Turning Tools

Screwdrivers

Screwdrivers, which come in many different sizes and styles, are one of the most common tools used to install and remove fasteners. The oldest screwdriver design is the flat tip type, which is basically a flat blade made to turn a screw with a single slot across the top of it.

The flat tip screwdriver is far less popular now in light of some newer designs, including the Phillips, Robertson, and Torx screwdrivers. A Phillips screwdriver is recognizable by its tip that looks like a plus sign. Robertson screwdrivers have a square tip, and Torx screwdrivers have a characteristic six-pointed star-shaped tip. All of these newer designs grip the fastener, making the screw easier to remove and install. Since the screwdriver makes better contact with the screw, it is also possible to fasten it more tightly.

Screwdrivers are used with only one type of fastener—screws, which are threaded fasteners that vary in size and shape depending on the project. The threads on screws are designed to tighten when turned clockwise. Read more about how fasteners are classified later in this chapter in the “Nuts and Bolts” section. Washers, disk-shaped rings, may be used alongside screws to protect the work surface and distribute the force caused by tightening the screw.

Wrenches

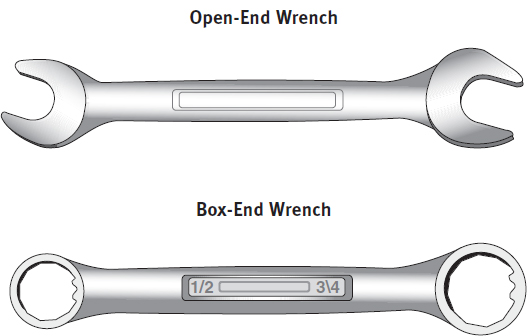

With all wrenches, the longer the wrench, the more leverage and the more twisting force (torque) it can apply to tighten or loosen a fastener. There are two basic types of wrenches; the open-end and the box-end. The open-end wrench is made for speed. Since the end is open, it is easy to slide the wrench on and off a fastener, such as a cap screw. To loosen tight fasteners, it is a good idea to use a box-end wrench. The box end wraps completely around the head of a bolt, and therefore makes greater surface contact, distributing the force more evenly.

The most common wrench arrangement is the combination wrench. This design has an open end and a box end on opposite ends of a wrench. Both ends are made to fit the same size fastener, but the technician can loosen the bolt with the box end, and then finish removing the bolt more quickly using the open end.

When the specific size wrench for a fastener is not available, an adjustable wrench (sometimes referred to as a Crescent® wrench) can be used.

Sockets

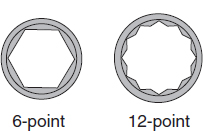

An alternative to using wrenches to loosen fasteners is the use of sockets. Like wrenches, sockets come in two designs. Six-point is a stronger design because of its greater wall thickness, and is usually the mechanic’s first choice in the smaller socket drive sizes. However, twelve-point is a useful design for certain applications, as it is easier to align with the bolt head in tight spaces.

To determine the size of a socket required for a job, simply measure the distance between two parallel sides of the bolt head. If the bolt head measures

" across two parallel sides, then a

" across two parallel sides, then a

" socket is required to loosen it.

" socket is required to loosen it.

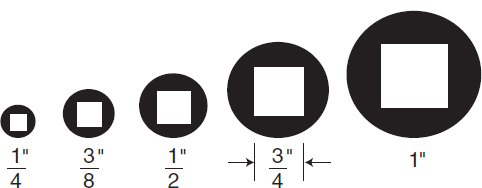

Sockets come in a variety of drive sizes, which are determined by the size of the opening that attaches to the drive tool. For instance, if the square end of a socket measures

" across, then that would be a

" across, then that would be a

" drive socket. The most popular drive sizes are

" drive socket. The most popular drive sizes are

",

",

",

",

", and

", and

". Larger drive sizes are available for the very large fasteners used in heavy industry. Take a look at the diagram below.

". Larger drive sizes are available for the very large fasteners used in heavy industry. Take a look at the diagram below.

Sockets are very versatile, because they can be used with a variety of drive tools. The most common drive tool for sockets is the ratchet, which turns the fastener in only one direction as the handle is moved back and forth through a narrow arc. Ratchets are reversible, so they can be set to tighten or loosen a fastener. They can also be more useful than open-end/box-end wrenches in tight quarters (especially when paired with an extension bar) because you do not need to replace the tool with each turn—just move the handle back and forth.

Sockets can also be used with pneumatic (compressed air) power tools, such as an air impact wrench. The air impact wrench can remove fasteners quickly by applying tremendous amounts of torque (twisting force) and using a hammering action that vibrates fasteners loose. It is important to remember that only impact sockets should be used with an air impact wrench.

Nuts and Bolts

Some of the most common types of tools to be tested on the ASVAB are fasteners (screws and bolts). It pays to review this wide range of hardware.

Wrenches of all types are used with a variety of threaded fasteners called bolts and nuts. A bolt has external threads, whereas a nut has internal threads. Bolts typically have a hexagonal or square head, which is held in place with a wrench while the nut is tightened (also with a wrench) to fasten the assembly. A threaded bolt can only be inserted into a nut or hole that has a similar thread.

While there is not a clear-cut distinction between screws and bolts, the most practical way to distinguish between the two is based upon the shape of the head and what tool is used to install or remove the fastener. While bolts have a hexagonal (six-sided) or square head and are used with a wrench and nut, screws typically have a round head with an indentation that matches the screwdriver that must be used to install or remove the screw. Both fasteners are threaded on part or all of the shaft.

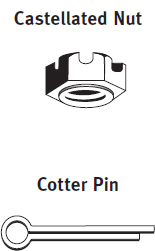

Nuts thread onto bolts to clamp assemblies together. Nuts usually have either a square head or a hexagonal head, and can be locked into position using several different methods.

Wing nuts make it possible to disassemble a component by hand. The two “wings” attached to the nut make it easy to tighten and loosen without the aid of hand tools.

A castellated nut uses a cotter pin to lock it into place. The cotter pin passes through a hole in the bolt or stud that the nut is threaded on, engaging the cutouts in the nut.

Lock nuts have a nylon insert incorporated into its threads that provides enough interference to prevent the nut from loosening, thus locking it in place.

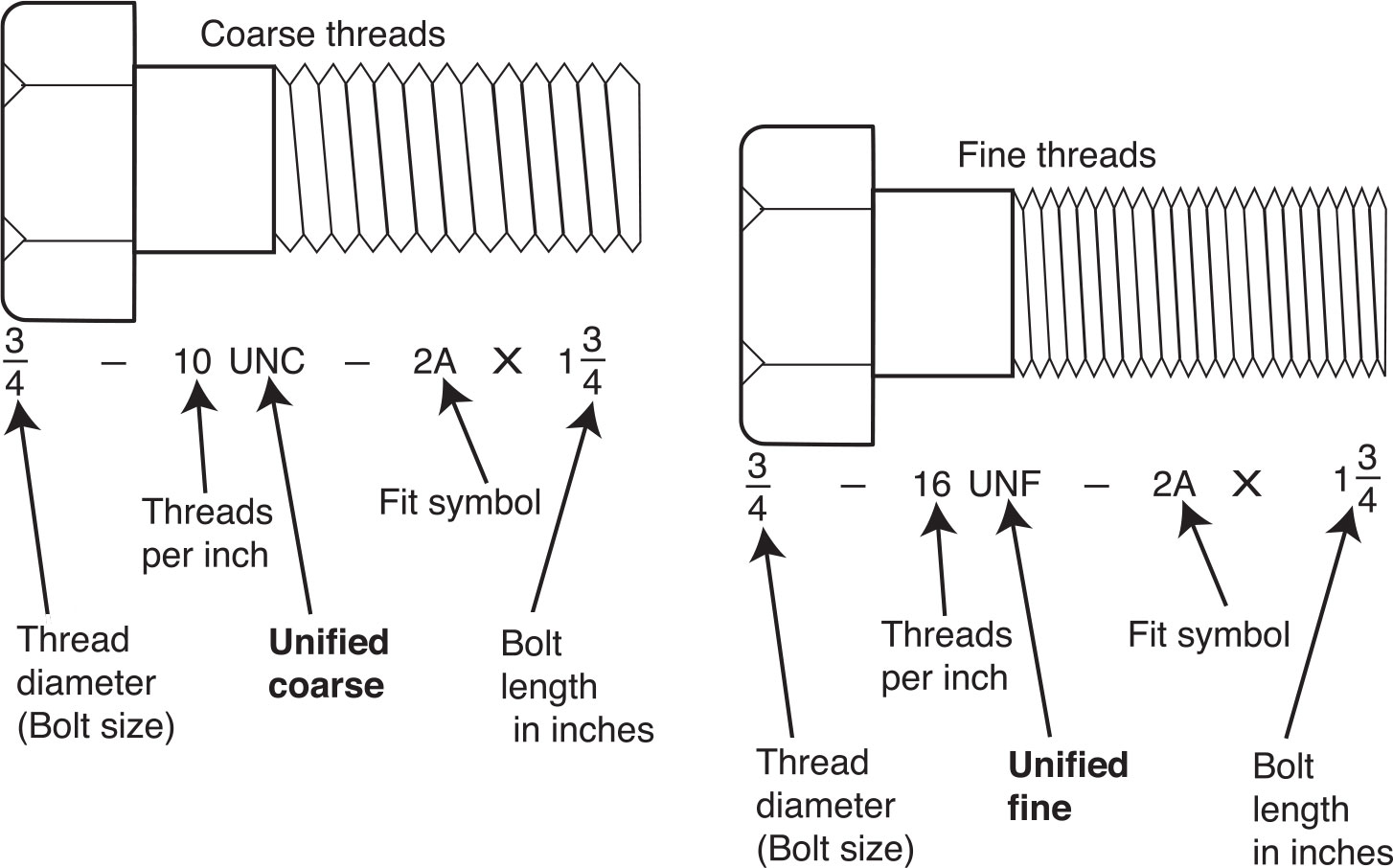

The type of thread that is placed on a fastener will vary according to the diameter of the fastener and the intended strength of the finished product. Threads are identified by their pitch, and this is measured using a thread pitch gauge.

Fractional-measurement fasteners (measured in fractions of inches) use threads that are identified by the number of threads per inch. There are two basic thread classifications within this group: Unified National Coarse (UNC), and Unified National Fine (UNF). A UNC or coarse thread would have relatively few threads per inch, where a UNF or fine thread would have a larger number of threads per inch.

A bolt that is

" in diameter could, therefore, have two possible thread pitches. If it were a UNC bolt, it would have 16 threads per inch, whereas if it were a UNF bolt, it would have 24 threads per inch.

" in diameter could, therefore, have two possible thread pitches. If it were a UNC bolt, it would have 16 threads per inch, whereas if it were a UNF bolt, it would have 24 threads per inch.

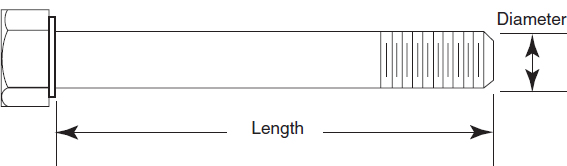

Two other important measurements of a fastener include the diameter and the length. The diameter is the distance across the unthreaded portion of the bolt. This would give an indication of the size of hole that the fastener is made to be installed in. The length of the bolt is the distance between the underside of the bolt head and the end of the bolt. Note that the bolt head does not count toward the length of the bolt.

Let’s check out one way fasteners could be tested on the ASVAB:

| Question | Analysis |

| You are assembling a project with bolts that you would like to be able to remove later, even if you do not have a wrench with you. What would be the best type of nut to use in this assembly? |

Step 1: You’re asked to determine the best type of nut to use in the given project. Step 2: The key phrase is “even if you do not have a wrench with you.” Think about what type of nut can be removed easily with just your hands. Step 3: Make a prediction: a wing nut can be removed using only your hands. |

|

Step 4: Choose answer (C). |

A Test Day question may ask you about the correct size tool to use. Take a look at this question:

-

You have a bolt that needs to be removed, but an  " open-end wrench is just slightly too big to fit properly. Which of the following sizes should be tried next?

" open-end wrench is just slightly too big to fit properly. Which of the following sizes should be tried next?

-

"

" -

"

" -

"

" -

"

"

-

Explanation

The key phrase to focus on in this question is that the

" wrench is just slightly too big. So, you are looking for a wrench that is a bit smaller. It can be tricky to tell which fraction is smaller, but a quick way to do that is to find a common denominator for each fraction. (Review the fraction rules in chapter 6: Arithmetic Reasoning if you need a quick reminder.) Convert all the fractions to have 16 as the denominator so they are easier to compare. Choice (A) is larger than

" wrench is just slightly too big. So, you are looking for a wrench that is a bit smaller. It can be tricky to tell which fraction is smaller, but a quick way to do that is to find a common denominator for each fraction. (Review the fraction rules in chapter 6: Arithmetic Reasoning if you need a quick reminder.) Convert all the fractions to have 16 as the denominator so they are easier to compare. Choice (A) is larger than

", so that can be eliminated right away. Choices (C) and (D) are significantly smaller than

", so that can be eliminated right away. Choices (C) and (D) are significantly smaller than

", so they also do not fit what we are looking for. Choice (B), on the other hand, is the size of a wrench just smaller than an

", so they also do not fit what we are looking for. Choice (B), on the other hand, is the size of a wrench just smaller than an

" wrench (

" wrench (

" is equal to

" is equal to

"), so that is the correct answer.

"), so that is the correct answer.