Chapter • 28

Mortising Jig for a Router

BY STEVE SHANESY

Most woodworking jigs fall into two categories: Those you use once and then pitch, and those you use over and over again. This mortising jig falls into the latter group. And if longevity and amount of use a jig gets is any indicator of value, consider this jig worth its weight in gold.

More than 20 years ago I made a version of this jig as a companion to my then-new plunge router (shown in the photo). The concept was shown in an early woodworking book by The Taunton Press by venerable woodworker Tage Frid. Both the jig and the router continue to see service in my shop, although I made a new jig for this article and added a couple new features.

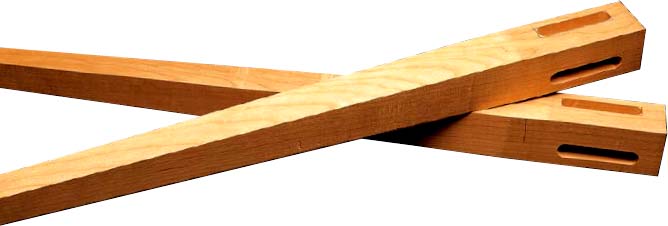

Over the years, I’ve cut mortises by hand, with this jig and using a variety of benchtop mortising machines. I find one big advantage of router-cut mortises is the smooth wall of the mortise itself, which is certain to produce a stronger glue joint than those made with a chisel or mortising machine. The smooth surface is especially advantageous given the cross-grain condition of typical mortise-and-tenon joints. The jig also sets up quickly and provides a high degree of repeatable accuracy. Combine the unit with an aftermarket router fence such as the Micro Fence (www.microfence.com) and set-up time is even faster. One downside to all router-cut mortises is the round, rather than square, ends produced. The problem is overcome most easily by rounding over the square corners of the tenons using a file.

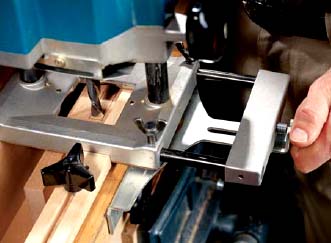

Once the mortise location is drawn on a part, you secure your work in the jig using the built-in clamps. Lower the router bit to the height of the part and adjust the router fence to align with the mortise location. The forward and backward travel of the router is quickly limited by the jig’s adjustable stops on the top of the jig’s side. Set the depth of plunge on the router and you’re ready to cut your mortise. Remember to pull the router toward you when making cuts; this uses the rotation of the bit to hold the router fence to the jig’s side.

Jig Construction

Building the jig is simple and should take an afternoon. When done, you’ll be able to rout mortises for a set of table legs, for example, in less than 15 minutes, including set-up time.

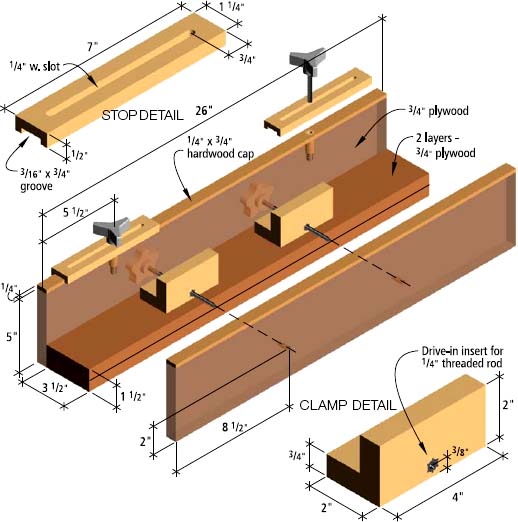

Buy your hardware before building the jig. It is easier to drill the holes and install the barbed inserts in the side of the jig before assembly. These are placed in a ⅜” hole that’s 2” deep on the top edge of the side.Take care to drill in the center of the plywood. Next, drill out a ¼” hole in a length of ½” dowel that will both plug the hole and further secure the insert — yet allow the bolt to access the buried insert. Now drive in the threaded insert. It’s a good idea to place the side in a vise to prevent the plywood from splitting during this operation. When done, chase the hole with a ½” drill bit to the depth of the insert so the dowel will fit the hole. Next, glue the dowel in place. Go easy on the glue so you don’t fill the inserts threads with glue. Apply the hardwood edgebanding on the tops of the jig’s sides.

When making the bottom, first glue up an oversized double-thickness plywood blank. Cut it to final dimension, making sure your table saw blade is dead square to the saw table. This will ensure your side parts will be square to the part you are mortising. When the bottom is ready, glue and clamp the two sides in place. Keep the bottom edge of the sides in line with the bottom surface of the bottom part.

Clamping Mechanism

While this assembly is drying, make the parts for the clamp mechanism and the adjustable stops. Use hardwood and make them to the shape and dimensions given in the diagrams and cutting list. Make longer lengths that can later be cut to final size. It’s both safer and faster.

Use a router in a router table to make the adjustable stops. First cut them to width, then rout the groove below so that it is centered on the stock. Check the fit on the jig side. You want it to move freely but without side-to-side play. When done, rout the ¼” slot. If you didn’t move the router table’s fence after routing the groove, it should be centered on the part. Take the jig out of the clamps, install the stops, bolts and knobs. Bore the holes for the clamp mechanism in the clamping blocks and jig sides. Also, install the threaded inserts in the clamp blocks. Complete the jig by installing the clamp assembly in the jig.

Tips on Use

When using the jig, be sure it is securely fastened to a bench or held in a vise. You will also need to clamp a stop block on the inside of the jig’s side to use as a gauge for placing successive parts in the exact same location.

Remember to make multiple passes when routing your mortises. I’d recommend no more than a ⅜”-deep cut at a time when using a router bit in the ⅜”- to ½”-diameter range. And as for bit selection, an up-spiral straight bit is best because the spiral design evacuates the waste up through the flutes in the bit.

Set-up can be a snap. With the bit set to just clear the work piece, set the stops for the router, then adjust the router’s edge guide to the mortise layout lines.

Rout mortises making stepped cuts for safety. Each pass should be ¼” to ⅜” deep. Pull the router toward you so the bit rotation forces the router’s edge guide to the side of the jig.

Mortising Jig