Homegrown Harvest

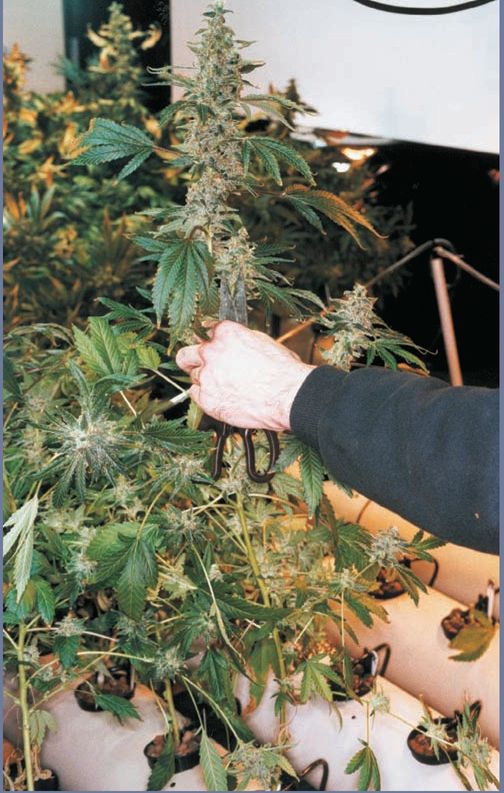

This garden consisted of 8-inch plastic tubes that held 3 1/2 inch mesh cups filled with horticultural clay pellets. The tubes were spaced about 1 1/2 inches apart. The cups were spaced on one-foot centers. As a result, each plant could fill an area of 12” x 9 1/2”, a little more than three-quarters of a square foot. The walls dividing the sections were made from 8 mm black polyethylene film stretched on a frame made from two-by-fours. Mylar was taped to the plastic for its high reflectivity. The lamps were horizontally mounted 1000-watt HPS lamps on chains. Normally the lights were kept 24 inches from the plant tops, but they were raised on their chains for harvesting. They were spaced about 5 feet apart and each illuminated about 25 square feet of space. The plants in this garden would have benefited from staking.

Johnny is no joker. His first garden was a technological marvel. The result was a very controlled high intensity grow area. Despite two tightly sealed doors, no windows and a sophisticated air-cleaning system, two officers testified that they were able to smell Johnny’s immature plants. The judge who decided the case exemplified the problem with American justice: role reversal. He forgot that he had left his job as a prosecutor. He also encouraged the prosecutor to practice playing judge.

While serving six months and waiting another three years for his probation to end, Johnny designed and redesigned a new system. Finally it was time for him to set up. A friend offered him a load of grow tubes, and after renting loft space in an abandoned factory, he began to organize his new farm. Rather than growing in one large section, he framed three large rooms and then used 6mm black polyethylene plastic to frame his space.

He covered the tops of the rooms to prevent light pollution and to contain the CO2. The low ceiling caused heat problems later because the heated air could not escape. The spaces were in an area with 18- to 24-foot ceilings. If the ceiling had been left open, the hot air would have risen. By enclosing the tops, he was holding the hot air in. As soon as he placed holes in the black plastic, a strong stream of warm air flowed out of the top of the garden, creating a draft and pulling in cool air from elsewhere in the structure. However, the temperature continued to climb into the high 80s (°F), heating the water in the irrigation units.

Sprayers on either side irrigated each cup. These constantly bathed the roots in a thin film of oxygenated water. The redundancy was a protection against emitter clogging. Once the water streamed down the roots it formed a thin pool as it slowly flowed to the end of the tube and drained back into the reservoir.

The reservoir: Water is pumped to the tubes through five 1-inch pipes. They distributed the water to half-inch tubing, which had been attached to the grow-tubes using plastic banding. The emitters were attached to the half-inch tubing and water flowed constantly.

The water was filtered as it returned to the reservoir for particles and smaller matter, then it trickled through an activated carbon filter (white and black devices inside right of reservoir).

On the way to the plants, the water flowed through an aquarium UV C sterilization unit (white tube to the right of the reservoir). These units are commonly sold for aquariums and other niche uses. The water flows in a thin stream along a fluorescent tube that produces UV C light. This spectrum is deadly to most organisms and is considered germicidal.

The roots trailed down the tube, bathed in the highly oxygenated water/ nutrient solution. This healthy root system, which is stained by the nutrients and additives, has grown more than a foot long. Most of it trails down the tube floor.

The garden used General Hydroponics tubes adapted to a continuous top-feed drip. As the water circulated, it picked up heat. As it heated up, it held less oxygen in solution. Roots need oxygen to stay healthy; lack of oxygen is referred to as an anaerobic condition. The result was unhealthy roots that were being attacked by anaerobic bacteria. They had a slight ammonia odor and the plants had a hard time surviving.

Johnny considered supplementing the water with oxygen using hydrogen peroxide, but decided instead to cool the water using an in-line water cooler. In a previous garden, he had attempted to cool the planting medium by hooking up a water-chiller with copper pipes - like the ones found in water fountains - to the water circulation system. This resulted in a bad case of copper poisoning for the entire garden. This time he installed a unit designed for keeping fish tanks cool, in which the water passes through stainless-steel coils.

General Hydroponics fertilizers, used in this system, consist of a three-part formula, which has different proportions of nitrogen (N), phosphorous (P), potassium (K) and micronutrients. Each grower has his/her own formula for using these nutrients, and several are listed on the label. During flowering, Johnny used General

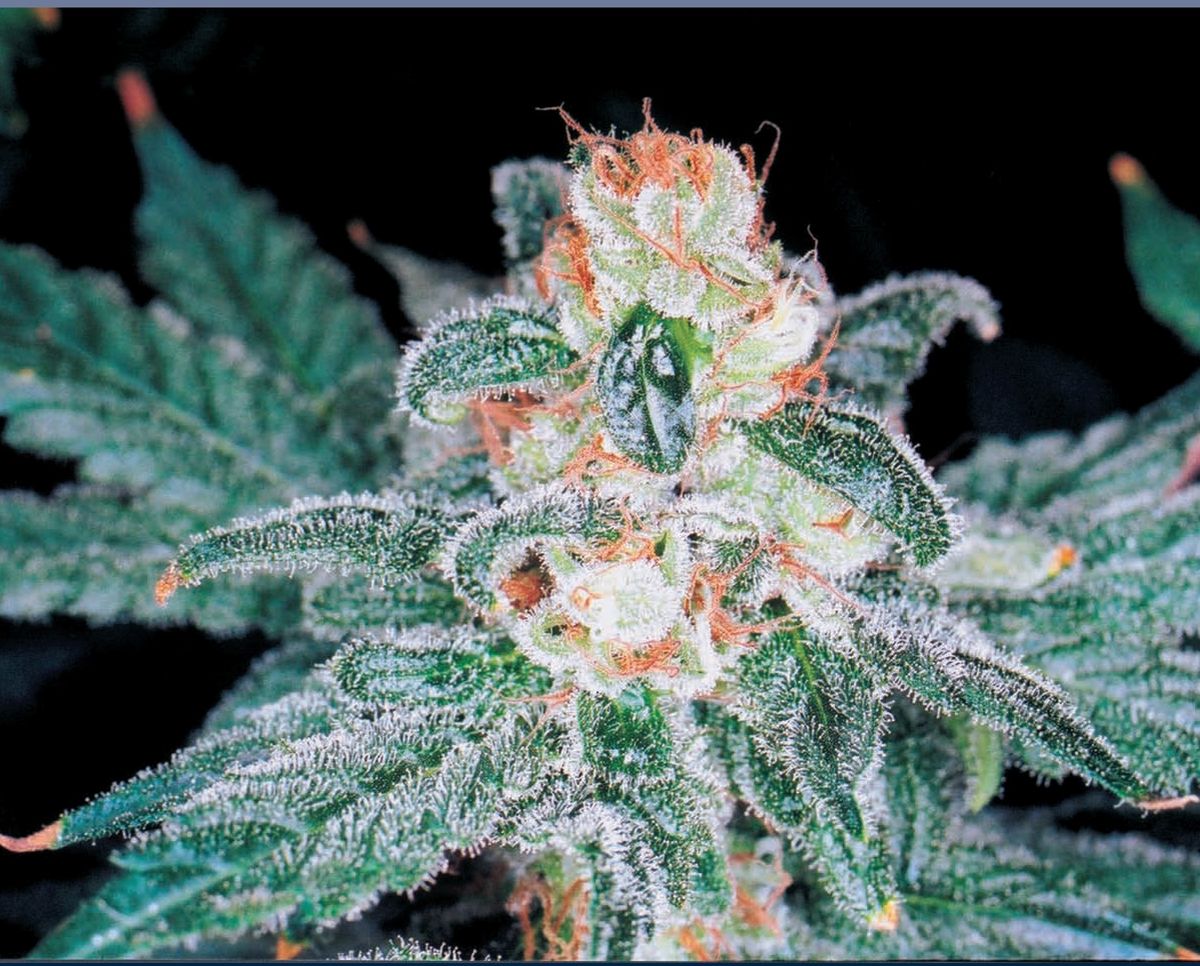

This Northern Lights hybrid was perfectly ripe. The glands were so thick that they outlined the bud’s edge. The range of greens and reds pastelled by the layer of white crystalline frost makes this one of the most beautiful varieties.

Johnny experimented with ways of keeping clones fresh for extended pariods, so they would be available as needed. He found that by lowering nutrient and light levels, the plants could be placed in a sort of suspended animation.

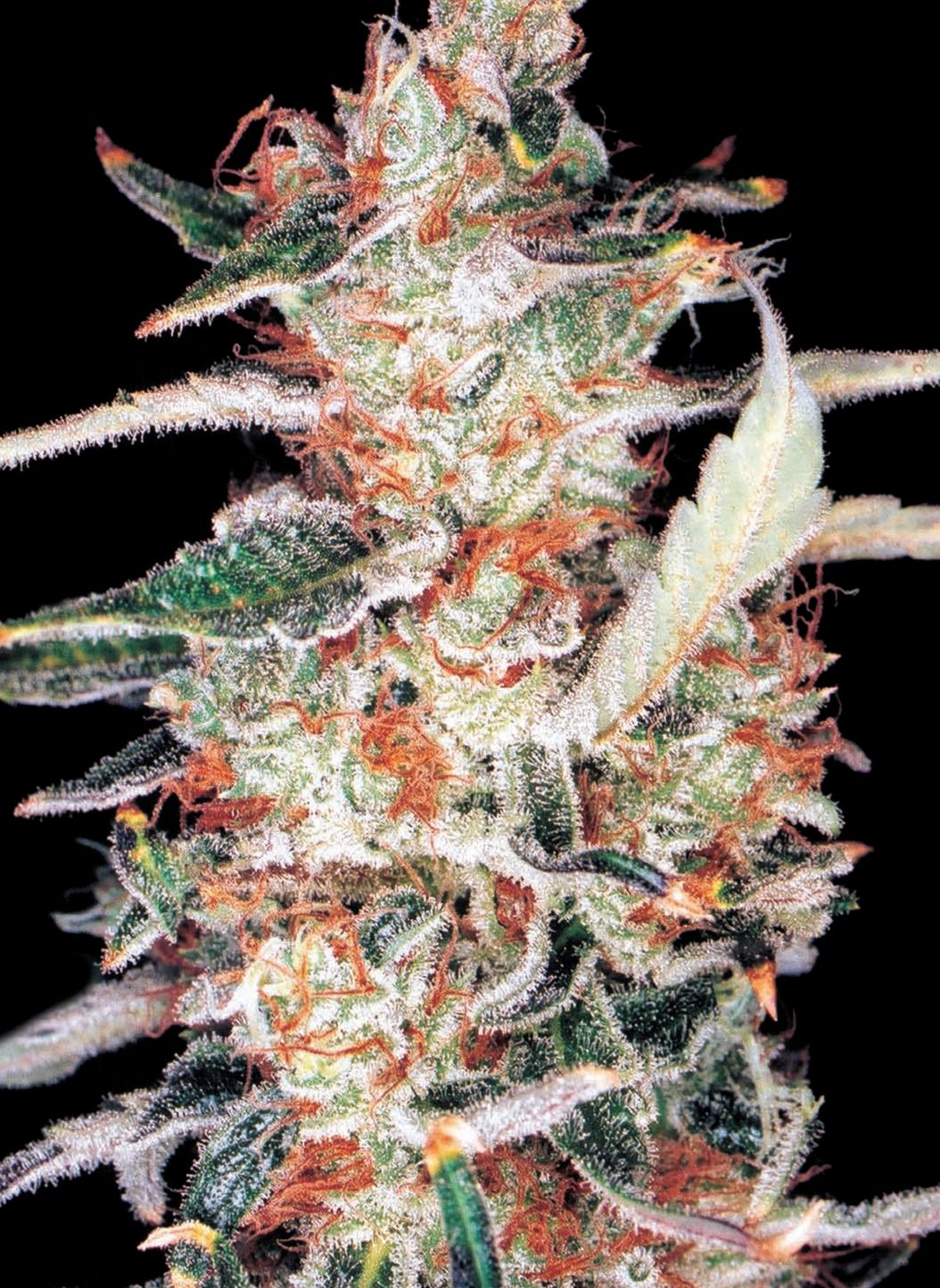

A Skunk hybrid ready to harvest for the post-season smoke-offs. Just by looking at it you know that this variety is complex and especially potent.

The plants were hung by their stems using twist ties.

This stem was left hanging in the harvested garden. Within two days the debris will be removed from the garden and it will be thoroughly cleaned, and the tubes readied for new clones.

Hydro’s ABC mixture in a 1-2-3 ratio at 1900-2000 parts per million, as measured on his electrical conductivity (EC) meter.

Electrical conductivity is a rough measure of the concentration of dissolved salts in the water. A conductivity level of 1,500 ppm indicates that 1,500 parts per million of the water solution are composed of dissolved salts. This takes into consideration both the fertilizer that has been added and the dissolved solids present in the tap water. EC is not a direct measurement of the salts; rather, it detects how well the water conducts electricity. The more salts, the better the conductivity. However, the electrical charges of fertilizer ingredients vary, so the concentration of salts is not absolutely proportional to the water’s conductivity.

Most farmers are very conservative about trying new techniques and with good reason. Even if the yield or quality of your crop isn’t great, you may be left with no crop yield at all if you try something different and it fails. But Johnny was so unhappy with General Hydroponics fertilizers that he decided to change brands after this crop. He was never able to get the plants to look totally healthy. No matter how he adjusted the ratios, there were signs of slight deficiencies. Now he uses the Genesis four-part formula.

In Johnny’s geographical area, tap water contains between 50 and 150 ppm of dissolved solids. This includes enough calcium for the water to maintain stable alkalinity, but is not so high that it affects the fertilizing program. In a previous garden in another city, he had to deal with up to 400 ppm of dissolved solids, so he installed a water purifier because the high level of minerals in the tap water affected the way the plants used the nutrients.

The plant has had its day in court. The judgment: Ripe. Cut her down, and hang her upside down by her stem until she dries out or is cut up. There were no appeals as the harvest continued inexorably down the row of grow tubes.

The last fan leaf on the branch is about to glide to the floor.

Johnny experimented with ways of keeping clones fresh for extended periods, so they would be available as needed. He found that by lowering nutrient and light levels, the plants could be placed in a sort of suspended animation. They are alive and photosynthesizing, but at such a slow rate that growth is hardly noticeable. They start rapid growth as soon as the environment has a high-light, high-nutrient level. When the clones were transplanted into the growing tubes, they were given continuous light for about 20 days. During this time they grew vigorously and reached about 15 inches in height. Then they were forced to flower.

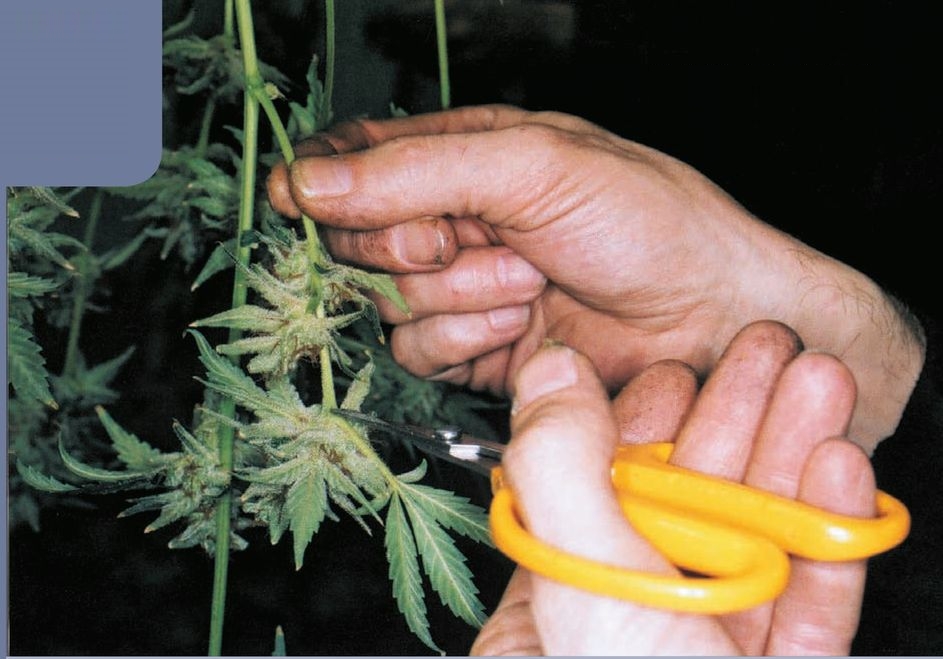

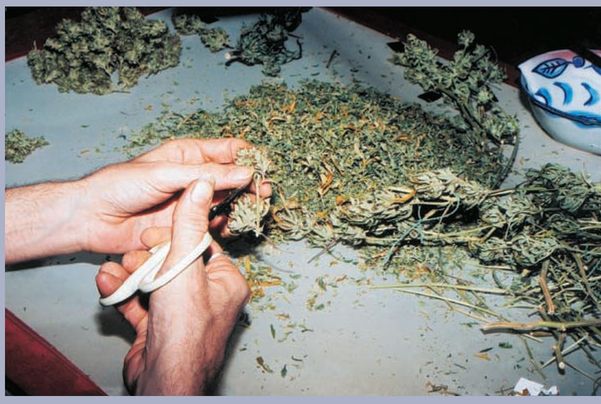

While the plants were still wet, the smaller leaves were clipped from the buds and then the buds were clipped from the stems. This manicurist preferred using a pair of small-bladed scissors.

Johnny has tried many varieties in his garden. There were ten different ones growing in his last garden, but he plans to eliminate some old ones and try some new ones. The next garden will have only three or four varieties, all descended from Dutch seed companies’ stock, that will produce tight, potent buds.

The plants were ready when the stigmas turned brown and receded into the ovary behind the flower as if it had been fertilized. You could see the glands swelling with THC. Normally, a garden is not harvested until almost everything is ripe and at peak, 65-80 days after forcing flowering, depending on variety. Johnny harvested after 8 weeks. Most of the plants were ripe. But a few varieties could have used another week.

The plants were clipped, making sure all the labels stayed with the proper strains. They were then hung on strings. Newspaper was placed underneath and a team of paid manicurist friends clipped the plants, removing both the large leaves and the smaller leaves surrounding the buds. They were left under dim light in a large dry area, with a nice draft. They were dry and ready to be smoked in a week.

Photo: Kamara Inc.

Friends were invited over for a trimming party. The plants were trimmed as they hung on stretched wires. At this stage all the large fan leaves were removed, exposing the smaller leaves and buds. As the leaves were clipped they dropped onto a tarp on the floor.

They were left under dim light in a large dry area, with a nice draft. They were dry and ready to be smoked in a week.