3

CHAPTER

Tools Needed for Installation and Repair

A basic knowledge of hand tools, electrical tools, and test meters is necessary to effectively complete most installations and repairs. This chapter will cover the basics of each tool. A working knowledge of these tools is a must for the installation and repair of appliances and air conditioners. Always follow safety precautions and manufacturer’s recommendations and warnings when handling tools.

Before starting on any type of repairs, take the time to put together a toolkit with a selection of good quality hand tools. A partial list of common hand tools includes:

• Screwdrivers A complete set of flat-blade screwdrivers, ranging from 1/8 inch to 5/16 inch. Handle sizes may vary with the blade dimension. Phillips-tip sizes also vary; the two most common are #1 and #2.

• Nut drivers A complete set is recommended. The common sizes are: 3/16, 1/4, 5/16, 11/32, 3/8, and 1/2 inch.

• Wrenches

• Socket wrenches Either 6-point or 12-point, ranging in size from 5/32 to 1 inch.

• Box wrenches Common sizes range from 1/4 to 11/2 inch.

• Open-end wrenches Common sizes range from 1/4 to 15/8 inch.

• Adjustable wrenches The handle size indicates the general capacity. For example, a 4-inch size will take up to a 1/2-inch nut. A 16-inch handle will take up to a 17/8-inch nut.

• Allen wrenches Sizes range from 1/16 to about 1/2 inch.

• Claw hammer

• Adjustable pliers

• Flashlight

• Drop-cloth

Safety Precautions

Safety starts with accident prevention. Listed in this chapter are some tips to help the technician when using hand and power tools.

WARNING Any person who cannot use basic tools should not attempt to install, maintain, or repair any major appliance or air conditioner. Any improper installation, preventative maintenance, or repair creates a risk of personal injury and property damage.

Individual Safety Precautions

Injuries abound when using tools. To be protected from injuries when using hand tools and power tools, do the following:

• Wear gloves.

• Avoid wearing loose clothing when working with power tools.

• Wear safety glasses to protect the eyes from flying debris.

• Use tools according to manufacturer’s specifications, and never alter their use.

Safety Precautions When Handling Tools

Regardless of which tool is being used, these same rules of care and safety apply:

• Keep tools clean and in good working order.

• Use the tool only for jobs for which it was designed.

• When using power tools, be certain that the power cord is kept away from the working end of the tool.

• If the tool has a shield or guard, be sure it is working properly and remember to use it.

• If an extension cord is used, be sure it is in good working order. Do not use it if bare wires are showing. Also, use a heavy-gauge wire extension cord to ensure adequate voltage for the tool being used.

• Be sure that the extension cord is properly grounded.

• Grip the tool firmly.

• Never use worn-out tools. A worn-out tool has more potential for causing injuries. For example, with a worn-out screwdriver, there is a greater possibility for slips, which could make medical attention necessary.

• If there is a problem with a power tool, never stick your fingers in the tool. Unplug it first, and then correct the tool’s problem.

• Make sure to use insulated hand tools when working with electricity and electrical components.

Screwdrivers

A screwdriver is a hand tool used either to attach or remove screws. The two most common types are the flat-blade and Phillips. The flat-blade screwdriver is used on screws that have a slot in the screw head (Figures 3-1 and Figure 3-3). The flat-blade screwdriver is available in many sizes and shapes. Always use the largest blade size that fits snugly into the slot on the screw head so that it will not slip off the screw. The screwdriver should never be used as a pry bar or a chisel; it was not designed for that purpose.

FIGURE 3-1 Flat-blade screwdriver.

FIGURE 3-2 Phillips screwdriver.

FIGURE 3-3 Combination screwdriver set.

A Phillips screwdriver is used to attach or remove screws that have two slots crossing at right angles in the center of the screw head (Figures 3-2 and Figure 3-3).

When using a Phillips screwdriver, exert more pressure downward in order to keep the tool in the slots. Always use the largest Phillips size that fits snugly into the slots, just as with the flat-blade screwdriver.

Never use worn-out screwdrivers when working on appliances. A worn screwdriver may damage the head of the screw. It can also damage the product on which you are working.

Nut Drivers

Many manufacturers use metal screws with a hexagonal head. A nut driver is a hand tool similar to a screwdriver, except that the working end of the driver is hexagonal-shaped and fits over a hexagonal nut or a hexagonal bolt head. Each size nut requires a different sized driver (Figure 3-4).

FIGURE 3-4 Hex-nut drivers.

Wrenches

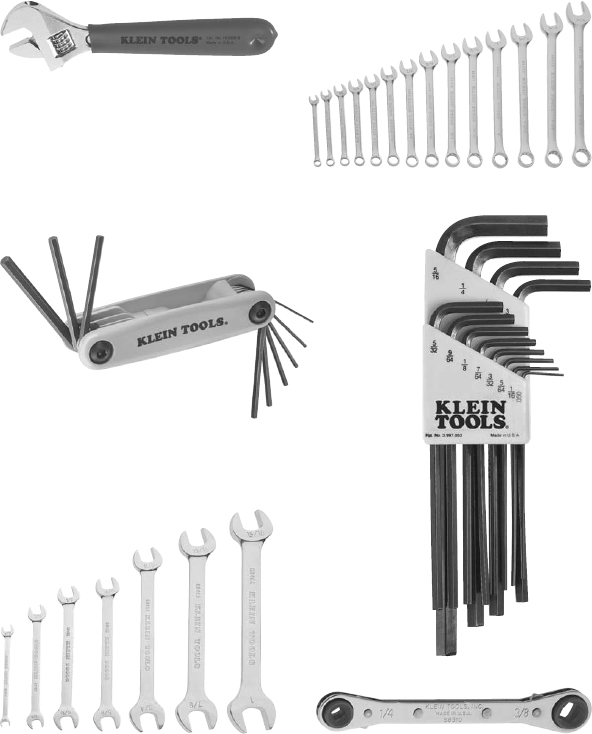

Wrenches are the most frequently used tool. There are many different types and sizes of wrenches. Their purpose is to hold and turn nuts, bolts, cap screws, plugs, and various threaded parts. Wrenches are generally available in five different types (Figure 3-5):

• Socket wrenches

• Box wrenches

• Open-end wrenches

• Adjustable wrenches

• Allen, or hex, wrenches

FIGURE 3-5 Wrenches are used to remove and fasten nuts and bolts. They are available in socket wrench, box, open-end, adjustable, and Allen types.

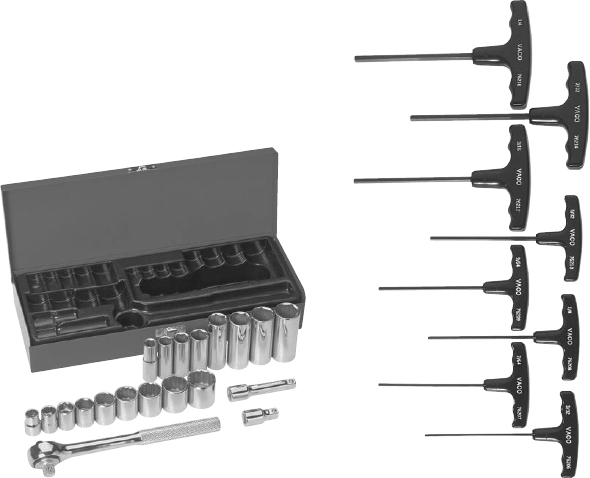

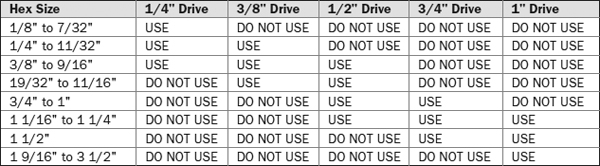

Socket wrenches are used to slip over bolt heads, as opposed to other wrenches listed, which are used at right angles to the nut or bolt. This arrangement allows more leverage to be applied to loosen or tighten the nut or bolt (Figure 3-6). Select the size and type of socket to fit the nut with the proper drive size for the load. See Table 3-1 for the proper drive size loading recommendations.

Always choose the correct wrench for the job. Box wrenches should be used for heavy-duty jobs and in certain close-quarter situations. Open-ended wrenches are useful for medium-duty work or situations where it is impossible to fit a socket or box wrench on a nut, bolt, or fitting from the top. Adjustable wrenches help with light-duty jobs, work well with odd-sized nuts and bolts, and are useful where a regular open-end wrench could be used. It is adjustable to fit any size object within its maximum opening. Allen wrenches are used for adjusting and removing fan blades or other components that are held in place by Allen set screws. The Allen wrench has a six-pointed flat face on either end.

TABLE 3-1 Drive Size and Hex Size Loading Recommendations

FIGURE 3-6 (a) Socket wrench, (b) adjustable wrench, (c) open-end wrench.

Hammers

A hammer is a hitting tool. There are many sizes and styles of hammers available (Figure 3-7). The most common type used in appliance repairs is the claw hammer. The claw hammer can also be used for prying objects.

FIGURE 3-7 While there are many different kinds of hammers, the claw hammer is the one most often used.

Prying Tools

Prying tools are available in many sizes and shapes. The most common are the crowbar, ripping bar, and the claw hammer. The claw hammer is basically used for light-duty work: removing nails and prying small objects. The ripping bar is used for medium-grade work, and the crowbar is used for heavier work.

Pliers

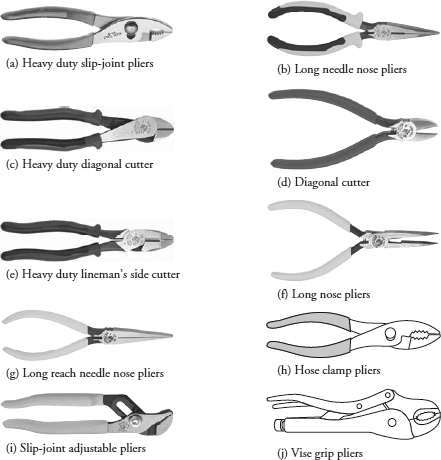

Pliers are one of the most frequently used tools. A pliers is a tool for holding or cutting, depending on the type. Generally, they are not made to tighten or unscrew heavy nuts and bolts. They are available in many sizes and shapes (Figure 3-8). Choose a pliers that fills a particular need, being careful that it is the proper pliers for the job. Some of the most common types of pliers include:

• Slip-joint

• Slip-joint adjustable

• Vise grip

• Needle nose

• Diagonal cutting

FIGURE 3-8 Pliers are available in many sizes and shapes.

Slip-joint pliers are pliers for everyday tasks (Figure 3-8a). The jaws can be adjusted into two different positions. Do not use them on nuts, bolts, or fittings. They can easily slip and injure both the technician and the device.

Pump pliers, also known as slip-joint adjustable pliers, are also used for general jobs (Figure 3-8i). They would be preferred over slip-joint pliers when working on a larger object. The jaws of slip-joint adjustable pliers can be moved into many different positions.

The vise grip pliers is actually four tools in one (Figure 3-8j): a clamp, a pipe wrench, a hand vise, and pliers. The lever holds the jaws in one position, allowing the vise to hold up to one ton of pressure.

The needle nose pliers are mostly used with electronic, telephone, and electrical work (Figure 3-8b, Figure 3-8f, and Figure 3-8g). Other uses include in confined areas, to form wire loops, and to grip tiny pieces firmly. (The long nose is particularly useful for this latter task.) They are also available with side cutters.

Cutting Tools

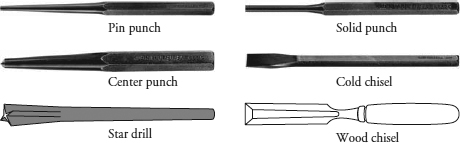

Many different types of tools are used for cutting. The key is to know which tool to use in each situation. Chisels are used for cutting metal and wood. They are made of high-carbon steel, which makes them hard enough to carve through metal (Figure 3-9). These should be used when removing rusted bolts and nuts.

FIGURE 3-9 Chisels come in many different sizes and shapes, such as wood chisels, metal chisels, and concrete chisels.

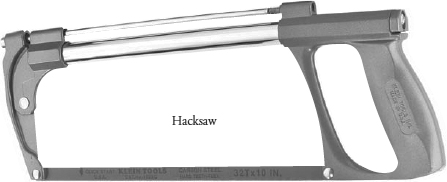

Hacksaws are used for cutting metal (Figure 3-10). The hacksaw consists of a handle, frame, and a blade. The frame is adjustable, so it can accept any length of blade. The blades are available with different numbers of teeth per inch.

FIGURE 3-10 Hacksaws are used for cutting metal, wood, etc.

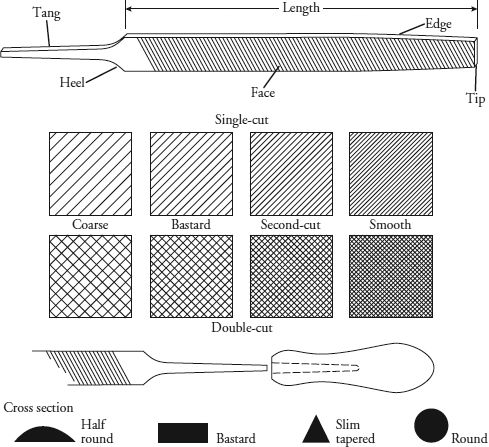

A file is also a cutting tool. It is used to remove excess material from objects. Files come in a variety of sizes and shapes (Figure 3-11).

FIGURE 3-11 Files are used to smooth the rough edges off metals, wood, etc.

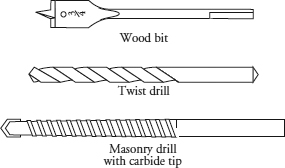

Drill bits are also cutting tools. They are designed for cutting holes in metal, wood, and concrete (Figure 3-12).

FIGURE 3-12 A general-purpose twist drill set will handle most of the technician’s needs. The wood bit and masonry drill bit are used in installation work.

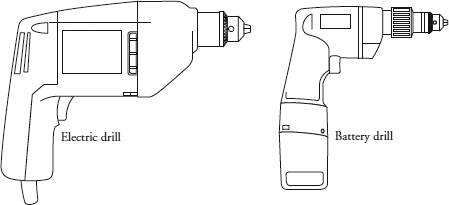

Power Tools

Power tools do the same job as hand tools. However, they do the job faster. The most common power tools can be either electric or battery-powered (Figure 3-13).

FIGURE 3-13 Power tools can have either a line- or battery-operated power supply.

When using power tools, there are some safety precautions that must be followed to prevent accidental injury. Always read the use and care manual that comes with each power tool.

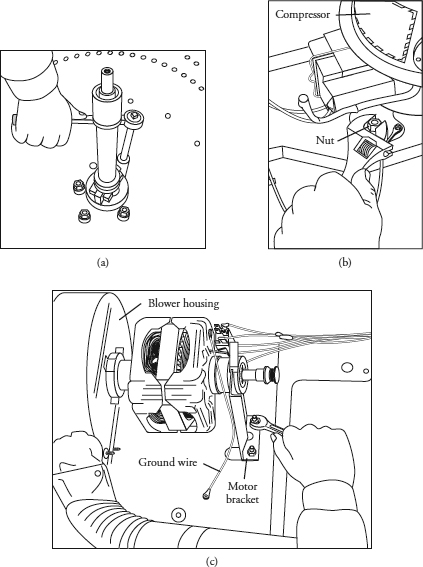

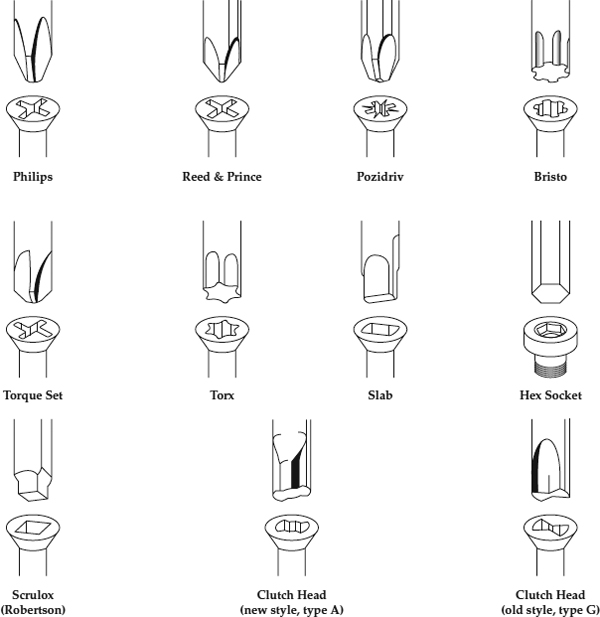

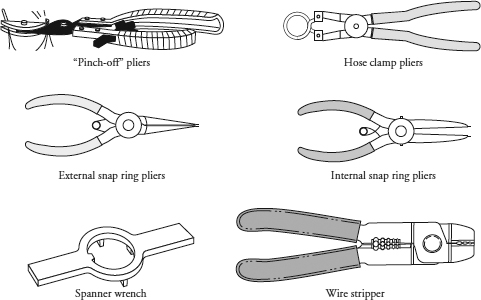

Specialty Tools

These tools are specifically designed for a particular use and are used for in-depth servicing of the appliance. For example, special tools are used for the installation and removal of special screws and nuts (Figure 3-14); they are required to remove the bearings in washing machines; and they are also used for adjusting switch contacts. Figure 3-15 illustrates some of the many types of specialty tools. Other specialty tools and their uses will be discussed in later chapters of this book.

FIGURE 3-14 Here are just some of the different types of specialty screws and the types of drivers needed to remove them.

FIGURE 3-15 In addition to the basic hand tools, a number of special-purpose tools are used in appliance servicing.

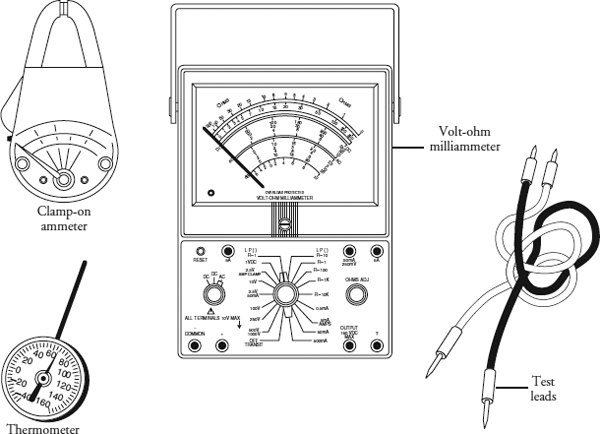

Test Meters

Test instruments are important tools used in assisting with the diagnosis of the various problems that arise with appliances. Varieties of test meters (Figure 3-16) include the following:

• The analog volt-ohm-milliammeter is used for testing the resistance, current, and voltage of the appliance or air conditioner. This type of meter moves a needle along a scale. It is also the most important test meter to have in the tool box.

• The digital multimeter displays a readout in numbers, usually on an LCD screen. This type of meter is similar in operation to the analog meter.

• An ammeter is a test instrument that is connected into a circuit to measure the current of the circuit without interrupting the electrical current.

• A wattmeter is a test instrument used to check the total wattage drawn by an appliance.

• A temperature tester is a test instrument used to measure the operating temperatures of the appliance.

FIGURE 3-16 Test meters are available in analog or digital readouts. For example, thermometers measure the temperature.

Advantages of Digital Meters

• A digital meter offers greater sensitivity, accuracy, and a better resolution in reading measurements.

• Digital meters have a faster readout as compared to analog meters.