Air Combat: Real or Nonsense?

For the most part, Richthofen’s war was fought against the British. His 80 air combat victories amounted to an extraordinary success. So one-sided a result creates doubts, for Richthofen was an improbable top ranking winner. He had too many drawbacks. One’s natural skepticism rises in protest.

He was no student. More to the point, he was no student pilot, flunking his flight exam twice before an ever-patient flight school accepted his uncertain efforts. In turn, he made for a poor aerobatic pilot at a time when aerobatic skill seemed a requisite for success; for example, that considerable score and fame achieved by Immelmann.

The one characteristic shared by all the great aces was fierce determination, offered at a level far beyond military requirements. Yet Richthofen’s record was that of a drifter, rather than an achiever. He served first in the cavalry and then in the Army food and provisions section. There was also service as an aerial observer and even some time spent training as a bomber pilot in an outfit hoping to become a strategic air force. He compiled a lackluster record in each of these positions, ending by transferring out. Finally, he hit upon service as a fighter pilot, and to our astonishment, accumulated those 80 victories.

As he truly was, handsome and carefully watchful. Source: La Guerre Aerienne, January 1918, p.183.

Are we to believe that he had found his true calling at last? Perhaps, but it seems a bit much. We cast about for a more likely explanation. Was it possible that his success came from shooting down a series of inept opponents, unequal to the challenge?

In pre-war days it was widely believed that France led the world in the design of aircraft and Germany held the lead in engines. Were opposing British war planes simply second rate? Was that the key to his success? For that matter, did British pilots receive proper training? In short: how well prepared were the British to fight Richthofen?

A look at pre-war British air planning turns up a curious official attitude: there were grave doubts that air war would ever happen. As a result, those few fighting types ordered were designed for air-to-ground attack, rather than aerial combat. When air combat came, British machines proved poorly suited for the task. Given time– more than a year–the British caught up, but in the meantime casualties were heavy, boosting the scores of those like Richthofen, who were truly prepared for air combat.

The British inability to sense the coming air war amounted to a startling lapse of judgement; a failure entitled to a closer look.

By early 1912, flight was an everyday reality, with air show aerobatics a popular attraction. It was also a time of loud European nationalism, of contempt for one’s neighbors and diplomatic threats. British Army planners moved to find solutions for the looming next war. What of aircraft, and their role?

Much was uncertain. The airplane was too new. One couldn’t be sure. The experts announced ever-changing opinions, confounded by trials and tests. Reconnaissance and only reconnaissance emerged as a perfect fit to aircraft potential, with observations made aloft wanted to supplement those of the cavalry. All Europe agreed. German planners started work on a series of Army-funded Taube designs centered upon observation needs.

The ever imaginative French thought that an additional aerial function might be served: that of artillery spotting. However, the Germans judged artillery ranging as too futuristic to be of real concern. In the spring of 1913 they assigned a total of only three officers1 to aerial ranging work – faint support indeed.

What of the British? As seen by Colonel J.E. Capper, known for his airship background2, the prime British Army need was for a field-worthy machine – one easy to fly, highly reliable, able to both land anywhere and fly in high winds, all while offering great natural stability. As for desired performance traits, he could “sum it up in one word –speed.”3 It was speed that would permit evasion of enemy machines, “for it must be remembered that an aeroplane must not fight.”

His refusal to consider combat reflected personal knowledge of the extremely light construction required for airship flight. Applying this finding to airplanes, he reasoned that the slightest blow meant total destruction. Fighting implied hits on both opposing machines, in turn suggesting mutual suicide. In similar fashion, ramming was impossible, for it meant the certain end of the aggressor aircraft. What then was to be done about enemy aircraft? Evasion seemed the only correct answer.

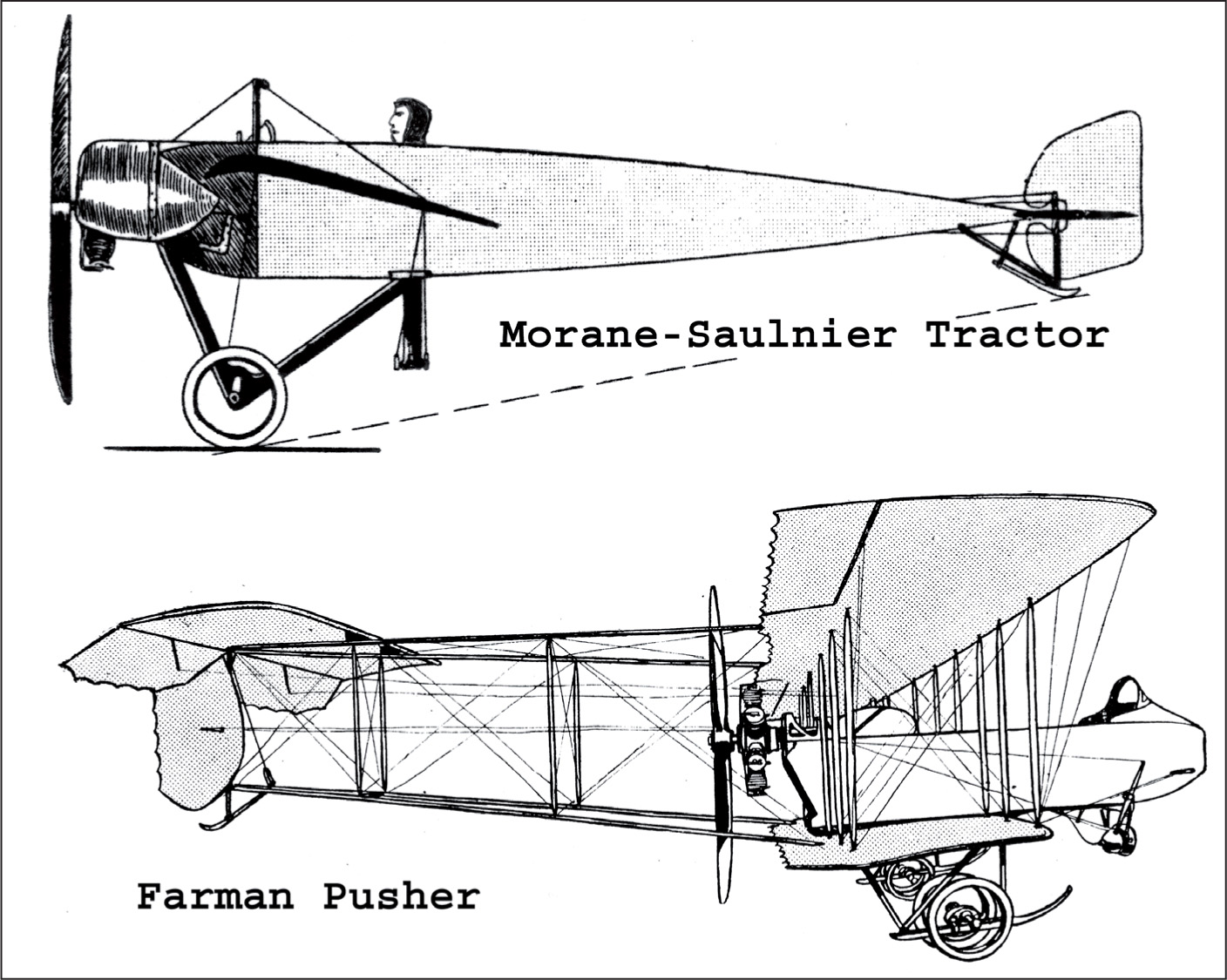

Each had problems. For circa 1913 tractors, especially severe were those of adequate vision below, plus that of providing a usefully large shooting sector. Competing pushers were slow. Choice depended on the machine’s purpose. Source: (top) Flight, May 24, 1913, p.562; (bottom) Flight, October 19, 1912, p.941.

As for firearms, they were to be employed, if at all, as a last resort, in a desperate type of self defense, in much the same manner as an officer’s side arms. Apparently uneasy at this decision, taken so early in the game, he then opted for a clear field of fire to the front of the aircraft. In practice, this meant that the pusher was wanted rather than the tractor. After all, he might be wrong about firearms and the human trait of hedging uncertainties is always a powerful driving force.

The pusher against tractor choice was not easy. The tractor was clean and fast, enjoying a perfect form for racing machines. In contrast, the pusher was inefficient, clumsy and slow. Yet, with its pilot located at the extreme front of the machine, the pusher offered two powerful advantages for military application: superb vision and an enormous field of fire to the front, all without propeller blockage.

Consider the successful and popular pre-war Morane-Saulnier tractor. The pilot could see everything located at a higher altitude, but vision down and forward was blocked by the wing presence. Unfortunately this very view – down and forward – was the one prized by military observers. Next, imagine a gun placed atop the cowling. Firing forward, or straight ahead, was prevented by that enormous propeller. Even pointing it in oblique fashion, and accepting some loss of accuracy, was not truly practical. The propeller was simply too large, forcing the use of a huge oblique angular offset–and resulting in correspondingly dreadful accuracy.

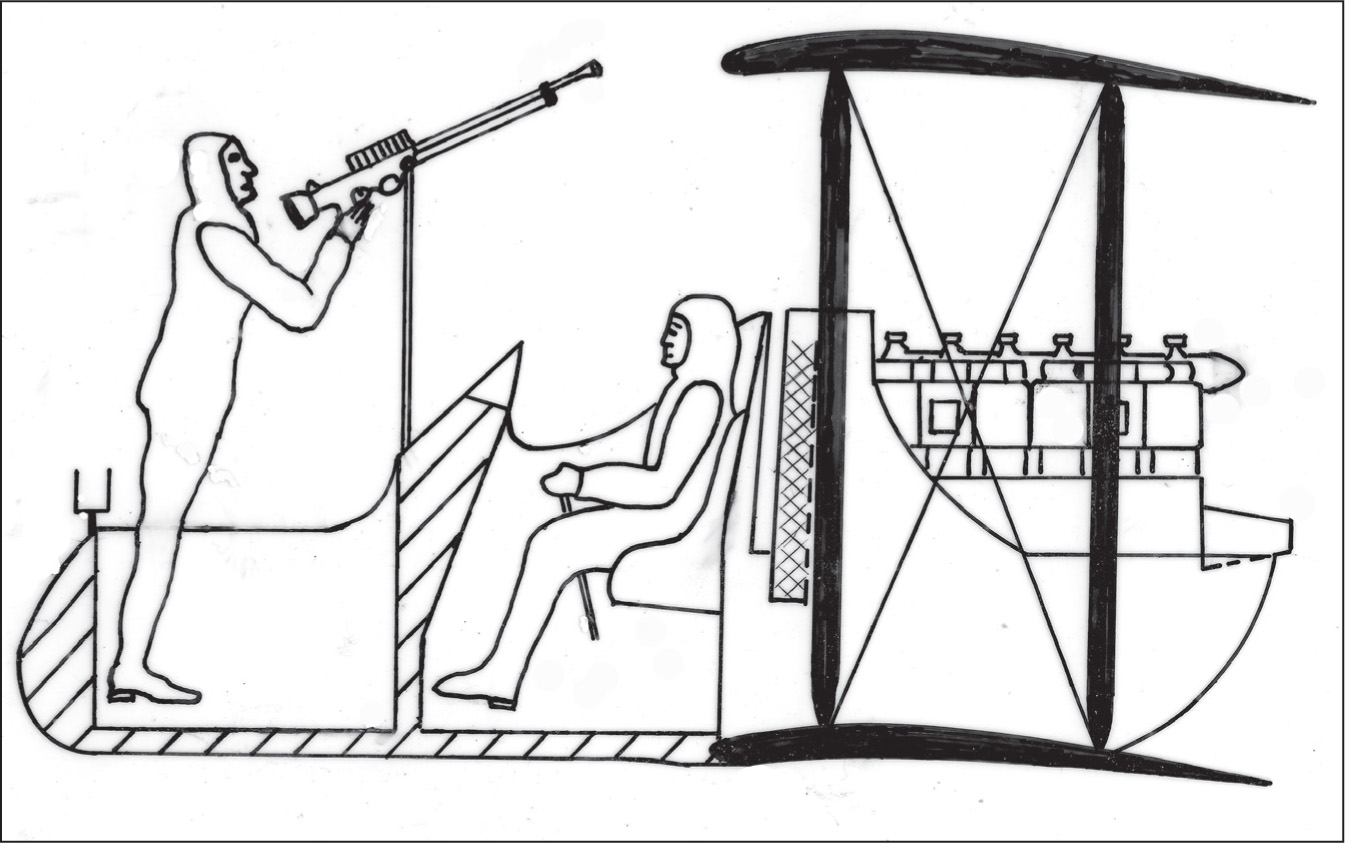

Next consider the Farman, a successful contemporary (1913) pusher design. The pilot, immediately behind the windscreen (extreme right), could see everything to his front–up or down. Given a gun, he was able to fire to his front or obliquely as he wished, without concern for the propeller. Clearly, there was much to be said for the pusher.

There were disadvantages. They were indeed slow – top speed for the Farman was all of 55mph.4 Vision to the rear was awkward. Accurate shooting to the rear was difficult indeed. Rumors of murderous spin characteristics clung to the pusher concept and not the tractor. However, all things considered, pushers were a better bet – if guns and shooting were to become an important part of the aerial task. Would they?

Management was hesitant. The uncertain approach to guns was universal. Summing up 1912’s official British opinion was the General Staff’s Major Radcliffe:5 “For practical purposes the aeroplane was invulnerable from the ground and had little to fear from hostile aircraft.” However, a weapon should be provided “to guard against eventualities.”

One’s backside must be covered.

German doubts were even greater, for in 1912 experiments with rifles and pistols fired from aircraft made clear “they were unfit for use in aerial combat.”6 Commanding General of the Air Service Ernest von Hoeppner also noted that the obvious next step – employing water cooled machine guns – was rejected for aircraft use owing to gun weight. As light weight air cooled machine guns were not manufactured in Germany at the time,7 the door was closed on air combat. Instead, evasion was seen as the only proper way to handle hostility in the air. The German conclusion came as a most important support for the widely held British view.

Struggling with their own uncertainties over air combat, the British felt it useful to spell out their airplane needs and hopes in a clear form, on the way to developing practical machines. Could it all be done with a single type? No, not really. Knowledgeable people pointed to a few basic designs as necessary to form up a useful air service. To influential pilot/manufacturer Claude Graham-White, a believer in the reality of air combat, at least two types were required. The first was a fast reconnaissance machine, and the second a “destroyer” capable of protecting brother aircraft from “hostile air patrols circling above the enemy’s lines.”8

This far-sighted view was backed by the well known tailless designer J.W. Dunne. He was certain that air fighting would come about; a certainty so strong as to question the practicality of any tractor airplane for military use. The resulting up front propeller would “impair its fighting value, for it impeded the line of fire straight ahead.”9 In short, only pusher type machines should be considered for the air service.

At the center of these arguments was engineer Mervyn O’Gorman, effective head of the Royal Aircraft Factory and as such, design impresario over all Army, i.e. Royal Flying Corps machines. It was O’Gorman who had the power to initiate a fresh design, either through his own Factory, or through outside contract. Always expansive, he contemplated designing fast and slow scouts in addition to “a small and large aeroplane for gun carrying.”10

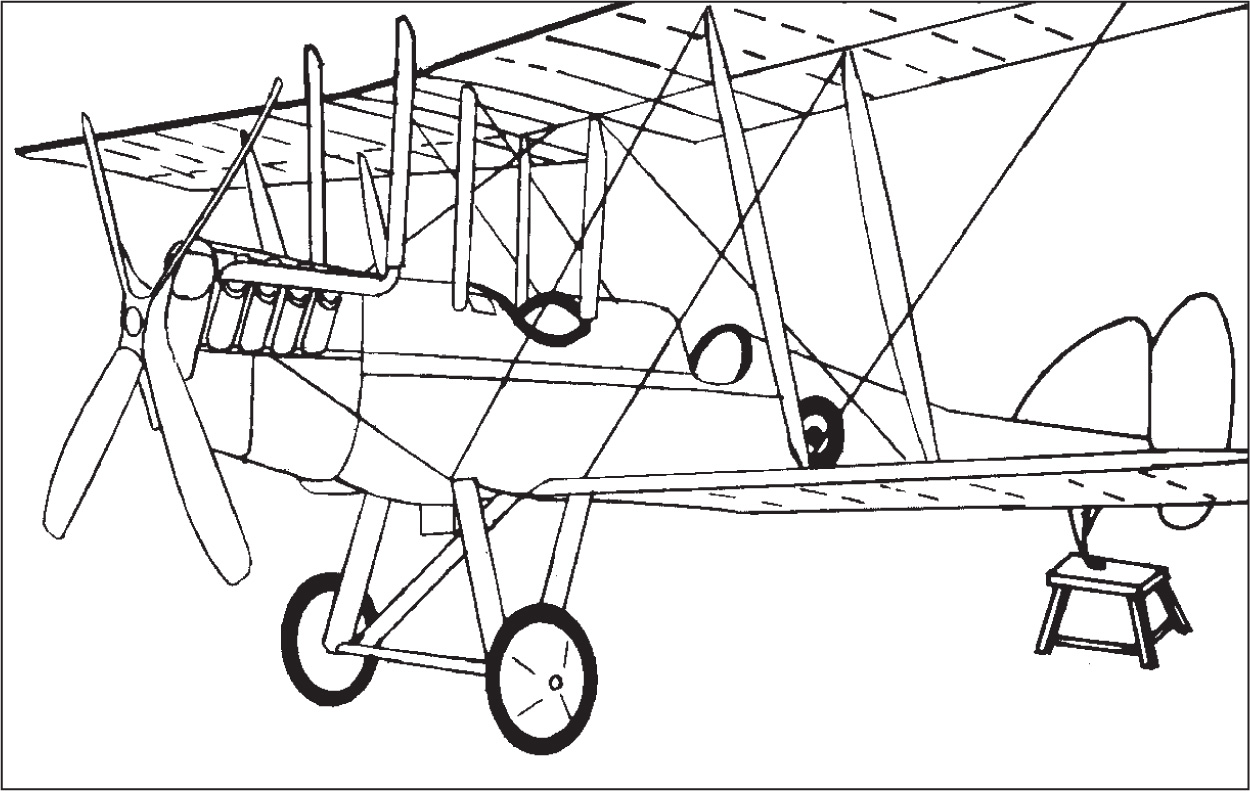

First though, came the BE2. Here was an Army cooperation vehicle, designed to serve as an observation machine and hack. Carrying a non-com pilot and officer observer, the goal was an all purpose machine capable of spying out a battlefield and then landing anywhere to turn in the observer’s report. High speed was of importance in arriving quickly; low speed for both a good view and a safe landing on an unprepared field. It wasn’t planned as a fighting machine. Should air fighting become significant, other designs would carry the load.

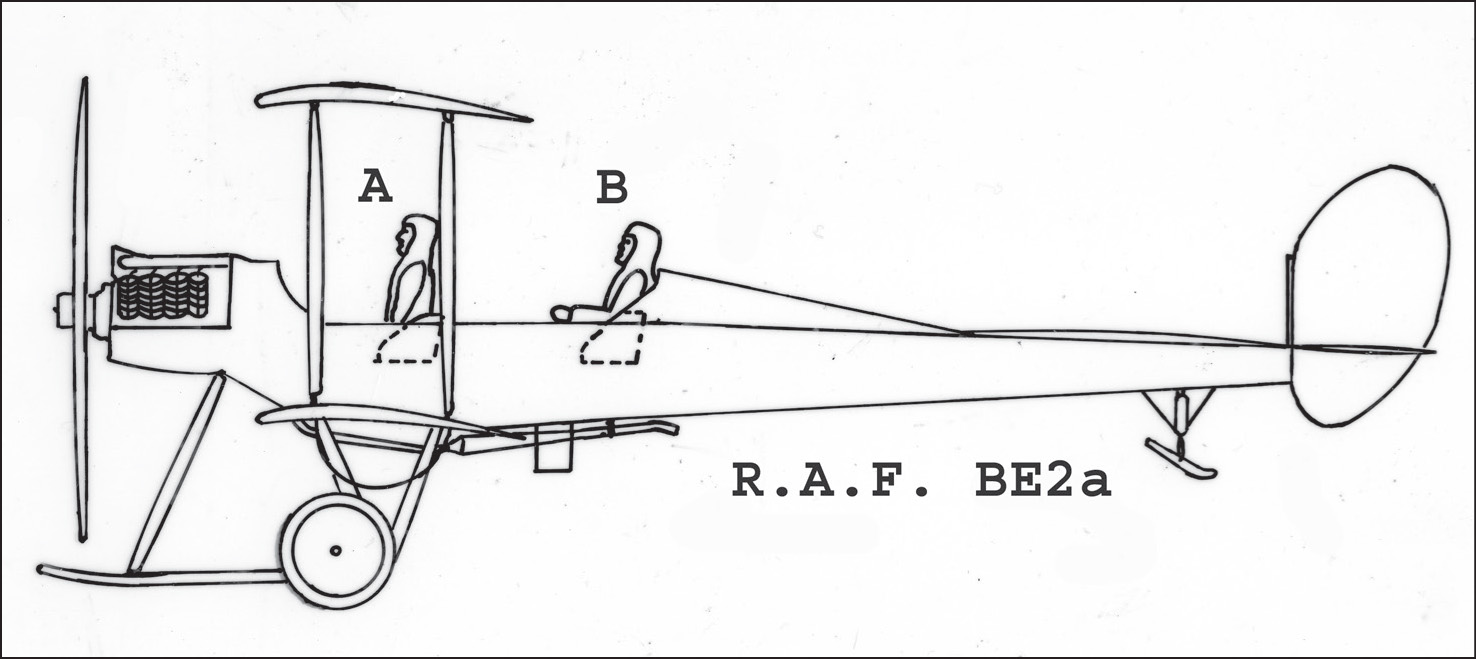

De Havilland’s sturdy design was prepared for an Army cooperation role. Source: F.W. Lanchester, Aircraft in Warfare (NYC: Appleton, 1916) plate 1.

As a non-fighter, the tractor configuration was chosen rather than a pusher. Experience showed that mounting a propeller up front eliminated the serious propeller blockage experienced by pushers; blockage caused by the physical bulk of the fuselage and wings. The blockage effect was to restrict propeller inflow, cutting thrust. Merely moving the propeller forward, freeing up the inflow, meant that a significant increase of top speed could be expected. Given the tiny engine available to O’Gorman, a French Renault offering 70 h.p., any measure serving to increase efficiency was prized. The other readily available engine, the rotary Gnome, was despised by many11 as unreliable. In short, designer Geoffrey de Havilland’s instincts were good and the BE2 tractor versus pusher and engine decisions were sound. Unfortunately, the wartime implications would prove vastly troublesome.

Seats A and B offered different forward and down vision prospects as well as different balance outcomes. De Havilland’s solution (pilot at B, observer at A) seemed logical, but led to much shooting difficulty. Source: Original sketch prepared by author from official 3-views, Flight, November 16, 1912, p.1062.

Positioning the crew followed logically from considerations of vision and balance. Placing the observer in front (A) permitted a far superior down-and-forward view as compared to that of the rear seat occupant (B). As this perspective was critical, the observer was located at A and the pilot in the rear, at B.

Another consideration was that of aircraft balance. In a rough sort of way, the balance point of the entire machine in flight was close to that of position A. As a result, flying without the A occupant didn’t change the balance–the aircraft felt much the same, though a bit lighter. On the other hand, removing occupant B drastically altered the balance, making for difficult flying. As Army missions were frequently short-handed, flight capability without an observer was a realistic requirement. Once again the practical solution was to put the observer in the A seat and the pilot in B.

This decision, like that favoring the tractor format, though logically based, would yet haunt the RFC. Their unfortunate effect was to make gun use difficult.

The BE2 was to become more than the first aircraft in wide use by the RFC. It also provided a means for full-scale experimentation, important not only for perfecting the machine, but for improving the breed at a time when little was known about design. An example of O’Gorman’s endless experimentation with the BE2 is shown below.

The issue was aircraft stability and his hope that of easing the pilot’s task. Could something in the way of modest design changes help? Specifically, what would the effect be of increasing the forward lateral or fin area? This was achieved by adding cuffs to the upper end of the wing struts. In the experiment shown, a total addition of 6 square feet was tested. The resulting machine had a slight tendency to bank automatically on turning; a feature well-liked by his test pilots. No disadvantages were noted.12 However O’Gorman was disappointed–the gain was too slight; it wasn’t good enough. Someday he would tackle the problem of truly automatic flight, but it would have to wait, for much more than a few cuffs were required.

Small fins placed at the upper ends of struts tested for stability effect. They helped find the correct angle of bank. Source: O’Gorman, M. Technical Reports of the Advisory Committee for Aeronautics, Reports & Memoranda # 86 (London: HMSO, 1913) fig. 15.

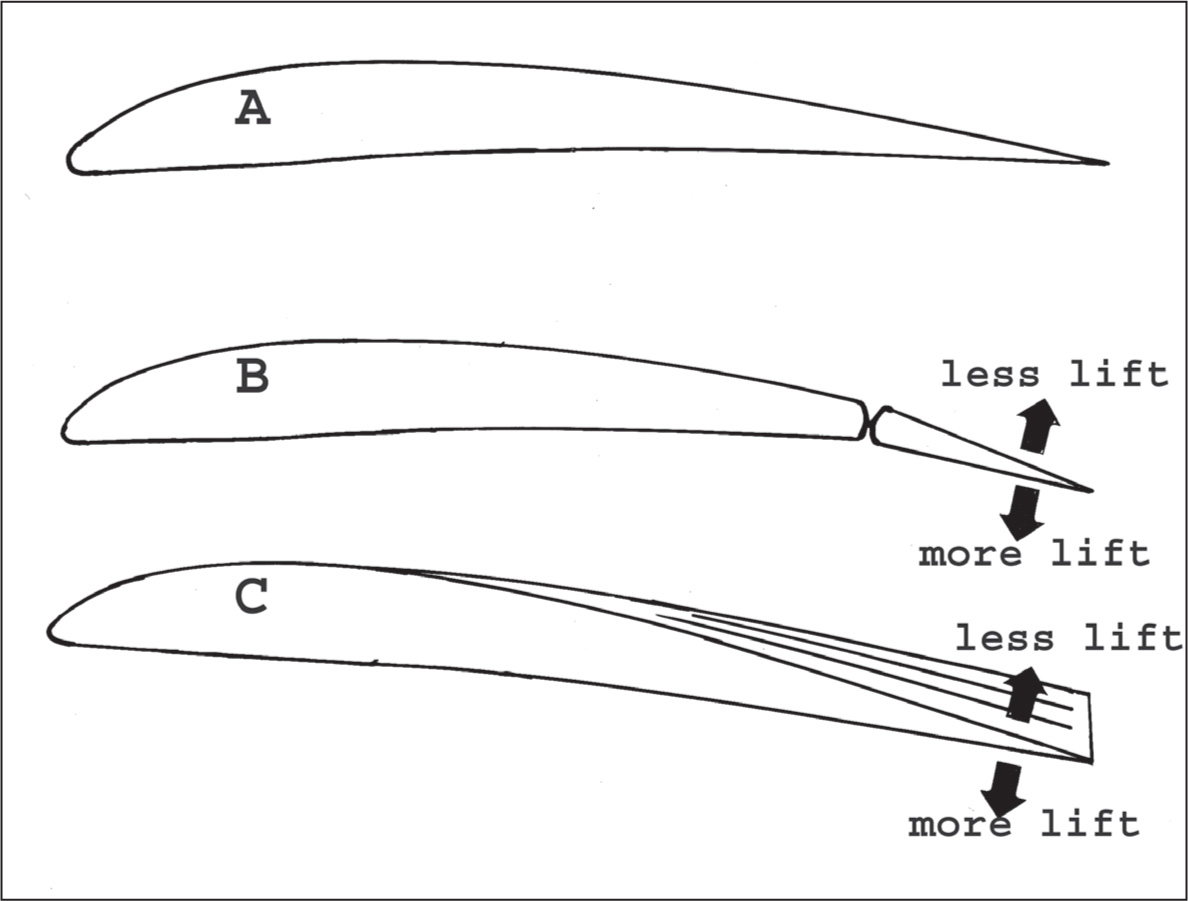

To alter local lift output, the Wrights learned to modify plain wing A by warping as in C. The modern equivalent is the aileron B. Over time, the BE2 design was changed, reluctantly, from warp to ailerons. Source: Original sketch by author.

Another, much studied problem was the twisting or warping of wings. If we examine the usual airplane’s wing cross-section (A), somewhere near the wingtip we will note an aileron (B), a device satisfying today’s piloting needs for local lift modification. It consists of a hinged wing portion able to swing down, generating more lift, or upwards to yield less. Starting with the Wrights, much the same result was achieved by warping the wing (C) in flight; a business of twisting it to vary the resulting lift until the desired value was reached. Warp was a time-tried process eliminating the need for the aileron’s hinged and separate flying surface. Conservative designs employed warp, rather than ailerons. De Havilland chose warp.

However, warp had its problems. For one thing, wing structures incorporating warp were never truly at rest. Any passing gust, encountered either in flight or when simply sitting on the runway, served to twist the wings. In effect, the wind itself became an unwanted co-pilot, modifying the lift capability of the wings as it saw fit. In contrast, an aileron’s controls could be locked when on the ground and made insensitive to gusts when in the air. Unfortunately, easily twisted wings could not. As a result, flight under gusty conditions was exhausting, requiring the pilot to fight against his virtual wind co-pilot at all times.

O’Gorman was that special engineer with a strong interest in difficult details. As an overall designer he was limited, and was wise to employ de Havilland as his chief designer. Granted sufficient self-knowledge to understand that his own strength was in the handling of tricky details, O’Gorman turned to the warp problem. What could be done to remove the sensitivity to wind?

As he saw it, some deflection when under gust loading couldn’t be prevented. What could be done was to vary local wing stiffness so as to change the type of deflection that resulted. He sought to eliminate changes in lift owing to unwanted twist and untwist, by encouraging simple up and down wing movement instead, as a harmless substitute.

Here was a tall order indeed. Gusts could come from any direction–front, back or side– and were of most any strength. Furthermore, wing resistance against twist depended on such difficult to control factors as the weave of the cloth covering the wing, the precise varnishing treatment given the cloth and the amount of weathering and exposure experienced by the wing.

Not discouraged, O’Gorman had a test wing built to his own design. He was pleased to report much progress13 in 1913. Mounted on a BE2 chassis and flown in wind, “the self-warp was small.” On the other hand, “the force [required] on the warp lever was heavy.” In short, the unwanted piloting force originating in gusts had been cut back. However, there was a price to be paid: larger warping lever forces in ordinary flight. There were other difficulties, for stability had worsened; i.e., “the aeroplane tended to overbank.”

O’Gorman shrugged off the bad news. He felt that employing a different wing section would alter matters favorably and looked ahead to further tests. However, another larger issue loomed and captured his attention, that of wing fatigue failure owing to twisting and untwisting.

We have each learned to be wary of bending a light structure back and forth. After enough tries a fracture is likely. We each make practical use of this failure type to break off thin pieces into something smaller. Known as work hardening and fatigue, this form of breakage is one that lies in wait for the unwary, defying calculations. If ever a seemingly perfect subject for fatigue failure existed, it was the very warping and unwarping of wings that had captured O’Gorman’s attention. Over time, wouldn’t these wings fall apart owing to their own accumulation of back and forth stress? Newsworthy just then, in 1912-1913, were numerous inexplicable airplane accidents involving monoplane wings. For no obvious reason, the wings had simply fallen apart in flight. Was the root cause one of too many warps and reversals?

The ever energetic O’Gorman moved to find out. Needed was a machine capable of twisting and untwisting wings automatically, attached to a BE2 wing. By December 1912, the test wing had withstood 120,000 cycles of twists and untwists, each a sizeable 4½°. By May 1914, the figure stood at 360,000 tries.14 All was well. He had shown that wing warping of a sturdy wing need not lead to fatigue failure, even after the equivalent of many years of use.

The wing twist episode supplies a sense of O’Gorman at work. Compared to today’s lot, he was a very different sort of CEO. His employee de Havilland, destined to become famous as a designer, described him as “no yes-man”.15 Instead he was a solid administrator with a mind very much his own. Though reasonably adept at soothsaying and politics, O’Gorman’s special abilities were those of an analytical engineer with enough egotism to prefer his own evaluation to those of any outside expert or committee. Once convinced that logic was on his side, he could be very difficult to move. Furthermore, he was driven by a longing to solve design problems that were generally regarded as hopeless; a tendency to relish the difficult rather than the practical. De Havilland sensed the undesirability of his own task – making O’Gorman’s dreams real – and left the Factory before the war, in early 1914. His Factory design experience taught him a bitter lesson about people and ability.16 There was such a thing as too much ability and pride in that ability; O’Gorman type engineers placed in positions of top level responsibility guaranteed failure. In short, the O’Gorman type had best stick to details.

British fighting pusher, as flown in 1913. The two-seater had a gunner/observer up front and pilot immediately behind. Source: W.F. Lanchester, Aircraft in Warfare, (NYC: Appleton, 1916) plate 6.

Unfortunately for the British, de Havilland’s departure removed the overall balance of outlook necessary in designing an airplane. O’Gorman was free to have his way. In time, the RFC would pay the price. Before moving on, de Havilland had much to do with the BE2’s brother aircraft, the FE2 pusher; designed as a fighting machine.

A close relationship existed between the two aircraft – initially the wings were interchangeable – though other details were quite different. For one, the known inefficiency of the pusher configuration plus the weight of arms to be carried dictated employment of an engine much more powerful than that in the BE2. Years of testing five different engine possibilities led to the 120 h.p. Beardmore, admittedly “copied directly from the [European] Austro-Daimler engine”17 but manufactured locally by British Daimler. Relatively reliable, stationary and water-cooled, the engine pushed the FE2 to a top speed of 81 mph, a respectable speed about 10 mph faster than its contemporary BE2a.

A pole mounted Lewis gun permitted the gunner to fire at enemies diving from the rear. Source: Original sketch by author; dimensions from A. Fage & H.E. Collins, Technical Reports of the Advisory Committee for Aeronautics, Reports & Memoranda # 305 (London: HMSO, Jan.1917) fig.2.

When serving as a fighter, the process of shooting to the rear offered problems for all pushers. The FE2 solution made use of a telescoping pole between pilot and gunner. Placing a Lewis gun on top of the pole, the gunner was to raise it as needed and then stand within his cockpit to aim the gun over the top wing. Doing so, he might hope to fend off an attacker diving from above. Should the gunner prove to be too short, yielding only a high angle of fire, height could be gained by standing on the contents of the ammunition locker: sturdy wooden boxes holding extra Lewis gun drums, carried in the gunner’s cockpit.

When standing, most of the gunner’s body was exposed to the passing wind. At 70 mph the drag load alone pressing upon his body could exceed 50 pounds.18 Taken together with the G-forces produced by maneuvering, the total load was enough to eject an unwary gunner from his cockpit. A wise gunner saw to it that plenty of restraining straps and hand holds were available. As for the resulting shooting accuracy – firing to the rear was hopelessly inaccurate.

Certainly the aids given the gunner – a telescoping pole and ammunition boxes – were primitive, even when measured by the crude standards of the time. Why was so little thought given to the problem? In part, the machine’s unhappy history served as a damper, discouraging all-out development.

Substituting for the FE2’s gunner, the standing preacher makes clear the position’s instability, one buffeted by every gust. Source: Flight, September 26, 1918, p.1075.

When under test, the freshly completed FE2 prototype crashed, spinning in and killing the passenger sitting in for the gunner.19 Many old wives’ tales associating pushers and spins were brought out once again, adding to the loud criticism of the FE2 design, and especially of its nacelle, containing gunner and pilot. Particularly bothersome was its length and considerable side area, unbalanced by any comparable side area located at the machine’s rear. To many British designers, the FE2 required a fresh approach, “for those who have done much flying on the pusher type [know] that a big fuselage tends to take charge and cause a spiral dive.”20 To some designers, ignoring the matter would only lead to more spinning accidents. To their annoyance, little was done.

FE2 designer de Havilland was generally well regarded. However, the reputation of the remaining O’Gorman designers was not the best. At this very time, one critical aero journal dismissed them as a “pernicious, obnoxious and deleterious gang of brain pickers”.21 True, the critic (C.G. Grey) was a professional scourge with a profound disrespect for the Factory’s staff and products. Still, the criticism had a certain appeal – to many readers, there was little to be expected from the Factory. To these, FE2 drawbacks were sensed as inevitable, and not as readily correctable.

Finally, the crucial period of early 1914, like that of 1912, offered many doubts about the reality of fighting in the air. Unsure that a fighting aircraft was even wanted, it was impossible to argue convincingly for the money and effort necessary to eliminate technical difficulties. Instead, there was a human tendency to simply sweep the FE2, along with its problems, out of sight.

The many doubters included Major Sefton Brancker, destined to achieve high RFC rank in the coming war and post-war retirement as an Air Vice-Marshal. Here was a most effective seer and doer, and yet in the spring of 1914 Brancker22 argued against the likelihood of air combat. As he saw it, the very process of arming an airplane necessarily lowered its performance owing to added weight and protuberances. If we imagine an encounter between a fast reconnaissance machine and a similar but heavily armed aircraft, the reconnaissance machine’s best tactic would be to flee, leaving its armed pursuer far behind. His startling conclusion: guns aloft prevented air combat. In short, aerial fighting was unlikely.

And yet, despite the performance handicap, the arming of some aircraft might be useful, enabling23 “the attack of troops, ships and important buildings.” As for actual fighting between airplanes, it was at best “tentative … within the range of possibility at the present moment.” Again the backside was covered, and yes, it might happen, but don’t bet on it.

Perhaps the most useful task for aerial fighting machines would be that of sentries, guarding some critical ground site against enemy observation. Here too, actual combat was unlikely; the presence of guns being sufficient to drive away interlopers.

In agreement was Major F.H. Sykes of the RFC, also destined for high rank. In 1913 he saw the fighting machine as necessarily heavy and the lighter scout as having24 “various advantages over the heavier type” – those of speed, climb rate and ease of piloting. The inability of fighters to close with scouts would result in open skies above the battlefield: “both sides will know a great deal as to what their opponent is doing.”

Finally and most important was the view of reconnaissance expert General David Henderson, who would head the wartime RFC. He expressed doubts (April 1914) over the ability of any aircraft to destroy another. Doing so required a position:

… within short range of the adversary and herein lies the difficulty … until a fighting machine is produced which will equal the unarmed aeroplane in speed, climbing power and handiness [maneuverability] … an enemy can very quickly return to the safety of his own lines.25

Once again, air combat was sensed as most unlikely. True, someday things might be different … but someday would take care of itself. To those struggling with the FE2 combat airworthiness and gunnery issues, these official RFC views amounted to disinterested lack of support. As for shooting backwards–useful only for air combat–why face up to the difficulties of solution when shooting forwards in the ground attack role was one attribute that was actually wanted – and simple to achieve?

Furthermore, there was the FE2 spinning issue, likely requiring the reduction of that considerable nacelle side area. Unfortunately, this need was opposed by the demands of improved rearwards gunnery – sheltering of the gunner from wind blast was vital – in turn leading to an increase of side area, rather than a decrease. The conflicting design demands made simple solution most unlikely. It was all too much for the Factory. The FE2 went to war, largely unaltered.

Yet another factor serving to dampen the reality of aerial combat was the development of a truly fast scout – an aircraft moving at so high a speed that nothing could catch it. De Havilland and the Factory prepared their own entries in the race for speed. Wanted was much more engine power – not merely squeezing out a bit more–but a truly generous gain – at least twice the old h.p. figure.

One way of achieving great power was to add engines in Siamese Twin fashion. Wanted were engines capable of being stacked, something like cards. Not stationary engines, for they were too long and heavy. Rotaries appeared to suit the notion. Light and thin, they could be joined one engine immediately behind the other, and arranged to drive a common output shaft. Available at the time were the Gnome 80 h.p. rotaries and the Monosoupape (single valve) 100 h.p. engines. Each seemed a good candidate for stacking.

High speed was the design goal of this neatly streamlined, high-powered SE-4. Bedeviled with imperfections, it was not to become a production machine. Source: W.F. Lanchester, Aircraft in Warfare (NYC: Appleton, 1916) frontispiece.

Designers were intrigued. With twin 80’s, a total of 160 h.p. seemed within easy reach. If as much as 200 h.p. was possible, why not press for all out speed, say 130 mph, or some 50 mph beyond the usual, and simply scoff at enemy aerial fighters? The concept’s appeal was enormous, especially so to Flying Corps intellectuals resistant to the notion of air combat. To these, any scheme for eliminating meetings between fast reconnaissance machines and enemy fighting machines was worthy of heavy investment.

Stacking two Gnomes seemed fairly straightforward and the Factory spent several prewar years pursuing this end. Of those aircraft resulting, the SE-4 was most promising, but this neatly streamlined and speedy aircraft never came out of development. Too many issues remained unresolved. For one, there was the sticky issue of engine reliability.

Rotaries were inherently less reliable than stationary engines. Rotary spark plugs tended to foul with carbon deposits; in large part owing to the burning of that lubricating oil mixed together with fuel. The result was a tendency for plugs to misfire or even stop firing entirely, leaving the aircraft with a windmilling propeller – and no power. In addition, exhaust valves jammed up when deposits of burnt carbon prevented proper closing, producing the same result – a dead engine. Pilots accepted such rotary disadvantages reluctantly. Fortunately, the extreme lightness of the rotary offered a compensating advantage: better performance. However, pilot tolerance for stoppages was extremely limited at best and offered little room for bargaining.

Experience with stacked rotary engines showed increased reliability problems as compared to the usual rotary, for there were twice as many cylinders, spark plugs and valves; i.e., there were twice as many things to go wrong. In addition were the new problems created by the stacking process itself. Properly done, an extreme precision of manufacture and assembly was required, not easily achievable at the time. All things considered, stacked rotaries were doomed, unless some compensating piloting advantage arose.

Rather than an advantage, pilots sensed a disadvantage in their new high-powered rotaries – a mysterious new force – gyroscopic – threatening to override piloting input. The problem’s nature – that of a physically complex detail – was exactly right for O’Gorman’s skills, and he quickly produced a mathematical solution, along with experimental agreement.

Gyroscopic force arises when a rotating mass, say a propeller, is moved at right angles to its axis either horizontally–right or left–or vertically up or down. The force produced is directed at right angles to the new motion and can be disturbingly large, if the rotating mass is large and the new motion quick. The stacked rotary with its many rotating cylinders, moving together with a propeller, amounted to a great spinning mass capable of generating “a sideways twist … which appears to be very significant.”26 (O’Gorman’s italics.)

Uncertain as to the load’s practical significance, he queried veteran French race pilot Jules Vedrines. To old hand Vedrines, who had tried stacked 50’s, rotary gyroscopic force effects were real but came well within the usual range of handling problems, being “much the same sort of thing as a gust.”27 Perhaps, but to Factory pilots the more powerful stacked rotary powered SE-4 was unacceptable. Its tendency to overheat28 was the last straw. A rumored top speed of 135 mph notwithstanding, the SE-4 never went into production. There would be no speeding away from interceptors.

What could be done within the skeptical atmosphere of 1914 was to improve the existing and well-liked BE2, altering a good machine into a truly superb cooperation vehicle. O’Gorman turned to the task, first dealing with the departure of designer de Havilland. A successor was chosen: recent science graduate E.T. Busk.29 He seemed of the O’Gorman persuasion; thoughtful, mathematically inclined and willing to try most anything. Soon a competent pilot, he flew his own BE2 modifications and was thus able to spot problems without the usual test pilot/engineer arguments and delays. Here was a highly competent designer with only one significant drawback–an eerie personal carelessness suggesting a suicidal nature.

His design efforts converted the BE2 into a stable machine, after which his life was ended by a strange accident. Source: Flight, November 13, 1914, p.1114.

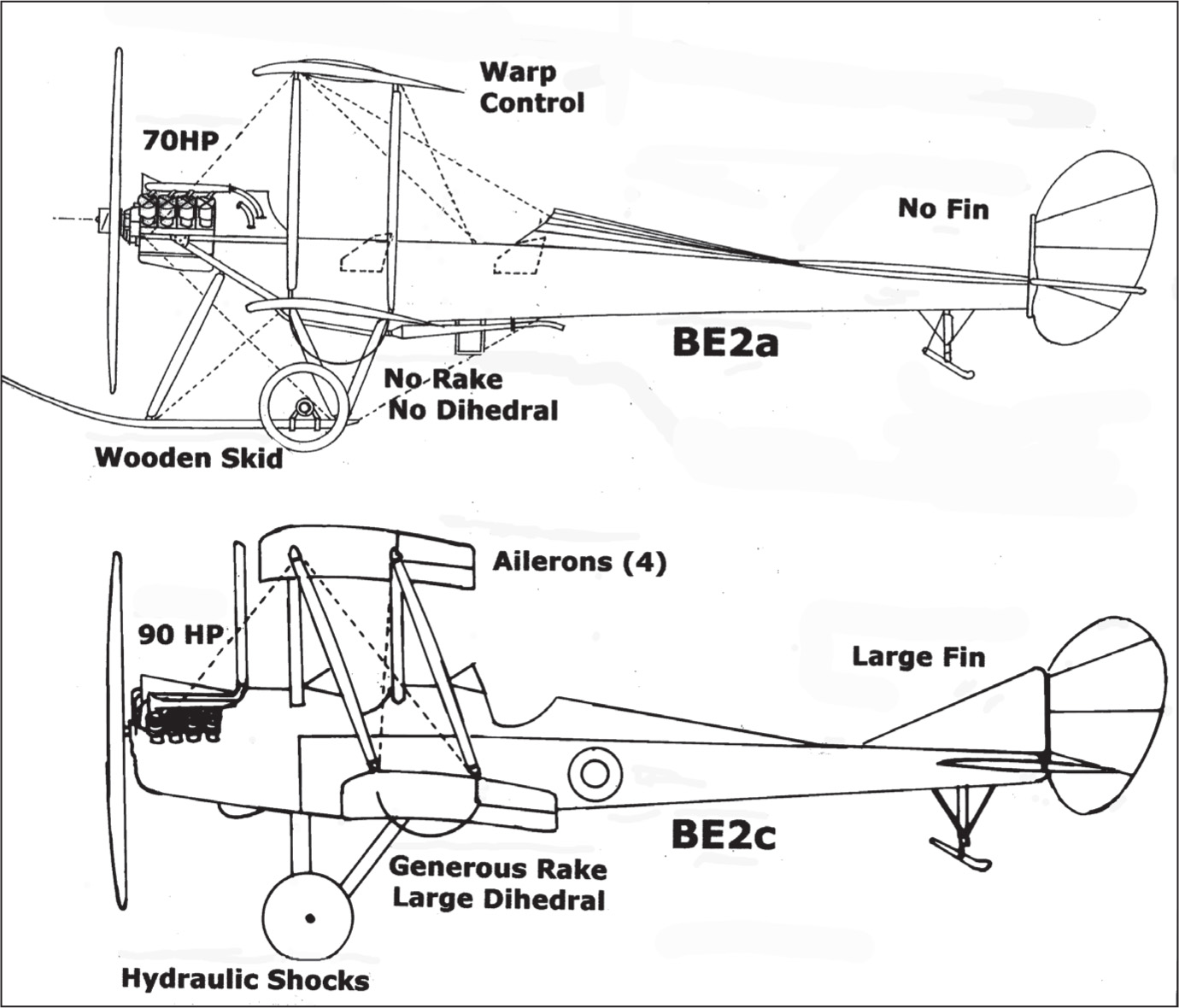

Two major changes were planned: more power and great automatic stability. The need for greater power was obvious; certainly, the old 70 h.p. offered a sadly minimal performance. Furthermore, dependency on Renault, or any foreign manufacturer for delivery, was unwise for a British war machine. Better would be a much larger engine manufactured under the direct control of the Factory itself. As for the format, the Renault design itself – stationary and air cooled – was fine, for it eliminated many of the headaches associated with rotary and stationary water cooled types. In time the new design emerged from Factory development as a 90 h.p. engine, reliable as any of its time. There was even a bonus: it resisted overheating and was well able to withstand tropical temperatures.

As for the 90 h.p. output, it was to 1915 as 70 h.p. was to 1912: a ticket to modest performance and no more. Though it served to improve the BE2 breed somewhat, 1915’s competing aircraft were far more powerful. In the event of air combat, the BE2’s ability to flee would be unimpressive.

Full inherent stability for aircraft had long been an O’Gorman goal and understandably so, for there was much to be said for it. Today’s pilots are pleased to employ devices to this end, and those of 1915 had an even greater need for relief, for at the time piloting was a study in exhaustion, with the usual two hour mission demanding fresh control input every second of the way. In war, with some pilots suffering from wounds or high altitude oxygen deprivation, the need for a largely self-flying machine was all the greater.

Stable and effective, but lacking in maneuverability. Source: Original sketch by author.

Busk’s approach was one of bit by bit solution, with much cut and try, all guided by a sophisticated understanding. Fore and aft stability requires an extra large horizontal tail and a forward balance point located just so – these were achieved. Lateral stability and its demand for upturned wing tips (dihedral) were met, and so on. O’Gorman’s wing twisting approach, despite his arguments and supporting experiments, were abandoned in favor of ailerons. All went well, as per plan. When complete, the resulting BE2c was capable of many minutes of automatic flight, not only reducing the pilot’s burden, but permitting him to act as an observer, or to work a wireless set.

Finding this hard to believe, Major Brancker checked the inherent stability feature by flying for half an hour at about 2000 feet on a gusty day30 – without touching the controls. All went well; Brancker was convinced.

There was a catch. Fully stable machines resist any call for a new flight path. The aircraft senses change of any sort – either those unwanted changes resulting from gusts, or those wanted from control action – as equally undesirable, and responds by altering course reluctantly. For most peacetime flights, this oddity is acceptable. Once accustomed to the slow control response, the pilot learns to think ahead. However, the need to escape bullets in war required an immediate response, and this was impossible with the BE2c.

Another aspect of the super-stable trait was the aircraft’s flat refusal to pursue flight paths sensed as undesirable. For example, steep dives were ruled out. A strong pilot could supply enough control stick force to produce a shallow dive, but no pilot was strong enough to create a steep dive. Again, this was not a problem in peacetime, but to a desperate pilot seeking to escape aggressive pursuit, this limitation was painful indeed. Not only the BE2c, but two other RFC machines were officially declared31 non-divers as well – when too late to permit change – the FE2 and the de Havilland fighter DH2.

Profiles of the BE2 as it altered from the pre-war (BE2a) to its definitive wartime (BE2c) version. Source: (top) Flight, November 15, 1912, p.1062; (bottom) TNA file # AVIA 14/5/2/29.

After the war, aerodynamicist L. Bairstow noted sadly,32 “the will of an aeroplane is not a fortuitous characteristic.” Wartime pilots used earthier expressions to denounce this trait. The consequences were to prove profound – for both the RFC and Richthofen.

Working up the BE2c took many months, a process continuing through the early period of the war. Just as predicted by RFC brass, the opening phase of the war proved a relatively peaceful period for aircraft, with negligible air combat despite an active ground war. Wanted for operations was exactly that machine being prepared by Busk: an easy-to-fly Army cooperation machine, and Busk drove himself hard to complete the project. However, something went terribly wrong and in November 1914, The Times (London) reported33 his death:

a biplane [BE2c] piloted by Mr. Busk caught fire … for three quarters of a mile the aeroplane, blazing more furiously every second, traveled down a slanting glide until it fell headlong to the ground …

Flying in formation with de Havilland, flames suddenly shot out of Busk’s engine.34 There was no chance whatever. It seemed a typical catastrophic engine fire of 1914, and yet odd stories began to circulate. There was Colonel J.E.B. Seely’s report35 of a flight demonstration in which he had served as a passenger. In flight, Seely’s face was suddenly splashed with fuel. Busk had overfilled the small overhead gravity tank and the excess was simply dumped on him, as the occupant of the front seat – located immediately behind a hot engine. Fortunately, there was no fire.

How to Shoot Forward on a Tractor

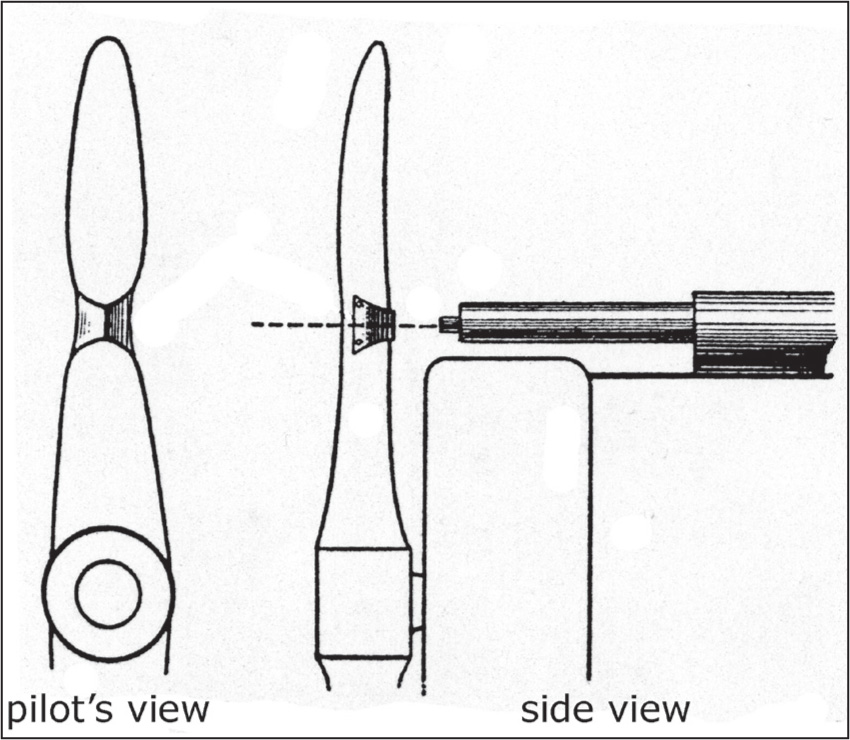

By bolting a steel wedge to the propeller, striking bullets were safely deflected. Source: Flugsport, January 16, 1918, p.30.

Soon after, there was a disturbingly similar report from scientist Geoffrey Taylor. Again a demonstration ride, and again a bath in fuel – this bath on the day before Busk’s final accident.36 A strange association existed between Busk and loose fuel.

The problem’s engineering solution was simple: by adding an additional tube to the overhead gravity tank, excess fuel would be piped safely back to the main fuel tank. Busk’s own solution – dumping the excess on the front seat – was strange indeed. Adding to the strangeness was O’Gorman’s defensive, embarrassed comment:37 “He merely took all the precautions of a clever engineer.” The facts were exactly the opposite: Busk’s neglectful actions were those of a twisted man bent upon suicide.

After Busk, the fuel problem was corrected. There the matter rested.

The BE2c had arrived and soon become the mainstay of the RFC. Several thousand were manufactured and served in its heyday from 1915-1917. Performance was modest,38 requiring 20 minutes to climb to 6500 feet, where it flew at a maximum official speed of 72 mph. For its protection, there was the FE2b, offering a nearly identical performance39 (19.5 minutes to 6500 feet and 73 mph once there) and the same super stability. Costs were typical, with the total BE2c airframe + engine cost at 1600 pounds in 1917,40 and the FE2b at 2345 pounds, also 1917.

Even as the BE2c was prepared for service, a new factor entered – the birth of real air combat. Major F.H. Sykes reported41 a “certain amount of fighting”, starting in October 1914. The object was to blind opposing artillery by knocking out the enemy’s seeing eye guidance, i.e., shooting down those enemy aircraft engaged in observing and correcting shell hit locations. Actual combat was rare, just as predicted by the pre-war doubters. When attacked, “as a rule the German made for his own lines.”42

The next step was one of shooting more bullets when attacking. This came from a French concept relying not on pushers, but on fast tractors with propellers protected with steel wedges. The prospect of air combat had suddenly become real. Should the French propeller protector be perfected, ordinary liquid cooled machine guns would become devastating aerial weapons. Germany had a gifted inventor available and interested – the self-taught Dutch engineer Anthony Fokker. He set to work.

The basic RFC premise: “air combat is unlikely” – a belief underlying the design of its key machines, the BE2c and FE2b – was about to be turned into so much nonsense.