INVESTMENT COMPONENT

Modernization

Recapitalization

Maintenance

Supports military load classification 100 (wheeled)/80 (tracked) vehicles over 40-meter gaps via a modular military bridge.

The Dry Support Bridge (DSB) is a mobile, rapidly erected, modular military bridge system. DSB is fielded to Multi-Role Bridge Companies (MRBCs) and requires a crew of eight Soldiers to deploy a 40-meter bridge in fewer than 90 minutes (daytime). DSB sections have a 4.3-meter road width and can span a 40-meter gap or two 20-meter gaps at military load classification (MLC) 100 (wheeled)/80 (tracked) normal crossing and MLC 110 (W) caution crossing. The system includes a DSB bridge, a launcher mounted on a dedicated Palletized Load System (PLS) chassis that deploys the modular bridge sections, and seven M1077 Flatracks to transport the bridge sections. The bridge modules are palletized onto seven flat, racks and transported by equipment organic to the MRBC. DSB is designed to replace the M3 Medium Girder Bridge.

DSB modular structure allows launch and retrieval from either end without a dedicated or special training area and can be placed directly over pavement to reinforce damaged sections, bridges, or spans. Air transport for the DSB system is accomplished by C-130 if divided (bridge: one flat-rack per a/c; launcher vehicle: split into three loads, five hours work), or by C-17 and C-5 intact.

This system has been fielded since 2003.

In this Publication

None

Other Major Interdependencies

DSB operations rely and are interdependent upon fully mission-capable M1977 Common Bridge Transporters and M1076 PLS trailer assets within a fully Modified Table of Organization and Equipment-equipped MRBC.

ACQUISITION PHASE

Technology Development

Engineering & Manufacturing Development

Production & Deployment

Operations & Support

None

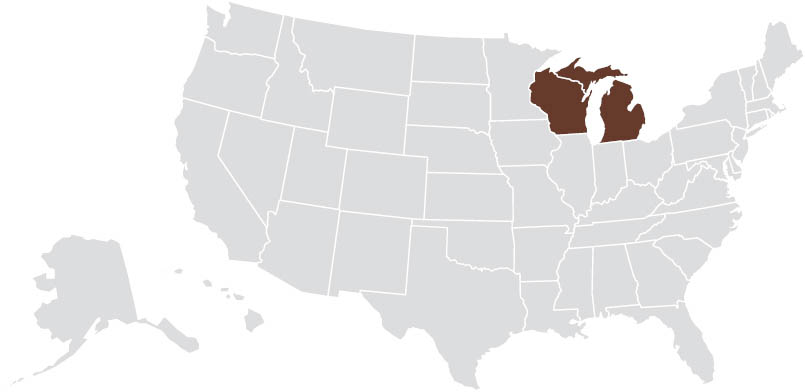

Manufacturer:

Williams Fairey Engineering, Ltd. (Stockport, United Kingdom)

PLS Chassis:

Oshkosh Corp. (Oshkosh, WI)

Logistics:

XMCO (Warren, MI)