GLOSSARY

Acetate—A clear or translucent plastic material upon which an image is painted in opaque paint to produce a resist with light-sensitive emulsion.

Acetic Acid—Used in a 5 per cent solution similar to household vinegar to neutralize the alkalinity of some screen-mesh cleaners and prepare the screen mesh for easy acceptance of emulsion-based resists.

Acetone—Solvent for hardened paint and lacquer; must be used with great care—away from fire—in a well-ventilated area.

Alcohol—Solvent for shellac.

Ammonium Bichromate—Chemical added to the gelatin emulsion to make the emulsion light sensitive. See Potassium Bichromate.

Anthrasol—Dyestuffs used in paste form for textile printing. Indigosol is another trade name for the same type of dyestuffs.

Art Deco—The style of decorative and applied design common in the early 1930s. The interior of Radio City Music Hall in New York City is an excellent example. It is characterized by a streamlined geometric line pattern.

Artist’s Proof—A print produced during the development of an edition that is not included in the edition but that is of high enough quality for the artist to be willing to sign it.

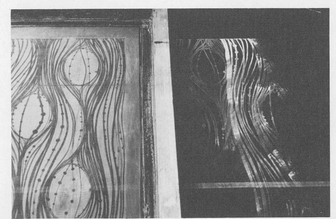

Art Nouveau—The style of decorative and applied design common at the end of the nineteenth century. It is characterized by a writhing, curvilinear line and an asymmetrical form and is organic in feeling.

Backprinting—Ink picked up on the underside of the printing frame in textile printing. It is caused by printing over a wet print.

Benzene—Solvent for rubber cement; must be used only in a well-ventilated area.

Bleach (Household)—Solvent for photogelatin-emulsion resist (usually used in a 50 per cent solution with water). Will also remove some ink stains on the screen mesh. Must be used only on nylon or metal screen meshes.

Blockout—The material used in or on the screen mesh to form those parts of the stencil that are impervious to the printing medium. See Resist.

Bridging—In stencil forms the little bands of the stencil material left to prevent the floating parts (such as the center of the letter “O”) from falling out of the stencil after it has been cut.

Bridging

Brush Printing—A method used in the textile industry before World War I. The color was applied with stiff brushes through a cardboard or zinc stencil. The spray gun soon replaced the brush.

Butyl Acetate—A solvent for lacquer. It will also remove hardened paint and paint stains from the screen mesh. Must be used only in a well-ventilated area.

Carbon Tetrachloride—Solvent for stains and paints on the screen mesh. Extremely toxic and should be used only in a well-ventilated area. Regulations govern its sale.

Casein Glue—A white glue that dries colorless. A thin or weak solution makes an adhesive for fastening a textile to the board while printing it. Also used in mounting a serigraph.

Caustic Soda—Sodium hydroxide, used in cleaning nylon screen mesh; sometimes called lye.

Cellulose-Based Printing Ink—A brilliant, somewhat expensive color used in printing.

Chalking a Design—Test-printing a design by powdering dry chalk through the stencil resist to space it and check the register on the printing board.

Chalking

Circle Cutter—A stencil-cutting knife that will produce a circle in a lacquer film stencil resist. It works like compasses.

Clear Base—See Toner Base.

Crystal Base—See Toner Base.

Derma Printing Method—A drawing is made on stencil with an ink containing an acid that eats into the paper to remove the areas to form a stencil for printing.

Direct Process of Fabric Printing—The color is printed directly on fabric through the open areas of the stencil resist.

Direct Method in Photogelatin Resist—Light-sensitive gelatin is applied directly on the screen mesh and exposed to light. See Transfer Method; Double Transfer Method.

Discharge Process of Fabric Printing—The fabric is dyed, and then a paste containing a bleaching agent is printed on it through the open areas in the stencil resist. The paste bleaches the pattern on the fabric.

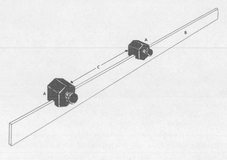

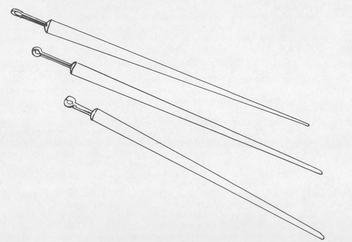

Double film cutters

Gauge stick: gauge bolts (A); gauge bar (B); distance between design units (C)

Double Film Cutter—A stencil knife that cuts a double line with two adjustable blades. It is used to produce lines of different widths on a lacquer-film stencil.

Double Transfer in Photogelatin Resist—The gelatin is sensitized on one base, transferred to a second base and exposed (often while wet), and when washed out transferred a second time to the screen mesh. When dry the base is removed and the printing resist is formed. See Direct Method; Transfer Method.

Dry Cleaner—Used to remove wax or paraffin and stains from the screen mesh.

Dry Copy-Printing Machine—A machine using heat to transfer or copy printed material.

Durometer—The rating method used in indicating the hardness of the rubber blade in the printing squeegee. Forty-five durometers is a soft and 80 durometers a very hard rubber blade.

Dye Paste—Viscous dyes including acid dyes, basic dyes, direct dyes, discharge dyes, fiber-reactive dyes, household dyes, prepared vat dyes, soluble vat dyes. Used by small-volume printers for textiles.

Edition of Prints—The number of finished, approved, and signed prints of the same design, produced by an artist.

Enamel—Available for screen-process printing in two types: (1) a fast-drying enamel that cannot be used outdoors without the protection of overprint varnish; (2) a high-gloss synthetic enamel that is very permanent and can often be baked onto the printing surface.

Enzyme Digester—A commercially prepared formula that removes gelatin-emulsion resists from the screen mesh after printing.

Extender—An additive for printing process paints that increases bulk and therefore reduces printing costs. Can be used up to one part extender to fifteen parts paint before the opacity and brilliance of the color are affected.

Fiber-Reactive Dye—Developed in 1956 by Imperial Chemical Industries, Limited, and produced under the trade name Procion. Used in textile printing for transparent and brilliant colors.

Film Line Cutter—See Scooper Cutter.

Film Presensitized Photo Emulsion—Commercially available photo emulsions on acetate bases, used to produce a photo resist.

Floating Part—The parts of a stencil that will fall away after the stencil is cut. For example, the center of the letter “O.”

Fluorescent Paint—Available for printing-colors that “glow.”

Free Lacquer Stencil—A “free” stencil resist formed by dripping, scraping, brushing, stippling, or dribbling lacquer over the surface of the screen. Creates attractive, textural prints for textile printing.

Gasoline—Solvent for asphaltum; must be used with great care-away from fires and in a well-ventilated area.

Gauge Bolt—A bolt fastened on the printing-board rail that fixes the distance between each printed design in the keying of a textile print.

Gauge Stick—Two gauge bolts placed on a stick (similar to a yardstick) to measure the exact distance needed to key the pattern. Used to set all the gauge bolts on the rail. Can also be filed to preserve the pattern key for future printing.

Gelatin—Ordinary household gelatin used in the light-sensitive photo-emulsion stencil resist.

Gelatin Emulsion—A light-sensitive mixture of gelatin, ammonium bichromate, Keltex, Calgon, and dye. Portions exposed to light become water insoluble.

Glycerin—Used with tempera poster paint in screen-process printing to retard the drying time.

Hide Glue—A brown heavy glue used in diluted form in a tusche-glue stencil. It is water soluble when dry.

Impasto—A heavy raised area produced by printing an extremely thick layer of ink. This can be achieved by using a thicker paper- or cardboard-stencil resist or by printing the same color area a number of times.

Indigosol—See Anthrasol.

Intaglio Printing—The image to be printed is scratched with a needle or etched with acid in the surface of the printing plate. This trough carries the ink.

J Bar—A hooked meter bar that secures the textile printing frame to the key rail to keep it firmly in place while printing.

Keltex—A commercial thickener used in the production of light-sensitive gelatin emulsion and in screen-printing dye pastes.

Kerosene—Solvent for wet enamel paint, lithographic crayon and tusche, oil- and varnish-based screen-process paints, oil-based texture paint, wax crayon.

Key Bolts—The adjustable bolts placed on the key rail to register a textile design in printing. Carpenter’s stair gauges are frequently used. See Gauge Bolt.

Keying—The process of adjusting each printing frame so that successive colors are printed in exactly the right place.

Key Rail—The rail on one or both sides of the textile-printing board used to key the printing frame in repeating the design.

Kodalith Film—An orthochromatic high-contrast photographic film that can be exposed in a camera or with an enlarger to form a negative or positive. Can be used in producing a photo-emulsion resist.

Lacquer-Based Paint—A brilliant, fast-drying paint that can be used in printing a serigraph.

Lacquer-Film Resist—A thin coating of lacquer adhered to a heavy sheet of acetate or wax paper.

Lacquer-Film Solvent—Solvent for lacquer. Must be used only in a well-ventilated area.

Lacquer Thinner—A volatile liquid used to thin lacquer. Solvents for lacquer must be used only in a well-ventilated area.

Liquid Brush Cleaner—Will remove hardened paint from the screen mesh.

Maskoid—A rubber-based solution sometimes used for the original design in a wash or a stencil resist, with glue as the second material.

Mat—The cardboard placed over the print to separate it from its surroundings with a blank space. Makes the print more presentable.

Mat Knife—A strong, heavy, sharp knife (similar to a stencil knife with a single blade) used to cut the mat.

Mineral Spirits—Solvent for wet enamel paint, oil-based lacquer, lithographic crayon and tusche, oil- and varnish-based screen-process paints, oil-based textile paint, wax crayon.

Mitograph—A term given to the commercial product of screen-process printing by Albert Kosloff.

Mixing Varnish—A varnish material added to printing varnishes to improve their printing qualities.

Naphtha—Solvent for wax paraffin in the screen mesh. Should be used with care in a well-ventilated area.

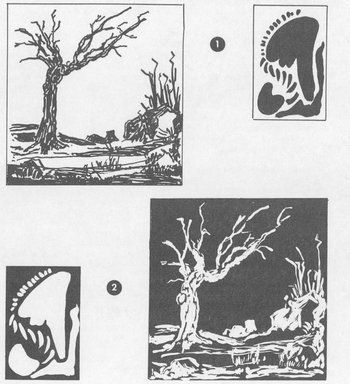

Negative Space—In a design or composition the area between and around the main objects and forms. For example, the space behind and between the people in a group portrait. See Positive Space.

Positive (1) and negative space (2)

Negative Stencil—A stencil in which the resist material is the actual image and the background is printed.

Nufilm—An improved lacquer film for the production of a lacquer-film stencil, developed after Profilm.

Oleum—Solvent for wet enamel paint, lithographic crayon and tusche, oil- and varnish-based screen-process paints, oil-based textile paint, wax crayon.

Opacity—The quality of a thing that does not allow light to penetrate it. In printing, an opaque color will cover the color underneath and not be affected by it. See Transparency.

Overprinting—Printing one or more colors over each other, thus creating a new color and sometimes a new shape.

Overprint Varnish—A varnish printed over poster screen-process colors to make them permanent for outdoor use.

Paint Thinner—Solvent for wet enamel paint, lithographic crayon and tusche, oil- and varnish-based screen-process inks, oil-based textile ink, wax crayon.

Paper Stencil—A stencil resist cut from a sheet of paper.

Paper-Transfer Printing—The transfer of a design or photograph to a

clear acetate with a dry copy-printing machine.

Photo-Emulsion Resist—A stencil resist composed principally of gelatin and a sensitizer that makes the gelatin water insoluble upon exposure to light. The unexposed portions are washed away with warm water creating the photo resist.

Pigment in Water Emulsion—A specialty ink that can be used to print textiles. Tends to have a slight stiffening effect on fabric.

Pinholes—Fine holes in a stencil resist.

Planographic Printing—The image is on the actual surface of the plate. The image is treated so that it holds the greasy ink while the wet surface of the rest of the plate repels the ink.

Pochoir—A method of stencil printing developed in France. Using a brush and water colors, the artist makes prints or copies of paintings with the aid of paper stencils. While originally used to copy other art, it has recently been used by some artists for original works.

Positive Space—In a design or composition the main objects and forms such as the people in a group portrait. See Negative Space.

Positive Stencil—The resist material fills the background of the design and the actual image is printed.

Potassium Bichromate—Chemical added to the gelatin emulsion to make the emulsion light-sensitive. Not as sensitive as ammonium bichromate. See Ammonium Bichromate.

Printing Board—The surface on which the paper or fabric is placed when printing. For textile printing it is padded.

Printing Frame—The frame, usually of wood, upon which the screen fabric is stretched.

Procion—A trade name for fiber-reactive dyes.

Profilm—A lacquer-type film adhered to wax paper. The lacquer is cut and peeled off to form a stencil resist.

Proof Prints—Trial or sample prints not identical to the rest of the prints in an edition, but whose quality is such that the artist is willing to sign them and label them as proof prints.

Pumice—A fine white powder used in cleaning a mat or screen.

Random Printing—The design unit is printed in several spots on a printing area without any predetermined placement. An irregular pattern develops.

Register Marks—Small crosses in the four corners of a design that help in placing the stencil on the screen precisely each time for multicolor printing.

Relief Printing—The image to be printed stands out in relief on the printing block, and this raised surface carries the ink.

Resist—Any stencil material that is adhered or applied to the silk or other fabric stretched on a printing frame. It holds back the printing medium, preventing its passage through the screen meshes. See Blockout.

Resist Process of Fabric Printing—A specially prepared paste is printed on the fabric through the open spaces in the stencil resist. The fabric is then dyed and the paste in the textile pattern resists the dye color.

Retarder—A liquid added to screen-process paint to slow up the drying time and help prevent screen clogging during the printing process. Especially valuable when humidity is low.

Roller Printing—A relief method for printing textiles in which the pattern or design is on a large inked drum or roller that makes contact with the textile to print the design. Commonly used by the textile printing industry.

Scooper Coater—A metal trough used to apply a gelatin emulsion to the screen fabric.

Scooper Cutter—A sharp knife for cutting fine lines in a lacquer-film stencil. The cutting edge is a small circle of steel sharpened on the inside of the circle. It scoops off the lacquer film. Also known as film line cutters or scratch tools.

Scooper cutters, or film line cutters

Screen-Process Industry—The commercial industry that uses the screen process as a method of printing.

Selectasine—A screen printing process in which several colors are printed with one screen by successive blocking out of various areas of the screen.

Serigraph—A print made by the screen-process method for fine-art purposes.

Serigrapher—One who makes serigraphs.

Shibu—The varnish used by the Japanese to cover and protect their stencils and also to hold the fine hairs or silk threads that tie the floating parts to the main stencil in place.

Sizing—A material, usually starchlike, in most commercially printed cloth that adds “body.” Sizing must be thoroughly washed out of the fabric before it can be safely printed.

Soap Flakes—Used to thicken tempera paint for screen-process printing. Makes tempera more acceptable in the printing frame.

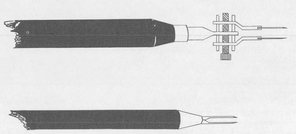

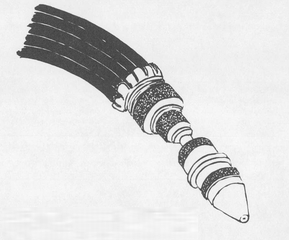

Spray nozzle with adjustable pressure

Spray Pressure Nozzie—A commercial nozzle that can give both a fine spray and a power-jet stream of water for cleaning gelatin-emulsion stencils for printing and for cleaning the screen mesh after printing.

Squeegee—The rubber blade in a wooden holder, used to pull the printing medium from one side of the printing frame to the other over the stencil resist. A simple squeegee can be made of cardboard.

Steam Box—A metal box designed to heat-set dye printed on a textile without wetting any part of the textile.

Stencil—A material (paper, emulsion, film, etc.) from which certain areas have been removed. When the stencil is laid on a surface, color applied to it passes through the holes and prints on the surface below.

Swivel Stencil Cutter—A stencil knife that revolves freely making it easier to cut a curved line on a lacquer-film stencil.

T Plate—A metal “T” screwed at the center of each end of the textile printing frame and used in keying the frame.

Thinner—A liquid added to screen-process paint to increase its flow and its printing quality.

Toner Base—Sometimes called crystal base or clear base. A transparent syrupy solution that improves the printing quality of inks and helps to overcome the tendency of some screen colors to flake off when dry.

Transfer Method of Photogelatin Resist—Light-sensitive gelatin supported on a base, usually of acetate, is exposed to light. After the unexposed portion, which remains water soluble, is washed out, the exposed portion of gelatin, which has become water insoluble, and the acetate are transferred to the screen mesh by gentle pressure. When dry, the acetate base is peeled off, leaving the printing resist.

Transparency—The quality of allowing light to show through. A transparent color will not blot out and will be changed by the color underneath. See Opacity.

Transparent Base—A thick material (looks like Vaseline) used to extend the printing coverage of screen-process paints and increase their transparency. Usually made of aluminum stearate.

Transparent Toner Color—A highly concentrated color that is mixed with a crystal type of transparent base to produce a printing color.

Trisodium Phosphate—A wall cleaner available in most paint stores and used to clean the screen fabric. Removes grease from the screen mesh.

Turpentine—Solvent for wet enamel paint, lithographic crayon and tusche, oil- and varnish-based screen-process inks, oil-based textile ink, wax crayon.

Tusche—A thick black greasy liquid painted on the screen fabric in producing a glue-tusche stencil resist. Often called lithographic tusche, also available in crayon form.

Tusche-Glue Resist—A washout screen resist in which lithographic tusche is used to draw or paint the design on the screen fabric and then is coated with a glue solution. When the glue has dried the tusche is washed out with paint thinner or turpentine, producing the stencil desired.

Urea—A chemical used in the screen-printing paste for a fiber-reactive dye.

Wallpaper Paste—A starch-based paste used occasionally in mounting prints.

Washout Resist—A screen-stencil resist that is made by applying the design to the screen with one material and then covering the entire screen mesh with a second material; the first is then washed out with the proper solvent. See Tusche-Glue Resist.

Water-Based Textile Ink—An ink in a water base, which must be heat-set after being printed on a textile. Its stiffening effect on the textile is usually minimal.

Xylol—Solvent for rubber cement. Must be used with great care in a well-ventilated area only.

Yuzen Style—A Japanese method of making a stencil. Two identical stencils were cut, with the floating parts held in place by a cross grid of human hair or fine silk. The two stencils were varnished and placed together with the hair grid between the two stencil sheets.