WILSON TACTICAL

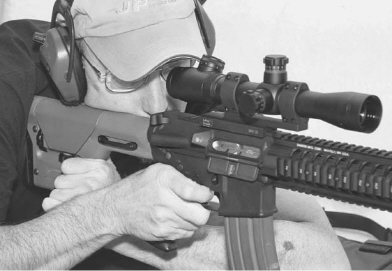

Along the way, the Wilson lower was built as the 6.8 Police Sniper.

Wilson Tactical is Ryan Wilson, son of Bill Wilson. After working in his father’s shop for years, Ryan struck out on his own. His first step was making knives. Wilson Tactical knives are known for being tough, one might even say “tough as nails.” I mean, testers who drive a knife sideways with a hammer, into a tree, then stand on the flat of the blade? Who does that? Apparently you just can’t break a Wilson Tactical knife.

Once Ryan had established a name for himself in knives, he branched out. He now does custom work on ARs and shotguns, and as I was writing this was in the process of setting up to produce ARs from scratch. My usual policy of reviewing complete rifles (or relevant conversion uppers) wasn’t possible here, as Ryan wasn’t completely set up to make rifles when it came time to hand in the manuscript. But Ryan did have lowers available. Curious, as most shops setting up to make ARs usually find themselves in the position of having everything on hand but lowers. Usually, they have customers wanting rifles, with bins full of barrels, uppers, handguards, etc., and no lowers.

Ryan sent me one of his lowers, and I proceeded to check-install three different lower parts kits in it. All fit without a problem. Five different buttstocks also fit without problem. I checked the fit of the lower with uppers on hand. You cannot guarantee that every single upper will fit any given lower, unless all your uppers come from someone like Colt, and the lower you’re checking against is a Colt – or CMT, LMT, etc. When you start checking across manufacturers, you can expect occasional “won’t go” or “loose as socks on a rooster” fits. The Wilson Tactical lower fit as many or more uppers as any other big-name lower I had on hand.

The lower is an A2, with reinforcements front and rear, so you Retro guys are out of luck here.

The final state: a telestock shorty, with Robar polymer finish in three-color desert camo.

Robar did the receivers in polymer and the internals and steel in NP3. Very trick, very slick, and tough to beat.

Given the reputation Ryan has in the knife crowd, and the years spent working for his father, the idea that an AR from him would be found wanting is pretty silly. The specs he proposes put it as a serious contender for the M4 crowd.

In the course of the book I built this lower into three different rifles, before settling on the last. At first it was an M4 clone with Vltor stock, and a “frankengun” upper. But I have plenty of M4s, so I then rebuilt it as the base of the 6.8 Police Sniper rifle. However, it finally came to rest as another project gun. I found out that GG&G makes folding front sights, as well as mounts, forearms and other gear. While they were in the process of building up a lower for the market, I had everything on hand I needed. So I plugged a spare shorty barrel into a flat-top upper, and installed all GG&G parts: a rear MAS, a folding front, their railed handguards, a flash hider. I then sent the whole thing off to Robbie Barrkman at Robar for a coating project. He sent it back done on the outside in a three-color desert pattern in his Polymax finish, with the internals done in NP3.

And that’s the way it is.

The NP3 is so slick, you can get by with very little lube.