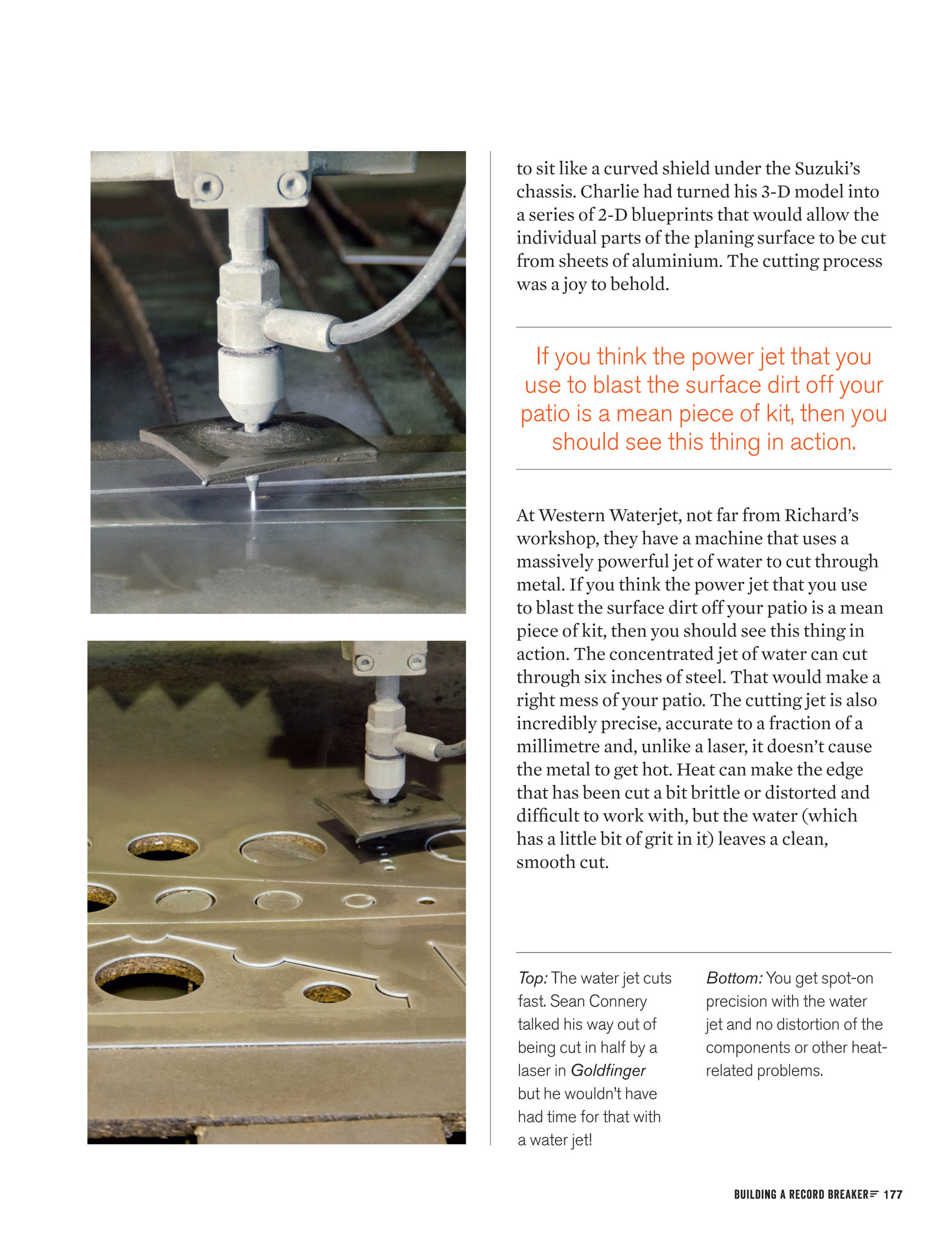

to sit like a curved shield under the Suzuki’s

chassis. Charlie had turned his 3-D model into

a series of 2-D blueprints that would allow the

individual parts of the planing surface to be cut

from sheets of aluminium. The cutting process

was a joy to behold.

If you think the power jet that you

use to blast the surface dirt off your

patio is a mean piece of kit, then you

should see this thing in action.

At Western Waterjet, not far from Richard’s

workshop, they have a machine that uses a

massively powerful jet of water to cut through

metal. If you think the power jet that you use

to blast the surface dirt off your patio is a mean

piece of kit, then you should see this thing in

action. The concentrated jet of water can cut

through six inches of steel. That would make a

right mess of your patio. The cutting jet is also

incredibly precise, accurate to a fraction of a

millimetre and, unlike a laser, it doesn’t cause

the metal to get hot. Heat can make the edge

that has been cut a bit brittle or distorted and

difficult to work with, but the water (which

has a little bit of grit in it) leaves a clean,

smooth cut.

Top: The water jet cuts

fast. Sean Connery

talked his way out of

being cut in half by a

laser in Goldfinger

but he wouldn’t have

had time for that with

a water jet!

Bottom: You get spot-on

precision with the water

jet and no distortion of the

components or other heat-

related problems.

building a record breaker 177