Gripping Tools

Pliers

Repair operations often call for objects to be gripped, twisted, bent, or turned. Sometimes these objects are irregularly shaped or otherwise difficult to hold. The best tool to use for gripping objects like this is pliers.

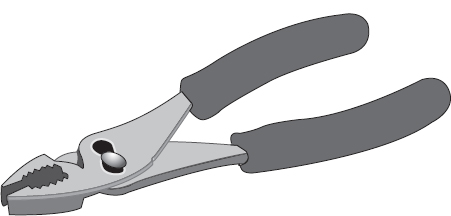

The most common type of pliers is the combination slip-joint. These are adjustable at the joint of the two handles of the pliers. With two different positions to choose from, these pliers can grip objects in a wide range of sizes. Sometimes, this design also incorporates a wire cutter for increased versatility.

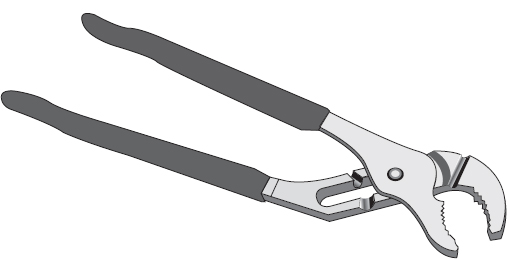

When large diameter objects must be gripped or twisted, a technician would use adjustable joint pliers to get the job done. These are adjustable over a large range of sizes, as they have multiple “arc-joints” that the pliers can be set into. The handles are also very long, which gives very good leverage and makes for maximum gripping power. These pliers are also commonly known as water pump pliers or Channellock® pliers.

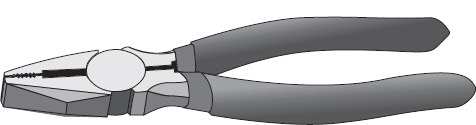

Lineman pliers are used for cutting and bending heavy gauge wire. These are not size-adjustable, but are made for maximum leverage at the jaws to make the cutting process easier. This type of pliers would most often be used by electricians, but all trades utilize them at one time or another.

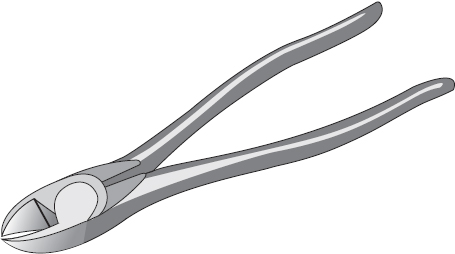

Diagonal cutters are pliers that are made exclusively for cutting. The two jaws are set at an angle (diagonally) to make it easier to cut wires straight across. Diagonal cutters are normally used for cutting wire and small cables.

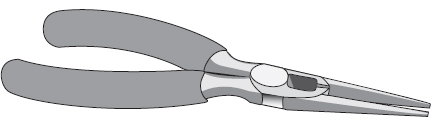

For holding small objects in tight places, a pair of needle nose pliers could be used. These have very long, pointed jaws for maximum reach. Needle nose pliers are often used for intricate jobs like soldering circuit boards and small components, and they will most often have a wire cutter built into them at the base of the jaws.

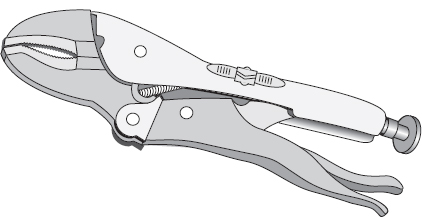

Locking pliers are used by technicians of all trades. Most people know them as Vise-Grip® pliers. They are adjustable, made in a large variety of jaw designs, and will lock tightly in place for holding or clamping objects together. Locking pliers often have wire cutters built into them as well for maximum versatility.

Questions on the ASVAB may give you a hypothetical “job” and ask what tool would be most useful. Look at this example:

| Question | Analysis |

| You are completing a job that requires gripping several different sizes of pipes. Which of the following would be the best tool to select for this job? |

Step 1: This question asks which tool would be best for gripping a wide range of pipe sizes Step 2: There is nothing to simplify. Step 3: You can narrow your prediction to types of pliers, since that is the tool of choice for jobs that require gripping. Your prediction can be even more specific if you recall that adjustable joint pliers provide the most versatility because they can be adjusted over a wide range of sizes. |

|

Step 4: Choice (A) matches that prediction. Choices (B) and (C) can be eliminated because they are not adjustable, and choice (D) can be eliminated because it is designed for tightening and removing fasteners rather than gripping pipes. |

Here is another question, this time dealing with terminology. Try this one on your own:

-

What type of wrench is commonly known as a Crescent wrench? - open-end wrench

- box-end wrench

- adjustable wrench

- combination wrench

Explanation

Crescent is such a popular brand that it has become practically synonymous with the adjustable wrench; (C) is the correct answer. Remember, a combination wrench has an open-end wrench on one end and a box-end wrench on the other.

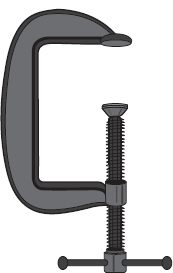

Clamps

A clamp is a tool that applies pressure to prevent movement between different pieces of a project. For example, a clamp would be useful for holding a project together while glue dries. Consisting of a metal frame (commonly C-shaped) with a flat-edged screw perpendicular to the bottom of the frame, a clamp gets tighter as the screw is turned.

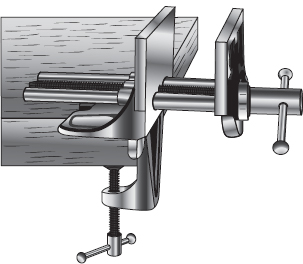

Vises

Vises are similar to clamps in that they are designed to hold wood or other materials in place. A key difference, however, is that vises are affixed to the workstation and are used to hold a material in place while you saw, sand, drill, or otherwise work on the material. Typically, one side (jaw) of the vise is fixed, and the other is moved by turning a handle.