THE FN MAUSER

In 1889, the Belgian Army adopted the Mauser Model 1889. That same year, a consortium of Belgian gunmakers founded a company to produce it. The company was given the name Fabrique Nationale d’Armes de Guerre—FN, for short—and it was set up in the town of Herstal, near Liège. Two years later, Germany’s great gunmaking conglomerate, Ludwig Löwe & Co., acquired 50 percent of the stock, and added FN to its wide-ranging stable of gunmaking companies that included the Mauser-Werke and, eventually, Luger.

Today, 130 years later, FN is still in Herstal, still making rifles, and is Europe’s largest exporter of military weapons. Tell someone—anyone—that a gun is made by FN, and it is a certain guarantee of quality.

The town of Liège is the historical center of Belgium’s ancient gunmaking trade, and Belgians have been master gunmakers for centuries. In the years to come, FN was at the center of so many seemingly disparate events in the world of gunmaking that you begin to think there must have been some divine plan. The government contract completed, the FN factory was rather at loose ends when, in 1897, American inventor John M. Browning approached it about manufacturing the semiauto pistol that later came to be known as the Model 1900. Five years later, he came back with a design for a semiauto shotgun that Winchester had rejected. FN snapped it up, and Browning personally placed an order for ten thousand guns. This ensured immediate commercial success. Browning’s ten thousand shotguns were imported by Schoverling, Daly, and Gales, and they sold out within a year.

John M. Browning maintained a close relationship with FN until his death in 1926. It then continued with his son, Val Browning, and with the Browning Arms Company of Utah.

For those who believe in omens and the like, here is an ironic series of events: In 1914, Gavrilo Princip assassinated the Austrian Archduke Franz Ferdinand using a Browning 1900 .32 ACP pistol. Five weeks later, Germany invaded Belgium, and the FN production line, where the gun was produced, was shut down for the first of only two times in its history. The Germans also burned down the ancient (and irreplaceable) library at Louvain. The second time the production line shut down was in 1940, when Germany invaded again. Poetic justice, perhaps, in its own tragic way.

My first encounter with FN occurred when, as a child, I surreptitiously dug out a pistol that my father kept under some sweaters in a bottom drawer, and found engraved on the side Fabrique Nationale d’Armes de Guerre, Herstal, Belgium. It was a Browning Model 1926, made under duress for the Germans during the war, complete with Waffenamt. My father acquired it during his time with the Canadian Army in Europe. Then, when I enlisted in the Canadian Army Reserve at the age of sixteen, I was handed an FN C1 rifle (the famous FN-FAL). Finally, as a gun-struck teenager who spent hours reading about guns when I should have been studying algebra, I discovered the FN name in the beautiful Browning catalogues, makers of the Superposed, the Auto-5, and the Browning Hi-Power pistol.

As one of the far-flung tentacles of Ludwig Löwe’s Mauser-making empire, FN continued to make the K98 for years after the rifle’s military role ended. After the armistice in 1918, when the Treaty of Versailles prohibited Germany from making certain military armaments, FN became an important supplier of Mauser 98s to countries such as Brazil, Yugoslavia, and Lithuania.

The plant at Herstal was back in civilian operation shortly after the second war ended in 1945, and one of its earliest products was the K98 action. These were initially K98 clones, but were gradually given civilian dress as FN made modifications—some for the better, some not. Between 1945 and 1965, the FN Mauser progressed through a number of models. These were sold in the white to gunsmiths for building custom rifles, and supplied in bulk to various rifle companies to produce their own rifles. Roy Weatherby used FN Mausers to build his earliest California rifles, before he designed the Mark V.

Browning Arms had its own line of FN-made, Mauser-actioned rifles through the 1960s, called simply the “Browning High Power.” They were built on the final iteration of the FN Mauser, called the Supreme. It was the last in a long series of commercial Mausers from FN. Frank de Haas wrote that he first saw FN actions for sale in the 1941 Stoeger catalogue. The action was called the “Peerless,” and he immediately ordered one, but received a refund because supplies were cut off when Germany invaded Belgium in May, 1940. When hostilities ended in 1945, FN resumed production of Mauser actions in a rather confusing variety that seemingly evolved faster than they could rename them. As a result, features that are supposedly unique to one model may be found on earlier or later ones.

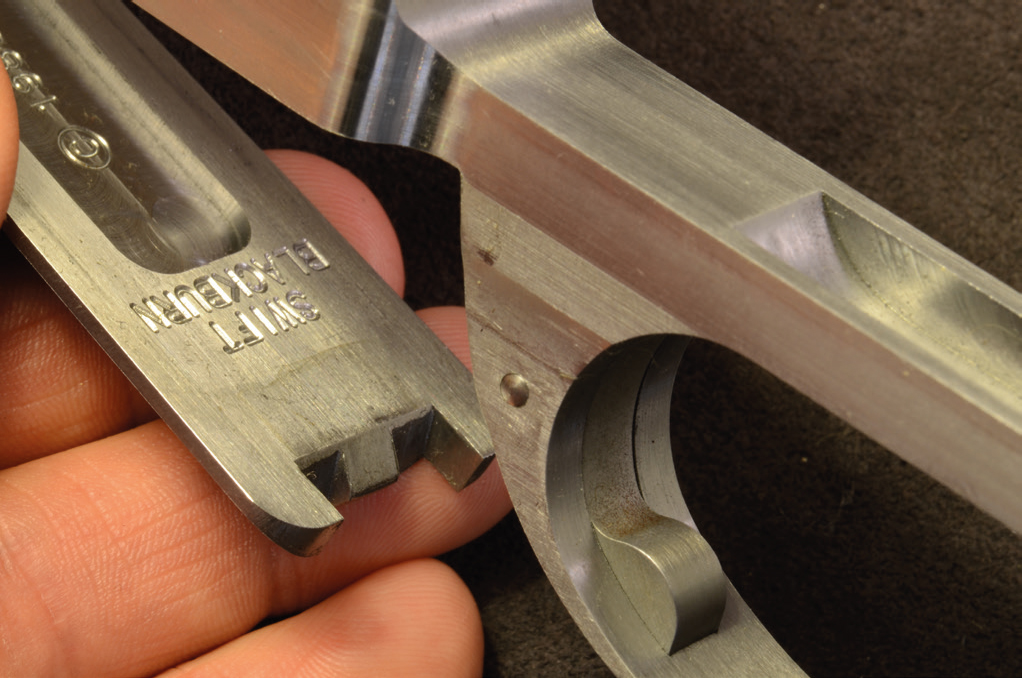

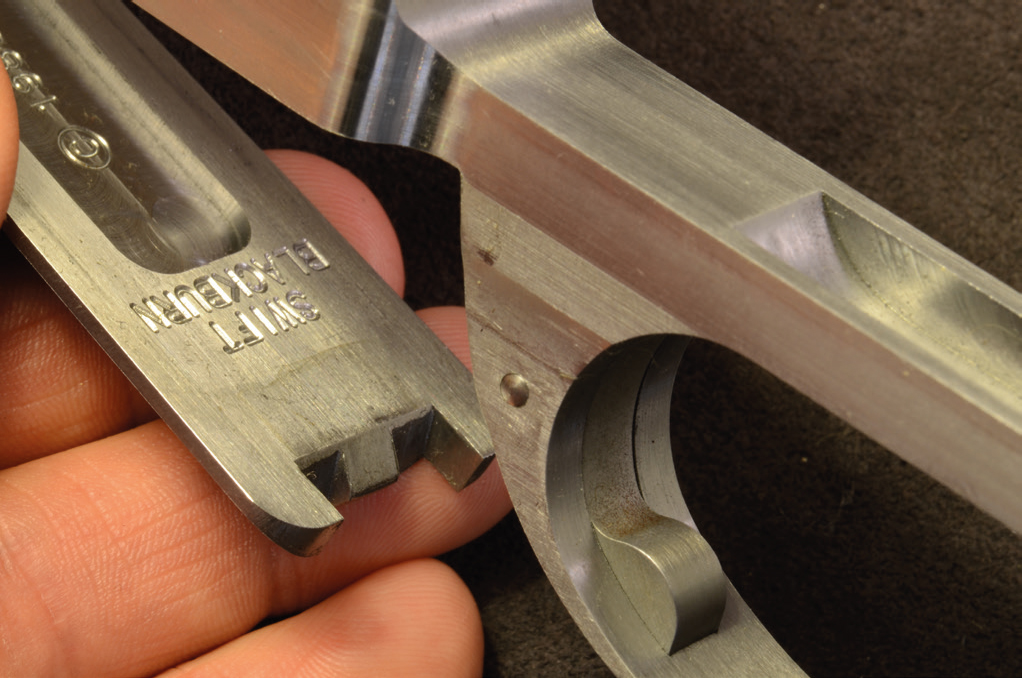

Officially, the post-war Mausers were the Series 300 and 400, sometimes called the Deluxe and, finally, the Supreme. The Supreme was the favorite civilian 98 on which to build a custom rifle, if you couldn’t afford an Oberndorf and didn’t want a military one. No one ever criticized the basic quality of FN Mausers, although some disliked some of the features. For example, the Supreme was marketed with a streamlined, polished bolt shroud without the original wing safety. Instead, it was supplied with a single-stage trigger with an integral safety. As well, on the Browning High Power rifles, the trigger guard and floor plate were made of some indeterminate alloy and given a polished black finish with chintzy gold filigree. Most gunmakers obtained steel bottom metal to replace it, and gunmaker Ted Blackburn later became the source for the highest quality bottom metal for that purpose.

After the war, Firearms International (FI) became a major importer, and offered a rifle called the Musketeer built on the FN action. Later, Harrington & Richardson marketed a bolt-action rifle using the FN, as did High Standard, Colt, Marlin, and a number of proprietary names like Montgomery Ward’s Western Field. The FN Supreme, it seemed, was everywhere. Even the other-worldly Winslow rifles, which out-did the Weatherby look by a substantial margin, were built on FN Supremes.

Blackburn bottom metal, now made by Swift Bullets in Quinter, Kansas.

FN pioneered a number of features on its actions aside from the bolt shroud. It dispensed with the thumb slot on the left side, which stiffened the action (an aid to accuracy), and in 1955 produced a single-shot version with no magazine cut-out. This made it stiffer still, and was intended for benchrest rifles. The FN bolt handle was swept back in a graceful arc, and the bolt knob was flat and knurled on the underside. Some professed to dislike it, but I thought it was the essence of style.

On the Supreme, FN changed the bolt stop and release, replacing the traditional Mauser box with a spring-loaded lever. Again, some criticize it as monkeying with Paul Mauser’s masterpiece, but it is both unobtrusive and rather elegant, and in my experience seems to work just as well. Earlier models had a floorplate release inside the trigger guard, but it was not the distinctive Oberndorf grooved button. Instead, it was a rather workmanlike affair that some gunsmiths went to great pains to replace or correct.

Not surprisingly, the quality of the rifles built on FN actions varied widely. There is no all-encompassing rule about them except to say that the basic actions were as good as Mauser actions get. I have never heard any criticisms of the FNs similar to those leveled against the Yugoslav Mark X (Zastava), for example, which were often sloppily finished. In the opinion of Frank de Haas, gunsmith, contributing editor to The American Rifleman, and author of Bolt Action Rifles: “FN actions are made to the usual exacting FN quality, a quality so outstanding no one should question it.”

The Browning High Power rifles are, to my eye, a curious combination of beautiful quality and questionable taste. As a teenager, of course, I thought they were wonderful. Later, I came to dislike both the alloy bottom metal and the two-position trigger-block safety. More than that, however, while the Brownings were stocked in nice walnut, their dimensions were less than graceful. The forend was a couple of inches too long, the buttstock a little too broad. There was neither an ebony forend tip nor a pistol-grip cap—decidedly low-rent in the ’60s. I later came to appreciate forends au naturale, but not the pistol grip. Still, it had good hand-checkering in generous patterns. There were two higher grades, the Medallion and Olympian, and they were truly lovely examples of the gunmaker’s art—albeit with some ’60s’ touches, now deservedly out of fashion. On the positive side, there was their lovely walnut, rosewood forend tips and grip caps, and varying degrees of superb Belgian engraving. On the negative side were the white-line spacers, skip-line checkering, ventilated recoil pads, and a high-gloss wood finish similar to Weatherby’s. Some years later, I owned a Browning Medallion grade .222 Remington Magnum, built on a short Sako action. In 1979, during a moment of derangement, I traded it for a snowmobile, which died in a snowbank before the winter was over. Not a happy memory.

One over-riding complaint about the Browning High Power was its weight. Although it was listed as being as light as 6¼ pounds, depending on barrel length and caliber, I have one (extensively remodeled, but essentially the original rifle) in .30-06 which, while comfortable to shoot, is not going on any hunting trips where I have to climb anything more substantial than an anthill. Incidentally, that particular rifle is built on the FN Supreme action, but does not have the flattened, knurled bolt knob—one more example of how some features migrate from one model to another, seemingly at will.

When FN finally discontinued the Supreme in 1975, it was one of the sadder days in the rifle business. Without that competition, however, the way was open for others to resurrect the K98 commercial action, including Granite Mountain in Arizona and, most recently, the Mauser company itself. There were others, of course—many others. Some were good, some not so good. For years, the Yugoslav Mark X filled the gap left by the Supreme, with both standard and kurz actions available from Brownells. As the price of original Oberndorf actions climbed relentlessly through the 1990s and beyond 2000, prices for FN Supremes in good condition slipstreamed along behind, although the bottom-metal question became critical as Ted Blackburn’s delivery times stretched ever-longer, eventually reaching, according to legend, ten years! That’s a long time to wait for an essential part on which to start building a custom rifle. Blackburn’s business was purchased by Swift Bullets around 2012, and bottom metal is now being produced at their factory in Quinter, Kansas. And very good bottom metal it is, too. That’s what I put on the Browning .30-06 described above, to replace the gold-filagreed alloy.

There are two particular rifles built on FN actions included in this book. Both are custom made. One I had built, the other I acquired in one of those lucky accidents.

The first is a .450 Ackley, built on an FN Supreme action. It has a checkered history, to say the least, and I only know the later chapters. This is at least its third iteration as a custom rifle. It could not have begun life as a Browning High Power, because it has no serial number. FN sold actions in the white with no number, allowing the gunsmith to choose his own. Eventually I had “TW 450” engraved on the trigger guard, and it has satisfied several generations of customs officers.

When I acquired the action, in a trade for a Browning 20-gauge SxS, it was the basis of a .375 H&H rifle put together by a rifle-loving acquaintance who fancied himself a gunsmith, but wasn’t. His plan for the Browning shotgun was to convert it, in some way, into a double rifle, which should give you some idea. This acquaintance had fashioned the .375’s stock himself, including a mediocre checkering job. He had also replaced the original bottom metal, whatever it had been, with a trigger guard and floorplate off a Whitworth, a medium-quality line of Mauser-actioned rifles imported from England. On my return from Africa in 1990, having hunted Cape buffalo in Tanzania and Botswana, I had some notions about what constituted my ideal buffalo rifle. I carted the questionable .375 H&H off to my old German gunmaking friend, Siegfried Trillus, and commissioned him to turn it into a .450 Ackley.

Blackburn bottom metal, made by Swift, fitted and finished on a Browning High Power.

Custom-built .450 Ackley, by Siegfried Trillus, on an FN Supreme action, wearing Swarovski Habicht 1.5X riflescope. The rifle is fitted with a claw mount, which is instantly detachable. Without the scope, the rifle becomes a stalking rifle supreme, pointing naturally and instantly at anything that might be coming.

Siegfried was a true German gunmaker of the old school who could do practically anything required of either a rifle or shotgun. Many years earlier, he had cut down a black walnut tree, sawn it into blanks, and painstakingly dried and seasoned the blanks himself. We picked one out, and he began carving it into a suitable stock for a hard-kicking dangerous-game rifle. He ordered a barrel from Douglas and a set of claw mounts from Germany. Swarovski had a 1.5X Habicht scope with a 26mm straight steel tube, decidedly old-fashioned even in 1990, but perfect for my purpose.

Being German, Siegfried liked his scopes high. I do not. We had a meeting of the minds over that, but eventually he got the lowest rings he could that would allow everything to work properly. Because a claw mount is released at the rear and tipped up and forward to remove, an objective bell creates a problem, but with the straight tube of that Swarovski, we could mount it very low.

The scope mount itself presented a few difficulties. The action was already drilled and tapped for scope mounts, but Siegfried did not believe that four screws were sufficient to hold everything together under the recoil of a .450. Accordingly, he supported the screws by silver-soldering the bases to the receiver. Mentioning this to gunsmiths, it is frequently met with horrified looks and blurted objections about the heat drawing the temper and softening the action. Siegfried shrugged this off. “If you know how to use a heat sink,” he told me, “there is no problem at all.” Obviously, some of the critics did not have that level of knowledge and skill. Tellingly, my rifle wears the same bases, mounted in the same way (a combination of screws and solder) as the old Mauser-Werke did in Germany.

The .450 Ackley has a custom bolt-shroud with three-position wing safety. The bases for the claw mount are both screwed and silver-soldered to the action.

The open sights also came from Germany. The rear sight is a single standing blade on a ramp with a broad “V.” This required refining in two ways. One, the elevation is adjusted by sliding the blade up or down its sloping dovetailed base. Under the .450’s recoil, it had a tendency to come loose and take up residence in the nearest patch of long grass. This was corrected with an auxiliary locking screw in addition to the original. The second problem was the sharp points on the sight blade. They could (and did) carve up a safari shirt, so those were rounded off with a file.

The barrel is 22 inches long, and in a misguided moment I took it to Mag-Na-Port in Michigan and had them cut a very slight integral muzzle brake. This consists of four short slots on the upper side of the barrel. It does nothing to tame straight-back recoil, but it suppresses muzzle jump considerably, while the increase in muzzle blast is minimal. If I had it to do again, I wouldn’t, but that’s life.

Unfortunately, Siegfried died shortly after the rifle was completed, and never got to hear about its many trips to Africa. He also never got to hear about some of the rifle’s adventures that can be laid directly at my door. One involved an imprudent handload, followed by a second, even more imprudent, handload. The second shot slammed the floorplate open, tendrils of smoke curled from the action, and the Swarovski’s cross-wires came loose and recoiled into little fish hooks. I didn’t know it at the time, but I had also set back the locking lugs ever so slightly, creating a headspace problem that was later corrected by turning the barrel one rotation and rechambering. The barrel is now 21¾ inches long.

The problem of the floorplate slamming open only occurred when I fired a really inadvisable load, but we felt it should be dealt with. It was solved by sculpting the button inside the trigger guard to be very unobtrusive, while fitting a removable pin through the guard to lock it in place. Since Siegfried’s death, two other gunmakers have worked on the rifle. One is Edwin von Atzigen, a Canadian of Swiss extraction who is one of the best gunmakers I have ever met. The other was a somewhat difficult London-trained gunmaker. The latter fitted the retaining pin and engraved the serial number, but bolt-action rifles are not his forté. Von Atzigen, being Swiss, was born with a bolt action in his hand. He was also a close friend of Siegfried Trillus, knows his work inside out, and believes my .450 Ackley to be the finest rifle Siegfried ever made.

A unique, highly customized method of preventing the floorplate release from springing open in an unscheduled manner.

Having said all that, what does the rifle look and feel like in action?

Fully loaded but without scope and sling, as one would want in thick brush with a buffalo’s rasping breath a few feet away, it is 8 lbs. 10 oz. Add the scope and sling, and it weighs in at a hair over ten pounds. The best way I can describe its handling is that it comes to the shoulder, with barrel perfectly aligned, like a London bird gun. In fashioning the stock, Siegfried built in a little cast off. The butt is proportioned to allow a generous recoil pad. The pistol grip is slim by modern standards, as is the forend, which in cross-section is a horizontal oval, tapering gently from the floorplate out to the tip. With Siegfried’s wrap-around checkering, it affords a secure grip without having to hang on like grim death. In the years since, I have tried to get other stockmakers to copy the design, but they won’t. They prefer a vertical oval with flat sides, so they can demonstrate their virtuosity with a checkering tool.

Siegfried had the tremendous advantage, as a riflemaker, that he was also a serious hunter. Every year, he took two weeks and headed for northern Ontario to hunt moose. He also hunted deer in the fall, black bear in the spring, groundhogs whenever he found them, and was an avid target shooter. He loved shotguns, but rifles were his religion. He knew how a big-game rifle should feel, and he also knew how to make them feel that way. The same is true of Edwin von Atzigen. In a riflemaker, it is critical that he not only know how a rifle should feel, but how to get it there. This is the element that is missing in so much riflemaking today.

Shortly after the war, English gunwriter G. T. (Gough Thomas) Garwood looked at the English gun trade, then in considerable disarray, and lamented the fact that too many shotguns were being produced that lacked the exquisite balance and handling of those made between the wars, and before 1914. The fact that shooters would happily accept such guns filled him with misgivings. He shrewdly foresaw that client demand was what drove the best gunmakers, and if clients did not demand good balance and handling (which is difficult to achieve), then gunmakers would not bother to provide them. Since the only way to appreciate wonderful balance and handling is to heft and carry and shoot such a gun, for an hour or a day, too many clients simply did not know what a gun could (and should) feel like. The same is true of riflemaking today, even among custom riflemakers. Fortunately for me, Trillus and von Atzigen did know.

The .450 Ackley in its natural element. Tanzania, 2006.

To borrow from Gough Thomas again, my .450 scores extremely high on the eumatic scale. One of the previous owners of the action found a way to make it as smooth as silk—smoother than any other Mauser 98 I’ve ever handled. According to the guy I obtained it from, he made the action smooth by pouring Ajax cleanser (a very mild abrasive) into the bolt channel, and then working the bolt back and forth as he watched television, evening after evening. I merely report what I was told. Also very eumatic is the claw mount: Wrap your hand around the ocular bell, pull back the catch with thumb and forefinger, lift, and the scope is released purely by feel. It comes away held firmly in the hand, and all without needing to look down even once. When you have an urgent need to take the scope off such a rifle, looking down is usually a luxury you can’t afford. The scope can be replaced by feel, too, simply by positioning the forward claws with thumb and finger, then pushing down on the ocular bell. It snaps into place.

The author in Tanzania in 2006, with the second of two Cape buffalo killed in a matter of minutes on a Great Rift mountainside. The trackers are, from left, Lekina Sandeti, Abedi Shimba, and Momella Torongoi. Lekina and Momella are both Masai, while Abedi was a Bushman. All of us were immensely grateful the buffalo went down where they stood, and did not disappear into the thick undergrowth.

Al Biesen .270 Winchester, built on an FN Deluxe action. It has been extensively remodeled, with a custom bolt shroud and three-position safety made by Biesen himself, and fitted with a Canjar trigger.

This is one of those rifles that are a pleasure to pick up, hold in your hands, work the bolt, take off the scope, and put it back on. It is eumatic and ergonomic to an almost unbelievable degree.

Since 1992, it has been to Africa several times and accounted for everything from gemsbok, zebras, and a greater kudu, to two Cape buffalo, the pair of them disposed of in a matter of minutes on a mountainside in Tanzania. I have used other big rifles in the meantime, for one reason and another, but every time I do, I find myself comparing them to Siegfried Trillus’s masterpiece, and every time they finish second best.

* * *

The second FN-based rifle was built by Al Biesen (the “genius of Spokane,” as Jack O’Connor described him) on an FN Deluxe action. Although the rifle was completed around 1985, the action is considerably older. It preceded the Supreme and was probably made in the 1950s. The Biesen family has no firm records of his work, so most of the details about the rifle we can only surmise.

Biesen was a highly skilled metal worker as well as a stockmaker, and he emphasized “hunting” rifles, as opposed to showpieces to hang on a wall. It is impossible to say, today, how much he absorbed from O’Connor, and how much O’Connor learned from him. Their relationship began in the late 1940s, after the death of Alvin Linden, when Biesen approached O’Connor and asked him to try some of his work. It endured until O’Connor’s death in 1978. During that time, Biesen completed about twenty separate jobs for him, from restocking shotguns to building complete rifles.

Al Biesen was one of the few custom riflemakers to engrave his name on his masterpieces. He always used the old-fashioned “WN” abbreviation for Washington.

As an early and devoted admirer of Jack O’Connor, it was only natural that I came to revere Biesen’s name. I longed to own one of his rifles, but never thought it would come to pass. And, along the way, a strange thing happened. As a writer, it became my habit to attend hunting shows, like the Safari Club convention in Reno. I also started visiting the American Custom Gunmakers Guild show, which for many years was held in Reno at the same time. I got to know some of the gunmakers there, both stockmakers and metal guys. I would ask about Biesen, and was usually given an answer like “Really nice guy, but . . .” It seems they did not feel that Al Biesen, riflemaker to the stars, was in their league in terms of painstaking, meticulous, nigh-perfect work. I can say now, although I could not then, that a Biesen rifle feels and handles like a hunting rifle, while theirs (most of them, anyway) felt and handled like something meant to be looked at, not fired, and certainly not hunted with.

Tom Turpin is the recognized expert on custom bolt-action rifles, at least as far as writers go. It’s his specialty, and he has written three books on the subject. Asked about Biesen, his response was that Al Biesen was skilled enough to produce a rifle that would stand in any company, including the finest the Guild members could turn out. Instead, he had chosen to avoid making show pieces in favor of hunting rifles—rifles to be used, carried, shot, and carried some more. To function flawlessly, to be both ergonomic and eumatic, and handle like an English game gun insofar as that is possible with a bolt-action rifle.

Biesen was a master stockmaker. Although not of precise “American classic” styling, it is graceful and harmonious. The cheekpiece blends into the grip, and the recessed checkering is exquisitely done. Yet this is an unapologetic hunting rifle, not a showpiece.

I acquired mine through chance. It was 2016, Mauser-actioned sporting rifles were going through a period of disfavor, and prices were low. It fell into the hands of a gun dealer who did not know what AL BIESEN GUNMAKER SPOKANE WN meant to a rifle lover. He thought it was just one more customized Mauser, and priced it accordingly. As soon as I saw the name, I knew I had to have it.

The rifle is a .270 Winchester with a 22-inch barrel. Fitted with a 3-9X Swarovski scope, it weighs 8 lbs. 2 oz. Loaded with six rounds of ammunition (five down, one in the chamber) and wearing a leather sling, it tips the scale at 8 lbs. 13 oz. That is light enough to carry comfortably, but with enough heft for solid shooting. The action is probably an FN Deluxe. Some of its features, however, are found on the later Supreme, and others are not. As well, it has had rather extensive modifications. Gone is the Mauser bolt shroud with over-the-top wing safety, replaced by a shroud of Biesen’s own making, incorporating the Model-70 style wing that moves forward and back. The FN bottom metal appears to have come from a Supreme, but the floorplate release has been converted to the Oberndorf style.

The rifle is wearing a checkered steel grip cap of Biesen’s own making, but instead of a steel buttplate, it has a thin recoil pad. This would be disdained by the purists of the gunmakers’ guild, but I personally prefer it. Hunting rifles need to be stood up at times on all kinds of surfaces, and the surest way to send your rifle banging to the ground is to stand it up on a slick surface. As well, in climbing, it’s inevitable that the butt will make contact with the ground, even if it is inadvertent. A recoil pad can take this without whimpering, but not a beautifully crafted, checkered steel plate. If nothing else, the damage will break your heart and make you more interested in protecting your rifle than hunting. A stockmaker once told Jack O’Connor that putting a recoil pad on a custom rifle was like seeing a man in evening dress, wearing rubber boots. Perhaps, but a recoil pad is functionally superior by a vast margin.

Biesen’s recessed fleur-de-lis checkering was almost a trademark.

Similarly, the Biesen rifle has glass bedding around the action—anathema to the purists. Whether this was his decision, or done at the request of the client, is impossible to say. Either way, it is functional, beneficial, and no one can see it anyway. The stock is not quite correct for modern tastes, having a very modest Monte Carlo comb. No matter whose decision that was, it works like a dream.

Every person who has picked up my Biesen has had the same reaction: “Unbelievable. I’ve never felt a rifle like this.” It feels, they say, alive—slim and light in the hands because it does not have the bulky dimensions of so many modern stocks, either in the pistol grip or the forend. The pistol grip has a circumference of 4 3/8 inches, while the forend, also slim, is a modest pear shape in cross section. The checkering is Al Biesen’s signature fleur-de-lis, recessed slightly so the lilies stand out.

The rifle is fitted with a Canjar, one of the great names in triggers from back then. It is crisp and the pull weight seems lighter than it actually is—exactly the qualities we want in a trigger but so seldom get.

The barrel is a Douglas, chambered by Biesen so precisely that when a 130-grain Nosler Partition is seated to exact SAAMI overall cartridge length (3.34 inches), the ogive of the bullet just brushes the lands. It shoots almost any .270 factory or handload very well, and some of them extremely well. The hunting load I developed, using Sierra 130-grain GameKings, will group five shots inside an inch consistently. It never strings shots, and is very predictable. When the velocity changes, it moves the group exactly where you expect it to move.

This rifle is a masterpiece of functionality as well as form and aesthetics. There is nothing on it that does not serve a purpose, except perhaps the forend tip. Nor does it lack anything you might need. It has no iron sights, but these are hardly necessary on a .270, even as a back-up.

When I bought the rifle, it was fitted with an older Leupold scope in Redfield Jr. rings, but whether that outfit was originally fitted by Biesen is impossible to say. I replaced it all with a Swarovski Z3 3-9x36 in S&K mounts with a customized rear base. All the parts look happy with each other.

* * *

Granite Mountain magnum action, .505 Gibbs.