs per year |

|

Mussel’s food source: |

Algae (phytoplankton) |

|

Food appeal in U.S.A.: |

• None – contaminated shellfish • Major accumulators of toxic chemicals in mussel tissue. (300,000 times greater than concentrations in natural environment) |

Attempts to Establish Aquatic Predators for Quagga Mussels

In 2004, it was determined that yellow perch would feed on quagga mussels but in doing so they would ingest toxic chemicals that had been accumulated in high concentrations by the mussels. This could lead to another, possibly larger problem if perch tissue were ingested by mammals, birds and humans, thus bringing the contaminants higher into the natural food chain. Similarly, redear sunfish were later discovered to prey naturally on quagga mussels and they have been introduced in the Colorado River system despite the potential of establishing routes for food-chain transfer.

|

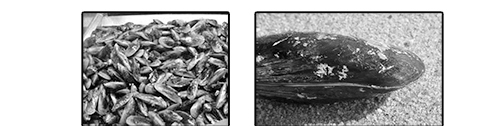

Asian Green Mussels |

|

|

|

|

Species: |

Perna Viridis |

|

Native region: |

• Indo-Pacific region • An economically important shellfish species in Asia due to its food quality when raised in clean aquaculture facilities. |

|

History in U.S.A.: |

• Entered Caribbean region via ballast water in 1990 • First discovered in U.S.A. in Tampa Bay in 1999 • Most recent non-indigenous mollusk to invade Florida |

|

Geographic range in U.S.A: |

• Southern coasts of Florida • Atlantic coast to South Carolina (southern temperate areas) • Spread along Atlantic coast is likely due to larval drift by currents |

|

Problem level: |

Severe |

|

Known predators in U.S.A.: |

None |

|

Preferred environment: |

Attachment to hard surfaces and flow intake pipes |

|

Adverse impacts: |

• Depletion of dissolved oxygen in water • Suffocation of local shellfish by attachment. Densities up to 35,000 mussels per square meter • Clogging of water intake pipes and submerged pumps • Encrustation of vessels, buoys and coastal structures |

|

Positive impacts: |

Water clarity is improved by filtering of particulates |

|

Shell size: |

Can grow to 3 to 4 inches in length |

|

Preferred aquatic environment: |

• Wide range of acceptable marine conditions. • Prefers regions of high water flow. • Saltwater and brackish environments (18 to 33 ppt) • Temperatures ranging from 50° to 90° F |

|

Reproduction cycle: |

• Strong filter feeders (1 liter of water per day). |

|

Mussel’s food source: |

Algae (phytoplankton) |

|

Food appeal in U.S.A.: |

• None – contaminated shellfish • Major accumulators of toxic chemicals in mussel tissue. • Deadly if accumulating dinoflagellate phytoplankton from seawater |

Asian Green Mussels are relatively new to U.S. coastal waters but have already become a major biofouling problem for vessels berthed in wet slips in Florida and the southeast U.S. coastline. Mussel fouling of industrial facilities also is highly problematic for those having seawater intake pipes and pumps.

|

Brown Mussels |

|

|

|

|

Species: |

Perna Perna |

|

Native region: |

• West Coast of Africa and coast of South America to Caribbean • Excellent food appeal in South America and Africa |

|

History in U.S.A.: |

First aquatic invasion was in Texas; accidental via ballast water from Venezuela |

|

Shell size: |

Typically 2.5 to 4 inches in length |

|

Color: |

Brown |

|

Preferred aquatic environment: |

Can exist in a broad range of salinity and temperature |

|

Biofouling potential: |

High but can be controlled by chlorination |

Addressing the Problem of Mussel Infestation on Vessels

Returning to the principal topic of this book, boaters are faced with two problems from invasive mussels:

- Biofouling of vessel hulls which causes speed reduction and fuel waste, and

- Infestation of mussels within through-hull fittings and ‘raw water’ lines to pumps (e.g., for air conditioning pumps for coolant water flow, for toilets using saltwater for flushing, for saltwater wash-down pumps and for inflow to live-bait wells).

Additionally, raw water is pumped in high volume to engines and generators for cooling. It is critical for efficient vessel operations that all of these intake lines be free of obstructions.

If a vessel’s raw water lines become infested with nuisance mussels inboard of the through-hull fittings (and thus inaccessible by diver cleaning) either the lines must be replaced or cleaned by an intensive flow-through process using a commercially available product such as Barnacle Buster. This liquid cleaner is a non-toxic (to humans) biodegradable solution designed to remove marine growth from interior surfaces of hoses, pipes and valves. The solvent is added to a large volume of clean freshwater and pumped through the lines to a recirculating reservoir and filtering system to remove mussels, barnacles and other unwanted deposits. Thorough cleaning can typically be accomplished after two to four hours of circulating solution.

Methods to Prevent Further Spread of Invasive Mussels

For boaters who operate in regions with non-indigenous invasive species, it is important they take actions to prevent further spreading of these unwanted species to other geographic regions. Recommended procedures (Best Practices) are given below:

- Be aware of invasive species that exist in your local waters.

- For vessels kept in wet slips, conduct periodic bottom cleaning to thoroughly remove all mussels attached to the hull, running gear and through-hull fittings.

- If possible, conduct bottom cleaning while the vessel is on land to prevent the scrapings from reentering the water.

- Immediately before cruising to another area, ensure that no mussels or non-native fouling organisms are attached to your vessel.

- Empty bilges and live-well bait tanks of water before cruising and be sure to dispose of the water on land or in proper liquid-waste containers.

Non-Invasive Mussel Species

It is relatively easy to confuse the various mussel species, especially recognizing that in the U.S., green mussels of Asian descent are generally poisonous if harvested in U.S. waters but green mussels imported from New Zealand are an excellent food source and consequently, are widely available in the U.S. To help the average consumer and concerned boater, basic characteristics are given below for mussels not categorized as invasive in the U.S. although most are non-indigenous.

|

New Zealand Green-Tipped Mussel |

|

|

|

|

Species: |

Perna Canalicula |

|

Native region: |

• New Zealand only • Great importance as a cultivated species |

|

History in U.S.A.: |

Strictly imported for human consumption |

|

Shell size: |

Up to 9 inches in length; largest species of mussel |

|

Color: |

Dark brown/green shell except for green-tips around edge |

|

Temperature environment: |

Cannot live in tropics |

|

Food appeal in U.S.A.: |

Excellent imported species |

|

Possible medicinal value: |

• Some believe this mussel has natural healing characteristics, including anti-inflammation and pain relief. • Marketed for treating arthritis and joint problems. |

|

European (Mediterranean) Blue Mussels |

|

|

|

|

Species: |

Mytilus Galloprovincialis |

|

Native region: |

• Mediterranean and Black Seas • Suitable for aquaculture |

|

History in U.S.A.: |

Introduced to West Coast around 1900 |

|

Shell size: |

3 to 5 inches in length |

|

Color: |

Blue |

|

Temperature environment: |

Cold waters |

|

Food appeal in U.S.A.: |

Excellent |

|

California Mussels |

|

|

|

|

Species: |

Mytilus Californianus |

|

Native region: |

• West Coast of North America • Strong natural species; not cultivated |

|

Shell size: |

3 to 5 inches in length but up to 9 inches |

|

Color: |

Blue |

|

Temperature environment: |

High salinity, preferably clear water, rough conditions |

|

Food appeal in U.S.A.: |

Excellent |

|

Blue (Common) Mussels |

|

|

Species: |

Mytilus Edulis |

|

Native region: |

• Both Coasts of North Atlantic and North Pacific • Also in southern Hemisphere |

|

Shell size: |

3 to 5 inches in length |

|

Color: |

Blue |

|

Temperature environment: |

• Temperate to polar waters • Intensive aquaculture |

|

Food appeal in U.S.A.: |

Excellent |

Bottom Cleaning

The following discussion pertains to relatively large vessels that are kept afloat for the boating season (at higher latitudes) or throughout the year in southern waters. Bottoms of small boats that are not marina residents can easily be washed each time they come out of the water and trailered. Larger vessels can either be scrubbed while berthed in the marina or when hauled out of the water for repairs or inspection. Regardless of vessel size, each hull should be power-washed and scraped to remove marine fouling organisms. During this process, it is essential that the organic debris and rinse water be collected and disposed according to local regulations for wastewater.

This task sounds very simple but don’t fool yourself into thinking there aren’t subtleties a boat owner needs to be aware of. Read the list below for starters.

- Bottom cleaners must be cognizant of local regulations that specify the types of tools and procedures to be used at their location. New regulations arise each year on account of growing concern about pollution of the marine environment, with some states such as California being very aggressive on restrictions for bottom cleaning. Beware.

- Ask your bottom cleaner if he/she is knowledgeable of non-indigenous mussel species and how to recognize them.

- Not all bottom cleaners know what they’re doing. Ask marina management if they recommend any local, reputable individuals or bottom cleaning companies.

- Disreputable bottom cleaners may clean only around the water line of a vessel as it’s the only part of the hull that can be seen by the owner standing on the pier. This actually occurs.

- Many trustworthy bottom-cleaning companies now offer underwater videography services to show the boat owner the condition of the hull before and after cleaning. This is an excellent capability as it also demonstrates the effectiveness of the cleaning process. It is wise to hire a company that offers this type of video service, at no extra charge.

- Professional bottom cleaning companies often encourage boat owners to subscribe to a regular schedule (i.e., monthly) for cleaning. The frequency of this service should be questioned by the boat owner to ensure it is necessary and not too often for their seawater environment and boat usage regimen. Ask owners of neighboring boats what is their best bottom-cleaning schedule.

- Frequent cleanings are recommended but they each erode some of the anti-fouling coating, especially the ablative materials and/or if the cleaning tools are inappropriately rough. The cleanest hulls may require more frequent anti-fouling paintings, ironically.

- Cost competition for bottom cleaning services is good but quite often, you get what you pay for: poor service at the lowest price.

- Whenever you plan to have your boat hauled out, have your bottom cleaner do his work but don’t tell him about the pending haul-out, especially if he doesn’t provide video records of his cleaning work. You can be the judge of his service quality when you see your vessel’s bottom exposed on the travel-lift.

Divers

The topic of bottom cleaning by divers is addressed above as a separate section because of its importance. Below are listed other services that should be performed by trained divers (or a highly capable owner or crewmember), preferably individuals who are certified and insured for commercial work. Even if you don’t have an immediate need for these services, someday you likely will, especially if you progress to a larger vessel.

- Inspection and replacement of zinc anodes. This can be performed by the diver who is conducting bottom cleaning but be sure he/she knows the tricks like using sandpaper to thoroughly clean the metal surfaces before the zincs are applied; a hammer to ensure the ball zincs have their entire inner surface in contact with the shaft before final tightening of the locking screws; etc.

- Cleaning and minor maintenance of the vessel’s underwater components of its propulsion system, including the running gear (which typically does not have anti-fouling paint), any bow or stern thrusters, rear-mounted trim tabs, vessel stabilizers, etc.

- Depth transducer and speed log maintenance. Typically cleaning surfaces and securing any wiring that may have come adrift.

- Through-hull intake port cleaning, including raw water intakes for engines, generators, air conditioning cooling water strainers, seawater for toilets, inflow for water makers, etc.

Boat Washing

Many boat owners conduct their own hull cleaning. Others hire individuals or a professional service for cleaning and detailing. If you choose to hire someone, here are some factors that warrant consideration.

- Always take recommendations from other boaters who have observed the work ethic of the person(s) hired.

- Ask the worker to introduce you to other boaters in the marina who hire them regularly.

- Make sure the washer(s) considers the job important rather than just an easy way to make a buck. Many unemployed persons walk the docks looking for work with no relevant experience. The quality of their services will correlate with their short resume.

- Don’t hire the kids who are often on their cell phones, smoking or taking selfies while they’re supposed to be ‘on the clock’. Although their hourly rate may be low, their productivity more than negates the investment.

- Look for washers who know the best cleaning agent for each part of the job. Because the work involves glass, fiberglass, metal, teak, painted surfaces, canvas, lines of different materials, nylon covers, etc., experienced personnel often know little tricks. Good cleaning personnel normally bring a whole assortment of products they use regularly. No single cleaning product works for all materials. Anyone who shows up with none should be sent away immediately.

- Furthermore, purchasing only the products from the cleaning shelf of a single marine megastore proves the worker’s inexperience and often wastes lots of your money. For instance, liquid dishwasher soap is a better cleaner for teak decks than most products ten times more expensive.

Engine Mechanics

When you arrive in a new area, first check with your marina to determine whether they have skilled engineers and technicians for your engine types. If not, go online, find a local marine service directory or use the Yellow Pages to locate the nearest certified marine repair company for your engine and generator manufacturer. Always ask other boaters with the same engine type for their recommendation on who provides the best engine service. Don’t wait until a problem arises. Additionally, this will be your source for engine parts and consumable supplies (e.g., filters, impellors, etc.)

After you have made a tentative choice, visit the service company, register your boat as an account if possible and discuss any discount terms such as eliminating transit costs if work on your vessel goes beyond the first four hours. Next, have one of their technicians come to your vessel to perform an hour or two of basic preventative maintenance. You’ll quickly learn about his work ethic, cleanliness, time keeping (e.g., do they charge for transit time to and from their facility?), technical value of his recommendations, etc. If you like this technician’s work, request him/her when other work needs to be performed on your vessel because he already has familiarity with your vessel’s engine room access, layout and equipment. If the service company cannot commit to sending the same technician for each service call, this should be viewed as a significant disadvantage for you and your budget because the learning curve will begin each time a new technician arrives.

Although there may be a certified engine dealership with full service capabilities in your area, there are times when an independent mechanic is better than a technician from the dealer’s representative. Quite often, the independent mechanic has more capabilities than new technicians at the dealership. Because of his proven skills, the independent mechanic often has no shortage of work from existing happy clients and/or referrals. His rate is often substantially less (say $80 per hour versus $120) than the dealership’s hourly rate for a less-skilled technician.

A good, independent engine mechanic is worth his weight in gold, especially if he provides his cell phone number in the event you have an engine emergency. Don’t abuse this privilege by calling about minor problems that can wait for a weekday and during normal working hours.

Navigation and Electronics Technicians

Today’s recreational vessels are equipped with complex electronics systems, including but not limited to navigation, radar, depth and fish finding equipment, sonar electronics, communications, audio-visual, satellite TV, cell phone and Wi-Fi. Best strategies for identifying skilled technicians for maintenance of these diverse systems depend upon whether you’re purchasing new equipment or servicing existing components.

Service

When it comes to anything electronic, realize that in today’s world almost nothing gets repaired. In most cases, major components are either returned to the factory for repair or replacement under warranty, or they are replaced at the owner’s expense with new, upgraded equipment. For example, if a computer chip or 20-cent resistor is blown inside a complex electronic unit, the labor cost for troubleshooting and repair, added to the cost for shipping of the replacement part will most likely exceed the cost of a new system. Yes, a 20-cent component can cause you to buy a new system altogether.

Before you start buying new equipment, there’s one more option: Craigslist.org (CL). This free and efficient sales website is the ultimate online Yard Sale for used equipment, even marine. Quite often, boaters purchase new electronics equipment via normal sales outlets then sell their used gear on CL with the result that cost-conscious boaters can (and do) purchase operable equipment at ten to thirty cents on the dollar. Look first on CL if you’re not keen on purchasing new equipment at retail prices.

Planned obsolescence seems to be getting shorter — maybe two or three years before the next technological breakthrough. If your electronic component is older than a few years, think seriously about replacement if it starts to malfunction; any older than that and the manufacturer may not support your product.

Given this climate of rapid technological advances, the verb ‘Service’ would best be defined as the two-step process of troubleshooting then making a decision on whether or not to replace. Having a technician fix the unit is generally not an option. Consequently, for most of your equipment problems, you need a fast and highly experienced electronics troubleshooter who can assess all of your electronics woes. This person often is independent and purposely not a manufacturer’s representative. If you find him/her via recommendations of other boaters, they’ll be very busy but worth the wait.

Some of these troubleshooters can also recommend the best state-of-the-art replacement technologies but don’t limit your options to this one source of information.

Purchasing New Electronics

If your situation does require purchase of new electronics equipment, regardless of the type or use, here are my recommendations and sequential order:

- Visit dealer showrooms of the leading manufacturers. Speak with the dealer’s salesperson (their technicians preferably) to learn as much as possible about the features of their newest equipment lines. Obtain written price quotations for a few appealing units.

- Go online and find the website of the same manufacturer and read about the specifications of the newest items to verify what the salesperson had stated. Obtain a price from the website if possible.

- Go online again, searching for reviews of the equipment you are considering for purchase. Preferably, find reviews that compare similar technologies of numerous manufacturers.

- Consult with your electronics technician to determine whether he agrees with your choice for the new electronics and that it does not pose any compatibility problems with other integrated systems aboard your vessel.

- Search on Amazon.com and eBay.com for the specific item you already have other price quotations for. Determine the lowest price online, including taxes and shipping costs. Then evaluate the quality of that supplier to be sure it is a reputable source of new equipment. Do not buy the item yet.

- Determine whether there is a major boat show or sporting goods convention in your area and in time for your purchasing needs. If so, you can often negotiate a substantial (i.e., 25 percent) discount off retail prices with the dealer’s representative at the show. This may be less than the price you have found on Amazon or eBay but possibly not, as online shopping is often the best source for low-cost purchasing.

If you follow this step-wise process, you’ll be confident you’ve found the best deal possible for the item of your choice.

Compass Calibration

Any time a new compass is installed on a vessel or when new electronic components are mounted in close proximity to a compass or autopilot heading sensor, the compass must be calibrated. For owners who are not familiar with the process of ‘swinging a compass’, it is wise to hire an experienced technician for this relatively simple but critical calibration procedure.

Other Maintenance Personnel

In addition to the engine mechanics and electronics experts mentioned above, the boat owner will surely need the services of other skilled marine technicians, including those with expertise in marine plumbing, hydraulics, fiberglass repair, woodworking, anchor windlasses, davits, air conditioning, water making, battery chargers and inverter systems, security systems, etc. Most marinas have a list of recommended local sources for such repair services. Additionally, if the coastal town or city supports an active boating community, local directories of marine service providers and suppliers abound. Fellow boaters in a marina enjoy providing rave reviews about their service technicians but first be sure the boat owner is capable of recognizing good service from bad, especially for your complex onboard systems.

On-Shore Necessities

Local Storage Facilities

If you plan to live aboard your vessel while berthed in a marina, it is unlikely you’ll be able to keep all of your belongings aboard, especially if you have a wife, partner and/or children. Some marinas lease small storage units but rarely are they large enough (say 10-foot by 10-foot floor area) for storage of household items or a small vehicle. Consequently, on-shore storage options are essential for many live-aboard boaters. In most areas clean, secure storage units can be leased from multiple sources and proximity to your marina is typically a key criterion for your selection. As you are evaluating options, note that some facilities have trucks that can be borrowed for transporting your belongings to and from the marina.

Airport

If you select a marina that offers resort amenities and/or is situated in a highly desirable location or climate, it’s likely you will have family and friends visit. Similarly, if your vessel is a fine yacht with spare staterooms, they will come from near and far. Surely you will offer to shuttle them to and from the airport so you had better consider the proximity to a good domestic or international airport when selecting a marina or general vicinity. Having to drive 3 hours each way to an international airport is less than optimum.

Marine Hardware Stores

All boaters frequently need assorted items of stainless steel hardware, boat cleaning products, filters, impellors, etc., for basic maintenance and problem solving. If the marina has a ship’s store, minor items can be purchased but boaters frequently need stores such as West Marine and Home Depot, which are easy to locate online or via phone searches. Marina personnel can easily identify local independent hardware stores and marine supply sources. Of course, online purchases can often yield good prices but the time delay for shipping often precludes this purchase option versus local shopping.

Propane Gas

Many vessels use bottled propane gas for cook stoves, outdoor grills and some lights. Marina personnel can provide local sources.

Other Common Needs

Close proximity of banks, grocers, liquor stores, barbers, hair salons and other essential services will make marina living easy.