VOL. II.

FEBRUARY, 1889.

No. 5.

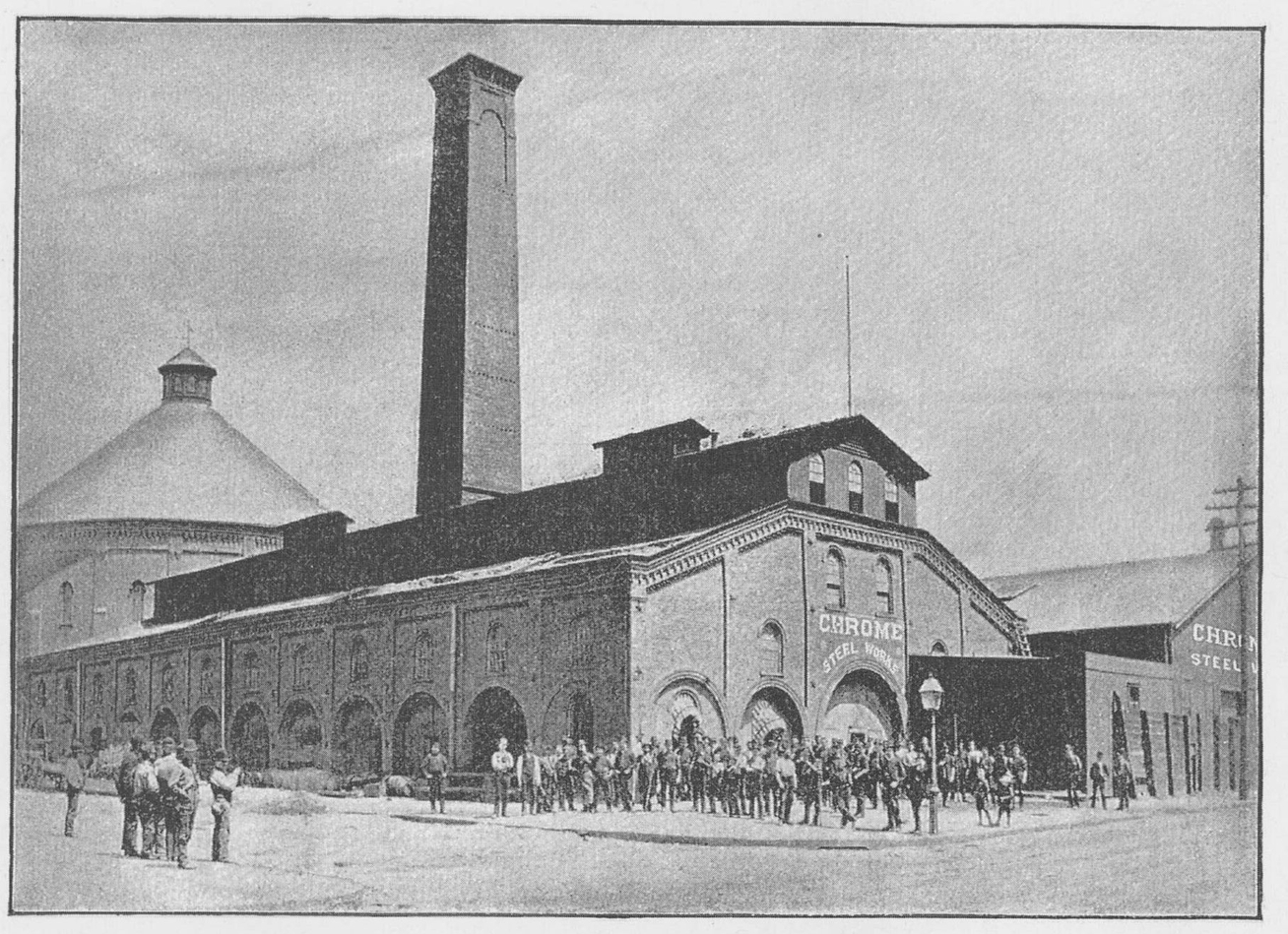

The Chrome Steel Works, Brooklyn, N. Y.

THE steel manufacturing interests of Brooklyn have increased wonderfully of late years and a description of these works cannot fail to be of interest to our readers. They were established in 1867 and are located on Kent avenue, Keap and Hooper streets, Brooklyn, N. Y. Mr. S. H. Kohn is the president, and Mr. C. P. Haughian, vice-president.

The foundry, rolling-mill, melting, hammer and other shops, which heretofore covered nearly two acres of ground, were enlarged in the spring of 1887, and gas substituted for coal in the heating and melting furnaces. The new plant necessary for this change was made complete in every respect, even to the gas generator for the manufacture of the gas used, and the productive capacity of the works was increased two-fold. Another advance step was taken last year when it was found necessary to have additional “rolling” facilities, and the works were further enlarged by the addition of a wing 80 x 150 feet. The establishment now presents an imposing appearance and takes rank with any of its class in this country or abroad. Here is turned out in large quantities the well-known “ Chrome Steel.”

Exterior Chrome Steel Works.

Ordinary or carbon steel is a compound of iron and carbon, the proportions of carbon being from 0.5 to 1.5. It differs from iron merely in the amount of carbon contained in it. We see, therefore, that steel is really more a condition of iron than a distinct metal. To demonstrate how closely iron and steel are related it is only necessary to mention that whereas cast-iron contains about 3.5 per cent. of carbon, and malleable iron contains 0.4 per cent., carbon steel contains about 1 per cent. ; thus being a sort of intermediate between cast-iron and mallealole iron. “Chrome Steel ”differs from carbon steel in the substitution of chromium for carbon in its manufacture. It is an alloy of chromium and iron, the proportions of which are accurately weighed and scrupulously exact in every grade ; both metals uniting perfectly in alloy, become integral in their unity, producing a uniform steel, which it is claimed is much superior to the carbon steel. Though it is an easy thing to claim superiority over competitors for almost any article of manufacture, it is seldom, however, as easy to establish the correctness of the claim. In this case the superiority of “Chrome Steel” is readily recognized, and lies in the fact that, when properly hardened, it cannot be cut by the finest saws, drills or chisels, as it is much harder than such tools are made. It is very tough when hardened, and will not deteriorate by the continued application of great heat. and unlike carbon steel, may be worked in large masses with perfect reliability—a quality of vital importance in the general uses of steel. It is very favorably reported upon by the authorities at the United States Navy Yard, Washington, D. C., after having been subjected to severe tests.

“Chrome Steel” may be made quite ductile and soft by using chromeisen instead of spiegeleisen in the Sieman’s steel process, where the resultant may be tempered to several grades of hardness within well-defined limits. It is capable of being welded and worked as easily- as wrought-iron, while it may be made into all the various forms required for machinery without the danger of being destroyed by over-heating. Its adaptability for manufacturing purposes is apparent. The manufacturers have put it upon the market in what is known as their Chrome tool-steel, made in rounds, squares, octagons and irregular shapes, which is very desirable for making tools and like purposes.

“ Chrome Steel ” is also used extensively for building purposes, and as it cannot be cut or broken it is found extremely desirable for window-guards, gratings, doors and other constructions where absolute safety is not alone desirable but necessary. In this connection it is proper to call attention to the celebrated five-ply combination plates, consisting of alternate layers of welded chrome steel and iron. This material has met with much favor among architects, builders and bankers for the construction of burglar-proof vaults, and safe manufacturers have found it singularly well adapted for making burglar-proof safes. If the cells of a jail or prison are constructed of this material it may be truly said to be positively jail-proof, as it is really impossible for the most expert jail-breaker to work his way through it, whatever means he may employ. We also find chrome steel turned to good account in the manufacture of the well known Adamantine shoes and dies for stamp mills, now in general use throughout the mining regions of both North and South America. Shoes and dies made of chrome steel wear even from end to end and will not “cup,” neither will the shoe break at the shank. They will outwear three sets of those made of the best cast-iron. The Chrome Steel Works also manufacture tappets, cams and bosses for stamp-mills, and crusher plates and shell-rolls, used in the crushing of ores and rock, and also cast to pattern in all shapes, such as crank-shafts, hears, pinions, stamp-dies, parts of steam-pumps and hydraulic presses. Those of our readers who are desirous of learning still more regarding these works, would do well to visit them and see for themselves the enormous quantity of steel that is produced to meet the constantly increasing demand for their specialty. The accompanying cut gives an exterior view.

M. A. B.

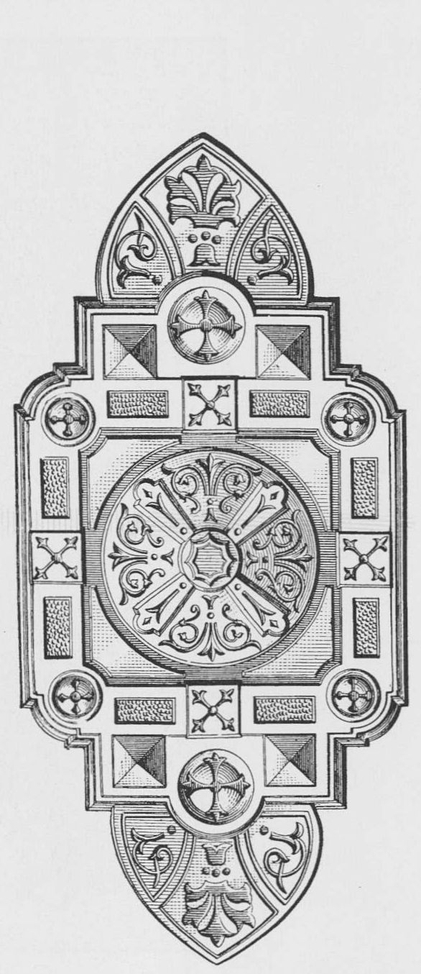

Sheet Metal Center Pieces.

THE time-honored material for center piece or decorative moulding on wall or ceiling has, until recently, been plaster either cast in moulds or run on by the use of forms. Many elaborate devices and beautiful designs have been executed in this material, and in almost any of our cities may be found plasterers skillful in this work who make a specialty of casting center pieces and ceiling ornaments for the trade, supplying frequently a large extent of surrounding country with the products of their skill. And in this country, up to the present time, the large bulk of this class of work is made of this material and in the manner referred to.

Ventilating center Piece.

The weight of plaster centers and the danger of breakage in transportation, as well as their liability to fracture when in place, from settlements, accidental blows and many other causes, has led to the trial of various substitutes with more or less success. One of these is presented in the accompanying illustrations, which are of sheet metal, manufactured by Bakewell & Mullins, of Salem, O., whose sheet-metal works is well known, here as well as abroad, in both architectural and sculptural work. They are now giving special attention to the use of sheet metal as interior decoration and finish.

The principal advantage claimed for sheet metal center pieces is the extremely low price at which they can be sold, beauty of finish, durability, lightness, the ease with which they can be put up, and the fact they may be shipped without danger of breakage.

The manufacturers inform us that these centers are all finished before leaving the factory, and painted a lustreless white to correspond with plaster finish of ceiling. They can, however, be painted and ornamented to suit the taste of purchasers and to correspond with style and decoration of room where used. These centers are simply screwed to the ceiling after plastering is put on and can at any time be taken down, cleaned and replaced without damage to the ceiling or center piece.

We have before us a new catalogue just issued by Messrs. Bakewell & Mullins, together with a price list of these ceiling centers. This catalogue also presents a number of designs of sheet metal interior cornices and ceilings.

The lightness of weight, freedom from danger of cracking or breakage and liability to injury from water make these especially worthy the attention of architects and builders.

Any of our readers will be furnished with this catalogue on application to the manufacturers.

Small Center Piece.

Special Mention.

MESSRS. AESCHLEMANN & PELLARIN, whose marble mosaics are known to many of our readers, have, we learn, recently contracted to furnish about 8,000 square feet of these mosaics in the United States Trust Company’s building at 45 and 47 Wall street. They are also about to commence work in Newark, N. J., for the Murphy Varnish Company. They are now engaged laying these mosaics at the Union Square Theatre and the Commercial Insurance Company’s new building, corner Pine and William streets. Among buildings recently completed where their mosaics have been used, might be mentioned the Garfield Safe Deposit Company’s building, corner Twenty-third street and Sixth avenue ; the Freundschaft Society’s building, corner Park avenue and Seventy-second street: the new Russian Bath Rooms on West Twenty-eighth street, as well as those of Dr. Ryan at 18 Lafayette place.