CHAPTER 1

ALCHEMY IN THE BEEHIVE

People have had a relationship with bees for many millennia. For most of that time, it consisted of finding the bees in their natural habitat and harvesting the honeycomb. It wasn’t until the 1500s that people built structures to house bees and not until the 1800s that moveable frame hives, similar to what are in use today, came to be. These frames allowed the keeper to manipulate the individual combs in a nondestructive way. The 1800s also saw the invention of the bee smoker, the comb foundation maker, and the honey extractor. Although there have been modifications over the years, all of these tools are still being used by today’s beekeeper.

HONEY

What we see as the golden nectar of the gods in a jar is in fact made up of an array of different components.

Approximately 80 percent of honey is composed of water and the sugars fructose and glucose. The remaining 20 percent consists of vitamins, minerals, amino acids, enzymes, and polyphenols. The exact makeup of a particular jar of honey will vary significantly depending on the region and on which flowers the bees visited. The wide variations in honey are part of the reason scientists have spent decades researching honey, its constituents, and their effects on our bodies, but there is still a lot that remains a mystery.

HOW HONEY IS MADE

The process of converting nectar into honey starts while the bee is still out foraging. The nectar that a bee collects from a flower is stored in the bee’s honey stomach, which is separate from the stomach the bee needs for digestion. While in the honey stomach, the nectar is mixed with various enzymes that start to break down the complex sugars of the nectar and convert it into a more “bee-friendly” simple sugar.

Once the bee returns to the hive, the partially converted nectar is passed to a hive bee to complete the conversion. Once it is converted, the hive bee transfers the nectar to a cell of honeycomb where the nectar evaporates, dropping the moisture content down from almost 80 percent to under 18 percent. This is accomplished in two ways. The first is passive. The ambient temperature in the hive, which is usually between 90°F and 100°F (32°C and 38°C), is hot enough to evaporate some of the moisture. The second way is active. Bees fan the nectar with their wings to evaporate more moisture from the nectar. What remains after this process is what is called honey.

HARVESTING AND PROCESSING

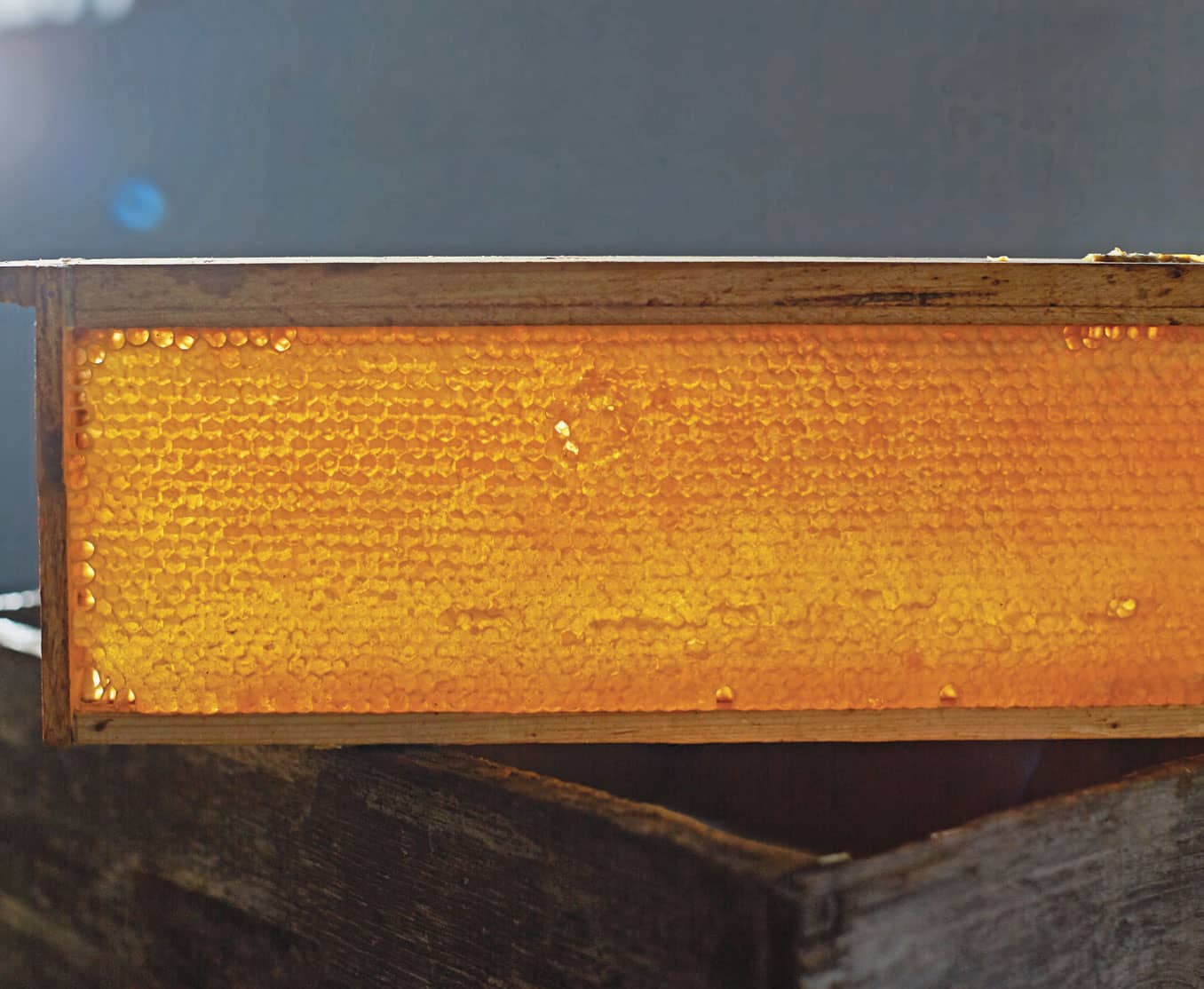

Once the cell is full and the moisture content is correct, bees cap off the cell with beeswax to preserve it. When stored in this way, the honey will last indefinitely.

Generally, honey contains some or all of the following:

Vitamins: B6, thiamin, niacin, riboflavin, and pantothenic acid

Minerals: calcium, copper, iron, magnesium, manganese, phosphorus, potassium, sodium, and zinc

18 or more free amino acids

Enzymes and polyphenols

Honey is generally harvested in one of two ways: crushing and straining or through extractor methods. Each method has its advantages and disadvantages.

The crush and strain method is exactly how it sounds. The capped-over honeycombs are removed from the hive, crushed to release the honey, and strained through a bucket top strainer or cloth. This method is great for beginning beekeepers and for top bar hive aficionados because it requires very little equipment—just a bucket and strainer. The disadvantage of this method is that all the wax is removed, which forces bees to make new honeycomb every year. That is an expensive process for bees because it takes 8 pounds (3.6 kg) of honey to produce 1 pound (455 g) of wax. This method also produces a lot of beeswax, which is great for candle makers. There are limitations to how many hives can reasonably be harvested using this method. It’s great for the backyard beekeeper, but a bit cumbersome for larger beekeeping operations. This method also leaves more honey trapped in the wax, which could be lost depending on how the wax is purified.

The extractor method involves cutting or scratching the beeswax cap off a traditional Langstroth (or similar design) frame and spinning it in an extractor to remove the honey from the comb. Because the beeswax cap seals the honey in the comb, it needs to be “opened,” either by scratching the cap with an uncapping scratcher or fork or cutting off the cap using some sort of knife. The frames are then put in an extractor and the honey is flung from the combs using centripetal force, keeping the main part of the honeycomb intact. The honey flows out the bottom and the cappings are strained to remove the honey. Because most of the comb is preserved, this method is less “costly” for bees in terms of honey needed to produce the wax. The disadvantages to this method are that most extractors are set up to use Langstroth hive frames exclusively, so they will not work with other beehive types, such as top bar hives. Extractors can also get expensive, depending on how many frames they hold and whether they are human powered or electric. This method also produces less wax, so although it’s great for the bees, it’s not so good for crafters who want lots of beeswax.

BEESWAX

Beeswax is the miracle of the beehive. The comb is built up from nothing and serves as a house, a nursery, and a food pantry. Over the millennia, bees have figured out that building their combs into hexagons allows them to hold the most honey while using the least amount of wax. It also serves as the perfect area for a bee to undergo its metamorphosis from egg to bee.

WHAT IS BEESWAX?

Most basically, beeswax is a wax produced by honey bees of the genus Apis. It consists of at least 284 different compounds, mainly a variety of long-chain alkanes, acids, esters, polyesters, and hydroxy esters, but the exact composition of beeswax varies with location. It has a specific gravity of about 0.95 and a melting point of over 140°F (60°C).

More specifically, it is a wax that is secreted from eight wax-producing glands on the worker bee’s abdomen. The wax is secreted in thin sheets called scales. The scales, when first secreted, looks a bit like mica flakes. They are clear, colorless, tasteless, and very brittle. Beeswax is typically produced by the younger house bees when they are between 12 and 20 days old. As the bee gets older and begins to leave the hive to collect pollen and nectar, these glands start to atrophy, but they don’t go away completely. When bees swarm, they will quickly produce wax comb, which serves not only as a place for the queen to lay eggs, but also as somewhere to store food.

HOW BEESWAX IS MADE

To shape the beeswax into honeycomb, the bees line up to form a chain. As the wax-producing bees extrude the wax, it is passed along the chain between the bees’ legs and mouths, which are used to chew and mold the wax to shape. The bees will then use this wax to build the hexagon-shaped honey cells we are all familiar with. It is during this process that the wax starts to develop its color and opacity. Depending on what kind of nectar and pollen the bees consumed and what came into the hive, microscopic bits of the pollen and nectar remain and are added to the wax. It takes about 1,100 scales to make one gram of wax.

Under ideal conditions, worker bees can produce beeswax on demand provided there is an adequate supply of food and the right temperature range inside the hive. The ambient temperature in the hive needs to be between 91°F and 97°F (33°C and 36°C). To achieve the correct temperature on cooler spring days, the bees cluster around the wax-producing bees as they are building comb.

The production of beeswax in the hive requires a tremendous amount of resources, however. It takes about 8.4 pounds (3.8 kg) of honey to be converted into one pound (455 g) of beeswax. This honey could be used to feed the nonforaging bees or be saved for periods of nectar droughts. For this reason, bees will often chew off beeswax in one spot and place it where it is needed. The reusing of old comb also contributes to the color, because it may have been used for brood rearing or honey storage and may contain cocoon remains, propolis, or pollen.

Most of the wax that is commercially available is made from something beekeepers call cappings. When bees produce honey, the foraging bee collects the nectar and stores it in one of her two stomachs—one is for honey collecting and the other is for personal digestion. The nectar in the honey stomach mixes with enzymes in the stomach, and when the bee returns to the hive, it places the nectar into a waiting cell. As additional nectar is placed into the cells, bees begin to fan their wings to create airflow through the hive to help dry out the nectar. Once enough moisture has evaporated from the nectar to prevent spoilage (less than 19 percent), the bees cap off the cells to prevent additional moisture loss. Bees will systematically work their way across frames or honey boxes, capping each cell as they go.

HARVESTING AND PROCESSING

To harvest the honey, beekeepers remove the frames with honey from the hive and bring them to the honey house for processing. Because all the honey cells are capped with wax, just adding the frames to a honey extractor would yield no honey. So, beekeepers first remove the wax cap using either a hot knife, scratcher, or some sort of flail. The wax cappings then go into a capping tank and the frames go into the extractor where the honey can be spun out.

How beekeepers process the wax cappings depends to a certain degree on how many hives they have. Most systems involve applying heat to the cappings to melt the honey and wax, which will separate into two layers: honey on the bottom and wax on the top. After several filterings, the wax will look pretty clean and is generally ready to use.

Beekeepers also melt down old honey and brood comb in order to install clean wax and do general maintenance on the frames. While wax from cappings and honey combs is fairly pure, the wax from brood combs contains a wide assortment of “stuff,” which may include cocoons from both bees and wax moths, excrement from bee larvae, mites, pollen, propolis, and bee parts. All this extra stuff is called slum gum. Removing the slum gum from the wax is a more involved process. One method is to put the brood combs into burlap sacks and then add the bag to a hot water bath. The melted wax will flow through the burlap and the slum gum will stay in the bag. The burlap sacks are usually pressed to release the rest of the trapped wax from the slum gum. The resulting wax is usually significantly darker than the cappings wax, ranging from light brown to almost black. If this wax were to be used for something such as candles, there would still be an unpleasant lingering smell. At this point, a lot of beekeepers turn their wax in to bee supply stores for credit toward clean wax, or wax that has already been turned into foundation for inclusion in new frames. The bee supply stores turn this dark wax over to commercial wax processing operations that have specialized equipment with carbon filters to filter the wax and remove the color. This is far better method than in times past, when the wax was literally bleached using noxious chemicals to remove the color. Thankfully, most of the white wax available today is processed naturally using carbon filters, not chemicals.

One drawback to the heavily refined, highly filtered wax is that the aroma and charm of beeswax (as well as many of its unique health advantages) actually come from the natural “contaminants”—honey, propolis, and pollen. Therefore, bleaching or advanced refining of beeswax in order to remove its color and fragrance yields a product that is a bit bland.

PROPOLIS

Propolis is a strange and wonderful thing. More specifically, propolis is the dark brown resinous mixture that bees produce by mixing tree resins, sap, and other botanical elements with saliva and beeswax. Bees use propolis to seal up small cracks and gaps in the hive. They also use it to mummify small animals that die in the hive, covering them in propolis and effectively restoring the hive to sterility.

Propolis is loaded with all sorts of good stuff. It is antibiotic, antiseptic, antiviral, anti-inflammatory, and analgesic. It contains bioflavonoids and polyphenols, which are compounds with antioxidant properties that scavenge free radicals and have an anti-inflammatory effect on the entire body. In comparison to other foods, propolis is one of the highest scoring natural antioxidants available.

HARVESTING AND PROCESSING

Some bees seem to propolize everything. This is a boon for those looking to use the propolis, but can be a nuisance as well. When checking on bees in the summer months, beekeepers often find that everything in the hive is glued in place, from the lid to the boxes and the frames. The propolis needs to be scraped off just to be able to replace boxes and frames. One good thing is that the propolis is soft and malleable because it usually contains more beeswax and at the time of harvest, the temperature outside is warm.

For bees that are a bit more discreet with propolis application, we usually leave most of the propolis in place and only harvest propolis when we are cleaning up equipment. After all the honey has been extracted, we scrape all the boxes and frames to remove the errant wax and propolis. To do this, we set up a makeshift scraping station over a barrel. Any kind of box or container works, but a 55-gallon (208 L) barrel is a nice height for cleaning lots of equipment without an aching back. Propolis can be a bear to work with. What I usually do is tincture the propolis in 95 percent pure grain alcohol. The tincture can then be used either as is or made into propolis oil.

HOW TO USE PROPOLIS

To use the propolis in skin care, I usually take the propolis tincture and create a propolis oil. The propolis oil is easier to handle and can be added to almost anything, just like any other oil.

POLLEN

From each flower they visit, bees collect pollen, which contains the male reproductive cells of those plants. The bees take that pollen and combine it with a bit of nectar and their own digestive enzymes to create pollen granules. They transport the pollen granules by adhering the pollen to their rear legs while they forage.

Much like honey and propolis, the composition of pollen is highly dependent on what flowers the bees visit. On average, the composition is 40 to 60 percent simple sugars, 20 to 60 percent proteins, 3 percent minerals and vitamins, 1 to 30 percent fatty acids, and about 5 percent other stuff. Interestingly, pollen may also contain some fungi and bacteria.

Although the jury is still out on actual health benefits, proponents of bee pollen use it to relieve inflammation, strengthen the immune system, ease symptoms of menopause, and as a dietary supplement.

Beekeepers harvest pollen by placing a screen at the bottom of the beehive, forcing incoming bees to crawl through the screen as they enter the hive. The screen is sized to just fit the bee’s body, but not the “baggage.” The pollen is shaved off as the bee crawls through the screen and is collected below. Because pollen is actually a source of food for the bees, it is important that the pollen trap only be in place for a couple days, so that the health of the hive isn’t impacted significantly.