Striking Tools

Hammers

Striking objects in order to remove or install them is the job of the hammer. Almost every technician uses a hammer of some kind, whether it is used to drive a nail or to loosen pieces of an assembly. Hammers come in many designs and sizes according to their intended use.

The type most often used by metal workers and mechanics is known as a ball-peen hammer. This hammer is designed with a regular striking face, like most hammers, but also has a rounded end that can be used for shaping metal and making gaskets.

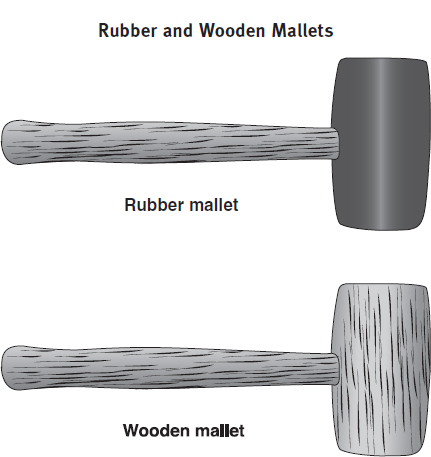

Mechanics will often use a rubber mallet to prevent damage to the parts they are striking. Rubber mallets are not made for maximum impact; they are designed to install or remove delicate parts such as hub caps while preventing damage to their surface. A carpenter would use a wooden mallet to achieve the same effect.

Carpenters often will use a claw hammer, which serves a dual purpose. The hammer head has two ends; one to drive nails and the other to remove nails. Claw hammers come in a variety of sizes, and these are determined by the weight of the hammer head. A general-purpose claw hammer would have a 13 oz. head, while a rough-framing hammer, typically used for framing wooden houses, might be anywhere from 16 to 20 oz.

Heavy jobs, such as driving fence posts or breaking down drywall, require the use of a sledge hammer. This is a long-handle hammer with a large steel head that typically requires both hands to operate.

Nails

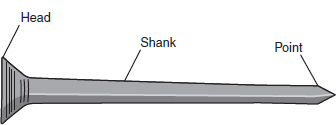

A nail is a pin-shaped fastener made of metal. One end of the nail comes to a sharp point, while the other end usually has a flat head. However, there are also headless nails. The length of the nail body between the head and point is called the shank. Nails are typically driven into wood by a hammer or pneumatic nail gun.

Rivets

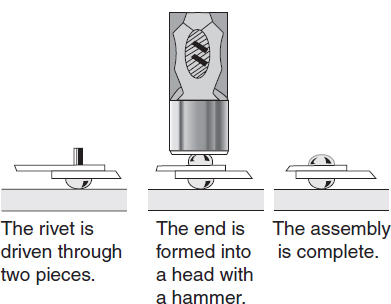

Rivets are metal fasteners that can be used to assemble parts. A rivet is simply a pin with a head at one end. A rivet is installed in a hole (the same diameter as the rivet) that is drilled through two pieces that are to be assembled. With the two pieces tightly clamped, the head of the rivet is placed on a hard surface, while the other end is formed into a head using a hammer or special riveting tool. This creates an assembly that is semipermanent, as the rivet must be drilled out to remove it.

Chisels, Punches, and Drifts

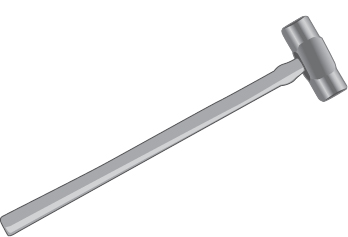

Hammers are often used in conjunction with a chisel, a punch, or a drift. A chisel normally has a long, sharp edge and is used for cutting. A punch is narrow and is used for driving small fasteners and making layout marks. A drift is used for striking an object where it is important that the hammer itself not come in direct contact with the work.

The most common chisel is the cold chisel, which has a straight, sharp edge for cutting off bolt heads or separating two pieces of an assembly. Cold chisels get dull from time to time and must be sharpened on a bench grinder.

Punches are made in a number of different designs, but the most common ones are the pin punch and the center punch. Pin punches are straight and cylindrical in shape. Pin punches come in various sizes, normally starting as small as

" and going up to

" and going up to

" in diameter. The pin punch is used to drive pins out of holes, and to follow the pin through the hole as it forces the pin out.

" in diameter. The pin punch is used to drive pins out of holes, and to follow the pin through the hole as it forces the pin out.

Center punches are used to make small indentations that serve as starting marks for drilling operations. Making a small indentation with a center punch can help the drill bit stay on target long enough to get a hole started. Attempting to drill a hole in metal without first marking it with a center punch can allow the drill bit to “walk” across the work and completely miss the original target.

When using a hammer to drive parts in or out of an assembly, it is easy to damage the parts if they are struck directly by the hammer. The head of a ball-peen hammer is made from forged steel, and thus can easily damage parts that are made from softer materials. Placing a drift against the object and then striking the drift with a hammer prevents damage to the part that is being driven. Drifts are often made from soft metals such as mild steel, brass, and even aluminum.

Here is a sample ASVAB question that asks you to differentiate between striking tools:

| Question | Analysis |

| Which of the following hammers would be most appropriate to install a hubcap? |

Step 1: This question asks which hammer would be most appropriate to install a delicate part. Step 2: Not much info to simplify. Step 3: You can narrow your prediction to hammers best used for delicate jobs like installing a hubcap. |

|

Step 4: Choice (D) matches that prediction. Choices (A) and (C) can be eliminated, because their striking heads are too hard. Choice (B) can be eliminated because it exerts too much force. |

Now try one on your own.

-

You hammered a nail into the wrong part of a board and you want to remove it. With which of the following hammers could you do that? - ball-peen hammer

- wooden mallet

- rubber mallet

- claw hammer

Explanation

Choices (A), (B), and (C) do not contain any device that could remove a nail. However, the claw on a claw hammer, (D), is designed especially to remove nails. That is the tool you would need.