Fokker Fodder

Air combat came about as the direct result of infantry demands. The lives of ground troops were made miserable by endless shelling, much of it guided by enemy observation aircraft. Troops pressed for an end to the menace. If enemy cannons couldn’t be destroyed, surely something could be done about the eyes of the artillery: slow observation aircraft or balloons hovering above the frontlines. Why not shoot them down, thus ending shelling accuracy? Shelling without accuracy would lack profit. Artillery fire would become a pointless exercise. As an important result, fewer infantry lives would be lost. The argument was convincing.

First to act were the French. Together with the British they manned a Western Front hundreds of miles in length, subject to the shells of German cannoneers. Repeated French infantry pleas resulted in action by the French Air Service. Most every type of aircraft and gun was tested, seeking the best combination.

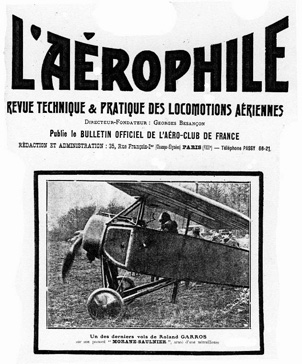

Pilot Roland Garros flying a deflector-equipped Morane N. Source: Oswald Boelcke, Hauptmann Boelcke’s Feldberichte (Gotha: Perthes, 1917) p.161.

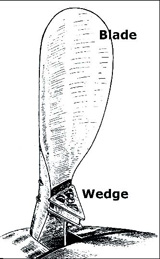

Pilot’s view of a propeller blade equipped with a deflector wedge. Source: Auguste L. Masmejean, Les Avions Allemands (Paris: Librarie Aeronautic, 1917) p.14.

To pre-war racing pilot Roland Garros, the optimum was a single-seat tractor airplane,1 equipped with a standard issue light machine gun and a propeller armored with wedges capable of deflecting bullet strikes. His choice had its good side: a speedy and highly maneuverable aircraft aimed simply by positioning the machine. However, there was a bad aspect as well, for the gun employed was the official French clip-fed machine gun (St. Étienne), notorious for misfires and stoppages.2 Overall, the system was workable but crude and accident prone. Pushed into combat starting in February 1915, Garros successfully downed three German observation machines by mid-April. Not only the French Air Service, but the German Air Service was impressed. There was something more important here than merely the fate of one more weapon: perhaps enemy artillery observation could really be stopped.

On April 19, Garros was caught with an engine stoppage over German-held Courtrai. Lacking altitude, there was little choice. The operational plan was to land, set fire to his machine and attempt to escape. His forced landing went well, but the airplane did not burn properly. Garros was captured. Even more disturbing was the loss of the deflector secret, for bolted to each propeller blade was a perfect working sample; the result of months of effort. To knowledgeable Germans, the intended use of the propeller’s steel wedges was obvious. Wanted immediately were copies for the German Air Service. Seeking immediate action, the wedges were turned over to Anthony Fokker’s aircraft firm.

Balzac noted that there are but two paths to great success: that of genius and that of corruption. Anthony Fokker employed both. In part a skilled airshow pilot and small-scale manufacturer, he had the searching imagination of an inventor. Though an original thinker, he was content to appropriate the inventions of others as starting points for his own efforts. As for payment, assigning credit or royalties to other men was not one of his strong points. Of all possible inventive abilities, his specialty was a shrewd assessment of what the customer really needed. He then moved energetically to supply it, without troubling himself over the intellectual property rights of others. Reflecting this trait, his early designs owed much to machines he admired; for example, the Fokker M.5 owed more to Morane-Saulnier’s design department,4 than to Fokker’s.

Handed a Garros deflector, he saw it as useful but flawed; i.e., not a complete answer to shooting needs. Its fundamental drawback came from the impact and destruction of about 10% of all rounds fired – those hitting the wedges. This wasted percentage was turned into flying bits and pieces of lead forming a metallic spray about the aircraft nose, sometimes acting to smash windscreens or clog engine air breathing intakes. It would be much better to eliminate bullet strikes entirely, with its wasted rounds and destructive bullet spray. Could this be done by interrupting the machine gun’s fire whenever a blade passed in front of the gun muzzle?

(our translation) “One of the last flights of Roland Garros on a Morane Saulnier Parasol, armed with a machine gun.” Source: L’Aérophile, front cover, May 1915.

Accomplishment was difficult. Engines and propellers of the time turned over at about twenty revolutions per second. This meant that the blades of a two bladed propeller passed by at about forty times per second. Machine guns fired at a rate of about ten times per second. There was no match. Furthermore, both propeller and machine gun rates could vary considerably. To detect the presence of a blade when in an undesirable position and prevent the gun from firing, all at a rate of many times per second was a tough challenge. Nowadays the task would be assigned to fast responding electronic devices. At the time, only mechanical devices were available, and these were usually too slow to cope.

One who tried was engineer Franz Schneider. His patent of July 1913, with drawings openly featured by Flugsport 5 just after the war’s start (September 1914), drew startled interest from every nation. The concept employed a cam mounted on the aircraft propeller shaft. As it rotated, the cam blocked access to the trigger whenever the blade passed in front of the gun. When the firing path was clear, free access to the trigger was provided for the shooter. In principle this was fine, but the extreme speed of operation was too much for Schneider’s slow moving components. Pre-war trials of the device were unsuccessful.

Fokker assigned several of his own employees – machine designers – to the problem. Their backgrounds happened to be strong in the area of metal stamping or punch press operation, a business of fast moving parts and violent accelerations. Exactly this experience was crucial to a solution and within weeks Fokker had a working “interrupter” consisting of Schneider’s concept, properly executed. Ignoring Schneider’s contributions and those of the Fokker company’s own machine designers, Anthony later announced that he alone had invented and built the interrupter within a 48 hour period.6 We doubt it – all known evidence indicates otherwise.

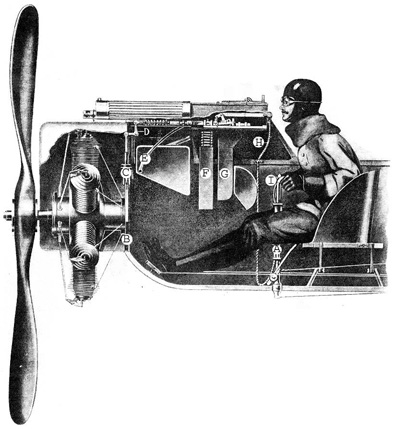

Fokker’s interrupter, as mounted in his E-III airplane. For description, see text. Source: Scientific American, December 30 1916, p.587.

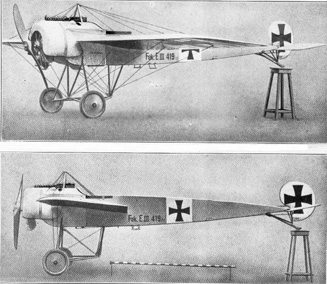

A humble start, soon revamped into the superb E-III. Source: Luftfahrt, March 1917, p.9.

Much remained to be done in the way of small improvements, but at the time (mid 1915) here was a truly revolutionary solution to the problem of air combat. What’s more, the system was reasonably reliable, even under conditions of inept maintenance. The interrupted machine gun quickly became the fighter pilot’s basic tool. Taken together with its matching airplane, the combination became the world’s first true fighter aircraft and the basis of Fokker’s fame.

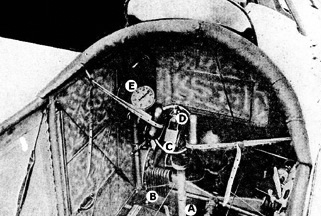

More than just shooting was involved in the interrupters’ application to an airplane. For example, there was the problem of helping the pilot clear those inevitable machine gun jamms – all to be done while he flew. In the case of Fokker’s E-III machine, this was accomplished by use of lever (A) at the pilot’s inner left thigh, which locked the elevator and enabled the pilot to take his hands off the control stick. He was then able to clear stoppages with both hands. Free use of the rudder bar remained, as did lateral movement of the stick, permitting him to correct aim with his legs, or even to turn out of trouble should he find himself under enemy guns.

The gun portion of the interrupter employed a huge cam (B) mounted on the engine crankshaft to drive follower (C), in turn actuating levers and springs (D) to actually fire the gun. Empty cartridges were returned to a storage container through tube (E). Fresh cartridges were stored in (F). Depleted gun belts were automatically returned to (G). Finally, firing itself was ordered through mechanical firing lever (I), which sent its message by pulling on a cable (H).

Fokker’s strong commercial sense correctly pointed to a fortune to be made through his interrupter. There was more – he sensed an opening to sell matching aircraft: those designed with the interrupter in mind. Starting with his factory’s M.5 monoplane, he turned its better aspects into something new: the Fokker E series, destined to become the interrupter’s perfect accompanying aircraft.

The Fokker M.5 and E types used the old 1912 Morane-Saulnier as a starting point. It suited him. He ignored the later (1914) French version offering a streamlined format. Fokker much preferred the earlier leaner and lighter model shown above. In his view, the gain from streamlining was less important than its cost: added weight. Better a low weight fuselage than a heavier, rounded fuselage.

Initially a French sport plane (top) Fokker converted the design (middle) into an early war Army co-op machine, and finally (bottom) into the revolutionary fighter. Sources: (top) Flight, May 24, 1913, p.562; (middle) Aerial Age Weekly, January 17, 1916, p.429.; (bottom) L’Aérophile, August 1917, p.277.

As for the aircraft’s rotary engine and associated gyroscopic force issues – matters that had given O’Gorman pause – Fokker refused to worry. Yes, strange forces did arise in rotary engine operation but fortunately: “experienced pilots carry out corrective control action instinctively, without understanding the reason for it.”7 He did admit to exceptions; i.e., difficult gyroscopic force areas. One example was flight at extreme altitudes, when little surplus control power remained to prevent flight path problems. Another was flight within a tiny circular path. However, as neither appeared significant in 1915, they were dismissed.

No rotary enthusiast, he properly assessed the rotary as “tricky, unreliable and difficult to operate.”8 His grim view reflected personal experience with the Gnome. Pilots generally agreed and British experience was much the same. Airplanes employing rotaries would not find easy acceptance.

Of course, there were positive features and one useful characteristic was the lack of water-cooling, with its need for extensive warm up. A rotary powered airplane could take to the air faster than one with a stationary engine, and was invulnerable to the curse of holed or frozen radiators.9 More important was the rotary’s low weight per horsepower –far lower than that of stationary engines-making for a reduced overall weight. As for the modest output of the engine made available to him – an 80 h.p. Oberursel – there were realistic plans to quickly upgrade the engine to a generous 100 h.p.. In the meantime, the limited power served as a goad to make every bit count. In short, though Fokker well understood the negative side of the rotary, weight considerations were decisive – his E series would be powered with a rotary.

E series design improvements were achieved through a trial and error process. A plastic side window (see sketch) permitting downward vision came and went as did innumerable redesigns of wing pinions and tail areas. The goal was a pilot’s airplane – not the fastest, for the engine was too small – but the most responsive; an agile machine able to nail an opponent engaged in close combat. This goal guided all decisions.

Even that “comma” rudder had a well thought-out function. There was no fixed fin area. Instead it was all-moving, supplying the fastest possible reaction to any new input. Without a fin and quite small, it rated low in the ability to control propeller blast at low speeds – as in takeoff. However, given a small engine, the rudder area was big enough to do its job if the pilot was willing to work hard at control. The balanced area and odd shape had the additional virtue of great resistance to stalling out – as much as 30° of rudder deflection10 could be applied without running out of rudder. Finally, the trademark outer shape was easily bent from steel tubing. In all, the “comma” rudder’s combination of high effectiveness at a low cost would carry it through many more Fokker designs.

The horizontal tail was a good match. Of small area and without a stabilizer, it too made for a demanding control surface. Horizontal tails do more than supply an “elevator”, though that is their main purpose. Offered also is fore and aft stability – the ability to sense a gust and react automatically, returning the aircraft to its pre-gust attitude. A horizontal tail needs plenty of area to create stability, for its ability to create a restoring force is sensitive to surface area; i.e., more surface results in more force. Knowing this, Anthony Fokker chose the smallest possible horizontal tail area – he didn’t want stability. He had learned much from his earlier too-stable Spider design: stability had its problems.

For one, there are times when great stability could actually produce a crash. A stable reaction to a gust might well include a good deal of roll, useful in restoring heading. At appreciable altitude, roll was fine. However, when landing too much roll meant striking the ground with a wing tip – and an accident. Of course, an alert pilot could override the sometimes suicidal wishes of a too-stable machine, but then where was the profit in stability? Yes, it permitted pilots to relax once altitude was in hand. Once there, the airplane almost flew itself. However, this feature counted for little in Anthony Fokker’s plans – relaxation was not his goal.

Stable designs offered another and more serious drawback – they placed a heavy restraint upon wild maneuvers. The resulting inability to dive steeply mattered in a warplane. Through their stable BE2c and FE2 aircraft, the British had learned the same lessons, but had shrugged off corrective action. Instead, there was always the hope that there would be no air combat, and no need for wild maneuvers.

Unlike the British, Fokker was not misled by wishful thinking. If O’Gorman thought stability a fine idea, interrupters mounted in the right aircraft would soon change his mind. As for the right aircraft, Fokker pushed for all-out maneuverability – wanted were aircraft with the ability to stunt their way into a dominant shooting position. He was content to counter the enormous BE2c horizontal tail with the E-III’s much smaller unit.11 At a time when stable designs12 were usually given a tail size equal to 16% or more that of wing area, the BE2c13 was granted 17%, while the FE2b14 tail area was set at 17.3%, Fokker’s unstable E-III15 was given less than 12%.

Once committed to a demanding aircraft and a hard working pilot, other design decisions fell into place automatically. The aileron versus warp choice that had proven so difficult for the BE2 and O’Gorman led to a very different solution: Fokker chose warp. As always, his case was logical.

The E series monoplane wing would necessarily be of greater span than the same area, arranged in biplane form. When warped, the planned longer wing resulted in less drag than an equivalent shorter wing biplane, employing ailerons.16 The superior wing efficiency – i.e., less drag – resulted in a pro-warp decision. As for those special warp drawbacks – a sensitivity to gusts producing an ever-moving control stick, along with an increase of piloting load – these counted for little in Fokker’s planning. Combat effectiveness ruled. Better low drag than a genteel machine.

When all was done and the E-III emerged, foreign designers were not impressed. Contempt prevailed, guided by the “not invented here” philosophy. For example, one important change introduced by Fokker was the substitution of steel tubes for wooden members. Not only the fuselage, but much of the wing and all of the tail and rudder were fashioned of steel. As compared to the usual improperly dried wartime lumber, steel tubes represented a tremendous advance in strength and durability. Yet one British review saw only drawbacks; for example, the kinking of a tube by the dropping of a heavy tool when under construction and subsequent failure in flight, or even disaster caused “by a misstep when the machine is on the ground.”17 It would take much war service before British designers conceded the virtues of steel tubing over wood.

Posing for official photos, its simplicity of line is striking. Note the “yardstick.” Source: Illustrierte Flugwoche, February 1927, Illustrations #14 & 15.

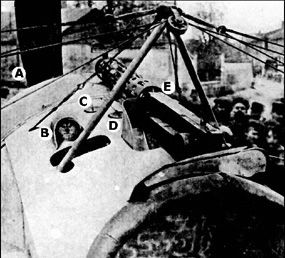

A French crowd examines a downed aircraft. Details: (A) propeller; (B) fuel gauge; (C) oil filler cap; (D) fuel filler cap; (E) machine gun. Source: L’Aérophile, August 1917, p.279.

To some French engineers, having the pilot shoot by pointing his entire machine seemed a poor idea. After all, “the pilot who was also the gunner, aimed not with his gun, but with his whole machine, which makes the task all the more difficult.”18 Experience would prove exactly the opposite to be true: aiming a gun by directing its surrounding airplane is a perfectly natural process. Though many sought profit by shooting from flexibly mounted guns aimed at an angle to the airplane’s own flight path, accuracy proved extremely difficult; few men and gun sights had the necessary ability. Aiming with the whole machine won out easily.

With the E-III in small lot production, machines began to arrive at the front in mid-1915. There were difficulties and hesitations in its use. The engine was still the 80 h.p. version and not the promised 100 h.p.. Secondly, interrupter use forced a reduction of the machine gun firing rate from a basic uninterrupted cyclic rate of 600 rounds per minute to a safe but sluggish 400.19 Was this modestly powered and slow shooting machine capable of effective fighting?

Among those assigned the early version was Oswald Boelcke, a German frontline pilot with a history of successful two-seater shooting encounters. At a time when all air combat knowledge was slight, Boelcke accepted his ignorance with a shrug and addressed his new machine’s employment with a rare combination of energy and thoughtfulness. His E-III experience would serve to write the book that defines air combat. He not only spelled out air fighting’s internal rules, but taught them to beginners – including Richthofen.

Left and right straps secured the control stick when parked. Details: (A) control stick; (B) shock cord to restrain landing gear; (C) gun trigger; (D) blip switch; (E) tachometer. Source: L’Aérophile, August 1917, p.278.

For example, in order for fighting in the air to occur, it’s necessary for the aggressor to fly at a speed sufficient to overtake his adversary.20 Only the faster machine’s pilot can decide: yes, I will fight, or no, I will flee. The slower machine offers its pilot no choice. At issue is not only the usual horizontal speed, but vertical speed as well, for it is possible to flee by climbing away, or even by diving away from an opponent. In short, combat can be ordered only by the pilot who has the necessary performance edge on hand. This basic rule is logical and was obvious at the time. For those lacking in performance, the design of combat tactics – especially aggressive tactics – was a matter of defying common sense; of substituting shrewd schemes for the rules. Fabricating successful schemes became Boelcke’s role.

He realized that one way to achieve that necessary edge in speed was by diving. If sturdy and unstable, a slow airplane could be dived at a steep angle, quickly building up speed. Achieving a high velocity, the aggressor aircraft could be leveled off within shooting range of its target. Using its momentum, the attacker could then easily dominate its prey. Should the attack fail, there was a fair chance of repeating the event-first climbing, and then diving as before.

As Boelcke and his protégé Max Immelmann worked to perfect the sequence, they realized that there were other advantages to the scheme. For one, there was the matter of unlikely or late detection by their prey: mostly artillery observation or photo reconnaissance machines. In performing their task, the French or British aircrew looked downwards as they searched for frontline positions, artillery strikes and mapped check points. Looking upwards was something done occasionally and reluctantly. In time the enemy would learn to reverse his priorities, but until then a diving attack from higher altitude – typically 2000 feet higher and of a dozen seconds duration – was unlikely to be detected until too late for an effective response.

The dive granted the E-III attacker another odd virtue: it made his nationality uncertain. Carefully painted with German insignia, E series wings and fuselage crosses seemingly offered clear identification. However, diving put the aircraft into a largely “head on” attitude, where no insignia could be seen by the prey. Instead of an E-III, target crew-members detected what appeared to be a French Morane-Saulnier aircraft complete with its well known monoplane wing and unusual nose. The first mention of the E-III in an official RFC communiqué (August 22, 1915) noted this very problem: “ … the observer mistaking the machine for a Morane did not fire … ”21 No easy solution would emerge. Fokker’s borrowed format was not only aerodynamically sound, but offered a “wolf in sheep’s clothing” form of disguise as well.

As for the shooting itself, when should it start? If used in the dive, it would likely alert the prey. Was the probability of success while diving high enough to warrant the risk of early disclosure – and possible escape by the prey?

The chances of hitting the target aircraft while diving were poor. Making for difficulty was the target’s own speed and trajectory. It was necessary to aim well ahead of the target to get a hit – perhaps 30 feet ahead – and to continuously change the center of aim as the dive proceeded. Bringing this off correctly was most unlikely. Yet despite the odds, there were hits. These resulted, not from brilliant shooting, but from the enormous scatter produced by airborne machine guns. The soft, springy mount offered by wings and air yielded a spread of bullets so great that the possibility of a hit, no matter how unlikely, could well occur.

As the working rule governing shooting in a dive, E-III fighter pilots learned to start shooting when the supply of bullets on hand was large, and the enemy clearly aware of one’s presence, as proven by a sudden change in position or flight path. In these circumstances, there was little to lose by shooting. However, if only a few bullets were on hand, or should the target aircraft seem oblivious to the impending attack, it was better to hold off shooting in favor of the flattening out, closing-in period following the dive. Shooting then offered a much higher probability of a hit.

A Deliberate Widening of the Pattern?

An erroneous German explanation of the too wide bullet dispersion produced by diving E-IIIs. Source: Die Luftflotte, September 1916, p116.

Effectiveness was generally ignored by those with an ample supply of bullets. In the early days of the E-III, some dove repeatedly, saturating the air with bullets sent towards a remote target – a tactic seen as both safe and acceptable. Coming from a single gun, expenditures of 300 to 400 rounds per engagement were known, with total shooting times approaching the best part of a minute in duration. Puzzled British on the receiving end of far too scattered a set of bullet sprays believed they resulted from deliberate E-III pilot action; i.e., pilots hoping for a hit were slamming tail and rudder controls back and forth to spread the gun pattern. In reality the huge dispersion was inherent in shooting from a light aircraft at a great range. Research would yet show that on a bumpy day, at a reasonable range, an airborne Vickers machine gun placed its bullets anywhere within a huge circle, one larger than a wingspan in diameter.22 Rather than working to increase the pattern’s size, E-III pilots needed the opposite: some means of reducing the dispersion. Their only effective solution was to decrease range. This was accepted reluctantly owing to the obvious catches: shortening the range meant that fewer bullets could be fired by an overtaking, speedy aggressor and also made it easier for the enemy to strike back accurately.

Even as Boelcke and Immelmann struggled to optimize Fokker’s weapon, Anthony worked to improve the breed. The 100 h.p. version was delivered at last. Next, company representatives went to the front to upgrade the interrupter with the latest improvement: a restoration of the pre-interrupter Maxim type machine gun firing rate of 600 rounds per minute. Suddenly the E-III was both speedy and powerfully armed.

Anthony himself appeared at the front to serve as a demonstrator, and equally important, to make friends for his company. A superb stunt pilot, he put on a striking show guaranteeing immediate acceptance. Then, to assure future respect, there was always a bribe. In the case of Immelmann, Fokker’s offer took the form of a post-war job as an engineer, complete with a personal cut for every machine sold.23 A suspicious Max was reassured when the offer was repeated before witnesses. From Anthony’s point of view, it was worthwhile – a generous offer might prevent public damning of those inevitable Fokker lemons that came Immelmann’s way.

And lemons there were. One grew from the attempt to stack two standard 80 h.p. rotaries into a package yielding 160 h.p.; a premise that excited Fokker as well as O’Gorman. It seemed the perfect replacement for the E-III’s original, too modest engine. Offered was not merely a boost, but a truly commanding amount of power, neatly contained within a lightweight package format. The resulting machine would not only be faster but could carry two guns, and just possibly three.

The usual rotary pluses and minuses were expected to continue, as usual. Yes, gyroscopic forces would be larger, but Anthony was unconcerned. Pilots would cope. They always had. True, there was another force issue as well – engine torque effect – but here too, Anthony was confident. Wasn’t this just another standard piloting problem, warmed over?

Every engine must generate sufficient torque – or twisting action – to drive its propeller. The aircraft reacts oppositely to the torque, employing its ability to roll as a means of action. For conventional engines, aircraft tend to roll left wing down as seen from the pilot’s seat. Control was easy; a matter of warping a bit more lift into the left wing and using some rudder to counter the resulting yaw. For experienced pilots, then and now, the corrective process was automatic. However, complications arose from one of the rotary engine’s advantages – use of a blip switch.

Both an innovator and scoundrel, he did much to shape Great War air combat. Source: Flight, November 2, 1916, p.963.

The rotary lent itself to a temporary halt in the delivery of power. A simply cut in ignition would do. It then coasted. The huge momentum – all those spinning cylinders – made it easy to start up again. As gas vapor continued to enter the cylinders while coasting, merely turning on the ignition was enough to produce full power. After a few barks and misfires power was restored, and all was as before. This method of temporarily cutting power had tactical merit. In a diving attack, if coming in too high, simply hitting the switch; i.e., “blipping” it off and on, served as a delicate means of altitude control. If under attack, blipping the switch could reduce height quickly, fooling enemy gunners. In landing, if coming in too high, blipping was the easiest and quickest way of reducing altitude. So important was the blipping function that the E-III’s blip switch was placed immediately above the trigger at the top of the control column, in easy reach of either thumb.

As always, there was a price. With the ignition cut and the engine coasting, engine torque was no longer developed. Yet the controls, previously set, continued to generate a corrective roll – a roll suddenly unwanted. Fortunately, the undesired roll was small and the pilot could easily intervene – unless he was saddled with an engine twice as powerful as the usual. Then he was faced with a problem. Even so, the difficulty could be handled. However, there was another problem as well.

Those gyroscopic forces developed with the massive rotating engine were also proportionally greater. Matters reached a point where Boelcke found it necessary to work the blip switch, cutting RPM, in order to make a sharp turn.24 Only by doing so was he able to control the gyroscopic forces liberated by the turn. However, working the blip switch unleashed the torque imbalance. He then had two nasty control forces to regulate. In an airplane intended for ordinary wartime fliers, this wouldn’t do; the combination of torque and gryroscopic force problems was too much. The 160 h.p. E-III was dead.

Even so, the 100 h.p. version was very much alive. General von Hoeppner’s E-III summary was fair: “The first real combat plane … an extraordinary gain in speed, maneuverability and ceiling … a terror to our foes.”25

There was another novel tactical aspect to E-III employment. With the fate of Garros and his deflector secret still fresh in German Air Service thoughts, steps were taken to prevent a repetition with the interrupter. Von Hoeppner noted: “ … in order not to fall into the hands of the enemy [the E-III was] ordered not to fly over the hostile front.”26

This prohibition produced a combat-free sanctuary for British and French aircraft, starting at the frontline and extending homeward. Ending of pursuit by E-IIIs at the frontier pushed both sides into altering tactics. British fliers had been granted a useful, safe zone; and the Germans sought to prevent entry.

Boelcke’s basic prey, Allied observation aircraft, made full use of the new incentive, usually fleeing when up against the E-III. Their departing move came as a dive, serving to increase speed while heading for home. Once reaching the frontline vicinity, some Allied pilots would even shut down their engines and glide to a forced landing on the safe side of the lines.27 Though an inglorious end, those who felt they had no chance preferred it to trading bullets.

As E-III pilots learned to use their aircraft for shooting, fleeing from them became ever more difficult. Testing many shooting attitudes and positions, Boelcke realized that the best was located 50 meters behind, and directly in line with his prey.28 Once in this spot, no aiming corrections were required for the speed or trajectory of his enemy. So close a range meant that allowing for bullet drop owing to gravity was unnecessary. Indeed, no special gun sight settings of any kind were needed. He simply fired, much as in the practice gun pit at the home field. If this sweet ‘50 and behind’ position could be held and enough bullets fired, the result was an almost certain victory.

Allied pilots reacted with new emphasis upon maneuver, hoping to shake any pursuing E-III. However, the Factory’s BE2c was too loaded with stability genes to maneuver quickly. An E-III pilot in a trailing position could read BE2c tail and rudder movement signaling a new maneuver to come. Able to predict the BE2c’s next move, and blessed with a fast maneuvering machine, E-III pilots were not easily shaken off.

As for the basic performance figures, all the numbers favored the E-III. A captured E-III was found able to climb to 6500 feet in 13 minutes; a task requiring 20 minutes for the BE2c.29 Once there, maximum speed equaled 83 mph for the E-III, while the slower BE2c achieved 72 mph. In short, pushed into combat, the BE2c had no easy way out. It couldn’t speed away, climb away, or dive away from a determined E-III. Something else was required. Interest focused upon a better means of shooting.

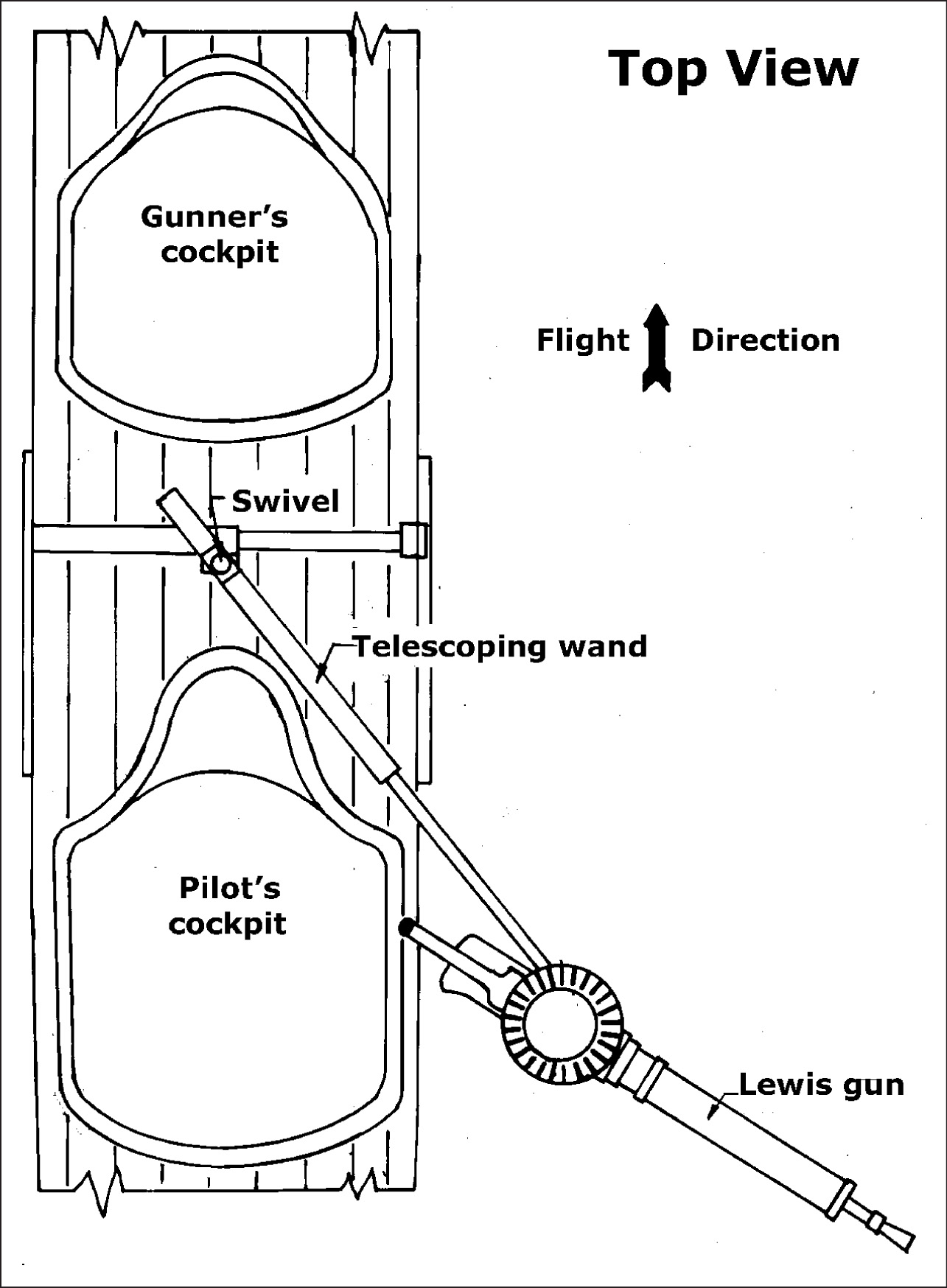

Factory engineers worked up new schemes for shooting backwards. Their design goal: blasting any E-III holding a trailing position. The BE2c had always been armed with a single flexible Lewis machine gun. The task was to make the gun potent. One approach was to improve the old mount system consisting of a group of small pylon tower supports surrounding the gunner/observer cockpit, front and back, into which the gun could be dropped as required. Rearward fire deserved something better–a smoothly moving swivelling mount controlling shooting.

BE2c Rearwards-Firing Gun Mount

Kneeling on his seat, the gunner fired to the rear, immediately over the head of the pilot. Source: Original sketch by author from Royal Aircraft Factory working drawings, dated Aug. 1915; TNA file #AVIA 14/5/1/67.

The improvement achieved was one of better gun balance and diminished vibration and creep, useful in achieving long range accuracy. Even so, rearwards shooting remained sadly inaccurate. The gunner faced backwards, kneeling on his seat, with his upper body exposed to propeller blast. Constrained by struts, wings and the pilot, his vision was limited. He fired immediately above the pilot’s head, knowing that a moment of carelessness would put bullets into his own rudder. When used at maximum elevation against diving E-III’s, proper gun sight alignment required the gunner to drop to the cockpit floor. In this position, he was blind to events occurring anywhere other than high above his aircraft.

In addition to these drawbacks of apparatus, the BE2c gunner’s task was inherently more difficult than shooting from an opposing E-III. As we’ve noted, shooting with the E-III’s gun bolted down along the aircraft axis eliminated any need for correction of aim owing to gun angle. Bullet direction was roughly the same as aircraft direction. Not so, for the BE2c’s rear gun. Unless corrected, when shooting at a diving E-III with the observer’s gun set at high elevation angle, serious aiming errors resulted – errors of roughly 40 feet at a range of 250 yards. In theory it was possible to apply gunsight corrections eliminating the error; however, the lack of time and continuously changing size of the correction made elimination in practice most unlikely.

Added to the above error – that resulting from angled fire – was a second major error, that resulting from guesstimating the necessary lead, or the moving target error. We have seen this problem before from the vantage point of diving E-III pilots, facing the likelihood of 30 foot errors in predicting target position at the time of bullet strike. BE2c gunners were faced with similar uncertainty as to target location a second or two after firing – when their bullets arrived. Merely aiming at what could be seen wasn’t good enough and applying the right amount of correction was a fine art that few possessed.

BE2c pilot and gunner employ a single Lewis by sliding it back and forth on a telescoping wand, while turning it about a swivel. Source: Original sketch by author from Royal Aircraft Factory drawings; TNA file # AVIA 14/5/2/26.

All things taken together, the odds heavily favored the accuracy of the E-III’s fixed Maxim over that of the BE2c’s flexible Lewis gun. As given by Canadian fighter pilot Captain Vivian Voss in 1918, “ … the observer’s [flexible] gun was never so deadly as the pilot’s [fixed] gun.”30 Much combat experience was summed up in Voss’s simple conclusion. However, in 1915 the issue was still uncertain. To some, there seemed a winning chance for a flexibly mounted Lewis, if given the right gun mount design. Factory engineers tried again.

The resulting telescoping, swiveling mount was a most ingenious arrangement offering a gunning partnership to a pilot and observer. Each could shoot the same gun, passing it back and forth as required. For the pilot to seize the gun and fire, use was made of the BE2c’s inherent stability, with the pilot simply releasing the controls when necessary. No solution was offered to the flexibly mounted gun’s sensitivity to angular directional error. If anything, the likelihood of angular use – and error – was increased by the arrangement. Furthermore, there was no shortage of Lewis guns and no real need to share a single gun. Standard wartime practice was to carry two guns.

One real advantage was offered. When used as a bomber, the BE2c carried too few bombs to yield much profit. To increase bomb load, it was necessary to fly without a gunner; i.e., the pilot flew alone. Before the E-III, with air combat rare, this procedure worked well. However once the E-III arrived, survival without a gunner became unlikely. In the cautious judgement of General S. Brancker, any BE2c lacking a gunner became “a somewhat easy prey for the Fokker.”31 A less reserved view would label the defenseless BE2c to be a perfect target. Resentful BE2c pilots knew this – they spoke of themselves as “Fokker fodder.”

The telescopic mount offered BE2c pilots without gunners a chance. If sufficiently dextrous, the pilot himself could shoot to the front oblique, or to the rear, or laterally. However, in reality the device was not widely employed. Experience soon produced a better solution in the form of dedicated fighting aircraft, serving as bomber escorts for BE2c’s. The telescopic mount signaled a desperate reaction to E-III use, but one with little real world effect.

In late 1915, with BE2c combat limitations clear, the RFC put its faith in dedicated fighting aircraft to end the E-III menace. However, the need for many BE2c’s continued; aircraft required to fulfil the observation/cooperation role. Whatever the doubts about the BE2c, it was in mass production and available in quantity. These machines were entitled to self-protection. Bowing to the pressure, a simple rear mount was found acceptable. So armed, the BE2c was to soldier on throughout the war.

The decision was not heartless. Many things other than accurate shooting count in deciding air war victory. As compared to the E-III, the BE2c’s engine was more reliable. The BE2c’s Lewis gun was without an interrupter and so incapable of berserk interrupter defects, such as shooting off one’s own propeller blades. Certainly the piloting burden of the stable BE2c was much lighter; a feature useful in getting the job done despite inadequately trained pilots, or with pilots suffering the oxygen deprivation of high altitude. As for shooting and self-defense, a BE2c with a good, alert gunner on board was not easy prey.

Consider the events of December 29, 1915.32 Two BE2c machines were sent to Cambrai, France. One was to serve as a reconnaissance machine, the other as a fighting escort. Two Fokkers were there, waiting. Their standard diving attack followed, centered on the reconnaissance machine. It was shot down on the first try. The Fokkers then turned upon the escort, attacking from the rear. The BE2c gunner bounced some tracers off one E-III that simply dived away, out of sight and action. However, another pair of Fokkers soon arrived and the battle odds against the BE2c increased to three against one. Though both of the BE2c’s Lewis guns were used, resulting intermittent jamming and desperate, fumbling clearing attempts acted to reduce return fire. Fleeing towards the frontlines the BE2c dumped altitude, diving as best it could, trying for a bit more speed and reaching for a height so low that the Fokkers would be unable to employ their standard diving attack. At times flying at an altitude of 15 feet, the BE2c fought off the E-IIIs for more than 20 minutes, finally crossing the lines to safety.

The incident showed the BE2c at its best and worst. In the first attack, the single machine working at reconnaissance was caught out by surprise. Its escort could do nothing. In the second, the fully alerted and determined escort defended itself in fine fashion. Given adequate warning, the BE2c could put up a sturdy fight. While in no sense an air superiority fighter, neither was it doomed to become “Fokker fodder.” Much depended on the BE2c’s use, aircrew skill – and operational luck.

Most BE2c trauma resulted from the efforts of Boelcke and Immelmann. Their tactical work had gone well. Not only were there many victories, but important lessons were learned and passed on to fellow fighter pilots. For example, repeated tries convinced Boelcke that a face-to-face or head-on shooting approach was ineffective. 33 He learned that head-on closing speed was so high that too few bullets could be fired before it was necessary to turn away from the target, preventing collision. The numbers supported him. Opening fire at 250 yards permitted the firing of less than 30 bullets before survival itself demanded taking evasive action. To Boelcke, whose combat encounters frequently required the firing of hundreds of bullets, 30 wouldn’t do. Something better than head-on combat was necessary. What?

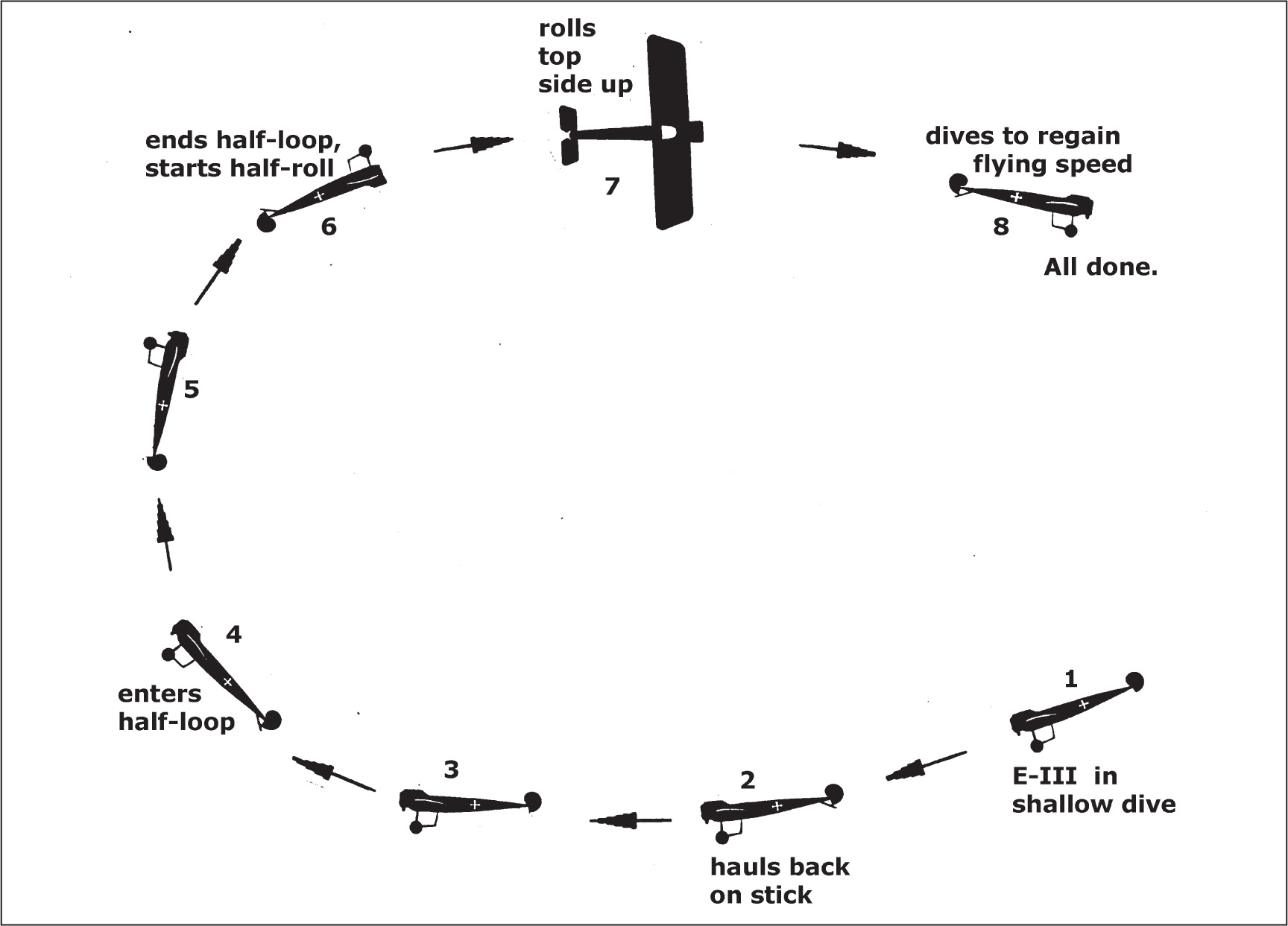

The diving form of attack was indeed superior to head-on. Among its virtues was a relatively slowly changing event yielding a longer shooting opportunity and a reduced likelihood of collision. However, the shooting dive lacked a good second act. If the prey survived, a circling contest usually followed with no certainty as to who would win – certainly an acceptable business, but one lacking in tactics assuring victory. In a few weeks of trial and error, Immelmann evolved a promising second act possibility: a maneuver leading to a repetition of the original diving attack.

Consider a diving attacker at the end of his run, as below. His excess speed is easily converted into a half loop. Once on his back, he rolls right side up. He need only dive slightly to restore flying speed. Altitude has been increased by some hundreds of feet, permitting a new diving attack. The process could be repeated as often as desired.

This maneuver could add altitude quickly; useful in preparing for a diving attack. Source: Original sketch by author.

A Variation on Immelmann’s Theme

Shallow diving aircraft (1) half rolls and zooms (2), then does an inverted half loop (3,4) to end the maneuver in a shallow dive (5). Source: Aerial Age Weekly, June 24, 1918, p.727.

There were drawbacks. For one, low powered aircraft such as the E-III required considerable time to execute the Immelmann Turn maneuver. In the interval, the designated prey was free to flee and, having been given full notice by the initial diving attack, would do its best to escape. In contrast, the aggressor machine completing its Immelmann Turn would find itself facing the wrong way and was many seconds behind, requiring a 180 degree turn and then much catching up in order to attack. If his machine wasn’t speedy, the chance was lost. Another drawback were the high wing loadings developed in the loop and roll – an Immelmann Turn was not to be undertaken with a damaged machine – an awkward requirement, for in the midst of combat, pilots had no way of assessing existing fresh damage.

Seeking improvement, other versions of the Immelmann came into existence. One variation taught to USA pilots in 1918 was based upon rejection of the diving attack, and instead the substitution of upward shooting. The shooting dive did have a major inherent disadvantage: directed against two-seaters, attacks were likely to be countered by alert gunners. Shooting upwards was safer, for it offered access to the enemy’s unprotected underside. In the variation shown, upward shooting was to occur at about position 2. A net gain in altitude wasn’t the goal, and even a loss was acceptable. Experience proved the maneuver itself to be useful, even when performed without a target. Its twisted path made pursuit difficult, and the directional change was frequently that sought. This variation became a useful part of the fighter pilot’s repertoire, and went on to acceptance by British WWII leading ace Johnny Johnson as the true Immelmann Turn.34

Sound Boelcke and Immelmann tactics led to growing British casualties. By the end of 1915 losses were disturbingly large; large enough to give the British sensational press an issue: that of a “Fokker Scourge” decimating Allied aircraft. With nearly 50 pilots and observers lost in a two-month period35 (early November 1915 through early January 1916) something new in the way of British tactics was essential.

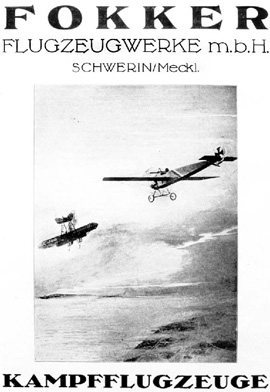

Flying Gun’s Advertising Debut

An E-III downs a Farman 20 in Fokker’s announcement of his new weapon. Source: Deutsche Luftfahrer Zeitung, January 1916, p.24.

Politicians reacted with comforting half-truths and lies. Under-Secretary for War H.J. Tennant admitted to a certain success by the Fokker, but noted its serious disadvantages. For one, it was incapable of crossing over the frontlines because its tiny fuel allowance made it unable to spend much time in the air – this was nonsense, but pleasing nonsense. As for the main duties of military aircraft; i.e., reconnaissance and artillery guidance, he saw the single-seater machine as obviously unsuitable and therefore not much of a war machine. Not so; it was simply another, novel type of war machine; one concerned with different goals. Finally, concerning the heavy British losses: “the Germans can hide their own whilst advertising ours … my military advisors are satisfied that our Flying Service has given a good account of itself in recent fighting.”36

The awkward fact was that losses were indeed severe. As most casualties consisted of reconnaissance aircrews surprised in ambushes, RFC General Hugh M. Trenchard ordered escorts for all reconnaissance flights. These were to consist of a minimum of three fighting machines for every reconnaissance machine.37 If this meant many fewer frontline missions, so be it.

In turn, Boelcke and Immelmann were faced with a new problem: fighting against enemy formations. Moving into spring 1916 they grappled with many new issues, from the aging of the once dominant Fokker, to questions of Air Service staffing and aircraft types suited for a tremendous expansion of size of fighting units. There were new fighter aircraft to be assessed and many new pilots to instruct in the tactical arts. For example, there was Baron Manfred von Richthofen, a tyro fighter pilot of uncertain merit.