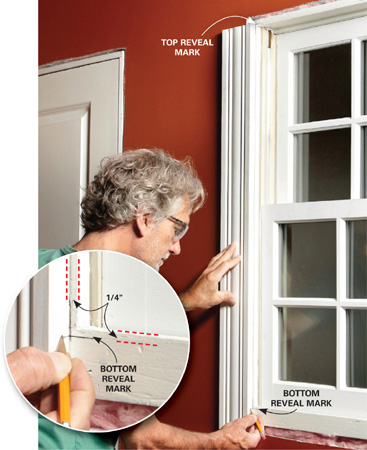

1 Mark the side casing. Cut one end of the casing square. Line up the cut end with the pencil mark indicating the 1/4-in. reveal and mark the opposite end for cutting. Cut and install both side casings, keeping them aligned with the reveal marks.

1 Mark the side casing. Cut one end of the casing square. Line up the cut end with the pencil mark indicating the 1/4-in. reveal and mark the opposite end for cutting. Cut and install both side casings, keeping them aligned with the reveal marks.

2 Install the stool. Cut the stool so that it extends an inch past the casing on both ends. Then round the edges with a router or by sanding. Nail the stool to the side casings.

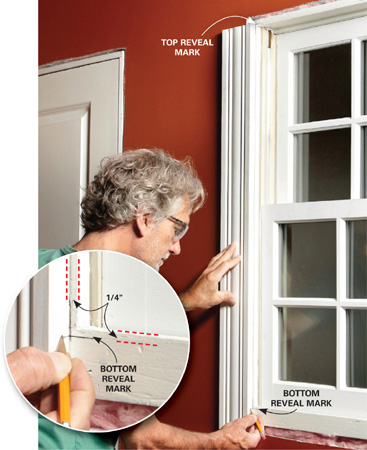

3 Cut the mitered apron returns. Set the miter saw to 45 degrees and cut a return from the apron molding. Use a sacrificial board to prevent the small cutoff from flying through the gap in the fence. Set the miter saw to the opposite angle to cut the other return from the opposite end of the molding.

4 Finish the apron. Glue in the returns to complete the apron. Avoid nailing problems by letting the glue do the work. Just hold the return in place for 60 seconds while the glue grabs.

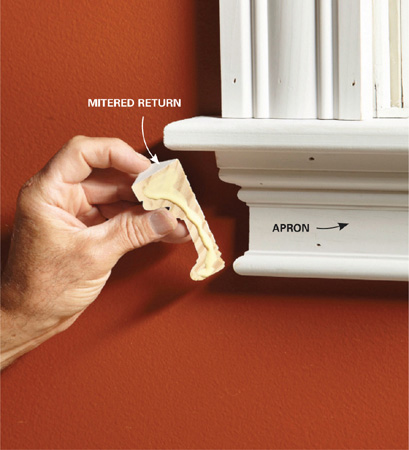

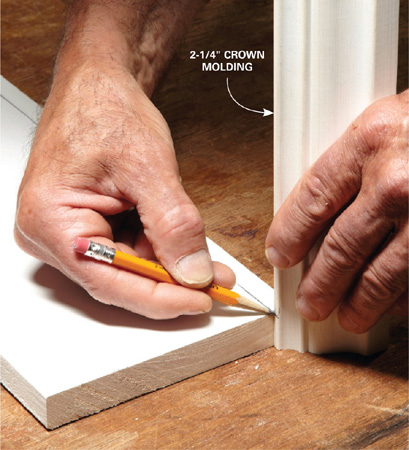

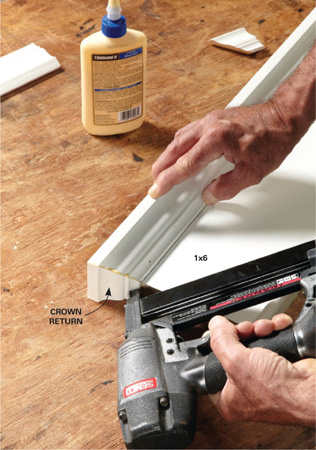

5 Mark the crown molding for the end return. Hold a piece of crown molding against the 1x6 you’ll be using for the head casing and mark it for cutting.

6 Build a crown-molding jig. Build a simple jig to hold the crown molding at the correct angle while you cut it. Position the molding upside down and set the saw to 45 degrees. Avoid cutting all the way through the jig.

7 Mark the front crown molding. Cut a miter on one end of the front crown molding. Line up the cut with one end of the head casing and mark the opposite end for cutting. Set the molding in your jig and cut the opposite miter.

8 Attach the molding to the head casing. Nail the crown molding to the 1x6. Then glue and nail in the end returns. Nail the fillet to the bottom of the 1x6 to complete the head casing assembly.

9 Finish the window trim. Set the head casing on the side casings, making sure the fillet overhangs evenly on both ends. Then nail it to the wall framing.

Doors are similar

Buying nail guns

Hide the nail heads