The Port-A-Closet

I recently met a grower who had a unique and innovative method of cultivating. Poor Starving Graduate Student (PSGS), as he wishes to be known, needed a discreet and unobtrusive system, but he had very little space in which to work. To make matters more difficult, he would have to relocate three times during the year to complete his post-graduate research. Using an armoire, PSGS designed his “Port-A-Closet” to utilize his space most efficiently.

Materials

PSGS, as his name implies, was a poor starving student supported by meager scholarships and summer jobs; his current recreational experience with ganja having been limited to gifts and joint circles. There was only one solution: to grow his own.

PSGS hunted and gathered his supplies on the streets and in the many thrift shops in his college town. He visited three shops, bought four shirts and some blue tinted drinking glasses before he found a metal closet that fit the space. It was 38” x 28” x 6’. After sanding away the rust spots, he spray-painted it a color matching the room in which it would be placed. It was a handsome addition and fit in perfectly with the rest of the décor. He also purchased 25 pounds of aquarium gravel, ten 1 1/2- gallon plastic plant containers (each measuring about 8 inches across at the top) and 25 three-inch containers.

The first part of recycling is re-using. PSGS noticed discarded wood while bicycling home from campus: 1” x 3”s, 2” x 4”s and 4” x 4”s that had already been cut to convenient carry-home sizes. He also picked up a torn reflective “space blanket” and a heavy-duty plastic tarp that people had left on the street.

At the hardware store, he bought eight ceramic incandescent sockets, two 6-plug power bars (with circuit breakers), a heavy-duty extension cord, a 24-hour timer and a few 14- x 9-inch plastic houseware trays.

While gathering the materials to build the system, PSGS was constantly on the lookout for abandoned potted plants. Most of these were poinsettias tossed after the season. Different pots contained different mixes; mostly wood bark and compost, vermiculite, perlite, peat moss and coconut hull. The various grow media were shaken from the roots of the discarded plants into a large box. Last to be added to the mix was a discarded bag of unused foam rubber bits.

The biggest expense was the 250-watt HPS system. He purchased a used system advertised in the weekly paper for $125. The ballast was equipped with a timer and the seller gave PSGS three half-used gallon containers of hydroponic fertilizer consisting of grow and bloom fertilizers and a micro mix.

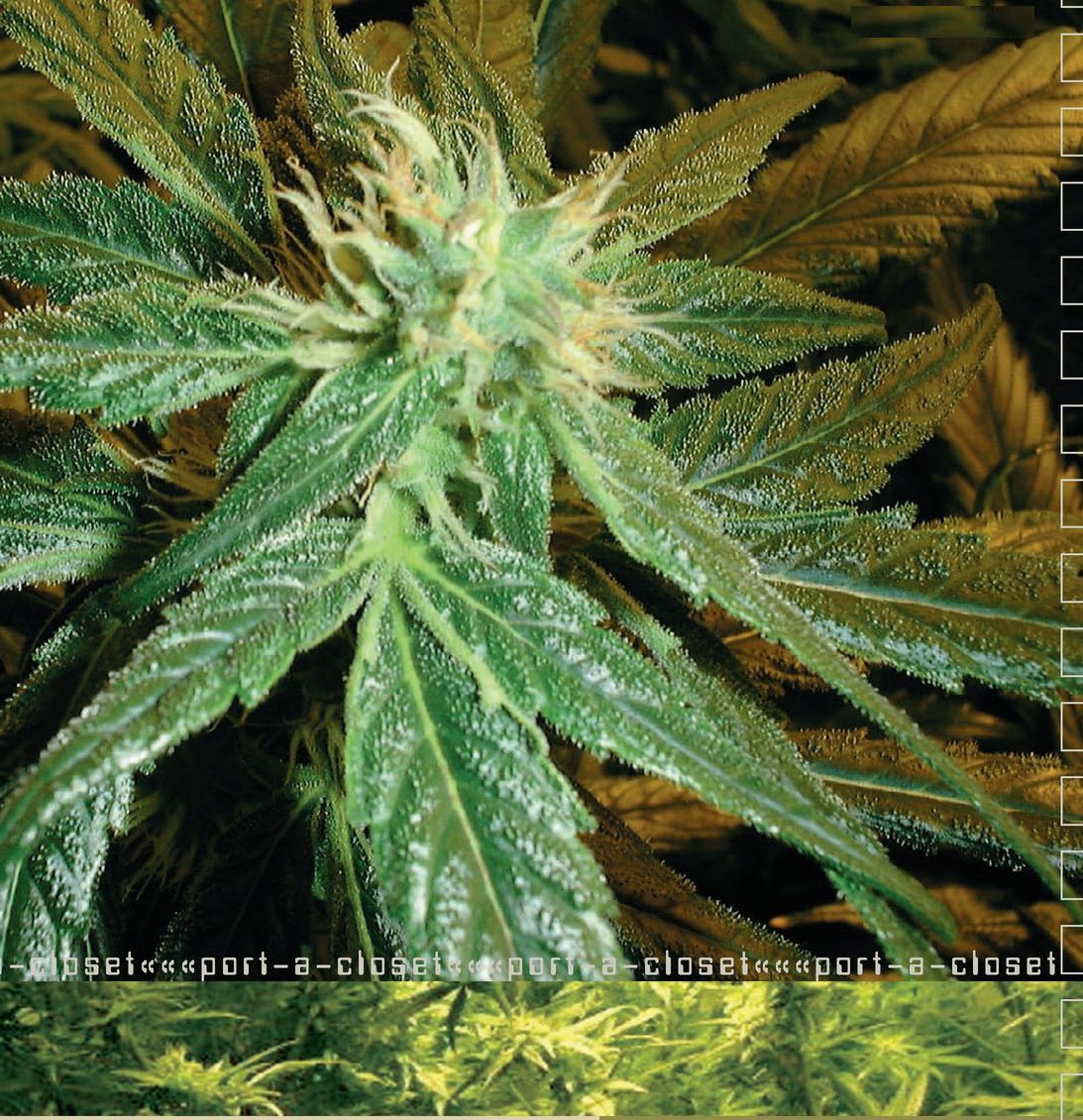

A closet-grown beauty.

Day eighteen

Construction

The inner walls of the cabinet were lined with the 6’ x 5’ space blanket. Areas not covered by the blanket were spray-painted white. The 250-watt HPS lamp was hung from the built-in hanger bar using several pieces of nylon cord. Then the side lighting, four 8-inch circular tube fluorescent fixtures, was installed. Each light was screwed into a ceramic light bulb socket and hung from either end of the hanger bar. The other two were hung along the back wall using eyehooks screwed into the top of the cabinet. To do this, PSGS drilled two holes through the top of the unit and pushed eyehooks through the holes.

Using a hacksaw and a pair of metal shears, he cut a six-inch hole in the top of the closet, and installed a six-inch velocity fan on top to remove the hot air. Placing a piece of foam rubber between the fan and the metal cabinet eliminated vibration noises from the fan. To allow fresh air into the grow space, a four-inch hole was cut in the lower back of the closet.

The lights and fan were plugged into the two six-outlet power bars with circuit breakers. These, in turn, were plugged into the heavy-duty extension cord that ran into an outlet near the closet.

PSGS hunted and gathered his supplies on the streets and in the many thrift shops in his college town. He visited three shops, bought four shirts and some blue tinted drinking glasses before he found a metal closet that fit the space.

The bottom of the closet was lined with two layers of the heavy plastic tarp attached to the sides of the closet with duct tape to help prevent spills.

Implementation

PSGS mixed his potluck medium thoroughly, adding 25 pounds of aquarium gravel. The result was heavy medium. When he added water/nutrient solution, the medium felt very porous, moist, almost wet, but nonetheless airy. He then poured the medium into the small containers.

PSGS had been planning to grow for about six months and had been saving seeds. A few were found in some stash sinsemilla and some were collected from friends. All were domestic.

The seeds were planted in the four-inch square containers, about 1/4-inch deep. The pots were placed in trays under the HPS lamp, but the fluorescents were left unplugged. The containers were watered with the hydroponic grow and micro solution, diluted to half of the strength recommended on the label. To keep the seeds moist, plastic wrap was laid across the tops of the containers. All the seed germinated within a week.

About two weeks after germination, when the plants were about eight inches tall, the lights were turned down to 12 hours per day. All the plants began to flower within 10-15 days. The males were pulled, leaving 16 pots with females. Only eight females were needed. Five of the plants looked less vigorous than the rest and were pulled immediately. The eight best were planted in the large containers set up with wicks and the light was then put on continuous illumination.

When the plants were between ten and fifteen inches tall – about 5 weeks after germination – the bottom layer of fluorescents was turned on so that the plants received light from the side as well as from above. At the same time, the tops of the plants were cut to even out length and to encourage branching. About a week later when the tops were between 18 inches and 24 inches tall, the light cycle was reduced to 12 hours per day to induce flowering.

The Wick System

PSGS wanted to try the wick system of irrigation. He began by cutting the 4” x 4” wooden beams into blocks. He placed them under the containers to raise them above the trays serving as reservoirs. For the wick, he cut eight pieces of 3/8-inch nylon cord, long enough to run across the bottom and out both sides of each container to the tray’s base.

To get the wick system going, PSGS simply filled the trays with water/nutrient solution. However, he enjoyed hand watering so much that he watered from the top regularly to supplement the wicks.

Finishing Touches

When the plants started to flower, they turned quite odoriferous. PSGS solved the problem with a negative-ion generator, which he purchased at a thrift shop for $15. He placed the unit on top of the closet and it zapped the odors as they blew out of the fan hole.

PSGS harvested the plants over a 15-day period beginning 70 days after forcing flowering. His yield was about six ounces of very high quality bud. Soon after his post-graduate research was complete, PSGS temporarily shut down his “Port-A-Closet,” packed it up along with his other furniture and set off for a new location.

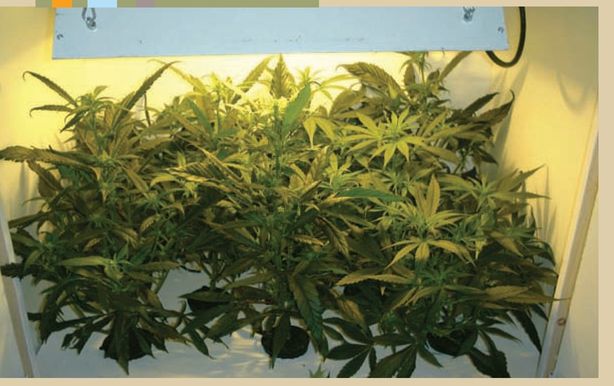

A personal grow unit