Chassis Systems

Drive Train System

The engine can produce power to move the vehicle, but this energy must be processed and transmitted effectively in order to accelerate the vehicle smoothly and quickly. Transmitting power from the engine to the wheels is the responsibility of the vehicle’s drive train.

An important part of any drive train is the transmission. The transmission is the device that matches engine speed to a desired speed of the vehicle. The two main types of transmissions are the automatic and the manual. Drivers who like to have more control over the operation of the vehicle will often choose a manual transmission, because the driver is responsible for shifting the gears up and down. A car with an automatic transmission is much easier to operate because it does not use a driver-operated clutch and does all of the gear shifting automatically.

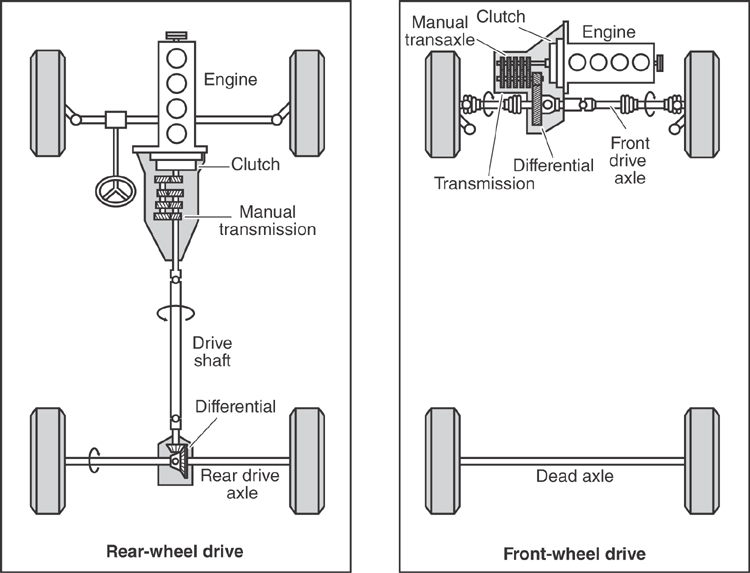

While rear-wheel drive was the most common design in years past, front-wheel drive has become very popular, especially in small- to medium-sized cars.

Components

The typical components found in a front-wheel drive vehicle with a manual transmission include the following:

- Clutch: transmits torque from the engine to the transmission. The clutch can be released and engaged to allow smooth starts and transmission shifting.

- Transaxle:has several “gears” that are selected according to the speed of the vehicle and how fast the driver would like to accelerate. The transaxle is a combination of the transmission and the drive axle, which are normally two separate components in a rear-wheel drive vehicle.

- Half shaft: a short drive shaft that transmits power from the transaxle to the drive wheels. Used mostly in front-wheel drive vehicles, the half shafts must be able to apply power to the drive wheels while allowing them to move up and down and turn the vehicle. There are two half shafts, one for each drive wheel.

- Constant-velocity (CV) joints: located at each end of a halfshaft, CV joints can transmit power through very steep angles. The inboard CV joint is located at the transaxle, while the outboard CV joint is located behind the vehicle wheel.

Other drive train components that may be found in other vehicle designs include the following:

- Transmission: used in rear- and four-wheel drive vehicles, the transmission is responsible for matching engine speed to the desired speed of the vehicle.

- Drive shaft: a longer version of the half shaft, the drive shaft transmits torque from the transmission to the drive axle. The drive shaft is also required to allow up and down movement of the vehicle’s wheels, but not to the same extent as the half shaft in a front-wheel drive.

- Universal joints: located at each end of the drive shaft, the universal joint allows the shaft to operate at an angle with the component that it is driving. Also known as U-joints.

- Drive axle: transmits engine power through a 90-degree angle, and splits that power between the two drive wheels. The wheels are attached to the ends of the drive axle. The drive axle incorporates a differential, which allows the left and right wheels to turn at different speeds as the vehicle goes around a corner.

- Transfer case: located between the transmission and the drive axles on a four-wheel drive vehicle. The transfer case splits the engine’s power between the front and rear drive axle.

Gear selection

Transmissions are built with several forward ratios that are based on the specific gears that are used. Typical transmissions are therefore said to have “speeds” or “gears.” For instance, a four-speed transmission would have four forward gear ratios and one reverse ratio. A driver would typically start from a stop using low (first) gear. In this gear, the transmission would increase the torque from the engine sufficiently to be able to start the vehicle from a standstill. However, this would limit the vehicle’s speed once it did start rolling, so the driver would then select second gear and so on as the vehicle continued to accelerate.

High (fourth) gear would be used to allow the vehicle to cruise on the highway. Engine speed would be moderate to low in this gear, allowing for maximum fuel economy and quiet running. To accelerate quickly, however, the driver would downshift to a lower gear in order to increase engine speed and power. Proper gear selection is important when operating a vehicle with a manual transmission. Modern transmissions now have as many as eight forward speeds.

Automatic transmissions

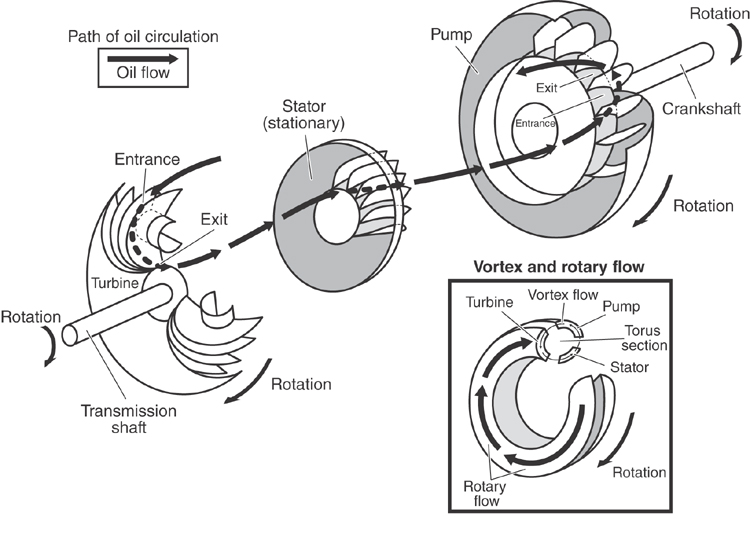

Automatic transmissions are much more complex than their manual counterparts, yet are much easier to operate. The reason that many drivers prefer them is that automatic transmissions do not use a driver-operated clutch.

Instead of using a clutch, automatics transmit engine torque from the engine to the transmission through a torque converter. The torque converter uses fluid to transmit power, and allows for a certain amount of slippage when the vehicle is stopped.

Automatic transmissions do all of the gear selection for the driver. This is done in the transmission using hydraulic pressure to select the proper planetary gear sets. Virtually all modern automatic transmissions are controlled electronically by the vehicle’s powertrain control module.

Another modern automatic transmission is the continuously variable transmission or CVT. A CVT transmission does not utilize specific gear sets to determine the transmission ratio (or gears). Instead, it relies on two opposing sets of cones, one for input and one for output, with a chain or belt running between the two cones. The effective ratio of the transmission depends on where the chain (or belt) is riding on the two cones. Because the transmission’s effective ratio is not limited to specific gears as in a typical transmission, the ratio can be varied continuously between the limits of the diameters of the two cones.

Suspension and Steering System

The newest suspension and steering systems have incorporated computer control in an effort to improve vehicle performance. While the sophistication of computer control has increased the overall complexity of these systems, the basic principles remain the same.

Components

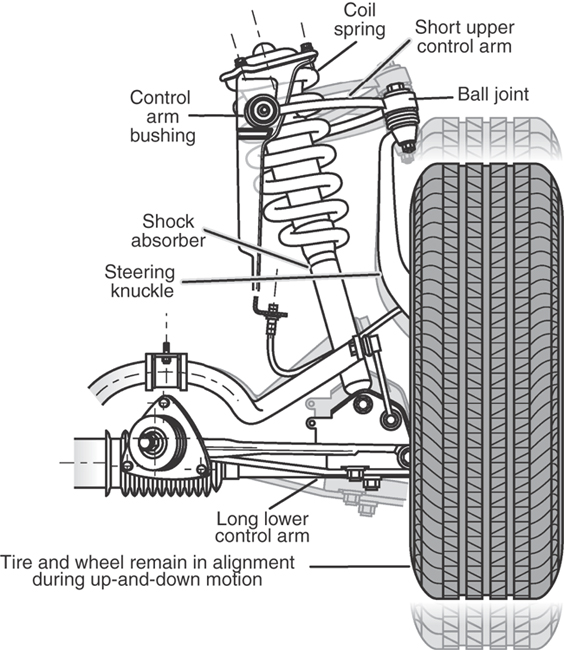

The major components of the long-short arm suspension system include the following:

- Springs: hold the vehicle’s chassis up and allow the wheels to move up and down in relation to it.

- Shock absorbers: absorb the energy released by the up-and-down movement of the vehicle wheels.

- Control arms (A-arms): the long-short arm suspension system uses an upper and lower control arm to maintain the vertical orientation of the steering knuckle as the wheel moves up and down.

- Steering knuckle: connects to the upper and lower control arms through the use of ball-joints. The wheel hub mounts on the spindle, which is part of the steering knuckle.

- Ball joints: ball-and-socket assemblies that allow the steering knuckle to turn and move up and down simultaneously.

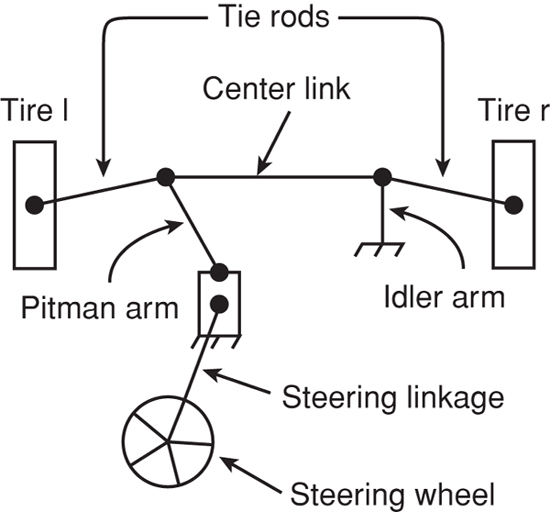

- Steering linkage: connects the steering wheel to the steering knuckle.

- Wheel hub: forms the mounting point for the vehicle’s tire assembly.

- Tire: makes contact with the road and provides a “footprint” to aid in vehicle stability and handling.

Construction and operation

In order to make a vehicle ride smoothly, the wheels must be able to move up and down while the vehicle chassis stays steady. This is the job of the vehicle springs; they must be able to allow this movement of the wheels without transmitting road shock. However, the springs absorb energy as this happens and must release this energy without bouncing the vehicle after encountering a bump.

The shock absorber is installed between the chassis and a control arm to help dissipate or absorb the energy stored in the spring as it is either compressed (or jounced) or extended (or rebounded). Without properly functioning shock absorbers, the vehicle will continue to bounce up and down after the vehicle has hit a bump in the road. The shock absorber uses a piston and hydraulic oil to absorb the excess mechanical energy from the suspension system and then releases that same energy in the form of heat.

The upper and lower control arms form the supports for the steering knuckle. The control arms are attached to the chassis through the use of control arm bushings. The spring is placed between the chassis and one of the control arms. The spring can be installed on either the upper or lower control arm in a long-short arm suspension. The control arm with the spring on it becomes the load-bearing arm as the vehicle weight is supported through it on the way to the steering knuckle and tire assembly.

An upper ball joint and a lower ball joint are used to attach the steering knuckle to the control arms. Ball joints are built similar to a human hip joint, with a ball and stud rotating in a socket to allow a wide arc of movement. As the control arms move up and down, the ball joints allow the steering knuckle to move freely with them. They also allow the steering knuckle to turn left and right as it is moved by the steering linkage.

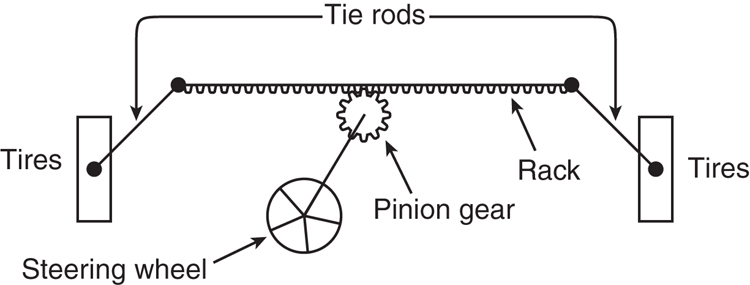

The steering linkage forms the connection between the steering wheel and the steering knuckle. There are two main designs in common use, the linkage steering and the rack and pinion. Long-short arm suspensions most commonly use linkage steering to connect the steering column to the pitman arm, center link, and idler arm. Tie rods are then used to make the final connection to the steering knuckles. Smaller vehicles most commonly use the rack-and-pinion steering system because it is the most compact of the two major steering systems.

Tires

Tires are one of the most critical components of the suspension and steering system. They support the weight of the vehicle and make final contact with the road surface. The most common tire design is the radial tire, which is known for its stable footprint and low rolling resistance.

Tire construction begins with the beads. The bead is a circular piece of high strength material like steel wire that is encased in rubber. The bead forms the mounting point for the tire on the rim. Body plies form the main body of the tire and run from bead to bead. All other parts of the tire attach to the body plies, including the liner (sealed surface inside the tire), the sidewalls, and the tread.

Belts are used between the plies and the tread to help stabilize the tire’s footprint (where the tire makes contact with the road). A stable footprint means better traction under all road conditions, and makes the vehicle handle and brake better.

Maintenance

The primary maintenance that should be performed on suspension and steering systems is lubrication of the ball joints, tie rod ends, and other components. This should be done with a hand-powered grease gun, and the amount of grease should be metered carefully.

The most important part of tire maintenance is proper inflation. Low inflation pressures can be very dangerous as well as increase the rolling resistance of the vehicle, thereby increasing fuel consumption. An underinflated tire can seriously damage the tire, which could lead to a blow out and accident. Too much tire pressure, or over-inflation, can lead to excessive tire wear. An extremely over-inflated tire can also lead to a possible blow out and an accident. Automotive manufacturers label each vehicle with the recommended inflation pressures for the front and rear tires.

Brake Systems

Of all the systems on a car, the most important may well be the brake system. It is one thing to not be able to move forward; it is another thing again to not be able to stop.

Components

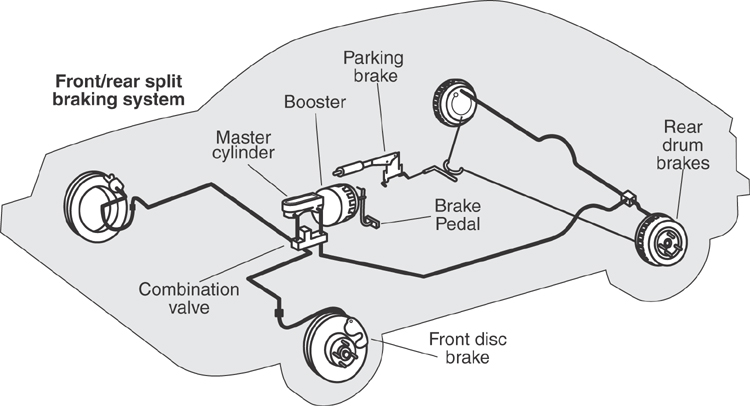

The major components found in any brake system include the following:

- Brake pedal: the mechanical connection between the driver’s foot and the master cylinder.

- Master cylinder: located in the engine compartment just in front of the driver, the master cylinder generates the fluid pressure to operate the brake assemblies at the wheels.

- Fluid reservoir: provides fluid to the brake circuits. The fluid reservoir is located on top of the master cylinder.

- Brake lines: transmit fluid pressure from the master cylinder to the brake assemblies. These can be steel lines that run along the vehicle chassis or flex hoses that are used to connect the steel lines to the brake assemblies.

Assemblies

Brakes work by converting the energy of the vehicle’s motion into heat energy through friction. The two major types of brake assemblies are as follows:

- Drum brakes: expanding shoes make contact with a rotating drum to create friction.

- Disc brakes: brake pads on either side of a rotating disc are “pinched” together to slow the vehicle.

Brake systems are hydraulically operated. A pumping piston, located in the master cylinder, is operated by the brake pedal and puts pressure on the system’s brake fluid. Since fluids cannot be compressed, the brake fluid travels through the brake lines and moves the pistons in the brake assemblies to operate the brakes. The harder the driver presses on the brake pedal, the more fluid pressure is developed and more braking power is generated.

Drum brakes

The parts that develop the friction in a drum brake are the brake shoes. There are two brake shoes in any drum brake assembly. As hydraulic pressure is applied to the wheel cylinder, which is located between the brake shoes, the pistons inside it push apart and act against them. The brake shoes then push outward against the inner surface of the brake drum, and the resulting friction between the brake shoes and the brake drum slows the vehicle.

Disc brakes

Disc brakes are much more powerful than drum brakes because of disc brakes’ superior ability to reject heat energy. The pistons used to actuate disc brakes are much larger, and can apply more force to the brake pads. Also, brake rotors used in disc brakes are more easily cooled, as they are better exposed to the cool air under the car and are often designed with air passages through them to enhance heat rejection.

The piston that operates a disc brake is housed in a brake caliper. This caliper “floats” laterally as the brake is applied and released, and makes it possible for one piston to operate the pads on both sides of the rotor. This makes the caliper operate similar to a C-clamp. As the screw is tightened on one side, the entire assembly is drawn together and “pinches” tightly on the item being clamped; in this case, the brake rotor.

Power brakes

Braking pressure is usually boosted using a brake booster. The brake booster is located between the brake pedal and the master cylinder. Engine intake manifold vacuum is utilized to generate greater force on the master cylinder, so higher hydraulic pressures can be generated in the brake system for the same amount of pedal force provided by the driver. Some brake booster systems use fluid pressure from the power steering system to increase braking power.

Antilock brakes

As in every other vehicle system, computer control is being incorporated into the brake system. Most cars now come equipped with antilock brakes (ABS), which prevent wheel lock under hard braking conditions. The ABS system uses speed sensors attached to each wheel to tell a computer (the ABS computer) the relative speeds of each wheel. If the ABS computer detects a difference in wheel speed more than a preset amount, the computer uses pumps and valves in the ABS system to adjust the brake pressure for the affected wheel or wheels. This gives more control to the driver in slippery conditions and allows the vehicle to stop more predictably and safely.

Let’s see how the test maker will assess your understanding of the chassis system, and what process you should use to address the question and pick up the points.

| Question | Analysis |

| Virtually all modern automatic transmissions are controlled by |

Step 1: This question asks you to recall what component controls almost all modern automatic transmissions. Step 2: There isn’t much information to simplify here. Step 3: Virtually all modern automatic transmissions are controlled electronically by the vehicle’s powertrain control module (PCM). |

|

Step 4: Answer choice (C) matches the prediction. |

Now try a similar question on your own.

-

Brakes slow a vehicle by converting motion energy into energy. - sound

- electrical

- fluid

- heat

Explanation

The correct answer is (D). Brakes convert a vehicle’s motion energy into heat energy through friction.