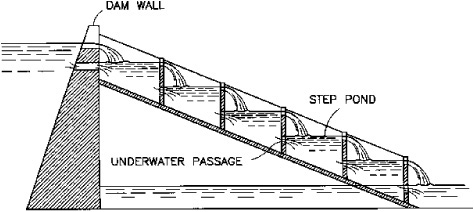

INVENTOR: Richard McFarlan

Bathurst, New Brunswick

(Patent No. NB Archives, RS 549, page 19, July 3, 1837)

Richard McFarlan invented a fishway around a mill dam, allowing fish to ascend and descend the river in the same manner as they had before the dam was built. The fishway was constructed with a series of step-like ponds with connecting underwater passages, which the fish could swim through to get around the dam. These passages were designd to maintain a certain level of water inside the ponds under normal river conditions while maintaining a certain flow of water to mill machinery.

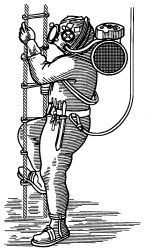

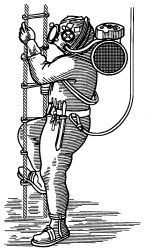

INVENTORS: James Elliott and Alexander McAvity

Saint John, New Brunswick

(Patent: NB Archives, RS 549, page 9, March 4, 1839)

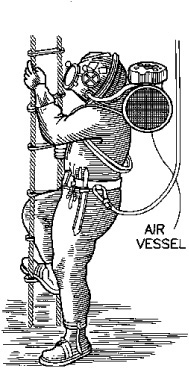

By patenting this “oxygen reservoir for divers,” the inventors made public their design for a piece of equipment that has remained essential to both amateur and professional divers for more than 160 years. Its modern name is an acronym: a self-contained underwater breathing apparatus, a scuba tank. Before Confederation, each province had its own patent system, and so this patent was granted by the Lieutenant Governor of New Brunswick.

The inventor wrote, “Instead of supplying air in that manner [with a force pump], the individual going under water carries with him a quantity of condensed oxygen gas or common atmospheric air proportionate to the depth of water and adequate for the time he is intended to remain below. This gas or air to be contained in vessels of any size made of copper or other suitable metal, and used in any requisite quantity by means of a pipe, regulated by stop cock, leading from the vessel in which it is contained and communicating with the interior of the dress, and which dress the inventors contemplate using either for the whole or part of the body. Another valve is placed at the top of the head, through which the foul air escapes, and thus in a great measure preserves pure the air which is inhaled by the operator under water.”

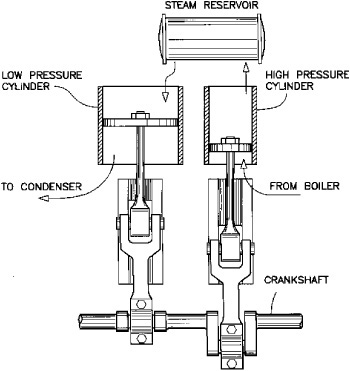

INVENTOR: Benjamin F. Tibbets

Fredericton, New Brunswick

(Patent Nos. CA 85, November 6, 1845, CA 411, July 2, 1853)

Benjamin F. Tibbets was the first in Canada to use the steam discharged from a primary cylinder of a marine steam engine in a second cylinder, thereby increasing the efficiency of the engine. His invention called for the use of a reservoir large enough to contain the steam discharged from the high-pressure cylinder. The reservoir then supplied a second low-pressure cylinder with steam of sufficient density to operate it efficiently. The original engine built by Tibbets remained in use in various ships for 70 years.

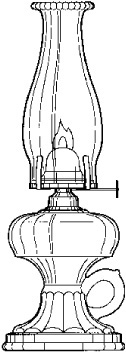

INVENTOR: Abraham Gesner

Halifax, Nova Scotia

(Patent Nos. US 11,203, US 11,204 and US 11,205, all issued on June 27, 1854)

Abraham Gesner seems to have been ahead of his time when he invented kerosene. Concerned about fuel consumption, he wrote in his patent application: “As the rocks whence the kerosene is most abundantly obtained are widely disseminated, the deposits of them are of almost unlimited extent, an immense mass of hitherto useless matter will by means of this invention be rendered available for the uses of mankind as a cheap and convenient substitute for illuminating purposes for the oils and fats which are yearly increasing in scarcity and price.”

Gesner’s method of obtaining fuel from either petroleum, maltha or soft mineral pitch, asphaltum, or bitumen involved dry distillation, treatment with reagents, and redistillation. The process resulted in three different types of flammable liquids, which Gesner labelled Kerosene A, Kerosene B, and Kerosene C, each of which had different properties and uses. Kerosene A was highly volatile and flammable but produced good light. Kerosene B was only moderately volatile and flammable but did not produce as good a light as did Kerosene A. Kerosene C, the heaviest liquid of the three, burned well in a certain type of lamp and was a good lubricant for machinery. Abraham Gesner’s inventions have often been referred to as the precursors of all modern petroleum fuels.

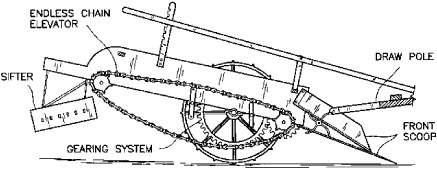

INVENTORS: William Bradford Allin and William Stiggins

Charlottetown, Prince Edward Island

(Patent No. PEI Archives, RG 7, Series 2, File 9, pages 1-13, September 2, 1868)

Modern potato harvesting machines and potato handling equipment owe their beginning to Allin and Stiggins’s invention of the endless chain elevator. It was operated by a gearing system mounted onto the wheels of the machine. The wheels had projections to grip the ground and transmit the torque required to turn the gearing system. The potatoes were raised by the endless chain elevator from a scoop at the front end of the machine and into a sifter at the rear end, thus removing the soil from the potatoes as they were harvested.

A forerunner of this machine was invented by another Prince Edward Islander. A cylindrical elevator with flat teeth to separate the potatoes from the earth was invented by George Jenkins, Township 49, Queen’s County, PEI (Archives, RG 7, Series 2, File 15, pages 122-126, August 1, 1860).

Patents for major improvements to Allin and Stiggins’s machine were later granted to other residents of Prince Edward Island as follows: patent no. 10,066 to John Solomon Cantelo, Grand River, PEI, June 11, 1879; and patent no. 21,999 to W.E. Reynolds, Murray Harbour, PEI, July 4, 1885.

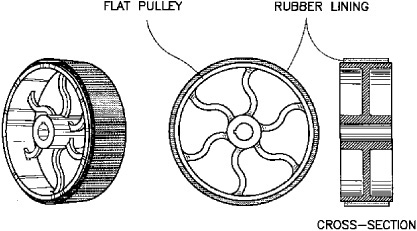

INVENTOR: Isaac McNaughton

Egerton, Pictou County, Nova Scotia

(Patent No. CA 1,451, May 7, 1872)

The object of this invention was to prevent endless belts or metal cables from slipping on shaft pulleys and sheaves during operation, thus prolonging their wear. This invention consisted in wrapping and bonding a band of vulcanized rubber around the periphery of pulleys and sheaves. Since this concept was introduced, the rubber lining of pulleys and sheaves has been standard practice in the manufacture of equipment used for power transmission.

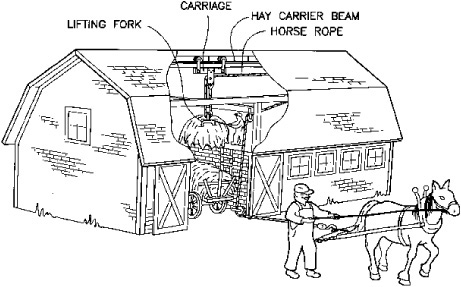

INVENTOR: Abraham Gill the Younger

Township 34, Prince Edward Island

(Patent No. PEI Archives, RG 7, Series 2, File 7, pages 199-203, October 8, 1872)

This patent describes a beam-and-trolley-type carrier mounted under a barn roof for unloading hay at various places in a barn’s loft. Although hay is now stored in bales, this type of carrier can still be found in older barns and was still commonly used into the 1970s. The patent document describes the invention as follows: “A hay carrier which consists of a long beam say three inches thick, nine inches deep, and from forty to fifty feet long suspended edgeways immediately under the ridge of the roof, and also of a carriage to run on the upper edge of this long beam. The carriage consists of a horizontal piece of wood about two feet long, three and one-quarter inches thick or square with an iron sheave at each end to run on an iron round bar on the top edge of the long beam. There is a seven-inch sheave suspended from the centre of the carriage for the horse rope to work in under the main beam. It is worked by a rope of sufficient strength with an American Lifting Fork at one end of the main rope and a single sheave at the end of the main beam in the building, another single sheave fixed at or near the lower floor and a horse attached for working at the other end of the main rope. As soon as the cross head of the fork rides to the large sheave under the running carriage, the carriage then moves to the place desired to deposit the content of the fork; the fork being cleared of its content by the use of a small cord attached to the lever of the fork and used by the person in the building.”

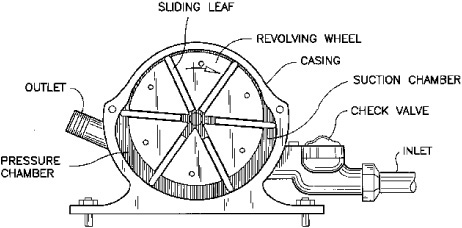

INVENTOR: Charles C. Barnes

Sackville, New Brunswick

(Patent No. CA 3,559, June 16, 1874)

The invention consisted of a wheel with diametrical sliding leaves which revolved in a casing that had a segmental enlargement. During operation, this formed a suction and pressure chamber that communicated with inlet and outlet openings. When the wheel rotated, the leaves slid in and out against the casing, causing a continuous suction through the inlet opening and a pressure flow through the outlet opening. A check valve was installed on the inlet pipe to resist back pressure and to keep the inlet pipe full. The same design is still used today.

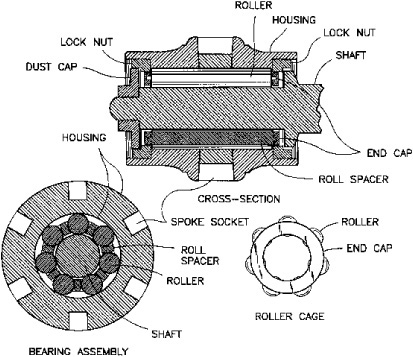

INVENTOR: George Welton Thomas

Bear River, Digby County, Nova Scotia

(Patent No. CA 9,843, April 12, 1879)

George Welton Thomas came up with an innovation that would prove to be an invaluable contribution to modern machine design. His objective was to design a way of assembling machinery so that the friction generated by the contact of moving parts with stationary ones (such as wheel hubs and their axles) would be greatly reduced, if not done away with entirely. The patent for this invention describes the combination of rollers and a roller cage with the shafts and housings of milling and factory machinery, vehicles, railway cars, and farming equipment.

INVENTOR: Donald Munro

Pictou, Nova Scotia

(Patent No. CA 21,779, May 30, 1885)

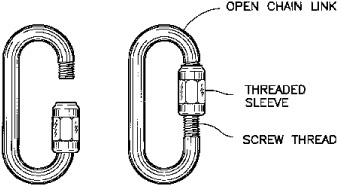

This invention consists of an open link, threaded on each end, with a sleeve that has an interior thread. By turning the sleeve in one direction, the opening in the link is exposed, and by turning it in the opposite direction, the opening can be closed. These connecting links can still be found, as first conceived by the inventor, in most hardware stores.

INVENTOR: Joseph Stuart Hughes

Chesley Corner, Lunenberg County, Nova Scotia

(Patent Nos. CA 52,680, June 17, 1896; CA 77,058, August 8, 1902;

CA 77,210, August 26, 1902; and CA 77,211, August 26, 1902)

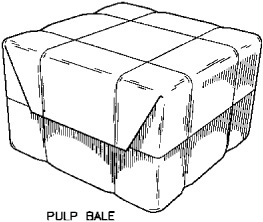

Not all pulp and paper mills manufacture a finished paper product. It is common for a mill near abundant wood resources to manufacture pulp as an intermediate product. This pulp is generally sold to other paper mills located in large cities far from a wood supply. Wood pulp of various types is also used to make blends to control specific paper characteristics, such as fibre length, strength, brightness, etc. The above patents relate to the packaging, storing, and transporting of wood pulp as an intermediate product. The first three patents describe pulp presses. The exclusive property granted to the inventor by the fourth patent is defined as “a new commercial product, consisting of uncut rectangular sheets, plain cakes or slabs of wood pulp in a dry or semi-dry state.” Joseph Stuart Hughes was the first to conceive of handling wood pulp in dry rectangular sheets. Since then, the drying and baling of pulp sheets has been a standard practice in the paper industry around the world for manufacturing, selling, storing, and transporting wood pulp.

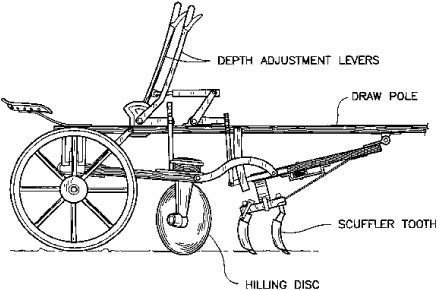

INVENTOR: Robert C. Holman

Summerside, Prince Edward Island

(Patent No. CA 341,416, May 8, 1934)

This invention combined scuffler teeth or tines with mould-boards or discs in a single implement, so that the earth could be thoroughly cultivated and hilled into rows in one operation. This concept has been in use ever since.