This chapter deals with the different types of pitched roof, such as mono-pitch, duo-pitch, lean-to, gables, hips and valleys, and also raises the need to consider weight, pitch, planning and exposure when choosing materials and suitable fixing methods.

ROOF TYPES AND TERMINOLOGY

Single-Pitched Roofs

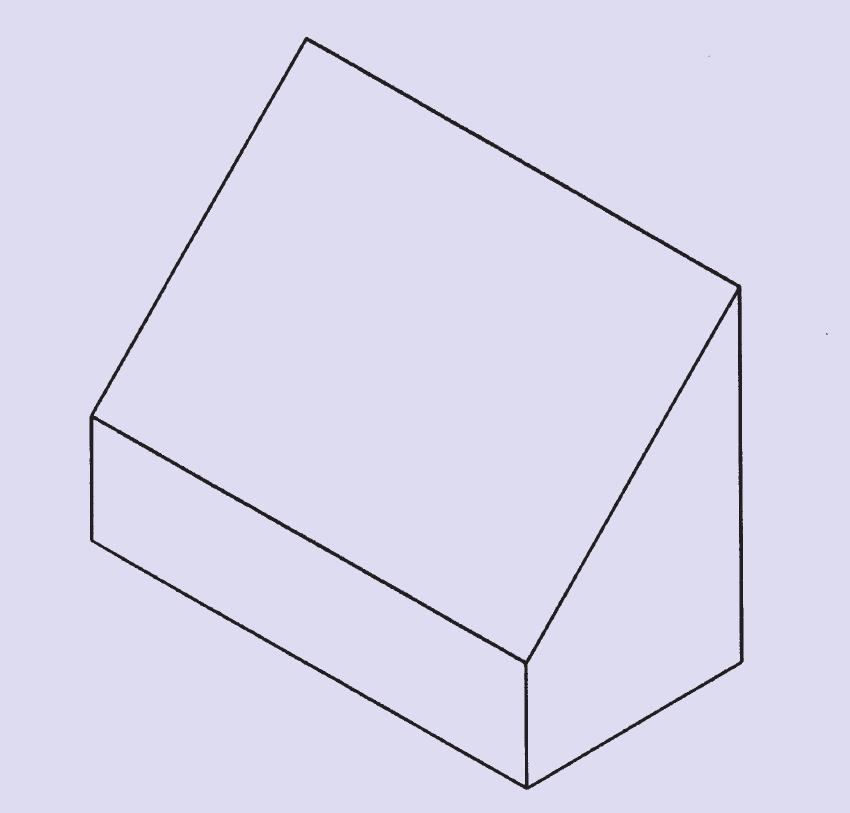

Mono-Pitched Roofs

The main aspect to consider with single-pitched roofs is how you are going to finish off at the top edges? For a mono-pitch roof, the most common method is to use special mono-pitch ridge tiles, which are easily obtained from tile manufacturers or roofing merchants.

Mono-pitched roof.

Lean-To Roofs

For a lean-to roof the top edge is likely to be finished with a lead flashing.

Lean-to roof.

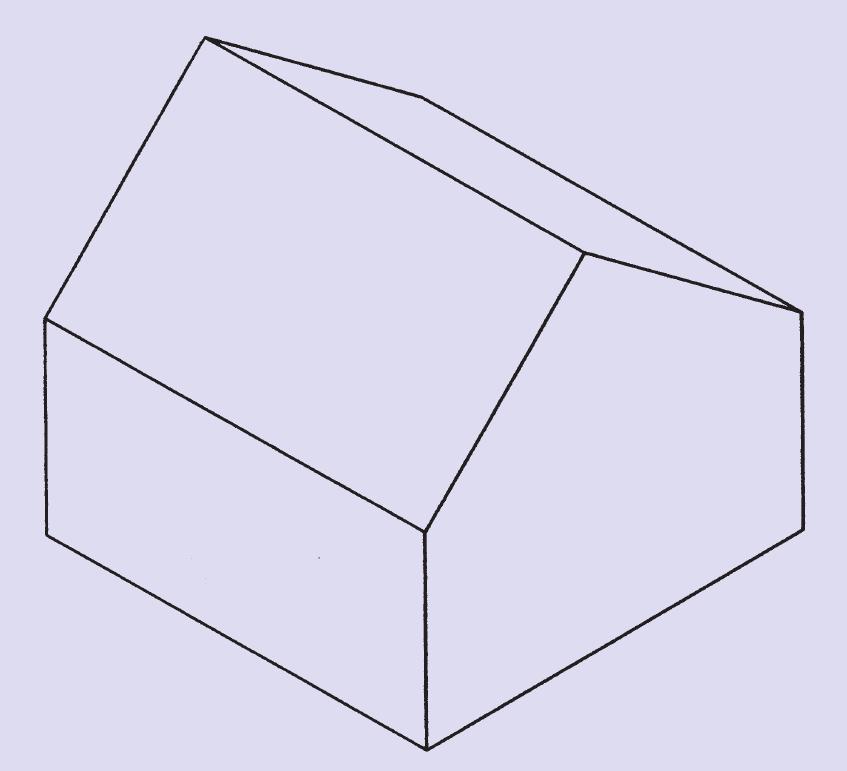

Duo-Pitched Roofs

You will hear roofers describe a duo-pitched roof as a ‘straight roof’, a ‘gable-to gable’ or an ‘up and over’, among other terms. In the majority of these the rafters are designed to be equal in length on both sides, but they can differ, either by accident or design and so it is always wise to check before ordering materials or starting work.

Straight verge-to-verge duo-pitched roof.

Hips and Valleys

Hips

Hips are an alternative way of finishing the ends of a roof instead of gables. There is more work and more skill involved in finishing a hip than a verge, and they do cut down the storage or living space within, so these factors should be considered if you are having a house or an extension built.

Valleys

Valleys are the junctions that are formed when a part of a building, and therefore the roof, comes off another at right angles. Small valley sections are commonly known as ‘pediments’ or ‘pikes’.

Roof with hips and valleys.

DESIGN CONSIDERATIONS

This section deals with matters such as fixing specifications, roof pitch and the suitability of materials.

Weight

With a new roof the architect or designer has the responsibility to ensure that its structure is planned with the covering materials in mind; but, if you are re-roofing a property, then you need to check that the roof is strong enough to take the replacement materials. The first consideration here is the weight per square metre of the new tiles or slates compared with that of the existing covering. The suppliers of the new slates or tiles should all have technical departments to assist with such enquiries and are a good place to start if you do have concerns.

Pitch

All slates and tiles have a minimum recommended roof pitch, as stated by the supplier or manufacturer. If the products are laid below this pitch and the roof subsequently fails then any warranties will almost certainly be void. It is therefore essential to check the roof pitch and the minimum pitch of the slates or tiles. For some interlocking tiles this can be as low as 15 degrees, with plain tiles starting at 35 degrees.

The minimum pitch for any natural or artificial slate depends very much on the size of the slates and the location. The minimum pitch for any double-lap slating is actually only 20 degrees, but there are many design factors that go into this and so, in reality, this is rarely seen; a more realistic minimum pitch for most slates is around 27.5 degrees, but even this depends on certain conditions. Generally, slates, and especially natural ones, are much ‘happier’ at steeper pitches of 35 to 40 degrees and upwards. Again, technical departments are a good source of information if you are not sure.

Fixing Specifications

It is worth remembering that pitch, location and the type of product (among other factors) can affect a fixing specification quite dramatically. You must make sure that the correct nails, clips or other fastenings are used in accordance with the specification recommended by the supplier, manufacturer or some other person responsible for the specification. Failure to adhere to a fixing specification can result in the loss of warranty, should the roof suffer any structural damage (such as the loss of slates or tiles).

Slates

Broadly speaking, the fixing specifications for natural slates are fairly straightforward (for instance, two nails per slate), as they are for artificial slates (two nails plus a disc rivet), because each slate is fixed.

Plain Tiles

Traditionally, the fixing specification for plain tiles has also remained fairly standard across the country for many years. For roof pitches up to 60 degrees, the minimum recommended specification has been two nails in all perimeter tiles and each tile on every fifth course. Vertical surfaces and all roofs set above 60 degrees require two nails per tile wherever possible.

Interlocking Tiles

The fixing specifications for interlocking tiles have, over the years, ranged from, for instance, being simply perimetrically nailed, to every tile being nailed and clipped, depending on the type of tile used, the roof pitch and the location. This variation has been caused largely by the fact that there are so many different types (shapes, sizes and weights) available. A common method was needed and a group of leading British manufacturers have addressed this by agreeing and producing a zonal fixing guide for all their roof tiles. The required fixing specification may be found by using simple tables that rely on information such as the tile type, roof pitch and the location of the work. The guide is freely available from all of the major tile manufacturers and is relatively simple to use. However, to be on the safe side, I would still recommend that you should contact a technical department to make sure that you get the right fixing specification.