WHAT IT TAKES

Time: 1–4 hours

Skill level: Beginner

WHAT IT TAKES

Time: 1–4 hours

Skill level: Beginner

Wire shelving is popular because of its price, flexibility and ease of installation. Wire shelving can be designed to meet almost any need at a fraction of the cost of a custom built-in system. And while installing wire shelving isn’t quite a no-brainer, you don’t need to be a master carpenter or own a fully equipped cabinet shop to get it done. We picked the brain of a pro for these tips to help you on your next installation.

Buy extra pieces

Even if you’re just planning to build one closet shelf, have extra parts on hand. It takes a lot less time to return a few wall clips than it does to stop working to make a special trip to the store for just one. And plans change, so if you decide to add a section of shelving, you’ll be prepared.

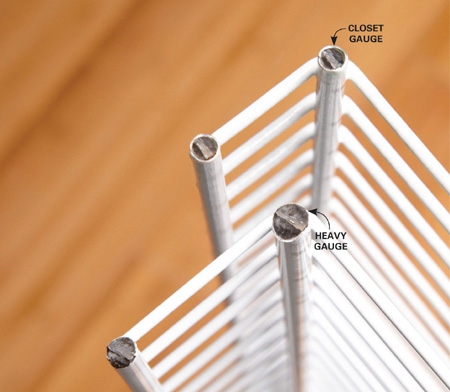

Leave the heavy stuff for the garage

For residential jobs, standard wire shelving sold at home centers works fine. Most manufacturers make a heavier-duty product for garage storage, but the regular stuff is plenty strong for the average bedroom, pantry or hall closet. However, if you’re going to store a bowling ball collection, you may want to consider upgrading.

Lay it out with a bubble stick

Use a bubble stick rather than a level. A bubble stick is like a ruler and a level rolled into one. Holding a level against the wall with one hand can be frustrating. Levels are rigid, and they pivot out of place when resting on a stud that’s bowed out a bit. A bubble stick has a little flex, so it can ride the imperfections of the wall yet still deliver a straight line. You can get one online.

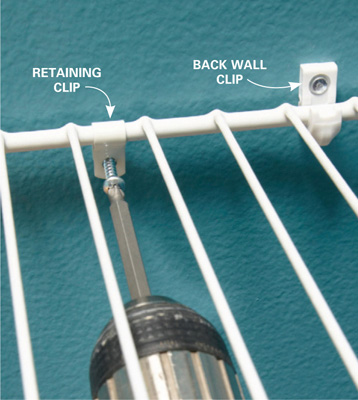

Avoid upheaval

Back wall clips are designed to support the shelf, but if there are a bunch of clothes hanging on the front of the shelf with nothing on top to weigh them down, the back of the shelf can lift. To keep the shelf in place, install a retaining clip in a stud near the middle of the shelf. One clip toward the middle of an 8-ft. shelf is plenty.

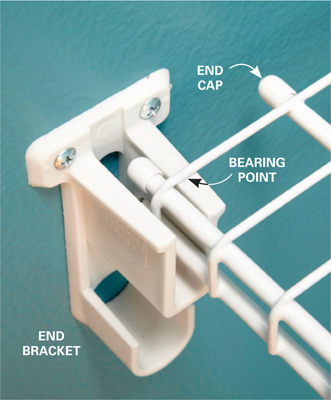

Use a template on the end brackets

The pro template used here has a built-in level and allows you to drill the holes without marking them first. At about $200, this is for people who do lots of closet shelving. But if that’s you, it’s a great investment. You can order one from your local shelving dealer.

Measure an inch short

When cutting the shelf, measure wall to wall, and subtract an inch. This allows for the thickness of the end brackets plus a little wiggle room. It’s the top, thinner wire that actually supports the shelf, and one wire per end is enough. Cutting exact lengths will only earn you wall scratches and a trip back to the cutting station.

A bolt cutter works best

Cut your shelving with a bolt cutter. It’s quick and easy, and it makes a clean cut. To make room for the cutter, use your feet to hold the shelving off the ground.

Space the angle brackets evenly

Consider aesthetics when installing angle brackets. If a shelf only needs one bracket, find the stud closest to the center. If two or three brackets are required, try to space them evenly, making sure that at least one bracket toward the center is hitting a stud.

When installing wire shelving in pantries, it’s a good idea to cap the top of the shelves with white 1/4-in. pegboard. This stops the skinnier items from tipping over. Use white zip ties to hold the pegboard in place. Find 4 x 8-ft. sheets at home centers.

Hanger sliding freedom

One common complaint about wire shelving is that it restricts the movement of the hangers because the hangers are stuck between the shelves. To avoid that, upgrade to a hanger rod. Most manufacturers make some version of one. A hanger rod allows clothes to slide from one end of the closet to the other, even past an inside corner. This upgrade will add about 30 percent to the cost of the materials on a standard shelf design. Make sure the type of shelving you buy will work with the hanging rod hardware you plan to use.

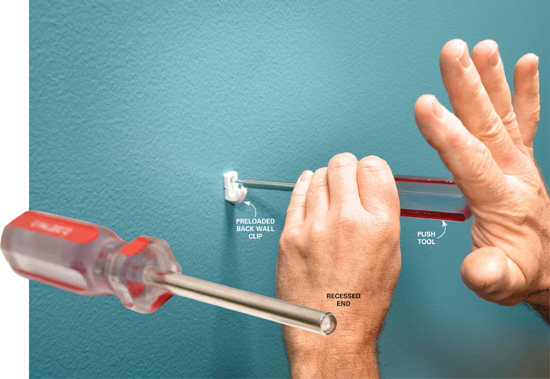

Back wall clips don’t need to hit studs

It may go against your every instinct, but hitting a stud when you’re installing the back wall clips slows the process down and isn’t necessary. After marking locations, drill a 1/4-in. hole and pop the preloaded pushpin in with a push tool. The push tool has a little indentation in the tip that won’t slip off the pin when it’s being set in the drywall. The occasional wall clips that do land on studs need to be fastened with a screw instead of a pin. You can order a push tool from your local shelving dealer.