8

Maintaining Our Nuclear Forces

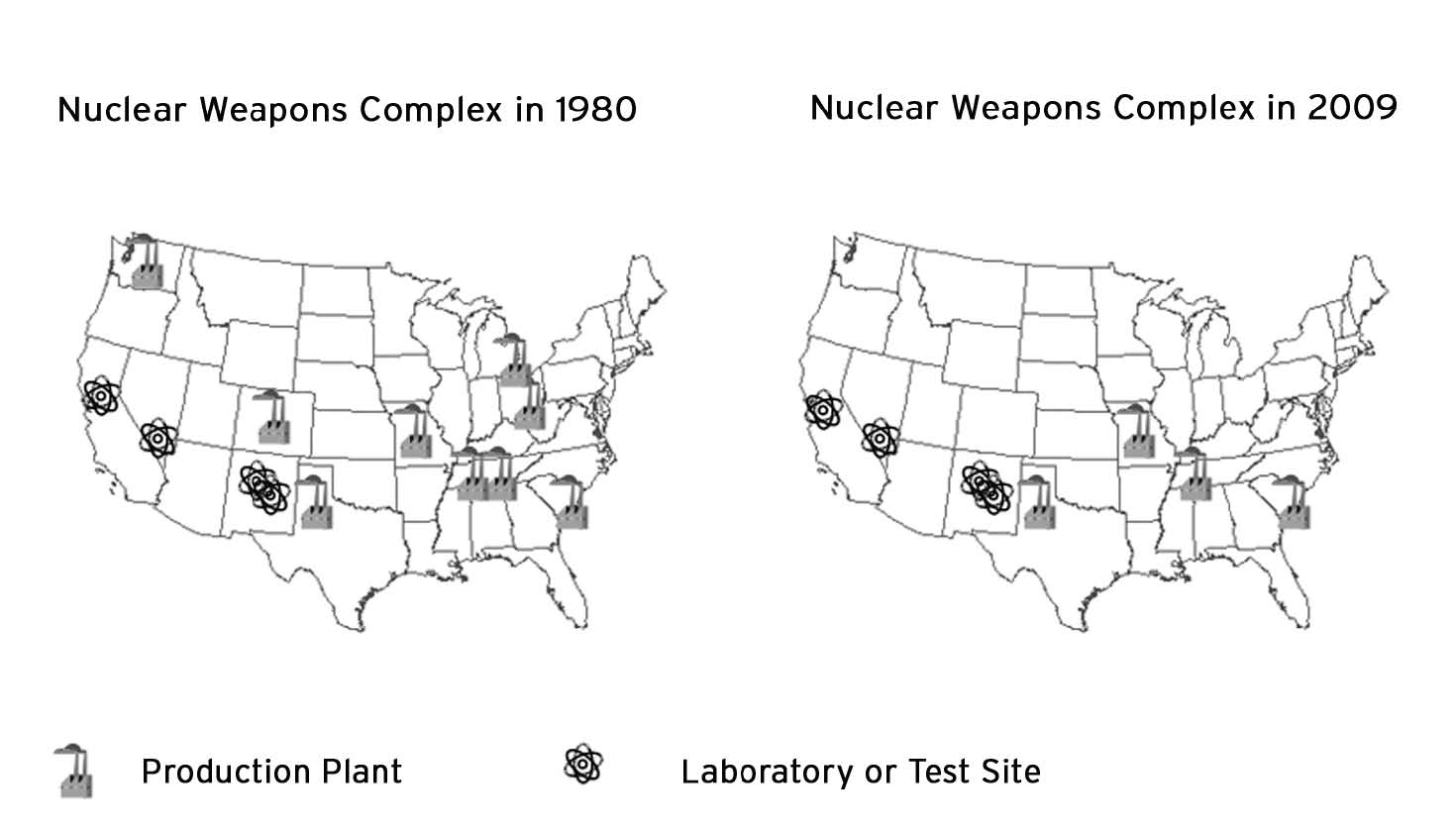

The development of nuclear weapons has always been in civilian hands. During the Manhattan Project, many of the scientists working on the bomb refused to don uniforms and report through a chain of command. Major General Leslie Groves, military head of the project, succumbed to their demands and allowed civilians to direct most of the research and development. After the war, the civilian tradition continued with President Truman’s formation of the Atomic Energy Commission (AEC), a group of five experienced individuals who ensured that nuclear weapons requirements were met, funds were properly expended, and safety and security were maintained. Subsequent administrations created the Energy Research and Development Administration, the Department of Energy, and, most recently, the National Nuclear Security Administration (NNSA), a semi-autonomous organization within the Department of Energy. Almost all the hands-on work relating to nuclear weapons development, from initial design to final assembly, is done by private contractors, including the three nuclear weapons laboratories (Los Alamos and Sandia in New Mexico, and Livermore in California), the four production plants (Y12 in Tennessee, Savannah River in South Carolina, the Kansas City Plant, and Pantex in Texas), and the Nevada Test Site. NNSA oversees these activities, particularly in areas such as nuclear safety, strategic planning, and the interface with the Department of Defense. Approximately $7 billion was allocated to nuclear weapons research, development, and manufacturing in 2009.

Each year the directors of the three nuclear weapons laboratories sign letters certifying the safety, security, reliability, and performance of the systems designed by their institutions. These letters are submitted to the Department of Energy, where a cover letter from the secretary is attached for transmission to the president. The secretary of energy can say what he likes in his own letter, but he is not permitted to change any of the input from the laboratory directors, thus ensuring that an accurate technical assessment of the nuclear stockpile is provided directly to the only person who can authorize its use.

As a check on the technical judgment and integrity of the laboratories, U.S. Strategic Command performs its own review of each weapons type. Its Stockpile Assessment Team (SAT), composed of retired weapons experts, some of whom designed and tested weapons themselves, conducts one of the most rigorous scientific examinations that I have ever encountered. Many “reviews” actually consist of prepared presentations intended to convince listeners of the speaker’s point, but the SAT digs into details, asks demanding questions, and sometimes assigns homework when it is not convinced by what it is shown. It provides its final report on the stockpile to the commander, who can then share it with the president.

Specific technical topics, such as how long a plutonium “pit” might last in a stockpiled weapon, are analyzed by other organizations, including the Defense Science Board and the National Academy of Science, and ad hoc groups formed as appropriate. All these studies are intended to bring fresh eyes to the assertions of weapons experts, but all have the shortfall of only reviewing what is presented to them. This differs from normal scientific peer review, where technical papers are sent to other scientists who have personal experience doing the type of work reported in the paper and who, at least in principle, could independently reproduce the results. New or provocative results are not generally accepted by the scientific community until someone else has independently verified them. One of the limiting aspects of tight security in the nuclear weapons program is that only a few dozen people are expert on nuclear weapons safety and performance, so it is difficult to arrange for a truly independent assessment.

ALL THE NUCLEAR weapons in America’s arsenal were developed through a process of design and testing. Today we face the prospect of maintaining them well beyond their design lifetimes without the opportunity to test them, a major scientific and engineering challenge. Consider the following analogy: Suppose that you lived on an isolated farm and that a family member suffered from a potentially fatal medical condition. The hospital is many miles away and you have several cars in your garage, but under an agreement with your neighbors you have promised never to drive them or even to start their engines except in dire emergency. How can you be certain that these vehicles will work when you need them, when the life of a loved one hangs in the balance? You could check that they are full of gasoline, that their oil is at the proper level, and that their tires are inflated. But suppose that during one of your routine inspections you find that the spark plugs are starting to corrode, raising doubts about the performance of the engine. Worse, the auto supply store tells you that they don’t make that type of spark plug anymore. Could you modify one of the newer types to fit? But how would you know that the new spark plugs really work without actually starting up the engine? Would you break your agreement with your neighbors, or would you accept the risk and hope for the best?

This simple analogy gives some insight into the challenge of maintaining our nuclear arsenal in the absence of underground nuclear testing. No one has ever tried to maintain objects as complex as nuclear weapons in perpetuity without testing them in their most vital function, which in the case of a nuclear explosive is its ability to explode when needed and to be safe in all other credible environments. During the Cold War, we created a stockpile of highly sophisticated weapons that were intended to be periodically tested to reveal unforeseen problems that might have arisen from aging, or “birth defects” dating from their original construction. We assumed that no weapon would remain in the stockpile for more than ten or twenty years, so relatively few spare parts were made during the original production run. Less consideration was given to making weapons last many decades than to making them more capable in their assigned missions.

The decision to stop testing was a combination of politics—the hope of impeding proliferation by preventing nuclear aspirants from testing their weapons—and an assessment of the technical risk of not testing our own weapons. President George H. W. Bush concluded that the potential benefits of not testing outweighed the risks and ordered, on October 1, 1992, a temporary moratorium on nuclear testing by the United States. President Clinton continued the moratorium and signed the Comprehensive Test Ban Treaty, which would have made the testing prohibition permanent, but the Senate refused to provide its consent; as a result, the United States was not obligated by the president’s signature. Congress did, however, endorse the de facto test moratorium by withholding funding for the nuclear test program, essentially making it impossible for the administration to conduct a test even if it wanted to, but it did not go so far as to make it against the law to test.

All the nuclear weapons in our arsenal are either beyond their intended design lifetime or rapidly approaching that point. Disassembly of weapons for diagnostic checks has revealed a number of problems that were never anticipated, and some of these findings have required considerable effort to understand and fix. Dealing with them has been complicated by the fact that the nuclear weapons production complex in the United States has all but collapsed, making some parts impossible to replace and others replaceable only by similar, but not quite identical, new parts. How did this happen, and what is the prospect for maintaining our nuclear arsenal without the ability to manufacture and test replacement parts?

THE EUPHORIA THAT accompanied the end of the Cold War was in full swing when nuclear testing ended in 1992. There was an almost audible sigh of relief that the threat of nuclear Armageddon, one that had hung over the world since the dawn of the Cold War, was receding. There was a hope that much of the money formerly allocated to nuclear weapons would be shifted to solve urgent social problems such as health care, education, and economic development. Since there were no requirements for new weapons and since testing had been halted, Congress began a series of budget reductions in the nuclear weapons program that, if carried on at a constant rate, would have resulted in zero funding in 1999. Each year the laboratories and plants jettisoned capability to balance the books, capability that they might never be able to replace given changing laws that protected the environment and worker safety. Some people applauded the reductions, believing them a route to nuclear disarmament. Others feared that the world was changing too fast and too unpredictably to risk giving up our deterrent; they fought for maintaining at least some capability in the nuclear weapons laboratories and production plants.

The Department of Energy tried to plot a middle course between the two extremes. Recognizing that there was simply not enough money to go around, DOE gave priority to preserving the intellectual capital in the nuclear weapons design laboratories, the people who understood why weapons were the way they were and how to design new ones if the need arose.

What suffered in DOE’s strategy were the production plants that, it reasoned, were not producing any new weapons at the time and that could be fixed later if required. Plutonium production facilities at Richland, Washington, and Savannah River, South Carolina, were put into standby status. The nation’s only plutonium pit fabrication facility at Rocky Flats, Colorado, was already closed (it had been raided by the FBI in 1989 for violations of environmental laws), and rather than refurbishing this aged plant, it was converted to an environmental research park with the eventual goal of cleaning it up and closing it for good. This was accomplished in 2005, ahead of schedule and well under budget. The Y12 uranium fabrication plant at Oak Ridge, Tennessee, lost thousands of workers as its focus turned from weapons production to environmental cleanup and the conversion of its once super-secret production lines to other, nonnuclear, industrial tasks. Collapsing budgets forced these decisions to be made so rapidly that there was not even time to mothball equipment—it was salvaged, destroyed, or simply left to rust for lack of funds to maintain it. Only the Pantex Plant near Amarillo, Texas, seemed to have a mission, that being the dismantling of thousands of unneeded weapons.

Deep budget cuts at the nuclear weapons production plants were designed to protect the three nuclear weapons laboratories, two focusing on the physics design of bombs and warheads and one focusing on engineering. Los Alamos National Laboratory, in New Mexico, was the original design laboratory during the Manhattan Project and grew into a multifunction scientific institution employing more than nine thousand people. Spread over forty-three square miles, Los Alamos is known for outstanding science and has extensive capabilities for experiments involving nuclear materials and high explosives. Los Alamos scientists and engineers designed most of the nuclear weapons in the U.S. stockpile.

The second physics design laboratory is Lawrence Livermore National Laboratory, located east of San Francisco. Situated in a compact one-square-mile area, Livermore boasts the fastest computers in the world and is finishing construction of the National Ignition Facility, a mammoth laser designed to produce thermonuclear fusion on a small scale.

Sandia National Laboratories has its main operations in Albuquerque, New Mexico, and a second facility in Livermore. Sandia does all the engineering work associated with the nonnuclear components of weapons—electronics, structural and mechanical parts, and security systems. It has a wide array of capabilities, including machines that can generate intense gamma ray and neutron pulses to verify that electronic and other components will continue to work in the radiation cloud near a nuclear blast.

Even though the United States was not designing any new nuclear weapons, DOE still thought it essential to maintain two physics design laboratories. Nuclear weapons were too complex, and the danger of overconfidence was too great, to place total reliance on one design group. Los Alamos and Livermore were well known for their intense competition—it was sometimes said that they designed their weapons with each other in mind. Competing designs were held in the strictest secrecy—not just from the Soviets, but from the other laboratory. A “separate but equal” attitude existed and occasionally was carried to an absurd degree. For example, at the Nevada Test Site where both labs performed nuclear tests, each laboratory had its own dormitories, automobiles, test areas, tunnels, and even radio frequencies. Given the intensity of their rivalry, DOE was sure that they would be critical of each other’s assessments of weapons status. Sandia could continue as the sole engineering laboratory since most of the components that it produced—those outside the nuclear explosive package itself—could be tested in nonnuclear experiments.

A key problem in maintaining capability at the laboratories was giving the personnel, many of whom had unique skills developed during decades of weapons development and testing, something useful and interesting to do. There was a very real concern that universities and industry would see the well-trained staff at the labs as easy pickings and that a “brain drain” would erode the nation’s nuclear weapons expertise. This situation was not unlike similar challenges faced by the navy or air force when they had to maintain unique submarine yards or aircraft design capabilities between major weapons systems acquisitions. DOE adopted what it called an “anchor store” approach (“Every shopping mall needs an anchor store.”) by funding one major facility at each laboratory—a large laser at Livermore, a neutron-scattering facility (for materials science) at Los Alamos, and a microelectronics research facility at Sandia—that were intended to retain the best people and recruit the next generation of weapons scientists and engineers. Each laboratory was provided with the most powerful computers in the world, machines capable of performing more than one hundred trillion operations per second, about the equivalent of one hundred thousand personal computers working in unison.

All these facilities are part of the Stockpile Stewardship Program that is designed to maintain the nuclear stockpile into the indefinite future without nuclear testing. By careful inspection of disassembled weapons and the analysis of old nuclear test data, scientists hope that they can identify all the essential elements of weapons safety and performance and address each one of them by means of computer calculations and nonnuclear experiments. For example, if you are concerned about tiny cracks in high explosive affecting the quality of a weapon’s implosion, you could disassemble the weapon, replace the plutonium with a nonnuclear material such as lead, and explode the modified unit. Scientists believe that if a computer code accurately predicts the implosion of the lead substitute, it should do as well for the real weapon. DOE approved construction of a giant x-ray machine at Los Alamos, the Dual Axis Radiographic Hydrotest Facility, to perform these tests. It uses a series of intense x-ray pulses—many millions of times more powerful than those used in medical x-rays—to peer inside a weapon while the implosion is in progress.

The advances made by the weapons laboratories in computational physics and weapons-related experiments are impressive, but several concerns remain about the viability of the stewardship program to maintain weapons forever without testing them. Most important, some key weapons processes simply can’t be duplicated in the laboratory since the energy densities achieved in a functioning nuclear weapon are higher than anything in nature short of a supernova or a black hole. Not even the stadium-sized laser at the National Ignition Facility can reproduce the extreme temperatures and pressures in a nuclear explosion. Scientists must extrapolate from what they can measure in the laboratory to what actually happens during a nuclear explosion.

Another assumption in stockpile stewardship is that one can study each piece of a nuclear explosion in isolation and then use computers to glue them back together into a prediction for a real weapon. Science has long used the principle of reductionism, or the taking apart of complex things to understand their basic elements, but it is less certain that the process can be reversed and that the pieces can be put back together to yield the original object. In some cases, scientists have found that it is impossible to model things as well as we would like, including the weather. We are getting quite good at modeling weather over periods of hours or days, but we now know that the chaotic nature of the atmosphere makes it theoretically impossible to make accurate predictions of the weather many months in advance, no matter how powerful our computers or how clever our programmers. Nuclear weapons do not appear to be as difficult to model as the weather, but they are sufficiently complex to raise concerns that, with no ability to test the results of our computer predictions, we can be sure of our answers. It was just this concern that led the U.S. Senate to demur from ratification of the Comprehensive Test Ban Treaty.

Perhaps the greatest potential danger of the Stockpile Stewardship Program is overconfidence based on lack of hands-on experience. It is not uncommon to hear nuclear weapons designers assert that “we can do that without testing” for concepts that formerly would have undergone an extensive series of underground nuclear tests. Are we so much smarter today than we were at the end of testing, or are we a victim of what Kenneth Johnston, former chief scientist of the Atomic Weapons Establishment in England, said happened during the UK’s moratorium on nuclear testing: “Our confidence went up as our competence went down.”

I no longer believe that we can maintain our existing arsenal of nuclear weapons indefinitely without nuclear testing. That does not mean that I advocate returning to testing, but only that I don’t think that we can continue on our present course and still have high confidence in the safety, reliability, and performance of the nuclear arsenal. We have several options: First, we could accept lower confidence in individual weapons and compensate for it by assigning more than one weapon, and perhaps more than one type of weapon, to each target, akin to keeping more than one car in the driveway. This works so long as we are confident that at least some weapons will work, but it necessitates keeping a much bigger stockpile than we need. Second, we could introduce a new class of nuclear weapon that is simpler and more rugged than the ones that we have now. This would require confidence that these untested weapons were more reliable than our older but tested designs. Third, we could simply allow our weapons to decay and our confidence to erode, our only comfort being that all the other nuclear states would be in the same predicament. But the United States already has the world’s oldest stockpile and no manufacturing capability for some key components, putting us at a potential disadvantage compared to other nations. Fourth, we could accept the political fallout resulting from an occasional nuclear test. There is no perfect answer to this question since each of the options has pros and cons.

My skepticism regarding the ability of the Stockpile Stewardship Program to maintain the arsenal indefinitely without nuclear testing is not shared by all my colleagues. Some believe that a method referred to as “Quantification of Margins and Uncertainties” can help us estimate the accuracy of our predictions and enable us to steer clear of performance problems. The idea underlying this method seems obvious: Find out what parameters in a weapon introduce the greatest risk to its safety and performance, and back off on those parameters so that the risk goes down. However, the notion that we can back away from a performance cliff assumes that it is indeed a cliff and not a table, where backing away from one edge only leads you closer to another edge. Not knowing exactly where the edges are makes it difficult to put yourself in the center of the table—the place with the least risk. Computer simulations can only describe those phenomena that are coded into them, and on more than one occasion we have been surprised when confirmatory experiments gave results different from our calculations.

A couple of examples might help to illustrate the danger of missing physics in a computer code. High explosive, vital to the performance of a nuclear weapon, is actually a mixture of explosive granules and a plasticizer that gives it mechanical strength and enables it to be machined to precise shapes. Over time this plasticizer evaporates, making the high explosive brittle and prone to cracking. The same thing happens to the plastic dashboard of an automobile when, after many years, the plasticizer evaporates and cracks appear. But while cracks in a dashboard are only cosmetic, cracks in high explosive can affect safety, raising serious questions about the handling and storage of weapons. Most computer codes model high explosive as a smooth and continuous solid and have no ability to model microscopic cracks. If you just looked at the results of computer calculations and did not look at the real explosive, you would never know there was a problem.

In 1994, several scientists proposed to use a large laser at Livermore to look at a simple process that had important implications for weapons performance. Some of their colleagues criticized them for wasting money. “If we know anything about nuclear weapons, we know that,” was one comment. When the experiment was performed it gave exactly the opposite result from the computer calculations—a puzzle to the scientists until they realized that a different process than the one that they anticipated—a process not included in the computer code—was responsible for the observed results. Subsequent calculations using the correct physics were able to model the experimental results, but this episode made some people nervous about using the phrase, “We can calculate that.”

Surprises happened in nuclear tests. One of my designs performed so unexpectedly that the recording equipment had trouble capturing the data. In designing it I ran every computer code available. Scientists at the other weapons laboratories ran their own codes and got the same results as I did. Extraordinary care was taken in the construction of the device, and numerous technical reviews were held to critique its performance. After all this diligence, nature had other ideas. I still remember with crystal clarity my division leader saying, at the end of a particularly detailed review, “There’s nothing wrong with this bomb.” There wasn’t, in fact—it just worked differently than we predicted. We eventually figured out what happened—it was an error in a data table—but no one found the problem before the device was tested.

Science has always proceeded through a comparison of theory and experiment. Lacking the ability to conduct nuclear tests, we will never be completely sure that we have included everything in our calculations. Many Nobel Prizes have been won by scientists doing experiments that “don’t need to be done.” Computer simulations are just that—imitations of the real thing—and I know of no way to be sure that a calculation produces an exact rendition of what happens in nature.

THE DECISION TO halt nuclear weapons testing had a strong political component. Some claimed that by not testing, the United States would discourage other countries from testing. The risk of our own weapons developing a problem was seen as lower than the risk associated with other countries modernizing their own stockpiles. Also, by not testing, we would pressure potential proliferants to refrain from testing their first designs, raising doubts as to whether they would work.

Russia, China, Great Britain, and France have also forsworn nuclear testing; each has its own approach to maintaining its nuclear forces. Russia has a program of laboratory experiments and computer simulations similar to that of the United States. It lacks some of the supercomputer technology employed by the U.S. program, but it compensates for this by the high quality of its scientists (“You compute, we think,” a Russian scientist once said to me) and by conducting an extensive series of experiments at its former nuclear testing range at Novaya Zemlya, north of the Arctic Circle. In the early years of the twenty-first century the Russians dramatically increased the pace of activity at Novaya Zemlya, even operating during the winter months when complete darkness prevails and attack by polar bears is an ever-present danger. Satellite photographs on GoogleEarth reveal new buildings, a school, and miles of cables leading into experimental areas located deep under mountains.

The United Kingdom, France, and China have smaller stewardship programs than the United States and Russia, but sufficient ones to maintain their smaller stockpiles. All rely on laboratory experiments plus computer simulations to assess the status of their weapons, and all have built large lasers and other facilities to compensate for the end of nuclear testing.

The United States differs from all other nuclear powers in that we are the only one that does not regularly remanufacture and replace our weapons. All other countries believe that the maximum shelf life of a nuclear explosive is in the range of ten to fifteen years. Beyond that they worry that corrosion, cracks, and other age-related problems mandate replacement of the entire weapon. The United States believes that quality control in the initial production of our weapons, along with improved understanding of fundamental phenomena made possible by stockpile stewardship, will enable our weapons to last many decades.

The United States could not emulate the remanufacturing strategies of the other nuclear nations even if we wanted to, since we lack key capabilities to make essential parts of weapons. DOE knew that it was dealing the nuclear plants a near-fatal blow in the mid-1990s by diverting resources to the laboratories, but it did so with the idea that at some point we could resurrect those capabilities, some of which resided in the nonnuclear industrial complex. “We’ll fix it later,” was the phrase used in many discussions. As the years have passed and more unforeseen problems have occurred in our weapons, we can say that “later” has arrived.

Of the three nuclear materials found in a modern weapon—uranium, plutonium, and tritium—we currently have a limited capability to manufacture two: uranium and tritium. There is a small plutonium capability at Los Alamos, but it is inadequate to deal with a situation that would necessitate replacement of hundreds of plutonium pits in a short period of time. Several starts have been made on plans for a new plutonium facility, each of them sunk by Congress, which refuses to commit substantial funds without a better estimate of just how many weapons we need, of what types, and how big the proposed plant would need to be to meet those needs. Since a plutonium facility is likely to cost more than $10 billion and take more than a decade to complete (three times longer than it took to make the first atomic bomb, including the construction of a national complex of laboratories and production plants), Congress has good reason to ask for a detailed justification of the expenditure. The blank checks that the country wrote to support the nuclear stockpile ended with the Cold War.

A further complication affecting plans for plutonium fabrication is that weapons scientists are uncertain about how long plutonium components will last and hence when we will need to replace them. Do we need to remanufacture all our weapons within a few years, or can we afford to spread out production over a decade or more, permitting us to construct a much smaller and less expensive plant? The natural radioactivity of plutonium causes damage to the metal at the microscopic level, damage that may—or may not—affect the performance of the weapon. Plutonium was first made in 1943, so our experience with its aging is poor compared to how long we anticipate keeping weapons in the stockpile. The weapons laboratories have done a few experiments to simulate the aging of plutonium, but the key word is “simulate.” Did the method used to accelerate aging give an accurate prediction of what happens in the real material? Knowing how long a plutonium pit will last is an essential data point in designing a new production plant. I do not believe that we have enough data to answer this question.

The Pantex facility, which assembles and disassembles nuclear weapons, near Amarillo, Texas.

Uranium components for nuclear weapons are manufactured in the Y12 plant in Oak Ridge, Tennessee. DOE has invested hundreds of millions of dollars to bring this Second World War–era facility back into operation. Tritium, an isotope of hydrogen and an essential ingredient in modern weapons, is stored at the Savannah River Site near Aiken, South Carolina. While essential to weapons, both uranium and tritium present far fewer challenges to scientists and engineers than plutonium.

Sometimes the problems in weapons remanufacture are associated with much more mundane materials—plastics, rubber, and metals such as beryllium. Changes in environmental law and the discovery that some of these materials might cause cancer or other diseases have led to a prohibition against their future use, even in nuclear weapons that contain far more dangerous substances. These laws mean that we are not permitted to “make it just like we made it before.” But even if we could get the same materials, it is hopeless to try duplicating what was done decades ago, something illustrated in the automobile analogy presented at the beginning of this chapter. A few moments of thought will reveal that we really couldn’t remanufacture a 1968 Ford exactly the way it was done back then without a massive investment in antiquated equipment that no modern machinist would think safe to operate. We would substitute one plastic for another, use different alloys of steel, and have to accept slightly different formulations of rubber. The same thing is true of a nuclear weapon manufactured in 1968. The cumulative effect of many small changes is one of designers’ greatest worries when considering the refurbishment of old nuclear weapons.

THE UNITED STATES has not ratified the Comprehensive Test Ban Treaty, so there is nothing preventing us from resuming underground nuclear testing should the president decide that it is in our national interest. Such an experiment would be done at the Nevada Test Site, located about sixty miles northwest of Las Vegas. Surrounded by Nellis Air Force Base and other federal land, the Nevada Test Site is arguably the best location in the world for conducting nuclear tests owing to its very deep water table, its geology of dry rock and sand, and its isolation from populated areas. Underground experiments would be conducted six hundred to two thousand feet below the desert floor so no radioactivity would be released into the environment.

Although nuclear tests stopped in 1992, the Nevada Test Site is still very busy supporting the weapons program. The isolation and high security of the site make it the preferred test bed for experiments involving plutonium, some of which are conducted in a laboratory complex nearly one thousand feet underground. These studies, called subcritical tests because they do not produce any nuclear yield, involve state-of-the-art diagnostics to gather data to test computer codes. They reduce the uncertainty associated with our assessments of weapons and occasionally reveal things that we didn’t know about the unique materials in nuclear explosives.

Estimates vary as to how long it would take the United States to resume nuclear testing. If the goal were simply to demonstrate that a weapon will explode, perhaps to show political resolve after other countries resumed testing, then an experiment could be conducted in as little as six to nine months. A more sophisticated experiment involving new measurement apparatus might take two years or more to develop and field. The United States has no plans to conduct a nuclear test, and funding for our readiness program is inadequate to maintain our capability. This is in stark contrast to the Russian test readiness program, which, I am told by Russian colleagues, is very well funded with the construction of new facilities and the development of new capabilities.

THE NATIONAL IGNITION FACILITY, the x-ray machine at Los Alamos, and refurbishments at the nuclear weapons plants are multibillion-dollar investments in America’s nuclear arsenal. But hardware alone will not provide the required confidence in our future stockpile. People design, maintain, and manufacture weapons. A major worry in the nuclear weapons community is how we recruit and train the next generation of weapons scientists and engineers. Fortunately, the technical qualifications of people who are willing to undergo the rigorous security investigations associated with a “Q,” or nuclear weapons clearance, have remained high during the course of the stewardship program. The scientific challenges, the opportunity to work with some of the most advanced equipment in the world, and the patriotism of young Americans have attracted a number of young people into a nuclear weapons career path. These new entrants will never be able to get the nuclear test experience of their older colleagues, so there is an urgent need to pair them with mentors who can guide and temper their enthusiasm for undertaking risks.

SO FAR WE have focused on the problem of maintaining our nuclear explosives. A similar challenge applies to the delivery vehicles that carry them. Missiles, bombers, and submarines are complex machines with finite lives, often designed and constructed by special teams not unlike those who worked on nuclear explosives. Unlike nuclear explosives, however, all our delivery vehicles can be tested, often under highly realistic conditions. Bombers are regularly exercised by loading and launching simulated nuclear bombs and cruise missiles. Each year the United States, Russia, and some other nuclear nations conduct ballistic missile tests in which an ICBM (land-based missile) or SLBM (submarine-based missile) is launched with dummy warheads replacing its nuclear payload. Extensive telemetry and radar coverage reports the detailed flight characteristics of the missile to assess its performance.

Our nuclear weapons delivery systems are aging—the B52 bomber first flew in 1954, and, while it has been heavily modified to keep up with the times, it is an old airplane. More serious is the fact that missiles can be flown only once—they cannot be recovered, refueled, and placed back in their silos for future use. Since only a finite number of Minuteman III missiles were produced, each one tested means one fewer in the operational force. The air force is actively debating the tradeoff between more tests and more missiles. With the agreement to reduce the number of strategic nuclear weapons from many thousands to between seventeen hundred and twenty-two hundred, we have some missiles to spare, but over time these too will be used up in tests. Arms reduction agreements have delayed but not eliminated the eventual need to build new missiles and bombers.

Test launch of a Minuteman III ICBM from Vandenberg Air Force Base in California.

NUCLEAR WEAPONS PRODUCE unique effects such as electromagnetic pulses, intense radiation, and super-strong shock waves. We need to maintain our understanding of these effects so that we don’t suffer catastrophic failure of critical systems in the event of even a limited nuclear attack. The sensitivity of microelectronics to electrical interference, combined with our nearly complete reliance on computers to manage our defense, demands that we have a better understanding of nuclear weapons effects than ever before. Yet these capabilities have all but disappeared. There used to be several experimental facilities to simulate the effect of a nuclear electromagnetic pulse on major systems such as aircraft, tanks, and commercial power networks, but today there are few to none, depending on funding in an individual year. Most of the expertise in nuclear weapons effects resides in the for-profit defense sector, and companies are reluctant to maintain expensive facilities in the absence of paying customers. Fixing this problem is not expensive on the scale of major defense programs—an increase of $40 million per year would be sufficient—but so far every attempt to secure even this modest level of funding has failed. Soon we will no longer be able to offer a credible answer to the question, “What would happen if a nuclear weapon exploded nearby?”