Sharkey’s Garden

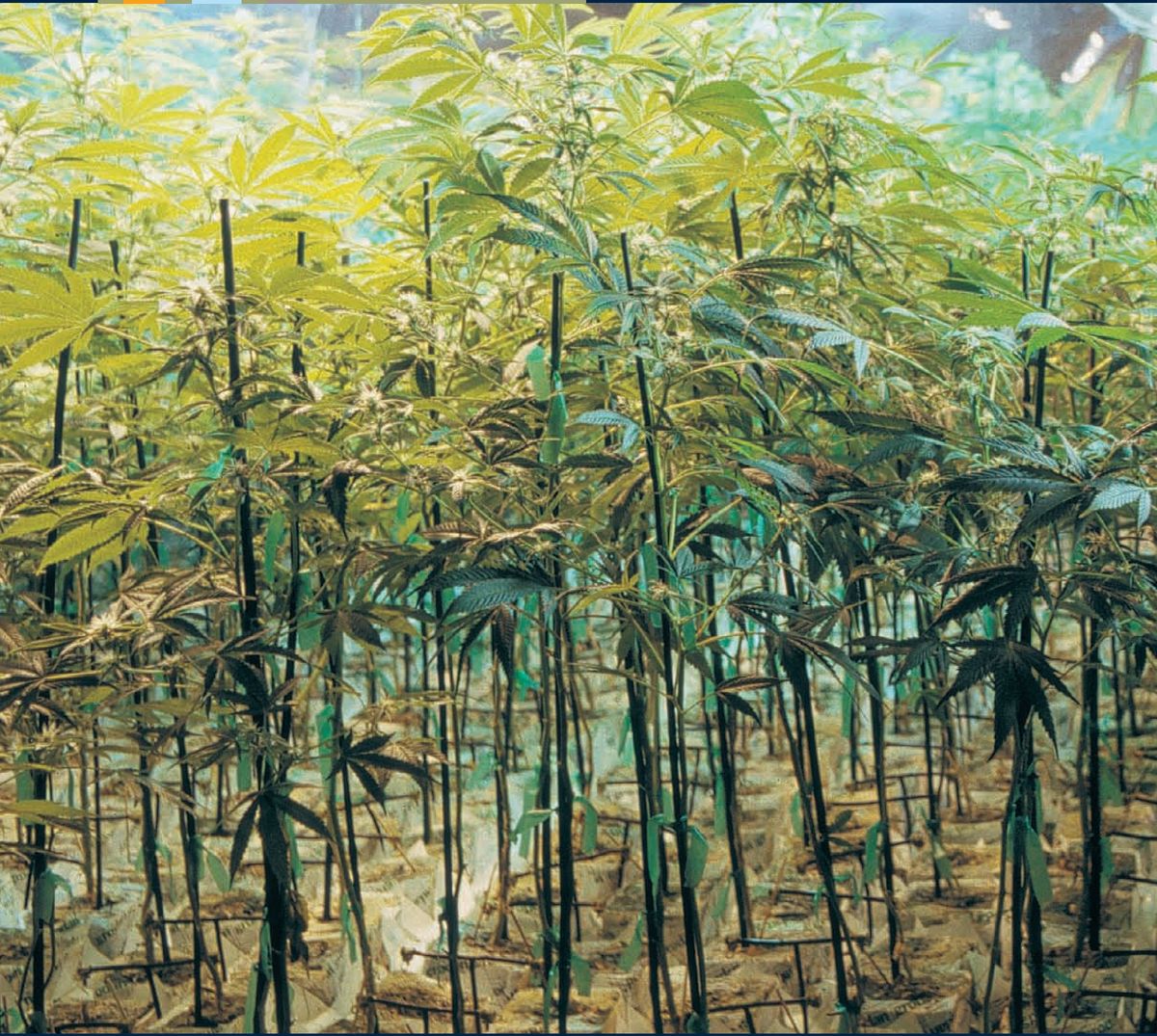

The bottom leaves have been trimmed from the plants to provide more air circulation and lower the humidity. The stakes are proving to be too short, but the flowers are still upright.

Sharkey is a professional grower who likes to work alone. He tried growing with a partner but found the fellow to be unreliable, which drove him up a wall. Sharkey takes the business of growing very seriously. He doesn’t smoke marijuana because he doesn’t like the high and sometimes it gives him a headache. However, he takes pride in the bud that he grows.

Sharkey has always been an achiever and he sets high standards for himself. He earned a degree in civil engineering but after working on a few projects for a big firm he decided instead to open a restaurant. The eatery was successful but it was driving him bananas so he sold it. He kicked back for a few years before deciding to start growing marijuana. Several factors drove him to it. First, it seemed very profitable. It was challenging because of the usual farmer’s woes as well as the surreptitiousness of the act. I should mention that Sharkey decided to enter the business during the mid-eighties, at the height of the drug war. He felt it was interesting, challenging work that was well rewarded.

Sharkey decided to enter the business during the mid-eighties, at the height of the drug war. He felt it was interesting, challenging work that was well rewarded.

Sharkey’s first project was a partnership with a fellow who had been growing for a number of years. Although his gardens were successful, he explained to Sharkey that, for one reason or another, he needed an investor-partner for his next project. Sharkey later related that he should have known better than to hook up with this gentleman. “If he had been growing commercially for a few years, why didn’t he have money for the next project?”

With the first crop Sharkey saw that he had made a big mistake. The plants were not properly cared for, there were beer cans in the grow room, and watering the plants was hit and miss. He heard a lot of “I forgot, sorry” and “it’s not worth the trouble”. Ultimately, his partner offered opinions and ideas about cultivation that Sharkey knew were wrong just from taking care of his yard and houseplants. Harvest was a disaster. Eventually, Sharkey dissolved his partnership because of irreconcilable differences. He told his partner that he was getting out of the business because breaking the law was making him paranoid. He took half the vegetative plants to “sell to a friend.”

If he had sold the plants he would have delivered more than expected. The plants were infested with aphids and mites. They were suffering from water stress, uneven light distribution, lack of fresh air and CO2, and were unpruned and unwieldy. Sharkey took clones from the plants, carefully cleaned them and treated them with pest killers. Then he threw the mothers away. His plan was to set up a large hydroponic grow in a different section of town.

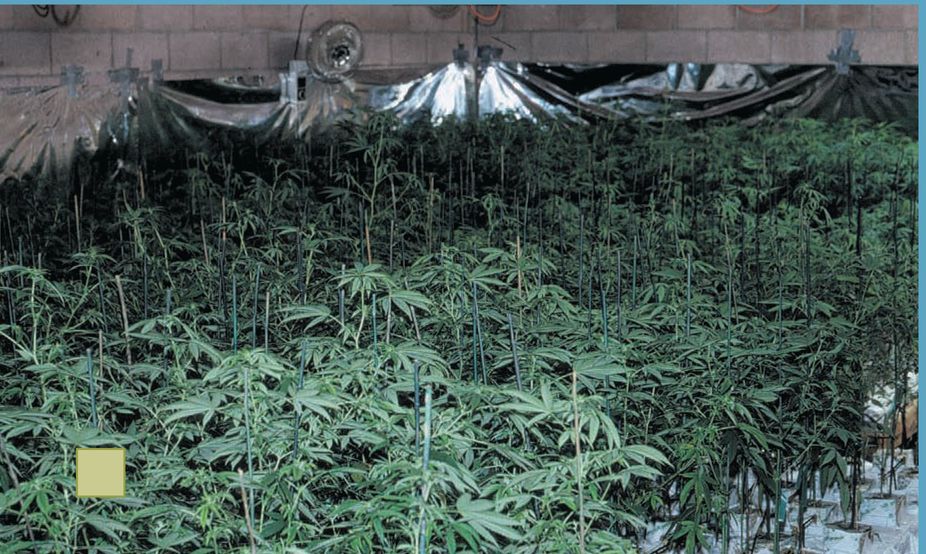

He rented a large space in an industrial section and re-wired it to carry the large electrical load. Large ventilator fans were placed in the roof so that the entire volume of air in the space could be replaced in about ten minutes. It took several months to get the space ready so he moved the clean young plants elsewhere to grow into mother plants as he was working.

The clone daughters were about two months old and two feet tall when the space was ready and they were moved into their new permanent home. They immediately started to fill out and develop healthy green leaves. Sharkey germinated several Dutch varieties and took clones from his mother plants. Both groups were growing in four-inch cubes placed on corrugated plastic sheeting on a 2% incline (one inch every four feet). The plants were spaced two per square foot. Since he had not had time to install the irrigation system when the clones were ready to grow out, he watered by hand several times a day. Sharkey decided to use a sweat line, which oozes liquid along its length, hooked up to a reservoir-recirculating system.

As soon as the clones and seedlings were about six to eight inches tall (about a week for the clones and ten days for the seedlings), the lights were switched to flowering cycle. Sharkey liked to start work in the early afternoon so the lights turned on at noon and went off at midnight.

Thirty days had elapsed and what should have been an uneventful period of continued construction turned out to be one of trouble and problems. Fate or carelessness took its course. An unidentified tan-colored insect, about 1/16th of an inch long attacked the plants. The insect grazed along both the bottom and the tops of leaves, exposing plant tissue to infection. All of the leaves on all of the plants showed extensive damage including spots of tissue necrosis. The plants were flowering and had about three weeks to go, but the insects had zapped all their energy, so the buds were small and the yield was not expected to be very large.

To get rid of the critters, Sharkey sprayed them with a ready-made pyrethrum mix propelled through a high-pressure tank. Then he used a Holiday Fogger to knock out any survivors. His insect control strategy worked.

The Dutch seeds were germinated in 4-inch x 4-inch Gro-Dan rockwool cubes. Each of his four tables measured 8’ x 12’. The 1152 plants on each table were still being temporarily watered by hand, as Sharkey continued working on installing the irrigation system.

Sharkey’s first crop: He and his partner had just split up and Sharkey took his half of the plants to the new space. These were an unruly undomesticated variety. They were a sativa hybrid with heavy vegetative growth but small flowers. This variety was eventually discarded.

In order to fill up his grow space and get ready for his next crop, Sharkey decided to grow a major portion of his new crop from hybrid seed, which he had to generate. He used females from his known variety, which was small budded, low-yield and fairly potent, and Dutch descendant males for pollen. Northern Lights and Skunk #1 were placed in separate rooms with females for pollination.

Pollen was also collected for controlled crosses with Dutch females. To catch the pollen, Sharkey constructed a box holder and placed the male plants horizontally in it. That way, the pollen didn’t have far to drop when the flowers opened. The purpose was to prevent pollen from getting in the air. More is collected and fewer uncontrolled pollinations occur. Meanwhile, the young plants growing from Dutch seed in the vegetative growth area were doing well. They were about 12 inches tall and almost ready to be transferred to the flowering space.

At the end of the second month Sharkey had encountered a few bumps. The infection had hurt the plants before it was eliminated and construction was taking longer than anticipated. However, the plants were in good shape. The completed construction was coming along well and soon the entire space would be automatically controlled.

A month passed and major changes took place in Sharkey’s garden. The original variety recovered from the insect attack after the pests had been eliminated. Fast growth resumed, but the plants developed loose, abundant buds. This indicated a lack of light intensity. Sharkey was using only four lights on his 12’ x 8’ tables. That’s 96 square-feet, with a power input of about 40 watts per square foot. Requiring a more intense light, the varieties that he was growing would have done a lot better with 60 watts per square foot, an increase of fifty percent. Some of the Dutch varieties, which sat on the same tables, were doing better. They had been pollinated selectively and seeds were ripening on them. Although their buds were small because of the heavy seeding, they were compact, unlike the clones from the original mothers, which tended to stretch out a bit even after they were forced to flower.

More clones had been taken and were sitting in the clone room. They would be flowered, but first Sharkey planned to start a new generation from the seed he was breeding. He would let the plants indicate sex and take clones of the females for the next crop.

More than two months later, the watering system was finally completed and hand watering was no longer required. The plants were irrigated as often as six times a day during the last part of the vegetative growth cycle. By the time the system was installed they required water only twice a day.

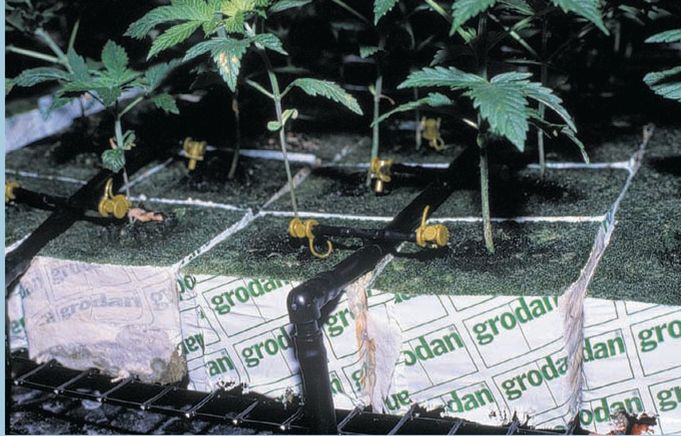

The four-inch rockwool cubes sat on top of six-inch rockwool slabs. Black feeder hose emitters watered under the plastic, irrigating each cube. The water soaked down through the threefoot pads.

A CO2 generator that burned natural gas was installed, but not without problems. The unit was near the ceiling and the CO2, which is warmer than the air, stayed at the top of the space rather than at plant level. Sharkey lowered the unit close to the floor so it could blow the hot CO2 gas down to the floor first. The cool floor acted as a heat sink, cooling the CO2 so it would remain at plant level.

Even with all the work that had been done and the sophisticated irrigation unit, the leaves still indicated a nutrient irregularity. It looked something like a magnesium deficiency with veining or a low-grade iron/manganese deficiency, which would turn new growth yellow, but the necrosis and particularly dull color of the leaves indicated that it probably wasn’t either of these. A calcium deficiency was another possibility. The plants lacked vigor and were not brightly colored. To eliminate the nutrient problem, Sharkey planned to rotate flowering fertilizers in his one-way system to assure a more balanced formula.

The first watering system Sharkey installed consisted of a soaker line the length of each slab of rockwool and sandwiched between the slabs and cubes. This system had not performed up to expectation. The blocks remained wet, but the nutrients seemed to be concentrating because of evaporation. He removed the soaker hose and installed a standard drip system.

To get rid of the critters, Sharkey sprayed them with a ready-made pyrethrum mix propelled through a high-pressure tank.

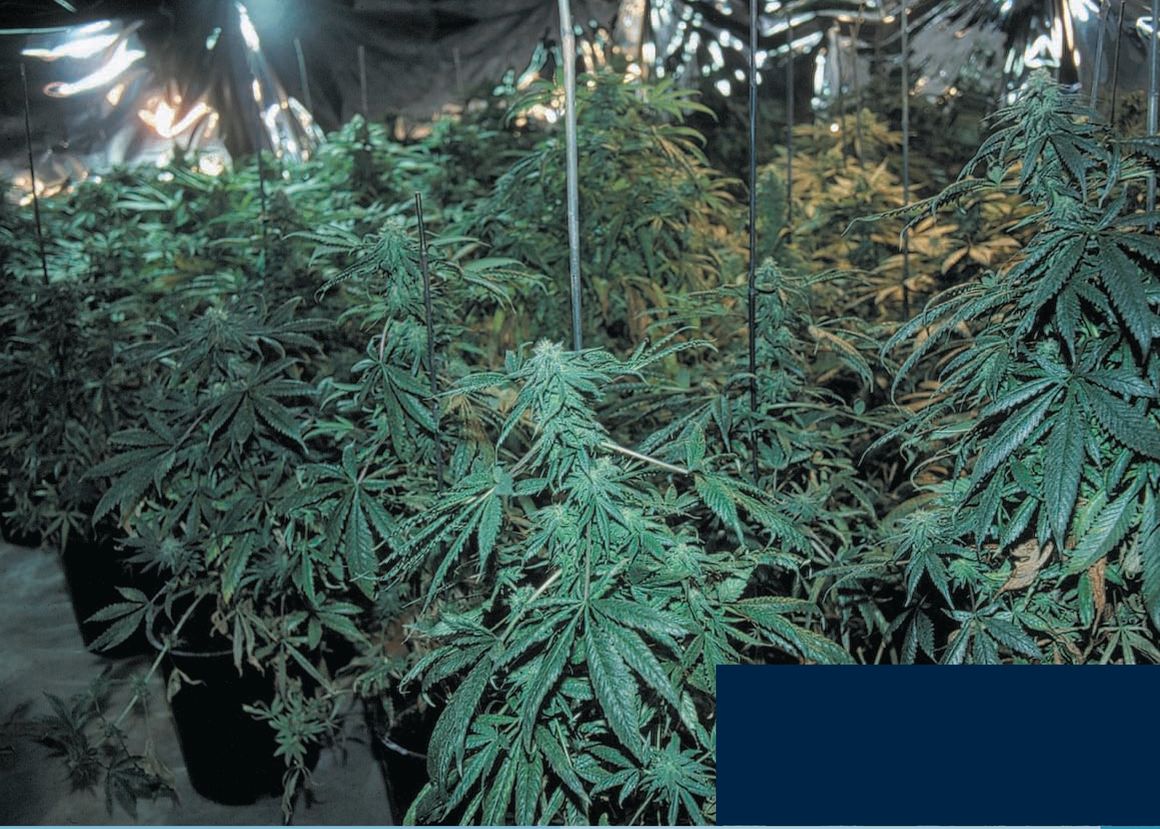

In spite of all the difficulties, the cycle continued and soon the flowering room was filled with buds. Sharkey had two groups of Dutch plants. The first was grown for seed. Some of these plants had matured, but the rest of the batch was still ripening. The other group consisted of plants that Sharkey started out with. These were a mixed group, mostly sativas with a few hybrids and indicas. Some of the plants were six feet tall when stretched out but they were bent over and interfered with their neighbors, often blocking their light. The sativas were the least appealing, with long internodes and airy, loose buds.

Before forcing the plants he brought to his new garden, Sharkey took clones and used them for the second crop. The cuttings were rooted in rockwool sheets in 10-inch x 20-inch trays. The trays were kept on heat mats, which kept the cubes at 72ºF.

Sharkey was working on this problem, too. He pruned the lower and side branches so that all that remained of each plant was a main cola and a few branches. The tallest, most gangly plants had the least bud development so he eliminated them from the garden. He thought that by removing extraneous material from the plants he could allow them to get better light and grow bigger buds as a result. The Dutch plants were pruned too.

Sharkey produced thousands and thousands of seeds from Dutch mothers in order to fill the space with high quality plants. The seeds were germinated in rockwool pellets pushed about a half-inch into the fiber. The rockwool germinating slabs were placed on small pallets so that they were not touching the heating mats underneath. In an effort to save a few dollars, Sharkey neglected to purchase a thermostat to regulate the mats. This dubious logic cost him three quarters of the seeds he planted. The temperature in the trays climbed to over 85ºF, spelling doom for the seeds. The few trays that were not placed on the heating mats had a much better germination rate.

Sharkey decided to grow the cuttings in the flowering room. He gave them a weak water/nutrient solution supplemented with corn syrup at the rate of about a tablespoon per gallon. Corn syrup consists of plant sugars; since the cuttings were stressed, he figured the extra sugar, normally produced by the plant as a product of photosynthesis, would give the plants some vigor and might enhance their growth. This idea was abandoned after a brief trial. The syrup messed with the irrigation and it looked like it was starting to ferment.

He also hoped that the remaining side buds on the plants, small because of their position below the canopy, would fill out given better light. With the fan leaves trimmed and the top buds removed, they could be spaced closely so that the yield per square foot of space would be relatively high.

Sharkey comments that growers sometimes become lackadaisical about things like trimming because it is so tedious. He is a one-man operation and wants no one else to be involved. If he could hire someone, as a legal business can, a trimmer could be had for $5-$10 an hour. Instead, he has to do the work himself. He says that sometimes he has half a mind to neglect trimming, but when he realized that those trimmings might represent a loss of a half-pound to a pound of trimmed, dry bud, it motivated him to buckle down to the hours of tedious work.

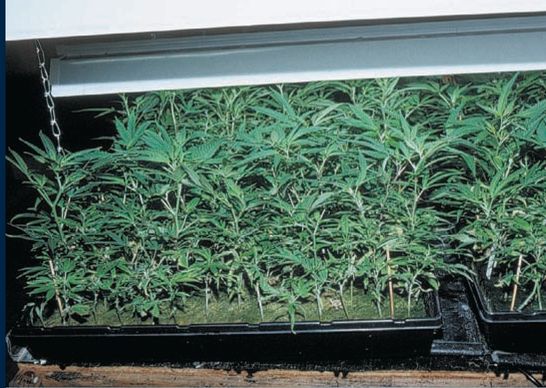

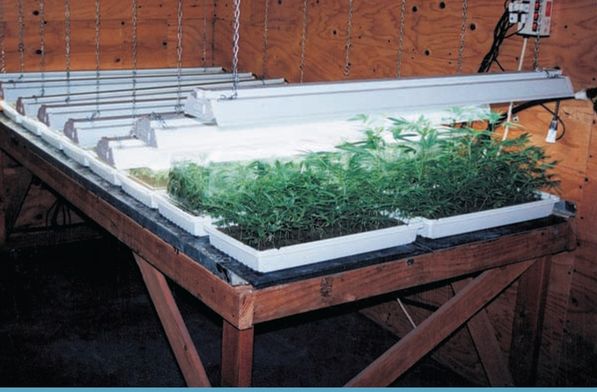

Two 10-inch x 20-inch clone trays were lit using two 48-inch cool white fluorescents. This table held two sets of clones. An older group was growing vegetation rapidly while the younger group in the back was busy growing roots. The trays were covered to keep the cuttings moist.

I visited the garden a month later. He was increasing the cultivation space while fine-tuning it for efficient operation and high yield. He had already harvested his Dutch seed crop, which yielded about 15,000 seeds of various varieties and crosses.

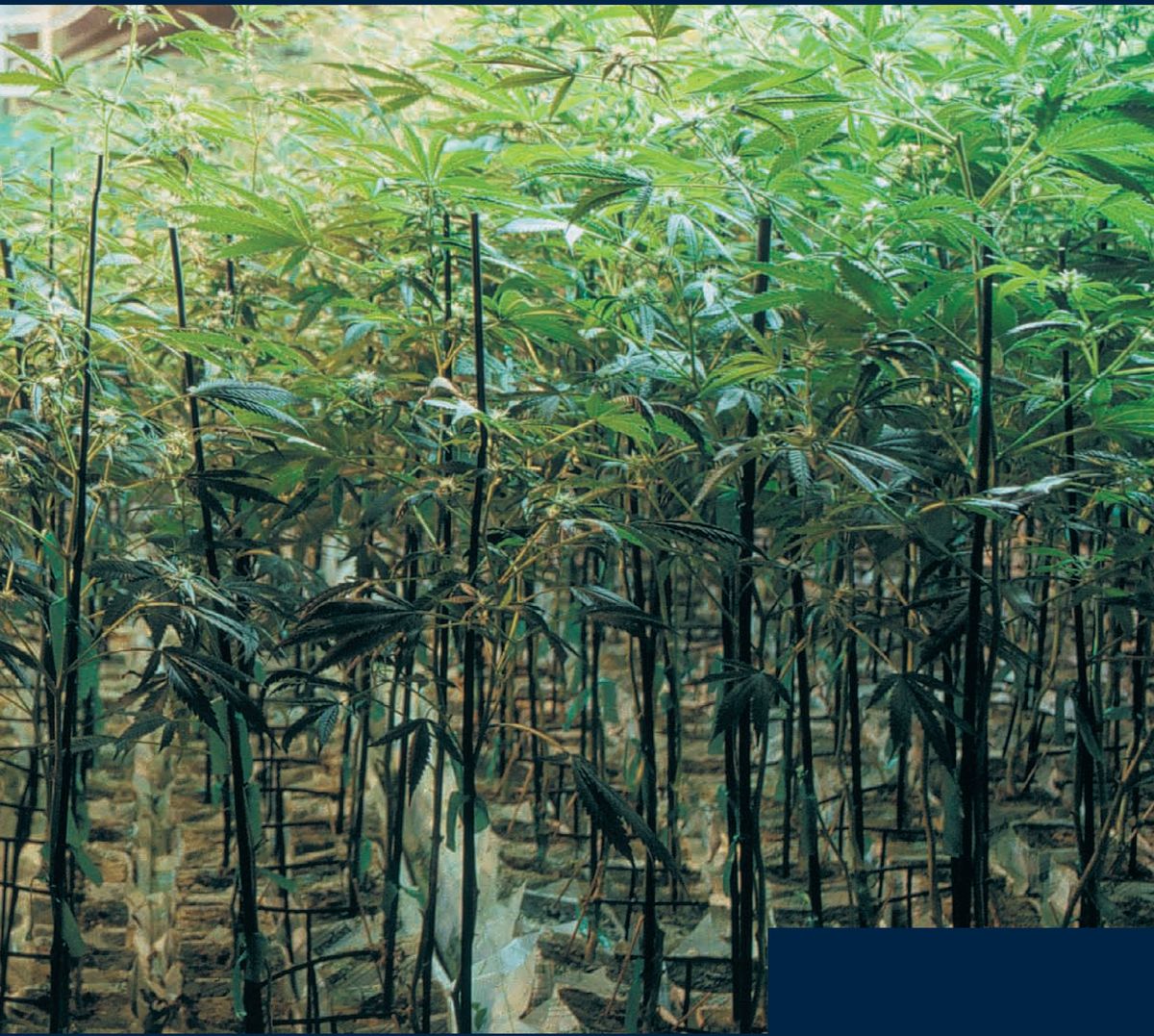

Most of the homegrown plant varieties, which were a mix of different sativas and indicas, had also been harvested. A month before, Sharkey had trimmed and thinned out the excess branches and all lower growth from these plants to promote growth. As a result, the light was more evenly distributed and the buds filled out a bit. Cutting the lower leaves allowed more air circulation so that there was less likelihood of mold problems. Potency varied from plant to plant but it was fairly high.

The plants yielded 10-14 grams per square foot. Here are the stats: the 96-sq.ft. table yielded about 1150 grams. There were four 1000-watt lamps. Each square foot had an electrical input of 41 watts. Each lamp yielded about 288 grams or .63 pounds. Considering that these were low-yield plants, this was hardly a disappointment. On the other hand, about 40 percent of the material was definitely grade B, lowering its value considerably.

The CO2 unit had not worked out as planned. Lowering the unit to ground level sent drafts of hot air around the plants, warming them too much. The ground did not absorb the heat as Sharkey had thought it would. His new idea was to scuttle the generator and replace it with a gas air conditioner. The CO2-laden exhaust from the air conditioner would be mixed with the cooled air and directed into the growing area at ground level.

Shortly after the clones were started, Sharkey started seeds from several Dutch varieties. They were watered using drip emitters. The cubes sat on a grill for easy water drainage. These seedlings were the start of the new population.

Plants in stage 2, vegetative growth. The clones in small cubes are placed in four-inch rockwool cubes that have an indentation to hold them. They are placed in a small section of the garden to harden the plants and give them some time to grow vegetatively under continuous light.

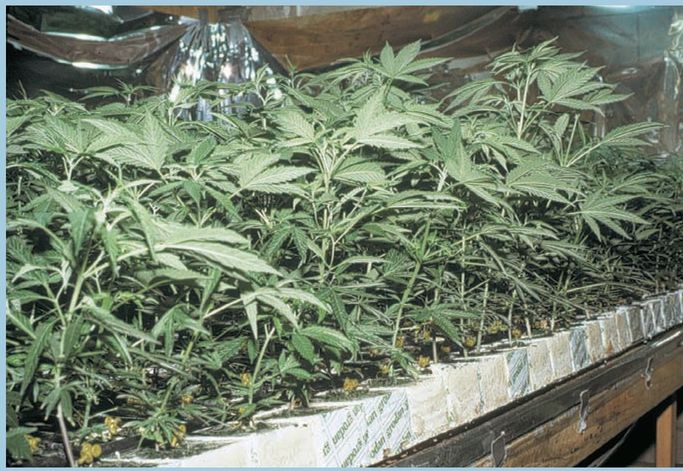

After two weeks of vigorous vegetative growing, the plants are moved to the flowering room. The cubes are placed on rockwool slabs wrapped in white plastic. Spaces are cut out of the plastic and the cubes are placed in position. The plants are given a couple of days under continuous light. Then the lights are cut back and the plants begin to flower.

The new crop in the flowering room would be ready in five to six weeks. These consisted of clones from the Dutch varieties. They were kept in vegetative state for a little extra time, then cut back in order to produce cuttings for rooting. There was also a crop that was almost ready to pick. Soon the garden would be producing one crop per month.

Sharkey eventually discovered that his nutrient problem was a lack of calcium and a touch of magnesium. The necrotic spots and slight veining were the result of using a fertilizer formulated for hard water, which contains more of these substances in a dissolved state. The purer water he was using did not supply enough. Adding a calcium-magnesium fertilizer formula to the water/nutrient mix solved the problem.

He added two lights to each table so the garden received an electrical input of 6000 watts distributed over 96 feet, a total of 63 watts per square foot, rather than the 41 watts the plants received previously. CO2 and temperature control became big problems for the garden during the hot summer months. First he had the roof painted white, rather than its natural gray color. This relieved some of the stress. Still, the ventilation air from outside was 90ºF and higher. Sharkey invested in a commercial air conditioning unit that was able to maintain a cool 75ºF even when the outside temperatures soared above 100ºF. Rather than create heat he invested in a CO2 regulation system that automatically kept the garden at 2000 ppm. The garden used about 10 tanks a month.

It took Sharkey more than a year to get all the details worked out. As each knot in the system was unraveled, the garden’s productivity increased. The garden eventually yielded about 1 1/4 pounds per light every 65 days. He worked out this schedule: Clones were taken from plants just before they were forced to flower – these were trimmings and side branches – and cloned in small cubes. They were transplanted into 4-inch cubes to grow for another two weeks at a spacing of nine plants per square foot. Two weeks later, a month after they were cut, the young plants were placed in the flower room at a spacing of two plants per square foot. They remained in vegetative state for two weeks and then were forced to flower. They were harvested at about nine weeks.

Twenty days after the lights are turned to 12 hours on/12 hours off, Sharkey’s plants are beginning to flower. They are staked so that each plant gets light without interfering with its neighbor.

Almost ripe seeded bud. The tissue covering the seed is beginning to pull away, exposing the seed. Seeded buds are heavy with glands. However there isn’t much weight to the smokeable material and many of the glands wind up on hands when the seeds are separated out.

The manicured glands are placed on racks to dry and kept in a constant draft. They are dry and ready to be smoked in about a week.