Back 2 Soil

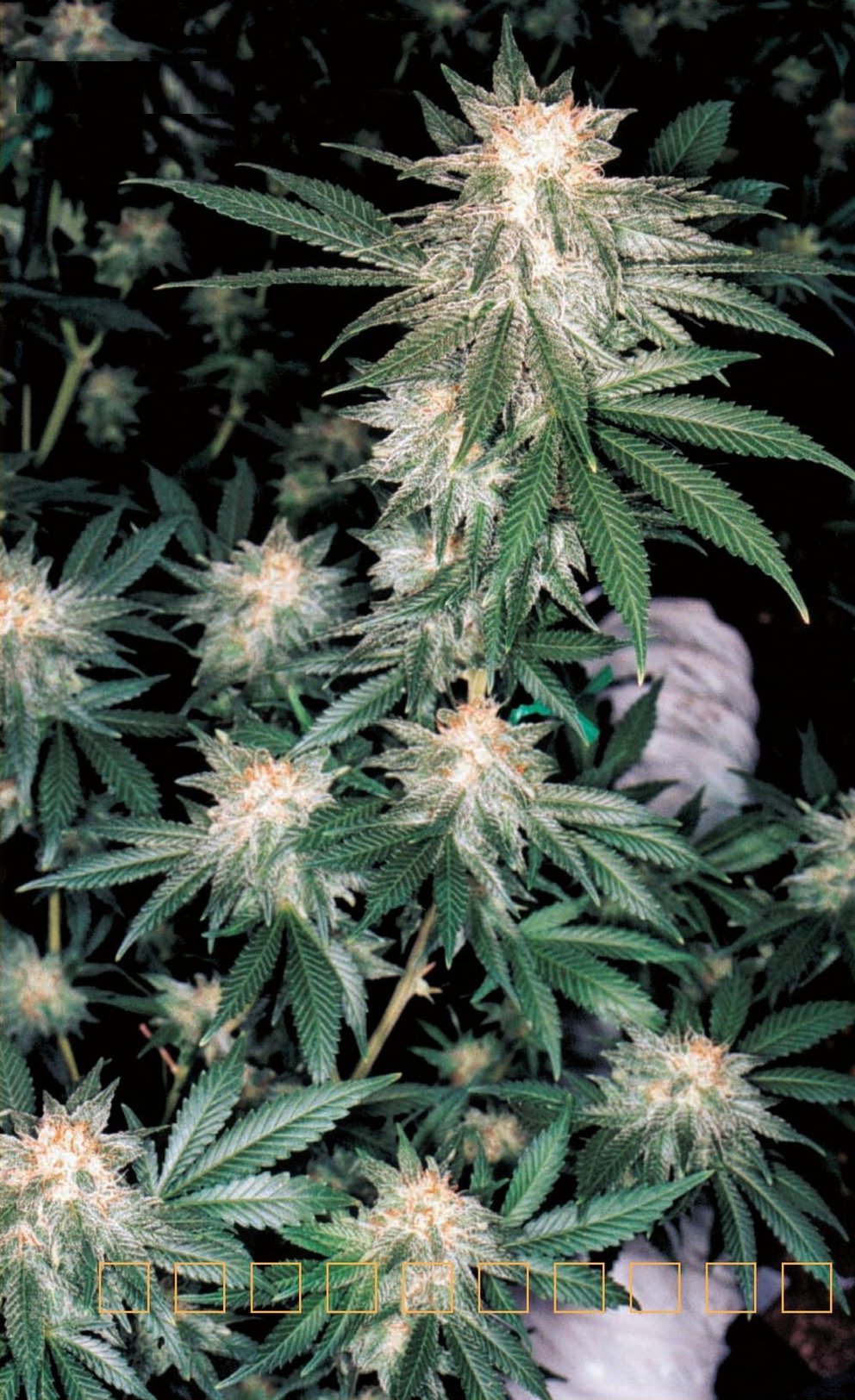

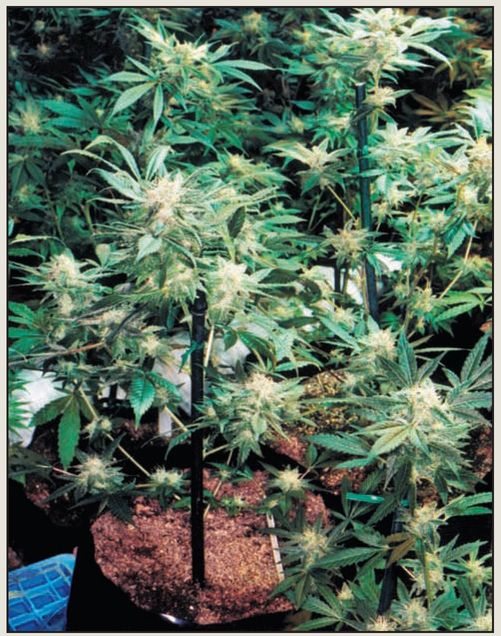

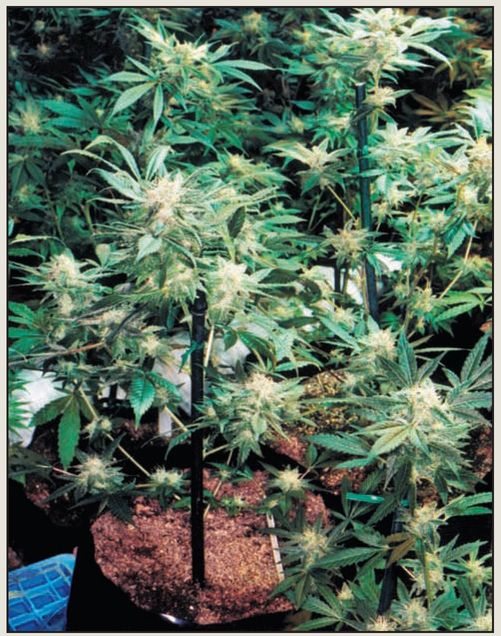

The plants were untrimmed, growing a large center bud and smaller buds on the lower branches

Johnny considered himself an excellent grower. He was very knowledgeable about cannabis and took his work seriously. However, after many successful harvests, he had been plagued wh three crop failures.

He rew his garden using a tube system. The plants were anchored into the tube using a little cup filled with horticultural clay pellets and a rockwool cube. Every ten minutes the roots were moistened with a fine spray of nutrient/water mix. This left a shallow pl at the bottom of the 8-inch diameter tube and very humid air above the tube. Usually the plants thrived.

It was only on is third 75-day crop that he faced problems. The crop failure took place in June, as he temperature rose. During the first twharvests, cool air drawn from outdoorkept the garden in the mid-70s (°F). Whthe temperature rose outside, the gardsoared to the mid-90s, and ventilatiodidn’t provide much cooling. Unfortunathe plants experienced this shift at theginning of the third week of floweringWhen the heat wave lifted two weeks ter, the plants were worth little.

Johnny could not afford another failure. Although he had grown ten successful hydroponic crops before the two failures, he decided to try his hand using a planting medium.

On the next crop, Johnny decito solve the heat problem by cooling the roots. He had read some articles that recommended cooling the water to mitigate high air temperatures. He thought, “the air temperature in the room is in the low 90s, so I’ll cool the roots to the low 60s.” A friend offered him a water chiller he had purchased at an auction of old laboratory equipment. Several clichés come to mind regarding Johnny’s decision to use this piece of equipment, like “always look a gift horse in the mouth” or “cheap is expensive.”

The plants started to improve as soon as the water chiller was installed. Ten days into the cooling process, the plants suddenly dried up. The leaves turned gray and shriveled. In 48 hours all the plants were dead. Johnny looked to the chiller as a probable culprit. The coils of the laboratory chiller were copper. Over the ten-day period, copper in the recirculating water system increased to toxic levels and killed the plants. Had he used an aquarium-grade chiller, the plants would probably have done well in spite of the hot air temperature.

The second crop failure was devastating to Johnny. He had pulled his first crop after seven weeks of growth. The second one was pulled after a month. He lost at least one of his four-and-a-half crops a year. He understood why all the songs about being a farmer are laments.

Johnny could not afford another failure. Although he had grown successful hydroponic crops before the two failures, he decided to try his hand using a planting medium. Knowing it was more forgiving and needing the crop, he was willing to sacrifice some yield to assure success.

I caught a glimpse of Johnny’s plants when they were four weeks into flowering, with another four or five to go. They were very healthy and the buds were developing well. The cuttings, a gift from a friend, were rooted in 6-ounce Styrofoam cups punched with drainage holes and filled with vermiculite, a soil amendment available at most garden shops. Once the plants were well rooted, they were each placed in 3- and 5-gallon plastic grow bags filled with Super Soil potting mix. Ingredients listed in the mix are fir bark, pine bark, redwood sawdust, Canadian sphagnum moss, peat moss, salt-free sand, added nutrients and pH modifiers.

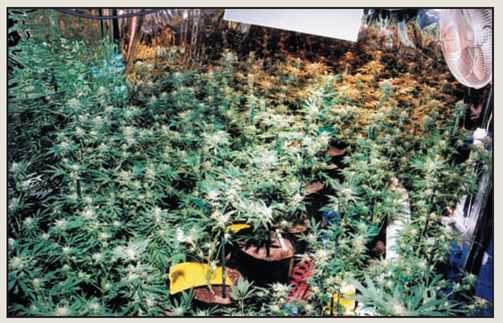

The 6’ x 10’ garden was lit using two 1,000-watt lamps and surrounded by Mylar-coated Styrofoam panels hung from wires. Two rail-type light movers were installed that covered the length of the garden. Each light covered a 5’ x 6’ area. There were a total of 86 containers. The plants were irrigated manually using a plastic watering can twice a week, which took 15-30 minutes. He used a nutrient/water solution made with General Hydro fertilizer. This brand has a three-part mix, labeled as “grow” (2-1-6), “micro” (5-0-2) and “bloom” (0-5-4). The numbers in parentheses show how much nitrogen (N), phosphorous (P) and potassium (K) the fertilizer contains and are always listed on the label in the same order. There are two reasons the fertilizers are separated this way. First, different N-P-K ratios are used at different stages of the plant’s growth. The second reason is that the chemicals lock each other up if they are placed together instead of being dissolved individually in the solution.

The terms used for the three parts of the mix are in a way misnomers, as each one is supposed to be used in the solution. More of the part labeled “grow” is used during the vegetative stage because it has the highest ratio of nitrogen. Most growers keep the “micro” part constant throughout feeding and increase the percentage of the “bloom” formula during flowering, because of its phosphorous content. The ratio of these mixtures can be changed, depending on the plant type and stage of growth.

During the 18- to 21-day vegetative stage, Johnny used three tablespoons of “grow” and one each of “micro” and “bloom” per gallon, resulting in a mix with a fertilizer ratio of 11-8-24. When the plants reached a height of about one foot, the lights were turned down to 12 hours to force flowering. Then the formula was changed to three parts “bloom” and one part each “grow” and “micro,” resulting in a 7-16-20 mix. Neither of these formulas is suggested by the manufacturer, who recommends a formula of 3 parts grow, 2 parts micro and 1 part flowering for the grow cycle and 1 part grow, 2 parts micro and 3 parts flowering for the flowering stage. Soil is a good buffer, as its organic matter locks up some of the nutrients and releases them over a period of time. This helps to prevent over-fertilization and acts as a residual source of nutrients. When I saw the plants they looked extremely healthy and dark green, and the nutrient content of the soil was very high.

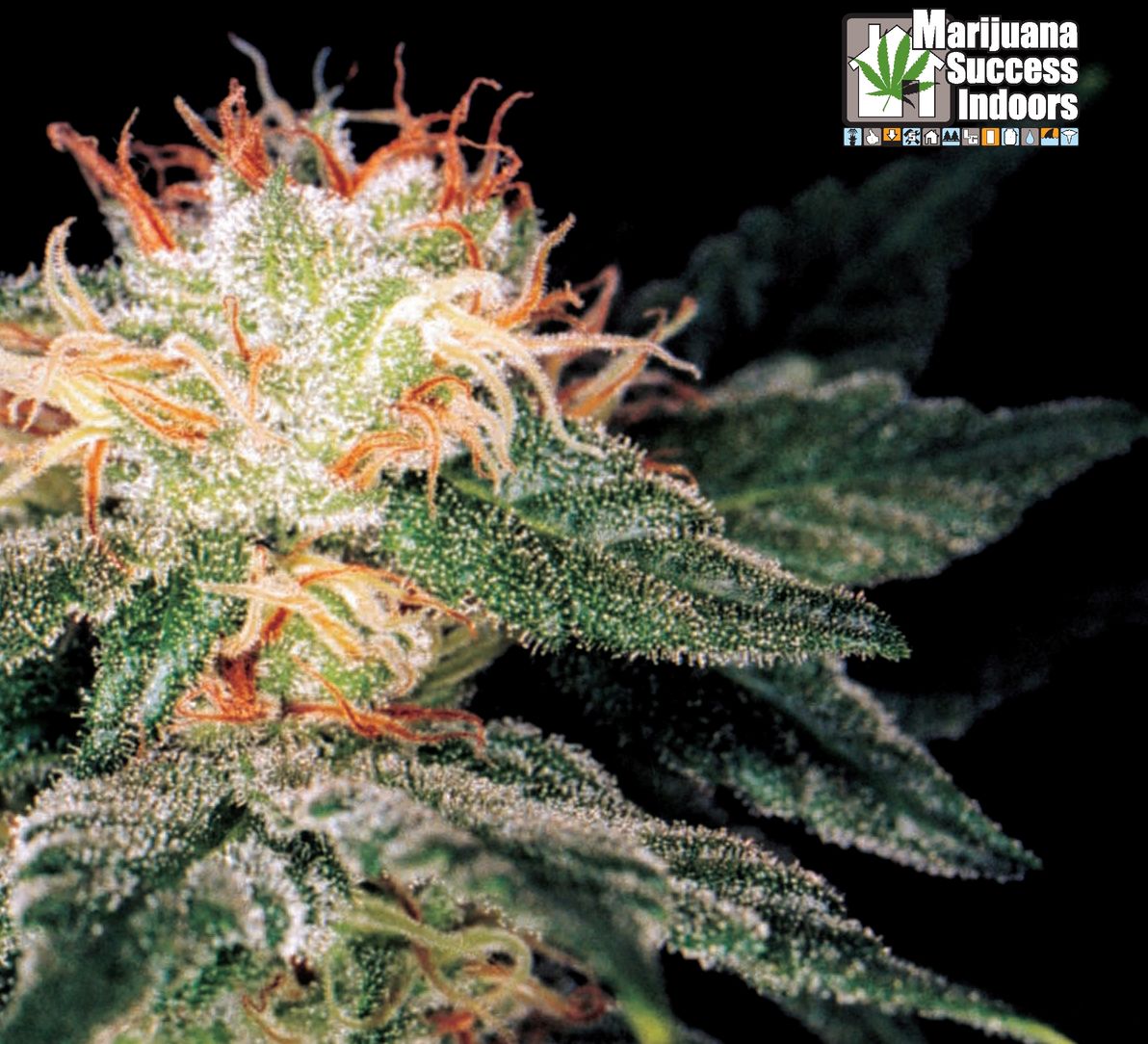

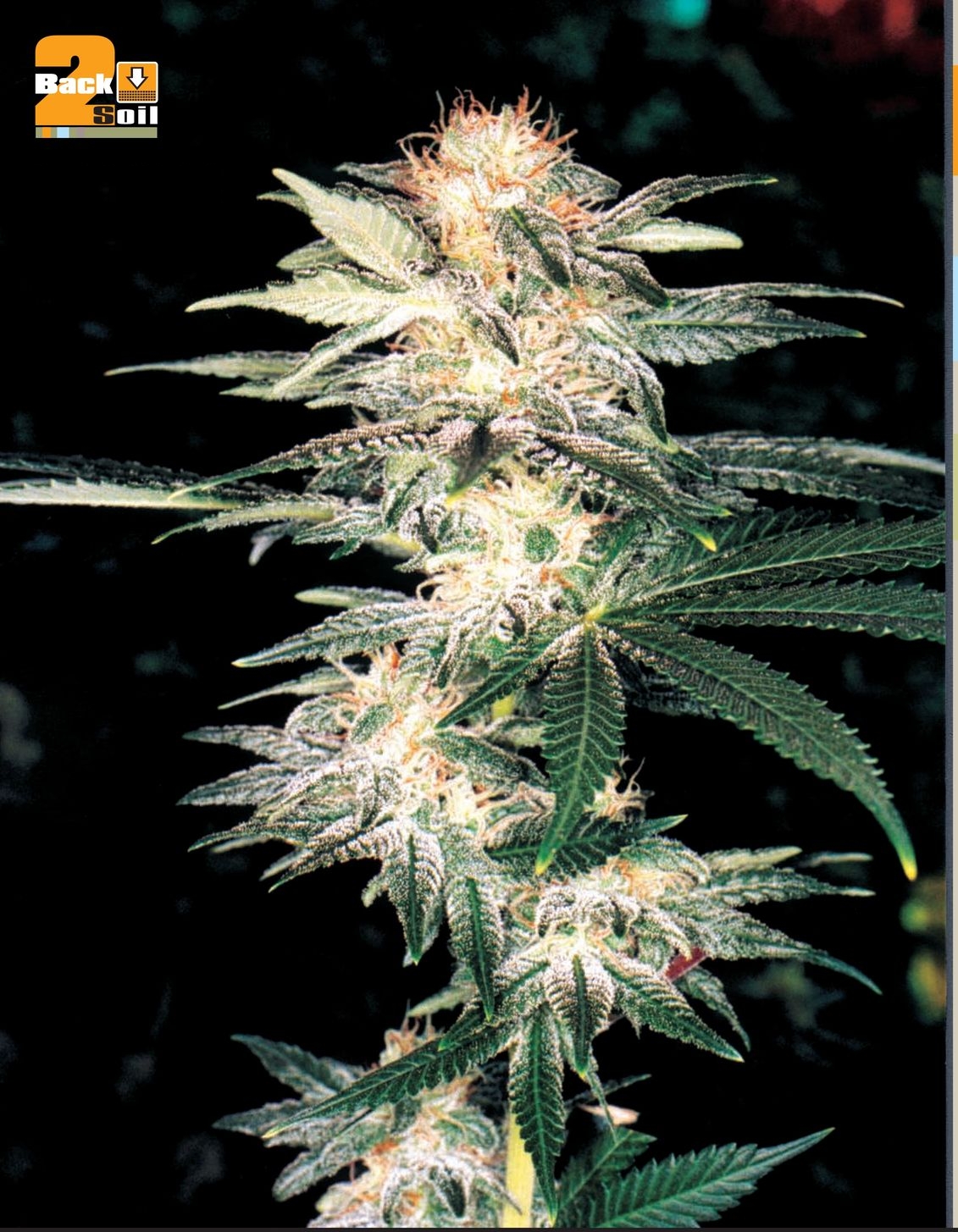

The central bud looks like it has been spray-painted with white crystals.

Instead of continuing with the General Hydro formula, the nutrient solution was changed near the end of flowering to Super-Phosphate (0-20-0) to promote bigger blooms. This fertilizer supplies ample quantities of phosphorous and no other nutrients. Instead, the plants use the nutrients remaining in the planting mix. The plants obtain adequate amounts of other nutrients, but tissue concentration is reduced. Any water runoff was caught in the tray under each container. If the tray got too full, it was emptied and the water was used in the outside yard.

During the cool winter months, the garden needs just simple ventilation. With the coming of spring the temperatures rise a bit and an air conditioner is needed. Johnny is already working on the technical considerations of installing an air conditioner to exchange heat between the room and the rest of the basement.

The plants’ short stature, heavy budding and 70-day maturation period proved that these were obviously improved strains, meaning their genetics have been developed since the 1980s. However, their original names have been lost in transition. Two of the varieties, B-1 and Mervin, were the result of stray seeds in some excellent weed. Other varieties, including local favorites, G.C.’s Northern Lights, S.U.’s Northern Lights, Juicy Fruit, Yoshi and Washington, were gifts from fellow growers.

The garden has been very successful since the day Johnny was given a “gift” of some sickly plants suffering from a virus or bacteria. When these hydroponic plants were placed in the soil medium they recovered somewhat and produced a decent crop. That experience gave him the growing “bug,” and he started his second garden with the varieties he now has, clones from better plants. He has plans for the future, too. “I’m using only half the room now. I plan to clean out the other half of the space and set that up with hydroponic tubes and CO2, and switch the soil system to totally organic fertilizers.” Meanwhile, he’s waiting for his harvest, now only a month away.

These plants are four weeks from harvest. The stakes keep each plant upright. Oscillating fans circulate the air and Mylar curtains reflect the light back to the garden.

Five-gallon horticultural bags filled with high quality planting mix are then fertilized with hydro fertilizer. The result was very vigorous plants with large, healthy buds.

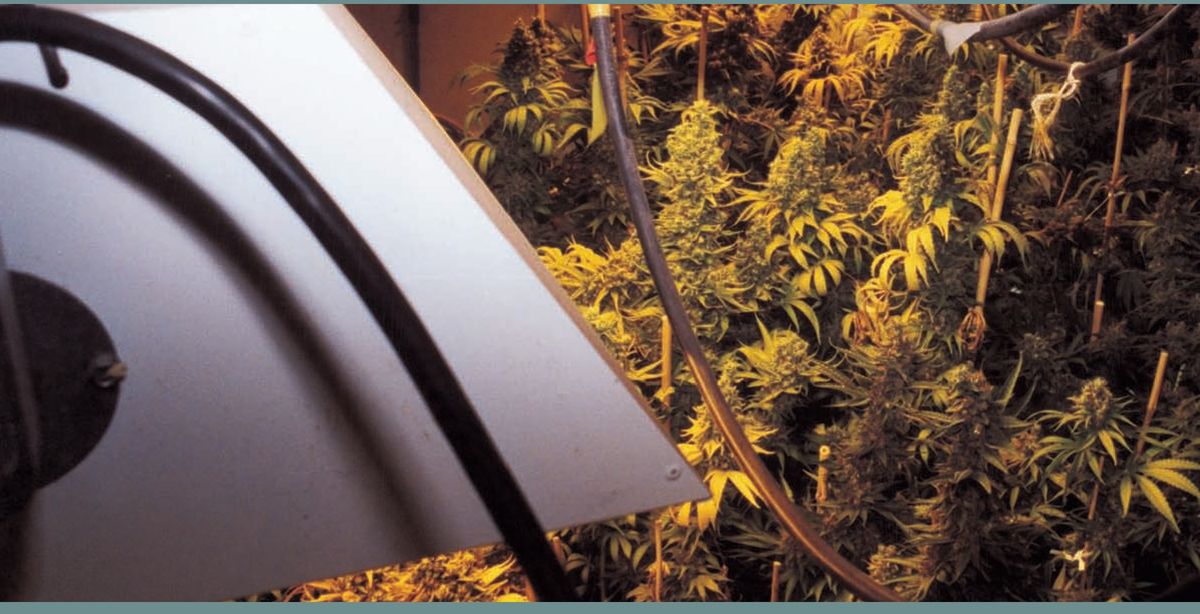

This 4-foot-wide garden is illuminated using 1000-watt, air-cooled horizontal lamps every four feet along the length. Each lamp illuminates an area of 16 square feet. The lights are stationary and hang about 36 inches above the canopy so that the whole area is illuminated. White polyethylene lines the walls and reflects light back to the garden. Four- by eight-foot reflective styrofoam boards (not shown in the photo) are used to reflect the light back from the aisle side. They are very easy to remove and replace. Five air-cooled reflectors are lined up in series. There are fans at both ends of the tubing, pushing and pulling the air through. The air is drawn from a hallway and vented through the ceiling to the attic where a roof fan expels it. The air-cooling removes at least half of the heat generated by the lights. The ballasts are in a separate space so they don’t add any heat to the garden.

*Notice that each plant is staked and the larger plants in this mixed-variety garden are at the side so they don’t block the light from the smaller plants.