The previous chapters introduced the key concepts of Microsoft Dynamics NAV as well as the details of the financial application and CRM. These horizontal modules can be implemented in most industries without big structural changes.

In this chapter, we will discuss three ways of implementing production in Microsoft Dynamics NAV using the standard functionality and customized features.

We'll discuss item tracking and item costing and what procedures and objects are used to get this working correctly in the application. For manufacturing, we will discuss the general concepts and data model rather than going into the details of each and every functional possibility.

We will also discuss kitting, which is only available in a limited number of countries such as North America, France, and Australia, but will most likely be moved to the worldwide version in future versions.

At the end of the chapter, we will look at the five different vertical industries and highlight two specific features of these industries that are not implemented in the standard product and discuss how the problems could be solved.

After reading this chapter, you will have a better understanding about the concepts of production in Microsoft Dynamics NAV, how this fits together with the rest of the application, and how to think out of the box if it does not immediately fit your process.

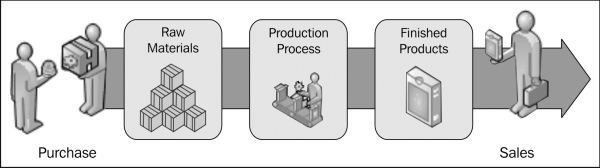

Production is the process of creating a new product using raw materials or prefabricated items and resources.

Production as we know it today started centuries before the industrial revolution with craftsmen and assistants creating products using raw materials produced by nature and farmers. Today, this method of production still exists for many luxury items such as custom-made furniture or clothes.

The industrial revolution changed production into manufacturing, with the introduction of machines and mass production. This allowed production to grow by being less dependent on craftsmen and manual labor.

The introduction of computers in manufacturing companies allows the production of more sophisticated items and has made manufacturing more flexible.

To implement Microsoft Dynamics NAV for production companies, it is crucial to understand which level of production is being used in your company.

In this chapter, we will differentiate between the following three production methodologies:

- Assembling production: When production is combining items into one new item without changing the items or scrap, we will refer to it as assembling.

- Manufactured production: This is the most complex production method to be implemented in Microsoft Dynamics NAV. Raw materials are combined into one or more products leaving scrap.

- Specialized production: These are often one off items or items produced in small numbers. The system should support the basics of the production process but should still be flexible enough to fit the company.

Each product we consume starts out as raw materials, such as cotton, iron ore, logs, and oil, which are then processed to be used in a production process. Other raw materials are water and air or fruits and vegetables. All raw materials are produced by mother nature. The production of some raw materials such as logs, cotton, fruits, and vegetables, can be influenced by humans. Other raw materials are more limited such as iron ore, oil, and water.