The standard 7.62x39 cartridge, before import restrictions were placed on it, contained a mild steel core. Not much expansion there, so not much use as a hunting cartridge.

For many AK shooters, ammo is indeed just ammo. They’re happy with whatever they can get, at the lowest cost, as long as it goes bang and hits reasonably close to the aiming point. For them, the case material, bullet design, and reloadability of the case are all moot points. Cheap ammo that goes bang, and comes close is all they ask.

Others want more. Someone who is planning to go hunting with their AK not only has to conform to DNR regs (No FMJ bullets allowed, typically) plus they expect to cleanly, humanely and efficiently dispatch their game.

Others are concerned about the use of the AK in self-defense. Yes, you can shrug off their concerns by pointing out the AK has been used for defense and offense for many decades now, but an effective and efficient military use is not necessarily the same as one for personal defense.

To a certain extent, it is a rifle cartridge much like any other. Primer in the back, impact extruded case of metal, with a shoulder, neck and bullet. Pull the trigger, it goes bang. Repeat as necessary. But there are some differences you need to know about, if you are going to do more than range play, especially if you are going to reload ammo to save on costs.

The original cartridge of the AK is the M43, developed in 1943, and field tested and refined during the latter days of The Great Patriotic War. As you can readily tell, the case is 39mm long and the bullet diameter is listed as 7.62mm.

Did the Russians invent the cartridge from whole cloth? Did they rip off the German R&D efforts? At this point in time, is there anyone left who knows the answer? Are any documents that might tell us still in existence? And does it really matter?

No, what matters is how it came to this. The Russians/Soviet/Bolsheviks were fighting a war with a mix of weapons that came from WWI and the gangster era. Gangster, that’s what people called organized crime back when Prohibition was in effect. The Thompson submachine gun was supposedly popular, but back then those involved used everything in fighting over territory for liquor sales. And by “everything” I include belt-fed heavy machine guns.

On the Eastern Front, the Soviets were using as their main infantry small arm the Mosin-Nagant, a bolt-action five-shot rifle chambered in 7.62x54R. The cartridge was a rimmed, .30-06 equivalent. (Actually, that isn’t really fair. The Mosin came first, in 1891, the Springfield round was first unveiled in 1903 as the .30-03. It was updated a few years later as the .30-06.) That cartridge also was what they fed their belt-fed machine guns. The big rim wasn’t a problem in a belt-fed machine gun then, because they were using the Maxim. In the Maxim design, each cartridge was extracted from its canvas belt backward. In that process, a big rim was a benefit, not a problem. It wasn’t until later, when they were developing the PKM that Soviet machine gun designers had to struggle with the rim. But we’re wandering afield, and should get back to WWII.

The standard 7.62x39 cartridge, before import restrictions were placed on it, contained a mild steel core. Not much expansion there, so not much use as a hunting cartridge.

Red Army infantry also used a mixture of submachine guns, all chambered in 7.62x25, the Tokarev pistol cartridge. As a mix, it worked, but for the individual it wasn’t much fun. The Mosin kicked hard, and while the power was useful in getting through chance obstacles, the rate of fire was slow. Not to mention that the rifle was long, almost five feet with the bayonet in place. The Mosin carbines were handier, but also lighter, and thus kicked even harder. The various submachine guns were fast-cycling, and put a lot of zippy little 86-grain bullets downrange, but they didn’t penetrate anything but fascists very well. There were a lot of chance obstacles that acted as cover, when being pasted by a Soviet submachine gun.

Rifle performance depends on the caliber and the bullet. This Corbon DPX really doesn’t care if it is launched from an AR-15, or an AK-47 in .223.

The Germans had much the same problems, compounded by the literal swarms of Soviet infantry with which they were faced. They wanted something that kicked less than the 7.92 Mauser, penetrated chance obstacles better than the 9mm Parabellum, and held more rounds than the Mauser rifle. It being an individual machine gun on demand would be awfully handy in an emergency. They fielded hundreds of thousands of MP-40 submachine guns, and pressed into service every Soviet one they captured. They captured so many Soviet small arms that the Germans actually set up ammunition plants to produce cartridges for them, and converted many other Soviet submachine guns to 9mm Parabellum.

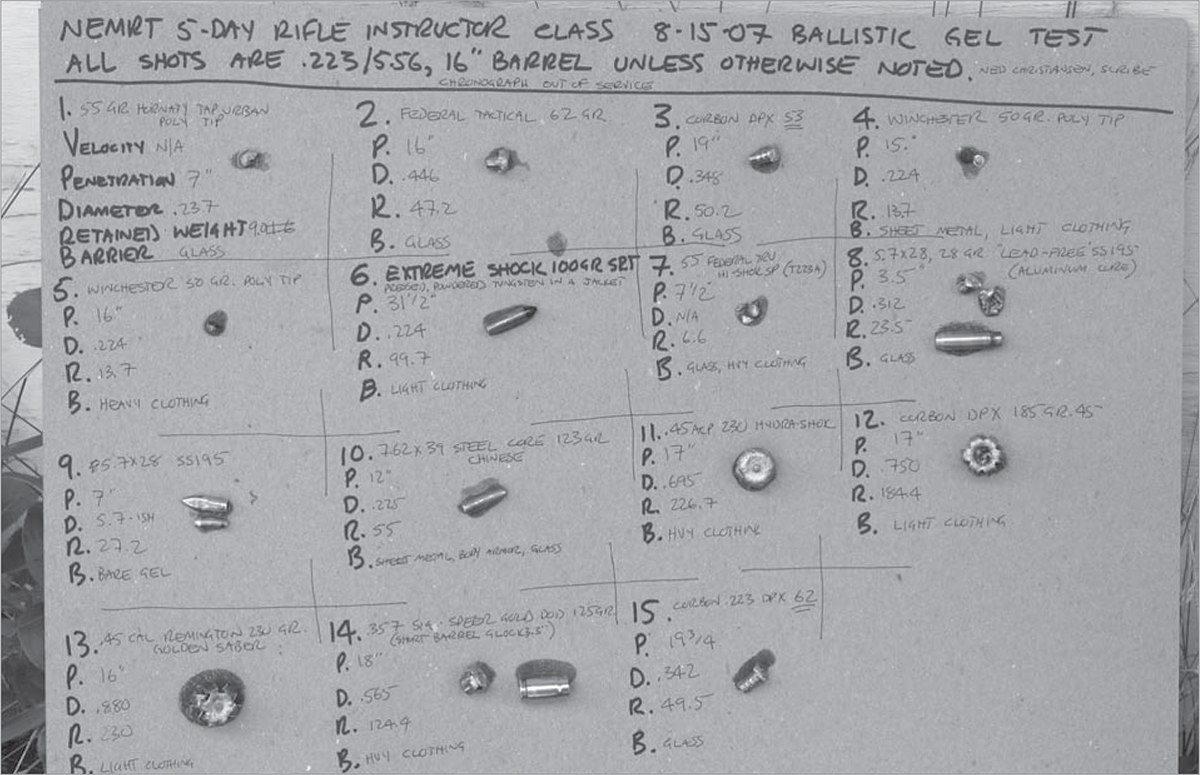

If you do ballistic testing, you have to take careful notes. This is the results board we create for rifle classes, so everyone can see what we’ve tested and how well it did.

As a means of hiding the new designs from Hitler’s gaze, the German R&D branches of the manufacturers and the Army came up with a cool new name — Sturmgewehr — and managed to develop what became known as the assault weapon or assault rifle. In its final form, the Stg 44 fired the 7.92x33 Kurz cartridge, which hurled a 122-grain bullet at a nominal 2,250 fps. (Does that sound familiar?)

Testing was simple, starting with the various contenders in 1942; they’d make a bunch, issue them, and get reports back from the front. There, the mild recoil, 30-round magazine and select-fire option were found to be useful. The Soviets also reported on their end of this testing, and recovered sample weapons for their own study.

Why the need to hide all this? Remember the derogative “gangster gun?” Hitler also viewed the submachine gun as a defensive weapon, and he didn’t want the Army on the defensive, he wanted it on the offensive. Once the new Stg design had proven itself, and that the Army really, really wanted it, he approved it. In much the same manner as with the Me-262, political intervention kept a useful tool out of the hands of the military for an appreciable time.

The Soviets, being on the other end of the Stg, took notice and upped their own research.

As a brief aside, none of this was new. The French had developed a cartridge in WWI, and were working on weapons for it, that filled the same tactical niche. Researchers between the wars, on all sides, had been working on intermediate cartridges. So, the popular notion that the Germans invented it, and the Soviets copied it, isn’t correct. Nor is the idea that the Soviets invented it independently. Everyone invented it, and all military establishments ignored, it, until they needed it. And then they all took credit for it. I’m sure the same thing happened with the tools of the infantry of Narmer, the Pharoah who unified Egypt, and was the first Egyptian butt-kicker.

The computer-controlled popups at the National Guard base. If you hit it, the computer registers the hit. If not, the scorer gets to announce your scores with glee.

The first firearm to be issued in the new Soviet cartridge was the SKS, also known as the SKS-45. While a self-loading carbine with the new round and a 10-shot capacity was much more useful than the Mosin bolt action, it was not the desired end product, but merely a useful tool that could be made and issued until the final product was arrived at. So even while the Red Armies were being equipped with the SKS-45, work on the real replacement continued, culminating in the AK-47. The two were issued side-by-side for a while, and then at least in Soviet and Warsaw Pact use, the SKS was relegated to ceremonial and second-issue status.

When I was in Moscow, the guard at the exit to the Kremlin was armed with an SKS, not an AK-47⁄74. One reason is, the SKS is just long enough that you can hold onto the muzzle, at attention, with the butt grounded. (Well, you can if you aren’t over six feet tall.) The AK, 5 inches shorter, is too short for that. The 30-round magazine of the AK can also make small arms drill and ceremonial presentations more than a bit awkward.

But the short-term thinking, need for massive amounts of material now, and the legacy of the war left a few odd aspects to the whole system. One was the bullet size, weight and stability. When the various R&D shops in the Soviet Union got to work on new products, they were faced with one unbending requirement: use the barrels they had. The 7.62x54R used a bore with a nominal diameter of .310 inches, and the bullet commonly used weighed 147 grains, yet there were relatively common loads in use up to 181 grains in weight. But, it had been developed in the late 19th century, and the original specifications were drawn up for use with a 210-grain, round nosed FMJ bullet.

In order for that bullet to be properly stabilized out to the expected infantry engagement range (back in the 1880s and 1890s, a thousand yards or more) the Mosin bore twist was quick; one turn in 9.5 inches. That made the later, WWI and WWII infantry round, with a bullet of 147 grains, a bit over-stabilized, but nothing that was critical. The bullet carried so much energy to (and through) opposing infantry, that the over-stability the twist produced was not an important consideration.

In the transition from black powder to smokeless, the calibers went down, the velocities went up, and bullets had to have jackets.

The Russians were not alone in this. All the major combatants were using cartridges developed prior to the 20th century, originally developed with heavy, round-nosed bullets. They were all over-stabilized. The American .30-06 used a twist of 1⁄10, for example, for a bullet of the same weight as the Soviets — 147 grains. The British, French and Germans were similarly equipped.

This meant that the Soviet submachine guns in use (PPSh-41 & PPS-43, some 8 million being made between 1940 and 1946) had barrels with the same bore specs as the Mosin. They were nominal .310-inch diameter, with a twist rate of 1⁄9.5. This meant the 86-grain bullet of the 7.62 Tokarev was grossly over-stabilized. But, since it was “only” going 1,700 fps or so, and the jacket was proportionally robust compared to the Mosin, there was no risk of it being torn apart by the centrifugal force of rotation. And being a stubby pistol bullet, yaw as a component of wounding was not a significant feature to attempt tuning the system to produce.

Machine guns rule the battlefield, and rifles just maneuver and do the cleanup. Here we have machine guns spanning over five decades and four continents.

The 7.62x39 was another matter. First, it was a bit longer, and having it yaw would usefully increase wounding. It was going 500 fps faster, and anything but a tough jacket would increase the risk of bullet destruction due to centrifugal force. But the lack of wounding was the big problem. Basically, despite so many shooters holding to its vaunted “.30 cal. rifle” affection, it produced the same kind of wound for which the M16A2 and its M855 bullets take a lot of flak — a straight, punctuate, perforating wound.

That is, it goes straight through, doesn’t tip soon enough, and isn’t going fast enough for a temporary wound cavity to have much effect.

We’ll get back to that.

How manufacturing and machining tolerances are specified can make a difference on what will work. For instance, the tolerances of many industrial products in the West are specified as “plus or minus.” That is, for example, a bullet will be listed on the drawings or in the specs as 0.3080±.0002. That is, an acceptable bullet will be one that falls out of the drawing/pressing machines with a diameter between 0.3078 and 0.3082 inches.

However, not all systems use these tolerances. For instance, it is possible to list an added dimension in only one direction. The M43 is so defined in some specifications, with the diameter listed as 0.310-.002, which means that any diameter from 0.3080 to 0.3100 inches is acceptable. As a result, a bullet that is 0.3079 inches fails, as does one that measures 0.3101. In the plus-or-minus spec, the first of these would pass (0.3079-inch being within the normal .308-inch spec.) while the latter would fail in both measuring systems.

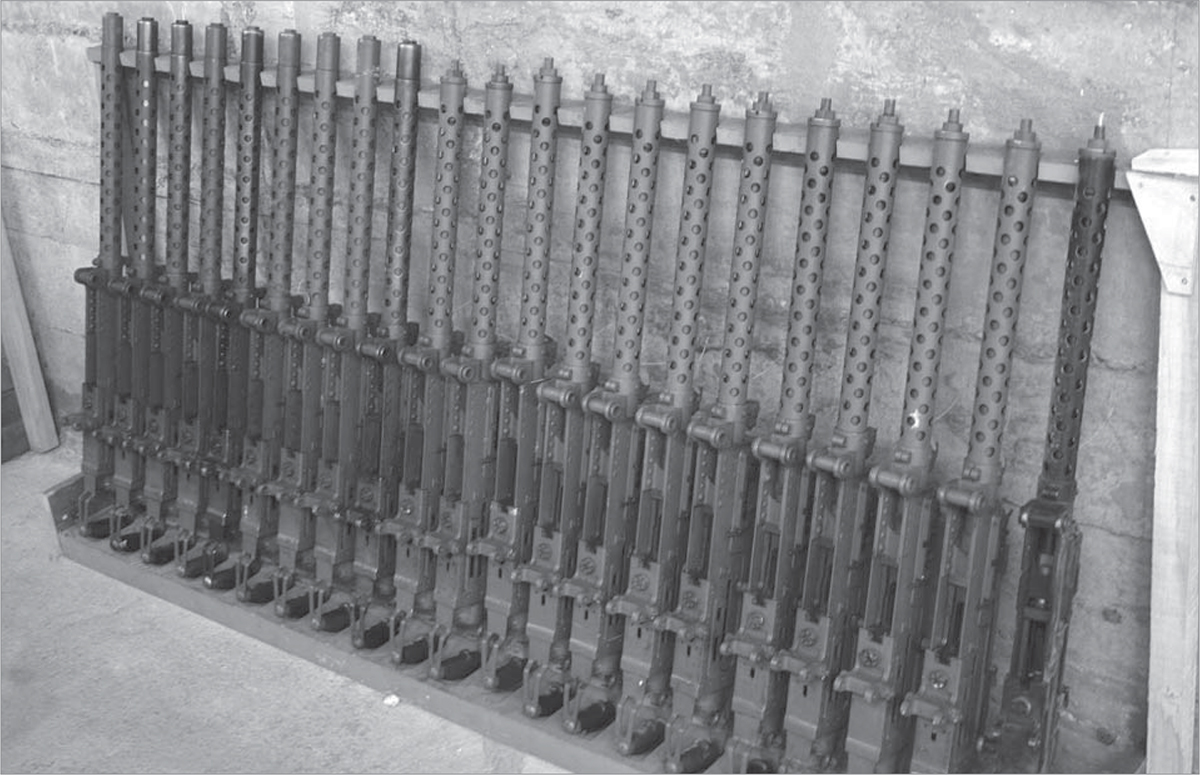

We forget what it takes to equip an army. Here we have a rack of Browning machine guns, with a very special mod: they’ve been converted to .22LR for training.

Pedants will argue that the “7.62” is supposed to be the average bullet diameter, the nominal groove diameter, the average of those and everything else, but the end result is pretty much the same; foreign-made ammunition or bullets range from .308 up to .312 inches with most of them right around .310 inches in diameter. However, U.S.-made ammunition will sometimes feature bullets of .308 inches and that is not just an average, but a pretty tight average. It is a sloppy U.S. bullet maker who lets their products (in this case, a .30-caliber bullet) wander as far as .3075 and .3085 inches.

However, bullets manufactured specifically for use in the AK will be offered in .310 or .311-inch diameters. You just have to find them. Does it matter, if you are loading your own ammunition? Yes and no.

As a result, you can find bullets for reloading your AK in diameters of .308, .310 and .311 inches. You should stick with the more-or-less normal weights, that is, right around 125 grains. The weight matters more than the diameter, for function, but the diameter can make a difference in accuracy. However, most shooters who are loading the 7.62x39 are doing so looking for economy, which means the more common .308-inch bullets will likely be less costly.

Which is just fine for a lot of applications. A .308-inch bullet, traveling down a bore rifled for a nominal .310/.311-inch bullet, will hardly notice the difference. Reloaders have to be aware of that, however. When rifle cases are processed for loading, or reloading in this instance, the case gets squeezed down to its minimum dimensions. The decapping stem, the pointy thing that sticks out of the bottom of the sizing die, is also a bullet-diameter-minus neck expander. The sizing die top end squeezes the neck down below minimum, and then the decapping stem and its expanding ball swage the neck back up to the minimum for the proper neck tension needed to hold the bullet in place.

If you are loading .308-inch diameter bullets, but you have an expander ball that is the proper size for a .310-inch bullet, you will lack neck tension. At the very least, the loose bullets in the case neck will get battered out of alignment on feeding, and accuracy will suffer. You need to be using the proper expander for a .308-inch bullet, and the other diameter for the .311-inch bullets. A reloading die manufacturer who offers a 7.62x39 die set will include one of each size for you. Make sure you use the proper one.

The MP-44, which got us started on this path.

In the switch to modern rifles, there was a brief dalliance with the .308 in the Armalite rifles.

The 7.62x39 case is tapered. If nothing else, the magazine shape tells you that. The taper is so severe that the magazine features a continuous curve from top to bottom to allow the rounds to properly stack, lift and feed. Why? The Soviets were used to dealing with harsh climates. The summers down near the Crimea could be hot, dusty and dry. Up around Leningrad, the winters could be months-long, bitter cold, and head high in snow. And in between it would be hot, cold, muddy, dusty, windy, gritty, and did I mention cold? Any day of the year could have two or three of those, and you didn’t get to pick which three.

They had to design weapons that would work everywhere they’d be needed. And continue to work even after they had been neglected. (They may have been communists, but in a lot of areas they were utterly pragmatic.)

A cartridge with a severe taper offers several advantages. First, it feeds easier, as the cone of the cartridge reduces friction on feeding, and keeps the round from stalling if it happens to bind at some point along the way. Second, it extracts easily. A cone-in-cone design breaks free of adhesion as soon as the system begins moving. If you think of a cartridge as a cylinder in a hole, then as you pull the cylinder out, it will drag the whole way. Not until it is clear will friction drop to nothing. A cone in a cone, even if it tips as it extracts, will have friction only on a line, along the bearing axis of the cone within the cone.

So, extraction is easier, an important point for the designers because the M43 was going to be made with steel cases. Steel was cheap (even in a communist/socialist command economy, the actual cost of acquisition matters) it was easy to work, and it was strong. The taper of the case helped there, also. Cases are made by a method known as deep drawing, in which a disk is punched out of a ribbon of sheet metal. It is then “cupped” after getting pressed into a die. This work hardens the metal, so it’s annealed, and then cupped again. Repeat as necessary.

The MP-44 sight is a simple blade with a small amount of adjustment out to 500 yards.

Once to length, it gets lathe-turned to create the rim, the base is hammered to harden it and create the primer pocket, and since it is a Berdan-primed case, the primer hole is drilled.

Then the case is sized down to create the neck and shoulder. It’s sized again to final dimension. As a last step before it’s sent off for loading, the case is plated or lacquered to prevent corrosion, which would negate all the hard work done to that point.

Steel anneals repeatedly with uncommon ease. It work-hardens at a known, and controllable rate. It is easy to leave the necks springy enough to clamp onto bullets, and make the head and rim strong so they won’t blow when fired. And the taper makes forming the body, shoulder and neck easy.

Here in the States, we’ve spent a lot of time and effort making brass cases, also known as gilding metal, do the same thing. And we’ve done such a good job that we don’t have to worry about making the cases tapered to ease problems in other areas. But this can make the AK round a bit of a puzzle for U.S. reloaders.

For instance, what to do about headspace? Headspace is the room in the chamber for the cartridge. The chamber and case dimensions are specified such that the largest round will fit into the smallest chamber. This requires a very high level of precision on the part of rifle and ammunition makers. And it is something U.S. shooters are not just accustomed to, but expect. The Soviets? Not so much. The taper of the case makes headspace on an AK a dimension that doesn’t matter a lot. Let’s use as an example the .308 Winchester. It doesn’t have a lot of taper. If the chamber has too much headspace, the .308 round can shift forward, leaving a gap between the cartridge base and the bolt face.

If the extractor holds the round, the gap is up front, and the shoulder will be blown forward. If the round has shifted forward, and the firing pin reaches the primer, the case will be trapped forward due to expansion, and can expand only to the rear. This usually causes a case separation.

The Schwarzlose machine gun is a blowback design, despite being a rifle caliber weapon. You can do that in a 60-pound plus weapon, but not in a rifle under 10 pounds.

Century Arms AKs being used in tactical drills.

The AK ejects forward and to the right, comforting to a left-handed shooter.

In the course of test firing the rifles, I dipped into the ammo supply. I found that some of the cartons had not been stored as well as they should have been. The steel cases had obvious oxide on them. The steel had been galvanized, so it wasn’t rust, but rather a splatter of zinc oxide. It felt like sandpaper. Had they been mild steel with a polymer or lacquer coating, they would have had rust on them.

Now, in the course of having shot rifles for many decades now, I know what the reaction of many shooters would be, seeing ammo like this. They would no doubt wonder, would it work. I know, because that was my reaction, back in the mid-1980s, when I scored a real deal on some surplus .308 ammo, cheap. Well, it was the ammo in the bottom pallet, on the ship that came over, because it was green and crusty.

My Springfield M1A ate it all without a problem. Had it been .223⁄5.56 ammo, I might have been less certain.

AK owners would expect such ammo to function just fine, provided the primer wasn’t killed by the exposure to whatever rusted it.

And so it was. The rifles I tested this ammo in worked just fine, ate it all, and kept on shooting. I saved a couple as photo samples, but the rest went downrange. As ammo is supposed to.

Other gun owners will look at ammo such as this and wonder will it work. AK owners look at this and think, of course it will work.

If the shoulder of the chamber is too far forward in an AK, the round will stop when the taper wedges it tight. No matter how far forward that shoulder is, the case can only go so far. And, being steel, it is not likely to stretch enough to break and separate.

However, if your AK has an overly generous chamber, you may have a problem as a reloader. Stretched cases, sized back to the minimum, are over-worked cases, and can crack, break or separate more quickly than those fired in minimum-size chambers.

If you have several AKs, the one with the largest chamber will work your cases the hardest. And if you reload by sizing cases to fit the one with the smallest chamber, you’re working them even harder. But, if you size them to last, for the largest chamber, they may not fit in the smallest chambered one.

The exemplar here is, of all rifles, the Lee-Enfield. (Can we find a more disparate pairing of military rifles than the SMLE and the AK?) The British did not care about reloading. They designed their rifle/ammunition combo to work anywhere in the world, literally. It headspaces on the rim, not the shoulder. So, chamber shoulders can be quite a ways forward of the case shoulder. Reloading for the SMLE is an exercise in frustration. I think the largest number of loadings I managed to get out of a batch of cases was five. And I managed that by resetting the case shoulder.

One drawback of a large magazine capacity is the inability to get really low in prone. Even the Germans recognized that with the MP-44.

This involved starting with new brass. (A big expense right from the start, new brass costing pretty much as much as new ammo of the time.) I then neck expanded them with an expander ball correct for .358-inch bullets. I then used the .303 British sizing die to resize the neck down to proper diameter for the .311-inch bullets I was using, but left the shoulder longer, enough to stop on the shoulder in the chamber.

And still they stretched enough to cause case separation after five loadings. I finally gave it up as a waste of time.

If you have an AK with a chamber that is similarly generous, save your brass cases from the torture, and yourself the frustration, and shoot that rifle only with steel-cased, non-reloadable ammo.

The M43 case is unlike anything else out there. The base is nominally .447 inches in diameter. This means the literal truckloads of .308 and .30-06 brass out there cannot be used as a base from which to make cases as they use a case with a base/rim diameter of .473 inches. As I’ve recounted before, my boss at The Gun Room, Mike Karbon, asked me to find a parent case from which to make AK ammo. Since the previous book, I came across some notes from back then, and I had actually found two — the 6.5 Carcano (rim diameter .449 inches), and the 6.5 Mannlicher-Schoenauer (rim diameter .453 inches). As both were imported, usually Berdan primed, and when boxer-primed, more expensive than the AK ammo we had, that was a non-starter. I think back on that time, and wonder why it didn’t occur to us that if it had been easy, someone probably would have already been there first, in the business of making AK ammo that was non-corrosive and reloadable.

The M1 Garand, with its en-bloc clip, was a huge advance in 1936. But the U.S. Army should have let go of it, post-war.

Military surplus ammo comes wrapped in paper and is stapled shut.

In a real pinch, we could have used .30-30 brass. The local ranges back then had not just drums, but dumpsters full of once-fired brass from deer hunters sighting in. I’m sure for a fee, and the value of the brass by weight, they’d have let us sort through and pull out buckets of the stuff. Of course, then there would have been the work of lathe-cutting the .30-30 rim off, and cutting an extractor groove into the base. We would have had to shorten, trim, neck down, full-length resize, then load as ammunition. There was no way we were going to do all that, just to shoot a non-select-fire AK, even in the early 1980s.

Of course, the Maadi, imported by Steyr, had a 1982 list price of $1,250, compared to a Ruger Mini-14 at $304, and a Colt SP-1 at $534. A “man’s” rifle, the Springfield M1A, was listed at $560. And that was at a time when the Median Household Income (MHI) in the U.S. was $19,200. Adjusted for inflation, the Maadi list price comes to $3,100 today. (Adjusted to a percentage of MHI, it would actually be $3,450 today. Yes, the MHI has slipped behind the inflation rate.) Now, there are some who will spend that much on a fully-spec’d, state-of-the-art AR-15. Somebody let me know when $3,100 is a common price for an AK, and a plain-Jane wood stock non-select-fire AKM at that.

Commercial ammo may come off the same production lines as military, but they use colorful pasteboard boxes to hold the paper wrapper.

Remember what we just discussed about the Soviets wanting a rifle that worked on the Eastern Front? That meant it had to work in all weather conditions and with no care. As a result, the gas system of the AK is grotesquely over-gassed. And they even did that despite the very short window in which the gas has to operate, time-wise.

When the bullet passes the gas port, gas is diverted to the system. Actually, what happens is simpler; no diversion needed. Gas will find a way into every space available. That’s what gas does. So, the gas travels up the gas tube, into the expansion chamber, pressing on the end of the piston. The piston doesn’t travel very far before the gas can escape through the vent holes, or past the piston down the slots created by the flutes pressed into the piston tube.

The designers deliberately over-gassed the system because they wanted it to work in sub-zero temperatures, when frozen shut by rain and snow, dirty, rusty, muddy or fill-in-the-blank. Over-gassing was easy, and to make sure the rifle handled it, they simply made the bolt carrier, and the trunnion or receiver shoulder it hit, big enough. When the bolt carrier bottoms out at the rear of the receiver, it has slowed down. It has a bunch of mass, but so does the trunnion. And the trunnion, made of cast steel, is tough. The impact is on a relatively wide surface. Even if slightly uneven one or the other will peen enough to hammer down any high spots, making the impact evenly spread.

The stock helps support the trunnion, and the only real stress is on the rivets. Since we do not see rear trunnion rivets loosening and falling out of AKs on a regular basis, the designers got that right. And on the original AK, the receiver is a machined forging, no rear trunnion, no rivets, and no chance whatsoever of things breaking from bottoming out.

Just on a lark, I test fired one of my AKs with the piston tube removed. It worked just fine, as long as I waited for the piston to find the center of the gas pillar on each return. The tube does nothing for gas retention, or residual gas pressure to drive the system. It exists for two reasons: to guide the piston head back into the gas pillar, and to keep your hands from being in the way.

Left to right: 7.92x33, 7.62x39, 6.5 Grendel, 6.8 Rem SPC, .223, 5.56 in steel case.

In the larger calibers, we have .308, 7.62x54R, 8mm Mauser, 12 gauge and .410. (Amazingly, I do not have a single 20 gauge in the house, shop or bunker. I’ll have to correct that.)

But it doesn’t make the AK fun to shoot. And it doesn’t allow for the usual handloaders’ trickery on powder selection.

Self-loading rifles are meant to work at a given chamber pressure, with the pressure existing over time in what is known as a pressure curve. Depress the trigger, the cartridge goes off. Pressure steeply and quickly rises, the bullet begins to move, and then as the bullet moves down the bore, pressure subsides, due to the expansion of volume and the bullet’s movement.

A standard rule of engineering is, “work is the area under the curve.” Work is what moves the bullet. To increase the area under the curve, you can increase the pressure at the peak. But, any given mechanism will only take so much peak pressure, and soon the gain of velocity becomes too costly, as the rifle falls apart quickly. Or blows apart.

The other way is to “lift” the tail of the curve, the down-sloping section. By keeping pressure higher as the expansion occurs, you increase area under the curve, thus work, and velocity. That’s where a slower-burning powder comes in. Slower burning powders are how magnum rifle cartridges manage to wring more velocity out of the same length barrels as their non-magnum counterparts.

Except, in the instance of the AK, we’re stuck. There is a maximum and minimum pressure we can allow to happen at the port. Above the maximum, and we overdrive an already excessively gassed system. Below the minimum, and we don’t generate enough force to work the action.

When reloading the AK, we are stuck with the middle-of-the-road powders, in the middle of the range. Your curbstones here are H4189 on the fast end, and H4895 on the slow end. Stray too far from them, and you are asking for trouble. As a result, you will find that you are pretty much stuck with factory ballistics. A 123-grain bullet, at or around 2,250 fps is all you can expect. You might find a load that extends that by 100 fps, but you do so at the expense of hammered brass. The extra port pressure will work your action harder, and hurl your mangled brass farther.

You want more than a 123 grains at 2,250 fps? Find another rifle and cartridge. The SKS can help here. You will find some versions with barrels as long as 20 inches. (Don’t blame me if you find that a “carbine” with a 20-inch barrel is not all that handy. You wanted more performance, I’m telling you your options.) But even that has limits.

Hornady lists loads, tested from an SKS with a 20-inch barrel that pushed a 123-grain soft point up to 2,400 fps. Just in case you are impressed by this, the same loading manual also shows loads for the .30-30 out of a 20-inch barrel. The 110-grain bullets can be pushed to 2,600 fps, and the 150’s to 2,300 fps. You are reinventing the .30-30 wheel if you try to push the 7.62x39 past its design limits.

And the maximum pressure ceiling for the 7.62x39, as loaded here in the States? 45,000 PSI, on-par with the .30-30.

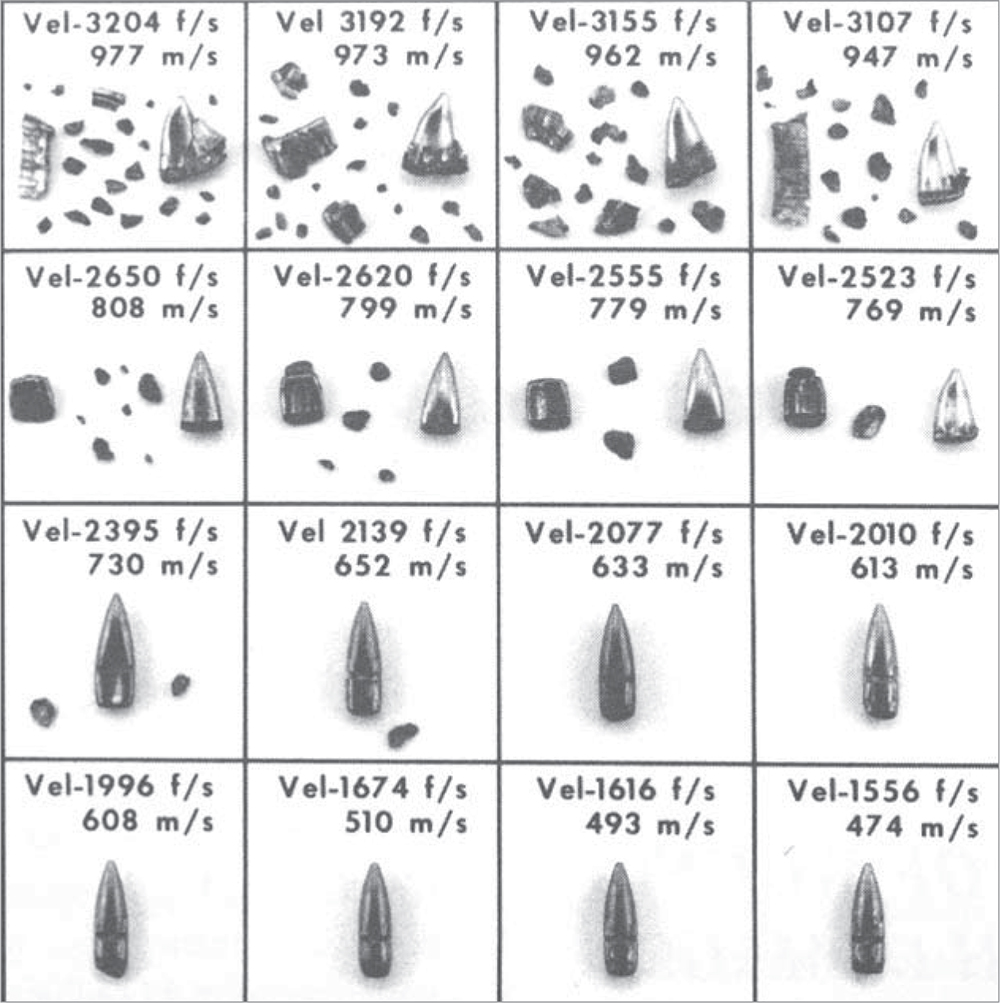

The typical wounds created by various loadings of the .223⁄5.56. Chart courtesy Dr. Martin Fackler and the IWBA.

Rifles need velocity to work. Short barrels and range to target both decrease velocity, affecting wounding and rifle effectiveness. Chart courtesy Dr. Martin Fackler and the IWBA.

The typical wound result of the 5.45x39, with a shorter, more consistent overturn than the 7.62. Chart courtesy Dr. Martin Fackler and the IWBA.

Why is loading slower-burning powders so alluring to some shooters and reloaders? First, the rifle has a reputation for being a lot tougher than it is. Yes, it will survive the utter neglect that it would receive on the Northwest Frontier, but that doesn’t mean it is equally capable of standing up to 50,000, 55,000, or even 60,000 PSI on a regular basis. It isn’t a magnum. Second, the case is rather large for its performance. The .223, for example, delivers a lot more velocity, and at a higher pressure from a smaller case. The case capacity of the .223 is 31.1 grains of water. (We’re using mass to determine volume simply because it is a quick and easy method, and one shooters and reloaders can do themselves.) The 7.62x39 has a capacity of 35.6 grains. That gives the commie cartridge 15 percent more space for powder. It is tempting to try and shovel more in there, to boost the performance of the AK.

This is compounded by the insistence of some to use “pressure signs” as an indication of the limits of a cartridge. Simply put you do not begin to see pressure signs until you are up past 60,000 PSI. By then you are far past the limits of the rifle. If you are loading your own ammo, use your loading manual, and stick with the published data. If you are using factory ammo, avoid loadings that offer you something for nothing, because they can’t.

There are two primer sizes, alas. Large rifle and small rifle. Remington has seen fit to load their cases with small rifle, and everyone else uses large rifle. The firing pin on the AK is not spring-loaded, and as a result many reloaders use tougher-than-normal primers. These would be the CCI No. 34 (large) and No. 41 (small). They are made specifically for semi-auto rifles, and have a different chemistry and tougher cups, to be a bit less sensitive. This reduces or eliminates what is known as a “slam-fire” where the cartridge ignites as the bolt slams home.

There are two things you can do to preclude slam-fires, without using these primers. One, make sure all your primers are fully seated, and below flush with the case head. Second, do not, ever, load your rifle by dropping a loaded round into the chamber with the bolt held back, and then allow the bolt to crash home from fully rearward. The bolt will have too much speed and force, and the inertia of the firing pin can cause it to slam forward hard enough to set off the primer. (It may only do that once in a million tries, but do you want to be the guy holding the rifle on that occasion?)

The AK rifle — like every semi-auto rifle — was designed to have some of its speed and force used up in stripping a cartridge out of the magazine, shoving it into the chamber. Load that way, not the “hold my beer and watch this” way.

The 7.62x39 is late to overturn, and with tumbling beginning past 20cm, in many cases it simply causes a puncture wound. Chart courtesy Dr. Martin Fackler and the IWBA.

In the late 1960s and early 1970s, the Soviets decided that the AK-47, despite having been perfected at the end of WWII, was in need of some updating. They looked at a number of features, namely to improve hit probability, capacity and sighting systems, but found that budgetary restrictions limited them to a product-improved and caliber-changed Kalashnikov.

(I’m sure the irony of a lack of budgetary ability to improve small arms, in a command economy, was not lost on those in the know.)

The end result was the AK-74, with a few changes to improve the QC and durability, and a new caliber to improve lethality. Vietnam was a war that provided a lot of information. In the words of Yogi Berra; “You can observe a lot by watching.” Being on the receiving end of the 5.56 cartridge must have made an impression on the Soviets (OK, they weren’t directly on the receiving end, but they had observers, and sources of information) because the 5.45 is basically the 5.56x45 dialed back a notch, and wrestled into a Kalashnikov package.

This bullet shed its jacket and still penetrated 12 inches after going through plaster, glass and wood.

The loaded cartridge length (57.00mm) is in between the 5.56x45 (57.40mm) and the 7.62x39 (56.00mm). That meant that the Soviets only had to do a small amount of fiddling to make it fit into the regular Kalashnikov receiver. (I suspect it was the other way around; “Comrade, make us a cartridge that duplicates the performance of the capitalist’s black rifle, but fits in the Kalashnikov and works with steel casings.”)

Despite being 39mm long, the 5.45 does not have the same head/rim diameter as the M43. Its diameter is only .394.

So, the 5.45x39 is a steel-cased cartridge still with a noticeable but less taper than that of the 7.62x39. It features a small-bore bullet, in this case a nominal .221 in diameter, and the bullet is … complicated. The “magic” or “poison” bullet is the 7N6, a 53-grain bullet at a nominal 2,900 fps. The alleged design magic is that its mild steel core is held in place by means of a lead sleeve, with an air gap in the tip. Supposedly, the gap lets the core slip forward on impact, this causing the bullet to yaw more quickly.

The steel core in original 7.62x39 loads weighs as much as the whole .223 bullet: 55 grains.

The bullet was not designed as an armor-penetrating round, as demonstrated here against mild steel. But it was cheap. If the Soviets could have made bullets from cement, they would have.

This is likely Soviet propaganda, because it is exactly the opposite of what you’d want a bullet to do. A core shifting forward in the jacket would throw the center of mass forward, increasing stability, and increasing the likelihood of a straight wound track.

What’s actually going on is, the designers of the 5.45, and the 7N6 in particular, are doing the same thing that British small arms designers had done three-quarters of a century before. When the .303 British was developed, it came in the usual late 19th-century form: a heavy round-nosed bullet, some 215 grains in weight, and a suitable fast-twist bore to keep it straight. When they went to a spitzer bullet, they found it to be over-stabilized. To increase the onset of yaw, they made the 174-grain spitzer with an aluminum or fiber plug inside the tip. This was the .303 Mk VII, a change that pushed the center of mass back in the bullet, behind the center of form and, as a result, the bullet proved less stable terminally.

They were not the only ones to do this, the Italians did the same thing with the 7.35 cartridge, a longish bullet that also had the center of mass behind the center of form.

The Soviets had to know this both from recovered .303 ammo in Afghanistan and other border areas, and from the Italian use against the Red Army on the Eastern Front. (They were stubborn, but not stupid.) Also, the .303 had been in use for many decades before the Soviets got around to developing the 5.45. The knowledge was common in the ballistics community. So the gap in the tip of the 7N6 is there to push the center of mass back. This speeds the onset of yaw. The twist of the AK-74 is 1⁄7.5 inches. That’s a little fast for a 53-grain bullet, but remember — there’s a bunch of steel in that bullet. The jacket is a copper-plated steel, and the core is mild steel, with the lead liner adding a bit of density, but not much. The lead is probably there to keep the core in place, as much as add weight.

A sealed crate, with two sealed sardine cans each holding 1,080 rounds. This ammo is good until the crate rots and the cans rust through.

If you don’t have side cutters or pliers, you aren’t getting the band off.

The “poison” part comes from the Russians and their Afghan War starting in 1980. Supposedly, the Mujahadeen were more afraid of being shot by the 5.45 than the 7.62x39, because the wounds were more easily infected. Well, given the utter lack of sanitary conditions there (and the concomitant increase in infections of any wound, of any kind) a messier wound caused by a quickly-yawing bullet will become septic faster.

Curiously, I have an acquaintance who was a Spetsnaz trooper in Afghanistan, and he reports that the Russian troops were much fonder of the 7.62, as it would get through chance obstacles better than the 5.45. Everything in life, even ballistics, is a trade-off.

The .394-inch base diameter means that the 5.45 and the 5.56, despite having eerily similar overall lengths, and similar performance, are in rifles that cannot be readily converted back and forth from one to the other. The rim diameter of the 5.56x45 is .378 inches, thus the difference is too great. You can’t use the smaller case in a bolt recessed to fit the larger one, and the larger one won’t fit at all. You have to pick one and stick with it. In the U.S., you could find or make a bolt to fit the 5.45, but getting a barrel for your AR-15 would be problematic. In the AK, fitting a barrel in 5.56 to an AK-74 wouldn’t be too terribly difficult, but modifying a bolt would be troublesome.

The 5.45 is flashy and muzzle brakes enhance flash.

The recoil difference between the 7.62x39 and the 5.45x39 is marked. Part of that is the muzzle brake on the end, one effective enough to confuse my chronograph until I figured out exactly where to stand. I had been doing chrono work for the book, using one of the 7.62 rifles. I swapped to the 5.45, and on the first shot I stopped, lowered the rifle, and opened the bolt. It had felt as if the rifle had not cycled. There was a loaded round in the chamber. The rifle had worked properly, the recoil was just much, much less. That’s the recoil difference, which makes a difference when you are trying to shoot quickly.

The brake also works, and if you aren’t careful you will become persona non grata at the gun club. When I first test fired an AK-74 many years ago, I simply flopped it onto the shooting rest where I had been testing other rifles. On the first shot, the loose paper, empty ammo boxes and other stuff on the shooting bench got blown off. If you are on a firing line where the benches are close to one another, your neighbors might not look fondly on your AK-74.

Two approaches to the same goal. On the left, the 5.45, a .221-inch bullet that weighs 53 grains. On the right, a bullet matching the latest M4 load — a 77-grain OTM. Yep, same length, but with a one-third difference in weight.

The real difference is in availability of ammo. 5.45 used to be cheap as dirt. I recall buying tins of it back for the first volume of this book, and a sardine tin of ammo would cost $120 shipped. Now, the same amount of ammo costs almost twice that, about the same as 7.62x39.

The 5.45 is very much a niche cartridge, as many shooters who want an AK, want one in 7.62 or not at all. If you are going to go the 5.45 route, be sure and stock up, and then once stocked-up, buy even more as your shooting ammo supply, and keep the ready supply on hand in case the importers stop bringing it in. At least that way you’ll have enough to shoot until you’ve worn out the bore of your 74.

The original round was designed to do a certain job, and was limited by the barrels available. The bullet is over-stabilized, and cannot yaw in time. Once it was adopted, there was no way to go back and make that change.

So, if you are using FMJ ammunition, it will do all the bad things that the DNR says it will, and that is why they do not allow FMJ ammunition to be used in hunting. It will pass cleanly through your deer, not expand or yaw, wound but not kill, and the deer will jump, run or wander off, not to be seen again. At least not by you, but probably the local coyotes.

However, that doesn’t mean you can’t hunt with an AK. (Magazine restrictions complied with, of course.)

Hornady makes the 7.62x39 with their SST, the Super Shock Tip bullet. This is a polymer-tipped hunting bullet that is perfect for deer hunting. A 123-grain bullet, at a nominal 2,350 fps, is right in the ballpark with the classic .30-30 in performance. (Admittedly, the .30-30 does have a bit more weight, but still…) Their 5.45 load uses the V-Max bullet, a superb varmint bullet. Admittedly, the average AK-47 clone isn’t exactly minute-of-varmint out to the other side of the beanfield, but if you’re having fun, and depleting the varmint supply, go for it.

Federal offers both the classic Power-Shok bullet and the new Fusion, both in 123 grains, in 7.62.

Winchester offers ammunition in both their Razor Boar and PDX1 Defender. The Razor Boar is a solid copper hollow point, designed for deep penetration while still holding together. The PDX1 Defender is a bonded-core bullet with two types of lead core — a softer forepart, with a notched jacket to initiate quick expansion, and a harder base, to continue penetration. (Not that the 7.62x39 lacks in that regard.)

Remington offers their REM-UMC line, full metal jacket bullets, 123 grains, at the standard velocities.

All of the brass-cased ammo from Federal, Winchester and Remington are reloadable, the steel cases are not.

In the more original form, Wolf imports steel-cased ammo, as does Century Arms. These are loaded by arsenals that were built specifically for the purpose of making AK ammo, and so you know they have a handle on it. Tula and Brown Bear are also suppliers.

Now, the soft-point ammo, designed as hunting ammo, works terminally just as you would expect such ammo to work. Upon impact, the bullet expands, creates the classic mushroom shape, and basically drops your deer dead right there — assuming you have done your job on shot placement, of course.

Left to right, the 5.45 7N6 bullet, a 55-grain FMJBT, an M855 “Green tip” and a 77-grain OTM. Because of their lengths they all need different twist rates for stability.

The wounding mechanism of the classic design, the steel-core and lead-core 123-grain flat-base bullet is different. First, the steel-core, which is not nearly as common as it used to be. It came over in the late 1980s from China as surplus. Well, “surplus” in that the Chicoms wanted to get cash, they were willing to sell us ammo, and everybody was happy. Until we found out that steel-cored ammo penetrates very well indeed. (We learned this way back in WWII, when we made literally billions of .30-06 armor piercing, but apparently forgot.) So, the Chinese ammo was banned from import, and we now use steel-jacketed, lead-core ammo, or bi-metal bullets. “Bi-metal” simply means a copper plating over a steel jacket to reduce bore wear. It still wears bores quickly.

Steel and lead, steel and copper or bimetal, the wounding process of the FMJ is the same; the bullet enters the target, and therein finds itself unstable. Bullet stability depends on the rpm of rotation, but also the density of the medium through which it is passing. The rifling in your bore is calculated to keep the bullet stable in air. Water (of which we and game animals are mostly composed) is denser than air, so the rate of twist needed to remain stable in water is faster.

The longer a bullet, for a given caliber, the faster the twist rate has to be to make it stable and accurate. The “for a given caliber” part is very important. If you have, as an example two bullets; a .308/.310, and a .222/.224, and they are both 1-inch long, they will require different twist rates to achieve stability and accuracy.

How does instability in the target manifest itself?

The bullet, with its center of mass behind its center of form, is now unbalanced. In air, the rotational stability, the gyroscopic force generated, keeps it point-on. It has sufficient gyroscopic stability to remain point-on in air. Once it enters a denser medium, it does not have sufficient gyroscopic stability to remain point-on. It begins to yaw, attempting to swap end-for-end. The gyroscopic stability is not sufficient to overcome the leverage the new, denser, media exerts, with the center of mass and the center of form not being in the same place. The trick here is, how quickly does it yaw? A very stable bullet will yaw, but only do so after it has passed through an appreciable amount of tissue. Yawing at (as an example) 12 inches deep, when a person is only 10 inches thick, means yaw after the target. You get a clean, straight, punctuate wound.

Now, if you are trying to reach 3 feet deep into a moose, or even deeper in a Cape buffalo, then you want stable. Other times, not so much.

How stable is the M43? That depends.

The classic calculation for stability is the Greenhill formula, developed by Sir Alfred George Greenhill back in the end of the 19th century. It calculates the needed twist for a given lead-core bullet.

These bullets are pretty much the same length. But they need different twists, due to mass and diameter.

This is a fired 5.45 7N6 bullet. The rifling marks (on the bearing surface) do not extend up past the halfway point. This is why the 5.45 case is short and fat, the bullet has to protrude out of the neck so very far.

The formula, which he derived experimentally, is;

Where T is the calculated twist rate, D is the diameter of the bullet, and L is its length. C is a constant, which he determined to be 150 for bullets/projectiles (he was calculating this for artillery shells) going less than 2,800 fps, and 180 for those going more.

You will notice that the weight of the projectile is not a function of the equation, only its density.

The value Sg is the specific gravity of the projectile in question, divided by 10.9, which is the specific gravity of a copper jacketed projectile with a lead core. For most rifle bullets, Sg is 10.9, so the two in effect cancel each other out. (What it really does is create a value of one, and the square root of one is…one.) What matters is not the weight, because length is the important consideration. Weight changes the force on the moment arm we are calling the bullet at this juncture, but not the length of that lever. As Archimedes pointed out, lever length is what matters.

If you had a bullet such as the original jacketed military bullets in the latter 19th century, you’d have a .308- to .323-inch diameter bullet that was up to 220 grains in weight, and was essentially a round-nosed cylinder. If you were to change that bullet to a very low drag, pointed bullet with long boat tail, but the same length as the 220-grainer, you’d have a bullet that weighs only 180 grains. And because of its length it would still require the same twist as the 220-grain round-nose.

If, on the other hand, you went with a not-so-low-drag pointed bullet with a flat base, you’d have a 150-grain bullet. That would not need as fast a twist, but if that’s what your rifles are made in then you now have over-stabilized bullets.

So, let’s take a bullet I just pulled from a Winchester load, a 123-grain FMJ. The bullet diameter is 0.3095. The length is 0.871. It is most certainly going less than 2,800 fps, so we cram all the numbers in there, kick-start the calculator, and come up with a Greenhill-predicted twist rate of 16.5 inches.

Greenhill is good, and Greenhill can be useful, but I took it a step further, and came up with a value I modestly named after myself, the Sweeney Stability Ratio, or SSR.

First, we drop the adjustment for density, since we’re only considering lead-core bullets for now. This leaves us with;

Then we divide both sides by the diameter squared, and solve for the constant;

So far, so good. Next, we use the latest equation to solve for the constant as calculated with the dimensions of the bullet and twist we have. And to generate our ratio, we divide the Greenhill constant (150 for less than 2,800 fps, 180 above that) by our calculated constant, and we now have a ratio of what we have, compared to what he experimentally derived.

If the twist with the bullet we’re using and the velocity agree with Greenhill, then the SSR will be 1.0. A less stable bullet will be lower than 1.0, and overly stable bullets will have an SSR higher than 1.0.

When I first did this, I calculated it for two sets of conditions: the M-193 5.56 cartridge, in a 1⁄12 twist barrel, and the M855 in a 1⁄7 twist barrel. The M193-1⁄12 set of parameters give a calculated SSR of 1.003. Hmm. The M855-1⁄7 parameters produced an SSR of 1.19. The M855 has a reputation for being overly stable and producing “through and through” wounds.

We can use that observed performance of the M855 as a benchmark, and consider that an SSR as high as 1.2 is perhaps a bit too stable.

FMJ bullets have as their final manufacturing operation the core being seated in the jacket. Here you see the dished-in seating attribute. Next to these is an OTM, with a solid base. No dish.

The M193, for all of the complaints brought to it, performs quite well when you don’t have to deal with barriers. The FMJ boat-tail bullet will yaw pretty quickly, and in ballistic gelatin, typically “J” hooks and exits the side of a gel block. Since a block is 16 inches (handguns) or 18 inches (rifles) and the bullet exits the block at the halfway section, it has hooked enough in 8 or 9 inches to have changed direction by 90 degrees — that is, when the velocity of the bullet has not dropped too low (at distance, for example). If the target is closer than 200 meters or so, when the bullet begins to yaw, it cannot withstand the stresses. The M193 yaws typically at closer than 200 meters (from a rifle, carbine or SBR a shorter maximum distance) then breaks at the cannelure and the fragments causing secondary wounds. The M193 has its faults, but open air shots (not behind barriers) on unarmored targets is not one area in which it fails.

And that’s with a stability ratio of 1.03. Clearly, we want to be closer to 1.0 than not, and 1.2 (the M855-1⁄7 parameters) is already giving us some problems. The problem with the M855 is not that the bullet won’t break, it will. But the bullet is so stable that it doesn’t yaw enough, in time, to break apart before it has exited the subject. If a person is (as an example) 10 inches thick, and the bullet begins to yaw at 12 inches or more, it has passed through before it can yaw.

A gun writer acquaintance of mine has had a total of four overseas tours, two in Iraq and two in Afghanistan. His report on the M855 was, “Sometimes it works, and sometimes it doesn’t. There was no predicting it, and you just kept shooting.”

The 7.62x39 is not “equal to” or even “close to” a big-bore .30. Case in point is the bullet. Left, a 168-grain AP from a .30-06 (and the same bullet would be in a 7.62NATO). On the right, an AK 123-grain FMJ. The armor piercing also has a starting advantage of 400-500 fps.

The twist rate of a bore is not always an easy thing to measure. The common method is to use a tight-fitting patch and a rotating handle cleaning rod. Poke the rod down the bore, bare. Insert a cleaning patch into the tip, in the receiver, and then pull back until you get it started in the bore, and you can see the rod turning. Take a section of masking tape, and tape it around the rod, at the muzzle, with the tail ends of the tape pointing straight up, as close to the muzzle as you can get it.

Pull some more. As you pull the patch through, the rod rotates to follow the grooves, while the handle does not. The tape acts as a flag to show you the rotation. Use the rotating rod to measure one full rotation as you move the patch. When the tape flag gets back to fully vertical, stop. Measure the distance between the muzzle, and where the tape is now. That is your twist rate.

This sounds accurate, but can vary a bit. The Mosin rifle twist spec was 1⁄10. I’ve seen some sources for the AK-47 as 1⁄9.45. If you measure your twist, don’t be surprised if you come up with measurements between 1⁄9.5 and 1⁄10.5, from the same barrel. A half an inch either way isn’t much especially when you are as stable as the M43 in the AK twist.

And the differences might be more. I don’t know what the Soviet mil-spec was for the AK — and I suspect no one outside of the factory knows, either — but there had to be some tolerances. So, the twist rate, measured in metric, is 240mm, which could have been allowed to vary. So, was it 240+/-5mm? +/- 10mm? 20mm? Different arsenals, on different days, from different rifling machines, could theoretically produce a spec barrel having a twist of anywhere between 230mm and 250mm. Who knows. But they would all have been overly stable.

So, for the Winchester 123 FMJ we plug the numbers in and come up with an SSR of 1.73. Yowza! This is interestingly stable, and it also bears comparison. If we were to fire the 55-grain FMJ M193 in a rifle with a twist of 1⁄7, we’d have an SSR of 1.71. So, the AK-47, with the Winchester 123-grain flat base lead core bullet, has the same stability ratio as a lightweight 55 FMJ out of an M16A2. The AK bullet is so stable that it clearly doesn’t have time to yaw much, if at all, before it has exited the subject.

Now, the common M43 bullet is not quite the same as the bullet used by Winchester. I managed to wrestle a bullet out of a loaded Wolf round, which wasn’t easy. (The 5.45 round of the 7N6 load was even worse.) The Winchester bullet is a flat-base bullet, but the M43 has a boat-tail. And to make it even a smidge longer, the final core-bump, to make sure the core is tight to the jacket, means the base is slightly concave. As a result, the Wolf bullet is 1.047 inches long. The calculated SSR for the Wolf M43 123 FMJ is 1,44. This is marginally better than the Winchester for yaw.

And that excessive stability is what leads to the through-and-through wounds of the commie cartridge.

A quick step back at this point. The original small-bore bullet (smaller than the common .45 of the time) was a 220-grain FMJ or soft point. The current closest thing to that is a Sierra 220-grain soft point. (Had I an original .30-03 cartridge, with a 220 FMJ, I would not be taking it apart to measure the bullet.) The bullet length is 1.310 inches. Also, as a reminder, that bullet was nowhere near 2,800 fps, so we’ll be using the 150 constant from Greenhill.

The Greenhill formula calculates a desired twist of 10.86 inches. The SSR for the bullet, fired in a 1⁄10 twist barrel, is 1.09. That’s a big, heavy bullet that is going to yaw pretty quickly. What would it take to bring the 7.62x39 down to an SSR of 1.0? A twist of 1⁄16.5. That’s pretty slow, but the 123-grain flat-base bullet is pretty short. Short means slow twist, just as long means a faster twist.

To put this all in perspective, let’s consider some recent history in small arms development. In 1940, the U.S. Army realized that war was imminent and that not every soldier was well served with the issue 1911A1. Not that it wasn’t, and isn’t, a fine sidearm. But soldiers needed more, and not all could deal with the bulk and weight of the new M1 Garand rifle while performing their assigned duties. Hence the M1 Carbine. The carbine cartridge fires a 110-grain round-nosed jacketed bullet. The normal twist of the .30 bore in use then, 1⁄10, would have made it obnoxiously over-stable. The designers settled on a twist rate of 1⁄20. Not that the M1 Carbine bullet, tumbling, makes for that much more effective a wound track, but it is enough to make it stable, and they wouldn’t have problems with bullet construction, running the little bullet at twice the RPM it needed to be stable, the situation that they’d have had with 1⁄10 barrels.

While they were at it, they also spec’d the cartridge to have a non-corrosive primer. That made it a lot easier to clean, and cut down on corrosion, at least corrosion caused by its own ammunition.

The M1 Carbine wasn’t perfect, but they did get a lot right. And they did not limit themselves to the one-and-only bore size and twist of the standard rifle, unlike the AK.

You do not simply rip the band off by hand. If you can, you probably don’t need a rifle, do you?

The inspectors’ tag, letting you know who boxed these cans.

The way bullets are made just makes things worse for the AK. Copper jackets are actually an alloy known as gilding metal. This is an alloy of 95% copper and 5% percent zinc, also known by the trade vernacular as “ninety-five-five.” It is soft, easy to work, easy to anneal, and the rifling “bites” into it very well. It has a reasonably low coefficient of friction, so you don’t overwork the bullet or bore while pushing a bullet out the muzzle.

Bullets are made by taking coils of gilding metal strip, and punching “coins” out of it. The coins are then shaped in steps called “draws” where the bullet is by steps punched more and more into a bullet shape. It gets work-hardened, and has to be annealed (softened) and cleaned.

Near the end, a section of lead wire is cut, inserted, and slammed into the jacket by means of a hydraulic ram. One peculiarity of gilding metal, vis-à-vis lead, is that it has a certain amount of springiness. So, if you push a jacketed bullet through a sizing die to bring it to a final diameter, the jacket gets pressed in, and then springs back. Microscopically, but at rifle velocities and RPMs, it matters. You see, the lead does not spring back, and that can lead to looseness, or gaps. So the final step of bullet making is to hold the bullet inside of a correct diameter die, and hydraulically press the base of the bullet, to press the core tightly into the jacket. Out of the die, the jacket tries to spring back against the pressure, and cannot because of the tightly pressed lead core. Look at the base, and you’ll see the imprint of the ram. The pulled bullet from the Wolf 123 FMJ is a perfect example of this.

Mil-spec AK bullets are tough bullets. I’ve joked that the .45 ACP 230 FMJ is so tough you could shoot it sideways through a railroad tie and not have it deform. The AK bullet is almost that tough, in gilding metal jackets. Steel? Even tougher.

The bi-metal bullets that are featured in a lot of European and former com-bloc arsenals are made by selecting from a couple of differently constructed coils of metal as the starting point. One is to galvanize the mild steel of the jacket metal coil of material. Galvanizing is a zinc-plating process that inhibits rust. They could also galvanize the jackets after forming, but doing it to coils is easier. Another method is to electroplate one side of the coil, the side that will be outside when the bullet is finished. The last is to use heavy rolling presses to bond a thin sheet of copper or gilding metal to one side of the steel ribbon, again the side that will be outside when finished.

The steel used is very soft. To call it mild steel is actually giving it more credit than perhaps is due. A pedantic metallurgist might be tempted to term it a malleable iron, as the carbon content is very low. I’d wager a good deal of money that the highest grade of steel used in jackets is not going to be better than SAE 1030 in equivalence. And more likely 1020. (You can, if you are average in strength, bend a rod of 1030 steel over your knee. The manly men among us could do it to a rod of SAE 1020 without a knee involved.)

But it is steel. That means it is hard on bores. A bi-metal bullet will have double the wear of a gilding metal bullet. And the galvanized? Off the charts, due to the abrasiveness of the zinc plating.

There’s an online ammunition seller who did an extensive volume ammo test with AR-15s. They fired 10,000 rounds through each of four rifles, and used a different ammunition for each of them. The rifles subjected to the gilding metal bullet ammunition had some service life left once the ammo was gone. The barrels that were treated to the bi-metal bullets were used up before the rounds were consumed, and accuracy analysis indicated that they had lasted for about 5,000 rounds.

Keep that in mind, as you merrily shoot through the AK ammo you bought so cheap.

The 5.45x45 is a different situation. First of all, the bullet is longer than a 55-grain FMJ, in part due to the large amounts — relatively speaking — of steel in the construction. We also have to go back and recalculate things based on the changed density.

Let’s use ballpark figures for starters.

With much hammering, cursing and effort, I managed to extract a bullet from a loaded round of 7N6. I’m going to make sure I save and keep track of this bullet, because I don’t want to have to do that all over again. The bullet is 1.003 inches long!

The 7N6 bullet, compared to the FMJ boat-tail M193 at .755 inches, makes the 7N6 a third again as long. Plugging in the numbers, we come up with an SSR that is 0.937 if we use the 150 Greenhill constant, and 1.125 if we use the 180 constant. (The 5.45x39 straddles the border, so it can be difficult to assign a proper constant to it.) That means the 5.45 is just about on-par with the XM-193 where yaw is concerned, and if the velocity drops below 2,800 fps, it becomes less stable in wounding than the 55 FMJ boat-tail. Hmm, a bullet that causes greater wounding at distance, than up close? Or rather, is more efficient in wounding? There’s something that’s just wrong with that, but it will require a different book than this one to parse out.

Lacking the can opener, you can try a lot of ways to get an ammo can open. This is one of the more expensive ways.

At least, with the rim milled off, I can frame the ammo can lid.

That SSR, however, ignores the difference in mass.

Iron has 70 percent the density of lead. If we assume the empty space in the 7N6 bullet partially balances out the density of the lead lining, we can assign a density of 75 percent for the 7N6 bullet, compared to a lead-core one.

That means our calculation has to be the square root of 75 percent of 10.9. 75 percent of the specific gravity Greenhill uses is 8.175. But we need that as a percentage, so we’re calculating the square root of 0.8175. The square root is 0.9041.

By cranking the various numbers in, we determine that our bullet, the 53-grain boat-tail from the 7N6 load, will need a different twist when it is all steel. So, by the Greenhill formula, it needs a twist of 1⁄7.99 to be happy and have an SSR of 1.0. Therefore, a lighter bullet, all other things being equal, requires a slower twist to remain stable.

What all this arithmetical juggling does is confirm that the 5.45 is indeed a less stable bullet in tissue than the original 7.62X39, and thus will (and does) wound better.

The first actual inquiry into the usefulness of the 7.62x39 came from Dr. Martin Fackler and the International Wound Ballistics Association. Dr. Fackler used 10 percent gelatin as a tissue simulant. The idea was to find a substance that would correspond, more or less, with tissue, to tell us what bullets did to tissue, and what tissue did to bullets.

There are two important factors to keep in mind. One is that it is a simulant, and as such it is not perfect. You can quibble about how well it replicates muscle, or fat, complain that it lacks bones and other, tougher-than-fat-or-muscle substances in the body. And, you can report that while bullets expand consistently in 10 percent gel, they do not seem to do so as consistently in tissue. No one said it was perfect.

Second, that it is consistent. If experimenters on the two coasts test the same bullet, at the same velocity, in their gel blocks, they will come up with the same results. That is the essence of the scientific method — repeatability.

Previous substances used either were not at all close to simulating tissue, or were so varying in their consistency that you could prove just about anything, if you coddled the test medium the right (or wrong) way. For all its faults, 10 percent gelatin offers consistency.

And density that offers us a way to explore non-expanding bullets. Remember earlier when I mentioned that bullet stability depends on the density of that through which it proceeds? When a bullet transitions from air, low density, into tissue, high density, it becomes unstable. That induces yaw. The less stable, the sooner it yaws.

For many years, those extolling the virtues of the 7.62x39 were to one extent or another equating it with the 7.62 NATO. This is not the case. Let’s review the specs. 7.62x39; a 123-grain bullet at 2250 fps. 7.62 NATO, a 148-grain bullet at 2650 fps. The AK round is from a barrel with a 1⁄10 twist, over-stabilized. The 7.62 NATO from a barrel with a 1⁄12 twist, not so much over-stabilized.

The IWBA process developed by Dr. Fackler was simple, it used a block of a known size, density, temperature and distance into which a bullet was fired. It would capture the bullet, and you could assess the effects on the block. Rifle blocks measure 8 x 8 x 18 inches. (Handgun blocks are 6 x 6 x 16.)

Since the formation of the IWBA (I was one of the original members, joining as soon as I heard about it, and corresponding with Dr. Fackler back in the late 1980s.) I’ve had a chance to test rifle bullets in gelatin.

What he found, back in the days before we had reliable expanding handgun bullets, and rifle bullets were still much of a mystery, was that the 7.62x39 as-issued was a great penetrator and wounder, yet not so much a killer. The typical bullet for the M43 was steel cored, with a lead liner between the core and the copper plated mild steel, or copper jacket. Why? Steel was cheap. One of the continual five-year plans was the increase in steel production. (Along with concrete.) Steel was cheap, easy to form, and it worked.

So, this steel bullet, over-stabilized by the fast twist, performed in the ballistic gelatin just as you’d expect. But back then, it was news.

The bullet would travel, on average, some 10 inches into the gel before it would start to yaw. It would turn end-for-end in the next 4 inches, and then do it again, before reduced velocity started causing it to wander off the original direction. It would stop at the 75 cm, or 29-inch depth. So, for the first 10 inches of depth, it was traveling in a straight line, and not expanding.

It is a husky person who is more than 10 inches deep, from sternum to spine. As a result, the 7.62x39 caused what is known as a punctuate wound. An in-and-out, with no expansion, and no extra damage due to yaw. If it hit a vital organ, or a structural part, the effect was immediate. But lacking that, well, there are more than a few Vietnam (and now Iraq and Afghanistan) veterans who have simple circular scars from where they were hit, to not much effect, by AK rounds.

How did this differ from the comparator, the 7.62 NATO?

The heavier .308 bullet, traveling at a higher velocity, and with less stability begins to yaw at 6 inches. And it does so with more energy. This is with the standard FMJ, a boat-tail 147⁄148-grain bullet. If the same rifle is used with a heavier bullet, such as a 178-grainer, the yaw begins sooner. This is offset somewhat because in many instances the users of such bullets are also using sniper rifles, commonly with a 1⁄10 twist. The heavier, faster bullet yaws sooner, and has not yet exited the body, thus creating a more effective wound.

The two 7.62s are not comparable. In testing them on gelatin, I have found that while the rifle blocks submit to the impact of the AK round, they must be lashed in place when testing with a 7.62/.308 round. Otherwise the forces will bounce the block up off of the supports, and if the support or table is not wide enough, your test block goes crashing down into the dirt. One shot of each is enough to dispel the idea that the two are at all equivalent.

How does all this compare to the 5.56?

The original was the M193, a 55-grain boat tail full metal jacket bullet, with a nominal velocity of 3,200 fps. That was from the 20-inch barrel of a full-sized M16/AR-15. Out of a carbine it delivered less, but not a lot less. I’ve gotten over 3,100 fps out of a 16-inch carbine, and over 3,000 out of an SBR. In the 1⁄12 barrel, the effect is impressive. The bullet begins to yaw just past 4 inches of depth. However, the velocity is so great (within what is known as the “fragmentation range”) that the bullet is not strong enough to yaw successfully. It flattens and breaks apart at the cannelure. Meanwhile, the fragments, driven at the remaining velocity, cause a much more severe wound.

Even if the bullet does not fragment, the forces at work cause the base to flatten, and the bullet “j-hooks,” turning in direction to exit the block to one side, top or bottom. We have learned that if we wish to save sample M193 bullets fired into ballistic gelatin, we have to wrap the blocks in old soft body armor vests. They will stop it when it tries to leave, almost invariably between the 8-10 inch deep part of the block.

The later loading, the M855, fired from a 1⁄7 twist barrel (it is not at all accurate when fired from a 1⁄12 barrel) is not so successful. Sometimes it will perform as the M193, and sometimes it acts more like the 7.62x39. In order to save sample bullets of M855, we have to put vests on all sides and on the back. If it does not yaw and j-hook, it will yaw and travel straight — exiting the rear of the block.

The 5.45 is an interesting mixture of the above. First of all, it is less stable than any of the others. The bullet begins to yaw almost immediately, at the 3-inch depth. However, since it is pretty much an all-steel bullet, it does not (indeed, it cannot) break apart. It then proceeds to yaw again, before curving off-track and stopping at about 20 inches into the gelatin. It occasionally exits the sides of the block, but not as consistent a depth as does the M193.

I won’t say that a 1-inch-long bullet, traveling sideways, isn’t making a serious wound, but it isn’t anything like the wound track of the M193, or the M855 when it is working the way it is supposed to.

As a bullet travels downrange, the resistance of the air causes it to lose velocity. Velocity is the force causing fragmentation of the M193 and M855 bullet. Once the velocity has dropped below the level needed to break the bullet (and this velocity differs from one design to the next) it will not fragment. It will yaw, and it may flatten and j-hook.

This is not of major concern to the military, as an opponent at 300 meters who may have been “knocked flat” by a fragmenting bullet at a shorter range is not going to be a problem with “only” a puncture wound. Well, not in the aggregate. He may still be a problem to the person who shot him, and that person’s teammates, but at least he got poked and is bleeding. Give him time, he’ll give up, and things will work out.

Here are some real-world data points.

A lot of people have experience shooting people with rifles. This includes non-sworn private citizens, police and military. The facts are clear on what cartridges do what, the confounding factors are that people are not equally motivated. Some will continue doing what they set out to do, pretty much regardless of what caliber you hit them with.

And others will use convenient obstacles for cover or concealment.

There is no such thing as a one-size-fits-all cartridge. Bigger may be better, but it comes at a cost — recoil, weight of ammo, weight of rifle. You have to pick for yourself.

As a quick and dirty (well, at least a quick and damp) method of checking you can shoot into 1-gallon water jugs, lined up to test penetration. What you will likely find (and I did this again recently, just to refresh my memory, and to check the info) is simple. The 7.62x39 bullet will exit the side, top or bottom of the fourth jug. The 5.45x39, at least with 7N6 ammo, will exit the side, top or bottom of the second jug.

How does this differ from soft-point hunting ammo? The exposed lead of the soft-point bullet is meant to begin expansion. The bullet does not yaw, because the expansion begins almost immediately, and as the expansion proceeds, the center of mass of the bullet shifts from behind the center of form, to at or in front of it. As a result, the soft point will penetrate in a straight line, expanding as long as the velocity is high enough to hydraulically deform the lead core and copper jacket.

While we now see more hunting loads for the AK than ever before, there are not nearly so many as in any normal hunting caliber. Why is that? A simple, and ironic, detail: the supply of cheap imports that make the AK so popular. Let’s take the .30-30 as an example, since we’ve compared the two before.

If you want to practice with your .30-30, you can buy relatively cheap soft-point ammo, the vanilla-plain stuff. It will not, however, be as inexpensive as imported FMJ, or soft points. The huge volume of imports creates a lower-price niche, or level, for ammunition expectation and consumption. Simply put, any AK shooter who wants to practice, will look at the import price, let’s call it at the moment $250 per thousand rounds. Then, the price of hunting ammo, which is on the order of $950 per thousand rounds, and say to themselves “I’ll practice with the ex-commie stuff, and use a box or two of the hunting ammo when I have to.”

The low volume of production and sales, relatively speaking, means the hunting load in 7.62x39 will always be more expensive than the FMJ, even when both are made here in the U.S. By comparison, the American FMJ runs around $800 per thousand rounds.

Even if the ammo makers could get the price of the FMJ AK ammo down to that of vanilla-plain .30-30 ammo, the typical AK shooter would look at the $700 per thousand price of the .30-30 and wonder if they can still find the import stuff at the “old” price.

That said, the average .30-30 shooter is not going to shoot anywhere near the volume of ammo as the typical AK shooter. If the .30-30 shooter, practicing for hunting, puts 40 rounds downrange, he feels it has been a full day. An AK shooter is more likely to be shooting 200 rounds downrange, and might want to do more, if he had only remembered the second range bag full of ammo.

Until the import supply dries up, or the prices come up, there will always be a few hunting loads available for the AK. They will be good loads, but they won’t be numerous. And how great is this disparity? I did a quick, but not comprehensive search for hunting ammo for the 7.62x39 and .308 Winchester. The AK round? I came up with a dozen, three of which were U.S.-made.

And the .308 Winchester? I came up with nearly a dozen just from Winchester alone. I have no doubt that if I were to tote the offerings just from the four makers that come to me at the moment — Winchester, Remington, Federal and Hornady — I’d have over 50 hunting loads in .308 Winchester without breaking a sweat.

It’s not a conspiracy, it is simple economics.