CHAPTER EIGHT

BOLTS

The extractor spring rides in a machined groove in the recess, keeping it in place. The Colt dynamic buffer rides inside the spring, the D-Fender outside.

The ejector needs to be spring-powered above the face of the bolt, but not past the locking lug shoulder.

If you neglect cleaning your chamber, your extractor will rip right through the rim of the case that won’t extract.

There is a secret about the AR-15 bolt that a lot of people either haven’t thought of, or have avoided facing: it isn’t hi-tech. Despite its “as modern as tomorrow” looks the AR-15 bolt is a 1930s design, built to 1950s standards and methods, with some 1960s enhancements. What we’re looking at is the firearms equivalent of the 1964 Ford Mustang. Now, the Mustang was a great car in its time. (And a pretty attractive one still, as well as being a desirable collectible.) But it isn’t by any stretch of the imagination a modern design.

If you should decide to get a degree in Mechanical Engineering, you’ll be spending a lot of time learning about steel. Basically, steel is iron with some carbon in it, for hardness. However, there are a lot of other elements that can be added to steel to change more than just its hardness. You can add nickel or chromium to reduce oxidation. You can add molybdenum to control crystal size and machining ability. Vanadium, sulfur, lead, the list encompasses almost the entire periodic table. As if the number of them wasn’t enough, you can add combinations of them, and vary the proportions. Adding to the permutations of additives is the great ability steel has: it can be tempered, heated and quenched, and vary crystal size and hardness. You can (and will, if you go for your degree) spend a large amount of time learning all about steel.

The AR bolt is a product of the knowledge of steel in the 1950s. The mil-spec for the AR bolt calls for it to be made of Carpenter 158, a relatively low-carbon casehardening steel. A case-hardened steel is one that has a hard “skin” or surface, but a relatively softer core. The AR bolt must be made to very exacting dimensions. The relative locations of the various surfaces cannot vary more than a thousandth or two in critical dimensions, and some are held to less than a thousandth. Basically, the bolt is machined to nearly its finished dimensions, and then heat-treated to make it harder than sin on the surface. Then, the bolt is ground to final dimension. The problems come from one aspect of the design: there are a number of thin sections. If the bolt is hardened too much, the thin sections can be hard all the way through. Hard-through parts are usually described by another word: brittle. If the bolt is rough-machined and left too large, when it is ground to final dimension too much of the hard surface will be ground off. The hard skin will be too thin, not take the load, and when the skin breaks it then subjects the inner steel (called the substrate) to the load. The substrate deforms, and the part breaks.

Now, AR bolts can last a long time. Cleaned, lubed, not subjected to full-auto fire, and used only in barrels with proper headspace, a bolt will last a lot longer then the military replacement schedule calls for: 7,500 rounds. I have several that are still going strong with more than 20,000 rounds each through them, and one with about 40,000. Why do military bolts not last so long? And can we do anything to increase useful life of bolts? The military views bolts, along with other equipment, as expendable. Bolts are consumed in training and combat, just as ammunition is. Rather than find out the hard way, in some lonely place, that a bolt was on its last legs, the government will simply replace them frequently enough to keep them from breaking. Can we increase bolt life? Yes; keep it clean (or as clean as you can), don’t let your barrel get too worn or develop excessive headspace, and don’t let your local gunsmith “AR expert” drill out the gas port to “increase reliability.”

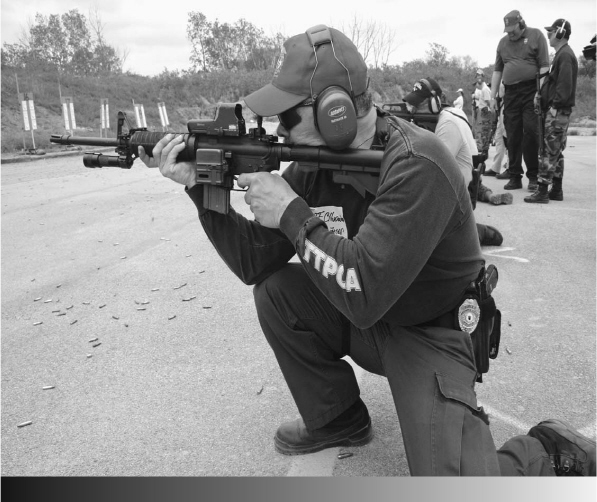

If you shoot your rifles when dirty and hot, put lots of bursts or full-auto fire through them, or generally work them hard, you’ll have to replace bolts (and other parts) on the military schedule. 2nd Lt. Anthony Aguilar, from Company A, 2nd Battalion, 1st Infantry Regiment, 172nd Stryker Brigade Combat Team, hones his shooting skills at a range in Mosul, Iraq. DoD photo.

The AR bolt, for all its apparent modernity, is not amenable to the tricks and improvements that gunsmiths routinely do to other rifles. It is common for a gunsmith to improve accuracy on a bolt-action rifle by using his lathe to “true” the lugs on the bolt, and then lap them to a perfect fit. You can’t do that to an AR. The lugs are too hard. Indeed, the hardness of the bolt has been an impediment to caliber experimenters who wanted to work on the AR. Without carbide cutters, and the right touch, trying to open the bolt face on an AR would be a disaster. You can’t true the bolt lugs or lap them. You can’t lathe-turn the bolt to smooth its movement in the carrier. You could gauge a bunch of them, if you had equipment precise enough, but for the cost of the measuring equipment you could buy a bucket of bolts, a truckload of ammo, and shoot until you found the perfect combo. (Sounds like a fun time to me.) All you can do is use good bolts in good barrel extensions, and find a gunsmith who knew how to keep his lathe work concentric while fitting a new barrel to your rifle. Luckily for us the people who make bolts work very hard at keeping to the dimensions and to making things concentric.

Your bolt does four things in your rifle: it feeds the round. It rotates and locks up, and unlocks when told to. It holds the extractor, and it contains the ejector. Oh, and it is the part that takes the hit when you run out of ammo. For absolute reliability you want it to do all those things without fail. Here’s how:

Feeding depends on good magazines. We’ve been over that in Volume 1, and here we’ve already covered upgrades and markings. The bolt also has to deal with the feed ramps. However, it is a rare rifle that doesn’t have properly-done feed ramps. So, if you see ovaled ramps in the front of the upper receiver, you’re probably OK. If you see ramps but your rifle isn’t feeding properly there are a lot of other things to consider before you look at feed ramps and the bolt. What about locking open? The magazine and bolt stop handle that; the bolt is simply the part that takes the hit. Again, if your rifle isn’t locking open regularly, the bolt is the last place to look.

Which leaves extraction and ejection: the two biggies for problems, mis-diagnoses and headaches. Let’s take the easy one first; the ejector. One problem we’ve seen in classes is the “too cheap to de-burr” ejectors. If the manufacturer simply cranks out ejectors and doesn’t take the time to de-burr the edges, you’ll have an ejector that has a sharp edge on the front corner. When the round fires, it hammers the ejector backwards. A hot load will actually flow brass into the ejector hole. When the bolt rotates to unlock, the friction of the expanded case will hold it against the force of rotation for a bit. It will break free, however, or else it wouldn’t extract. You can see the result in a shiny circle on the headstamp, and sometimes the shiny circle has a bright smear away from it, from the rotating bolt. If the edge of the ejector is sharp, the brass driven into the ejector hole can be shorn or abraded. Especially with soft brass, little bits of brass will get carved off the case. They will collect in the ejector hole, and eventually bind the ejector. When your rifle starts getting double feeds, take a look at the bolt face. Lots of brassing? Does the ejector move in and out as it should? Check the ejector by removing it (use the bolt disassembly tool) and you’ll probably find lots of brass shavings in the ejector hole.

To solve the problem, first stop using that soft-brass ammo. Look at the headstamps of the ammo you’ve been using lately, and see what one or ones show bright circles on the headstamp. Stop using that stuff. Then, modify your ejector. Since you have it out, things will be relatively easy. Chuck it in a drill press or power drill, and run it a low to medium rpm. Use a fine, hard stone to break the edge of the end that bears against the brass. You need not chamfer it. Indeed, chamfering it could lead to a worse problem. You simply want to break the sharp edge. If you can see your results with the naked eye as more than a bright line on the corner of the ejector, you’ve probably gone too far. Not to worry, ejectors are inexpensive. You can probably buy a fistful of ejectors for the cost of the ammo you’ll burn testing your handiwork before you’re satisfied. Do ejector springs wear out? Perhaps, but I’ve never seen one exhausted. Usually they get dropped and lost, or bent and tossed away before they could wear out.

When you re-assemble, get a bunch of oil in the hole (excess will run or be pumped out via hydraulic action, so don’t worry about “too much”) and get both ends of the ejector retainer roll pin flush on both ends. You’re done.

Extractors are a different matter. The problem with the AR extractor is that it was designed to be too weak. No, I’m not kidding. If the case won’t extract, and the extractor is strong enough, you’ll rip the rim off of a fired case. In larger calibers the rim is stout enough that they don’t rip. The cases extract. Someone out there has probably done it, but I’ve never seen an M-14 or M-1A rim the rim off of a case. Even when my friend Bob Gerak and I were grinding through several cases of surplus .308 that looked like it had been salvaged off of a sunken freighter, we never ripped off a rim. (That ammo was literally green and crusty. It all went bang, it hit to the sights, and it was incredibly cheap. Cheaper even than 7.62X39 AK ammo in the 1980s, and that’s saying something.) The huge extractor on the M-14 gripped the large, thick rim on the .308/7.62NATO cases, and the empties got extracted. I think that a large part of that was the size of the extractor. When the bolt turned the case turned. There could be no hesitation. That primary extraction then precluded cases from not being pulled rearward when the bolt moved. The AR extractor is much less likely to turn cases when the bolt rotates. So, the decision was made to not have the extractor ripping through rims, and allow the bolt to not extract and yet cycle. I guess the resulting double feed was felt to be less of a problem than a stuck case with the rim ripped off. (The ultimate solution was to chrome-plate the chamber and bore, eliminating pitting and difficult extraction.)

It slices, it dices. Well, the MOACKS does a lot, including let you move a recalcitrant gas tube.

Yes, we see rifles from time to time that lack carrier key staking entirely.

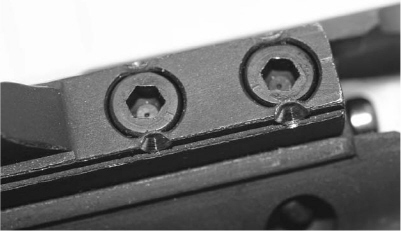

Once you’ve cleaned and degreased the screws, tighten them down and apply the MOACKS.

We’ve been boosting the extractor tension ever since. The first extractors lacked a little gizmo you’ll see today, the plastic booster. When I went through the Colt M-16 Armorers course, I found that Colt has a fancy name for it: the harmonic dampening buffer something-or-other. I was drinking coffee at that point in the course, and almost snorted coffee through my nose. Everyone else just calls it “the plastic extractor gizmo.” I guess to come up with a fancy name takes a corporation or government agency. The early ones were white. Progressively stronger ones (the measure of elasticity in plastics is called “durometer”) got darker and darker. Now the current assembly for M4 carbines is a black gizmo with a gold-colored spring. (The gold denotes a stiffer spring.) I’ve seen a lot of early-production M-16A1 rifles and none have a plastic gizmo at all. And many of them work just fine. But who wants to find out the hard way?

When you tighten the staking screws, you’re staking that carrier like it’s never been before.

In an effort to boost extractor tension, we have taken to using boosters that nestle around the extractor. The one I heard of first is the D-Fender, designed by Mack Gwinn and sold by MGI. A lot of people figure “Hey, it’s just a little bitty O-ring. I’ll buy one at the auto parts store for fifty cents instead of the ten bucks Mack charges.” You could do that. But is your little o-ring proof against all known solvents including New Jersey tap water? The D-Fender is a lifetime part. You can transfer the one you buy from one to the next AR you own for the rest of your life and not wear it out.

I have one in all my rifles. Or, I did. At the class I was working while writing this chapter, I took advantage of a sudden lack of broken rifles to get some drills in. (At these classes, if rifles break, I work. If they don’t, I teach. When things go smoothly, I chance it and try to get some shooting in.) Ned was watching, and my rifle choked. Empty left in the feedway. “Hmm” he says “That thing have a d-ring in it?” I had my mouth open, in the act of saying “Of course” when I remembered: no it didn’t. I had taken my D-Fender out at the last class to install in a student’s rifle, and obviously hadn’t replaced it. I promptly went back to the truck, stripped the bolt, installed a D-Fender and went back to the line. There I pounded three magazines through the rifle just to make sure it was working properly.

Now, other people make the same kind of product. And I’m sure they went to the same lengths (all you’ve got to do is ask the polymer makers) to find something indestructible and proof against gun solvents. But the D-Fender is the one I first learned about. It works. I get no money (not even free D-rings) from Mack for telling you this: your rifle should have one.

Gas Rings

As my friend Jeff Chudwin says, “You must buy gas rings. Even MacGyver can’t make new ones out of a soft-drink can.” Gas rings are consumable items. If all you did once a year was to take out the old ones, install new ones and test-fire your rifle, a lifetime supply of gas rings would not cost you as much as two or three new magazines. One thing shooters look to is the one-piece gas ring. The “problem” they have been told is to avoid lining up the gaps in the gas rings. If they allow the gaps to line up, the rifle won’t work. Balderdash. Poppycock. Nonsense. First of all, even if you try to line them up, they’ll squirm out of line when you force the bolt into the carrier. I’ve run rifles with only two gas rings that ran fine. I know of a shooter at Second Chance whose rifle ran fine with a single gas ring in it. Now that’s asking for trouble, in my book, but his rifle ran that way. Mine wouldn’t. But keeping gas rings in is no big deal. Don’t clean your bolt with a brush. You’ll likely hook a gas ring with a bristle, and fling it off the bolt into the grass. Use something like (or the very thing) the MOACKS to scrape your bolt clean. Check your gas rings. They wear smaller as you fire your rifle. There are two ways to check: visual and mechanical. Visually, the ends of the gas rings look like a pair of snake heads facing each other. (Yes, exactly like the snake symbol in the Conan movie. It’s a coincidence, probably.) When the snake’s “neck” is half as thick or less than the head size, replace your rings.

Staking done: keys that won’t move.

The mechanical test is simple: with a clean and lubed bolt and carrier assembly, extend the bolt all the way forward. Stand the assembly on the bolt face on a hard surface. If the weight of the carrier cases the bolt to collapse, the rings lack friction. Install new ones. If it stands and the carrier does not descend, your rings are fine.

The one-piece rings? In many rifles they create too much friction. Rifles can short-stroke. When it comes to extractors I want all I can get and more. But for gas rings old school is good enough for me. I leave one-piece rings out of my rifles.

Firing Pins

Firing pins come in two collar sizes. The smaller M-16 size, and the larger AR-15 size. The larger flange or collar is Colt’s attempt at keeping idiots out of trouble, and placating politicians. The collar, in conjunction with the slotted rear of the carrier and a notched hammer, is there to catch a hammer that is attempting to follow the bolt forward. I had a fellow shooter as the question “My rifle and its firing pin have 14,000 rounds through it. The firing pin tip is jagged, and the flange keeps binding on the carrier. Should I replace it?” My answer was “Hell, yes.” The flange also pointed out a minor weakness in the Colt modification: the slot in the carrier now puts the force of cocking the hammer onto the firing pin. Instead of the rear corner of the carrier cocking the hammer, the firing pin had to do the work. And the flange took a lot of that effort. The rear corner of the flange on his firing pin had been peened to an angle.

Bolts are made with a hard skin and a tough core. If anything goes wrong in the manufacturing process, the resulting bolts will break.

The cam pin hole of the bolt is a high-stress area. If the manufacturer did it wrong, there’s nothing you can do to keep your bolt from breaking.

If they did it right, you’ll have a long and useful time with it.

The AR bolt has lots of thin sections, high-stress surfaces and generally lives a short, hard, miserable life. Saving a nickel (or even five bucks) on a bolt is false economy.

Can you tell which is which by looking at it? I doubt it. If you want to be sure, you have to have some measuring device with you. Me, I just ask for “M1-6 firing pins” and if the parts supplier doesn’t know the difference I move on. Those who are lathe-equipped can simply turn the flange to the smaller diameter, which is what I did twenty years ago when I ran into a firing pin with a flange that “was too big.”

One question that comes up is “titanium?” A titanium firing pin is lighter than the standard steel ones are. However, the standard ones are already pretty light. The idea is that the lighter pin shortens lock time, the time between your pressing the trigger and the bullet exiting the muzzle. I suppose if I were on the line at Campo Perry, duking it out with David Tubbs for the championship of the universe, I’d want every advantage, real or imagined. Any contest less than that, the difference in lock time is utterly inconsequential. I’ll take the surety of firing instead. For anything but a competition rifle, don’t bother. Stick with steel.

More interesting bolt stuff! The mil-spec blueprints call for bolts to be made of Carpenter 158 steel. A low-carbon case-hardening alloy. The problem is, it can be case hardened too deep if the proper heat-treatment process isn’t followed. What accentuates the over-hardening problem are the exacting specs for the cam pin and cam pin hole. Basically, the blueprints call for the cam pin and hole to be the same size. Well, when the blueprints call for a hole of .31275" plus-or-minus .00075" they want the hole to be exactly a certain size. To ease production, and reduce returns, some makers make the holes too big and/or the pins too small. When the pin is too small, the unlocking force isn’t a lateral force to rotate the bolt. The pin rocks in the bolt hole, kind of like the old advice to use a hammer handle in a revolver frame. It works until it doesn’t.

The old-style solid pin. Yes, they work, but no better than a cotter pin, and for a lot more money. However, for someone looking to do a Retro build, they’re required.

Take a bolt with the case hardening too deep and the cam hole too large (or pin too small), and the cam pin acts to pry the hole, not rotate the bolt. Result? Broken bolts. I have an inside source who knows the bolt makers, the carrier makers and the hardening process, and he predicts that broken bolts in some rifles are going to be an occasional thing in the future. A bolt company may ramp up production to meet demand, or someone hires a new guy who doesn’t quite understand the processes as well as he thinks. Bolts go out that pass inspection but are in actuality marginal, and then they break. File it under “stuff happens.”

You can minimize the probabilities of a broken bolt by sticking with a brand that is marked as having been magnetic particle inspected, from a maker that does it to all bolts in a lot, and not just a percentage. I’d love to tell you exactly who they are, but outside of Colt, we have no way of knowing. And makers can change their methods.

Bolts do not last forever. Given enough time and abuse, they will all break. The design, materials and basic fabrication method of the bolt come from the 1950s. Except for the “style” points, who would want to drive a squad car that dates from 1957? The M-16 bolt was improved and updated through the 1960s, but once it was cast in stone to mil-spec, that was it. If any company wanted to make bolts of a new wonder steel that meant they’d never break, the government wouldn’t buy any. Not mil-spec. And would not buy them until the mil-spec was changed to allow it. So, we’re all using the firearms equivalent of a 1957 Chevy BelAir.

Soft brass and sharp ejectors lead to brass shards clogging your ejector. Then your rifle stops working.

How often should you change bolts? The only real answer is, “Before you need to.” The government puts a rough limit of 7,500 rounds on bolts. But they also have a user base that is prone to using the M4 as an impromptu SAW. Used that way, the barrel quits in less than 1,000 rounds and the bolt soon after. I have one rifle on its third barrel (40,000 rounds on that bolt) and several others on their second barrel each (20,000+ rounds on those bolts each) and the bolts show no sign of quitting. I do not, however, do full-mag full auto dumps, suppressive fire, or other hard-use shooting like that.

The Stoner bolt is right on the edge of the performance envelope. Push it too hard and it will quit on you. We can do things to the 1911, the 98 Mauser and other designs that stretch them far past their original limits, and they keep working. The AR bolt was meant to be pushed to the limit from the start. The kind of use a police officer gives an AR is less than that of a competition shooter, which is still less than that of someone in Iraq. Most departmentally-owned rifles will have barrels in need of replacement from abuse and neglect, not from round count.

FN bolts are the other all-military and mil-spec bolts, and are not available to us. They are DoD-only, and their bolts may as well be made of depleted uranium for all of their availability to us. How can you find out who made your bolt? I can’t, nor can you. Unless it is marked and we know the code, it’s a mystery. All the AR makers are remarkably closed-mouth about who makes what. The market is intensely competitive, and high-quality suppliers are kept a closely-guarded secret.

What matters more for you or a police department is service. If your department (or you) own enough rifles and put enough rounds through them, you’ll probably break a bolt. (You’ll likely have broken a lot more other parts before then.) If you have a good relationship with the provider, you’ll get a replacement right away. If not, you won’t. Short of rewriting the mil specs to reflect the advances in steel and parts fabrication, you cannot guarantee never breaking a bolt.

My experiences are a small slice of what is going on. No one has a complete grasp of the field. The fact that I have seen a few bolts break from a few suppliers, I now realize, may stem more from local availability than anything else. Were you to ask me to raise my right hand and swear as to how to get the best bolt, I’d say this: Ask your supplier what they’d do if a bolt broke. If the answer isn’t “replace it,” then keep asking. If you’re in charge of a department, or the armorer, be sure every rifle in the inventory is thoroughly tested, zeroed and logged. If, sometime before you retire, it does break, get a replacement. And don’t lie awake at night, worrying about breaking bolts.

A little arithmetic might put some light on things. Our LEO AR classes are high volume. An officer in a 3-day class will go through 800 rounds, a 5-day 1,200. (I know there are places where you’ll shoot more. But not many.) After that, if the officer to whom the rifle is issued shoots a qual course twice annually (50-60 rounds each time), and repeats the 3-day class every five years, the barrel and bolt will be due for replacement in 30 years by the military standard. If you practice and compete to the tune of a thousand rounds a year, and shoot in a high-volume training class once every five, you’ll need a new barrel (according to the military) every five-year cycle. In that time, you’ll have gone through roughly $1,500 in ammunition, and paid two to three times that in travel, tuition match entry fees and other expenses. Don’t feel guilty about buying a new bolt to go with your new barrel.

Some classes and qualifying courses involve few rounds. Ours include lots and lots of shooting. If your rifle works through a NEMRT class, you can be sure of it on the street.

Basically, life is too short to spend it obsessing over bolts. (Obsessing, however, is what mechanical engineers do. They can’t help themselves.)

M-16 Carriers:

One more time

People continue to try to get a definitive answer out of the ATF: “Can I install an M-16 carrier in my rifle?” And the result is pretty much the same: like trying to nail jello to the wall. You can send your own letter to the ATF if you’d like, but what you get will be this: The response will first acknowledge your letter and the question you’re asking. Then, the letter will quote the definition of a machinegun from the U.S. Code. Next, you’ll be advised that if you possess sufficient parts to meet the definition or a rifle that fires more than one shot for each pull of the trigger, you’re in violation of the law. And that will be pretty much it.

Why? Because a letter is permission. And the ATF knows just how clever and in some cases mischievous, some gun owners are. If the ATF says to someone “sure, one M-16 part doesn’t make any difference,” they now are on record as approving that part. For all they know, someone has figured out how to use that part, and that part alone, to make a machinegun. I mean, someone figured out how to use a shoelace to convert a rifle into full-auto. (No exaggeration, a shoelace.) They do not want themselves to be boxed into a corner, having given permission here and there, over the course of years. So, they simply quote the law, and advise you (if even that) that you cannot own a rifle that fires more than one shot for each pull of the trigger.

That said, can you do it? Sure, shooters do it all the time. Manufacturers ship rifles with M-16 carriers in them. (But no other M-16 parts.) Of all the parts, it is the one that you can actually get some benefit from using, and the least likely to cause problems.

Here’s what happens when you bolt breaks. If you have any warning, it’s that accuracy will go to hell just before the bolt lets go.

Do I use them? Some of my rifles have them, some don’t. I don’t go out of my way to include an M-16 carrier in a build but I don’t go out of my way to avoid them, either. Faced with a pair of carriers to build with, I’d select the one that best fits the bolt I had for the project.

Some people out there take it personally: the ATF refusing to allow them the use of an innocuous M-16 carrier is oppressing them, denying them their civil rights, trampling two centuries or more of free expression and choice. Guys, lighten up. It’s just a bolt carrier.

At the latest class before sending off this chapter, I ran into a rifle that had one of the old solid firing pin retaining pins in it. Or so I thought. We yanked it out and replaced it with a new cotter pin. The next day the officer told me his armorer was very cross with us. “He put those in because they are better,” the officer said, referring to the armorer. “He wants it back.” OK. The government went away from the solid pins to the cotter pins forty years ago. They probably went for the simple reason of cost. A cotter pin a standard, cheap industrial product. The solid pins were precisely-machined firearms-specific items. Still, the cotter pin has worked. Unless you’re doing a Retro rifle, and you have to be absolutely detail-correct on everything, I wouldn’t seek out a solid pin to install it.

A broken bolt, with a “D” marking on it. MPI tested? No way of telling.

Carrier Security

Again and again in the classes we see ARs that start malfunctioning. Usually short-stroking is the culprit, and one of two causes usually surface: lack of lubricant and loose carrier keys. Lubrication is easy: use more. Just like sunscreen, you have to keep applying it with use. As for the carrier keys, some come staked well enough, others don’t. In the old days we hardly ever saw keys come loose. Now, we sometimes place bets on how many we’ll see in a class. The solution is to go to Ned Christiansen’s website (www.m-guns.com) and get his MOACKS. At first glance it may seem pricey, but good gear is almost always the best bet. Before you dismiss the cost (I’ll admit it can be a bit at first) consider what it would cost you to buy the bits and pieces it replaces. And for staking with other than the MOACKS you have to have a vise, pointed punch and hammer. I took a quick look at the current Brownells catalog. For $50 you can get a carrier scraper and a gas tube wrench. There are no bolt tail scrapersnor firing pin scrapers to be had. And packing a vise to stake the key is a real hassle. If you plan on keeping more than one AR running, the MOACKS is your best investment. Ned is a friend of mine, and he’s appreciative of my mentioning it, but he does not give me a fee for each one sold. Spend your money where it counts. Get a MOACKS.

Carrier Mass

JP Enterprises makes a number of carriers that are different from the normal AR carrier. The heaviest is the stainless lightweight. Lighter still are the aluminum carriers. Combine them with a lightweight buffer weight, and you have the least-possible reciprocating mass the AR can work with. However, you must pay a price for those parts. Not the cost of purchase, but the cost of tuning and ammo. In order to make your rifle work properly with the lightweight parts, you must change the gas flow. The AR gas port and tube are designed to blow the mass of a carrier and buffer weight made of steel, even with tungsten weights in the buffer. The gas port and tube will deliver too much gas to the lightweight JP Enterprises parts. You’ll find partial or no-extraction problems. What you have to do is install an adjustable gas block or gas tube and restrict the gas flow until the empties are barely ejecting. That is your minimum. Then slightly increase gas flow for normal ejection. Most shooters do it in this order: settle on a bullet, powder and load that delivers the Power Factor and accuracy you need. All chronographing and accuracy testing is done with the gas tube throttled down to no flow. No cycling. Once you find a load that works, gradually open the gas block adjustment nut until you have normal ejection and no more.

The experienced shooters among you will recognize that you will then be limited to a single bullet and powder, at a single weight. Any change will require retuning the gas flow for proper (i.e., sufficient but not too much) gas flow.

What do you get for this work? Combined with an efficient muzzle brake, you reduce the felt recoil of a competition AR to not much more than that of a .22LR. The lightweight carrier and buffer have much less mass to bottom out (if they do) in the buffer tube. The muzzle brake reduces further the felt recoil. With a properly tuned competition rifle, it is possible to watch the bullet strike on steel, through the scope. The field of view does not appreciably change during recoil.

The JP Enterprises carriers are not for duty or defensive rifles and they say so right in the instructions. But if you want the trickest of the trick rifles you have to have them.

The front of the bolt falls free, while the rear is trapped in the carrier by the cam pin.