CHAPTER 1

EAL Unit QELTK3/002

Understand environmental legislation, working practices and the principles of environmental technology systems

Learning outcomes

When you have completed this chapter you should:

1. Understand the environmental legislation, working practices and principles that are relevant to work activities.

2. Understand how work methods and procedures can reduce material wastage and impact on the environment.

3. Understand how and where environmental technology systems can be applied.

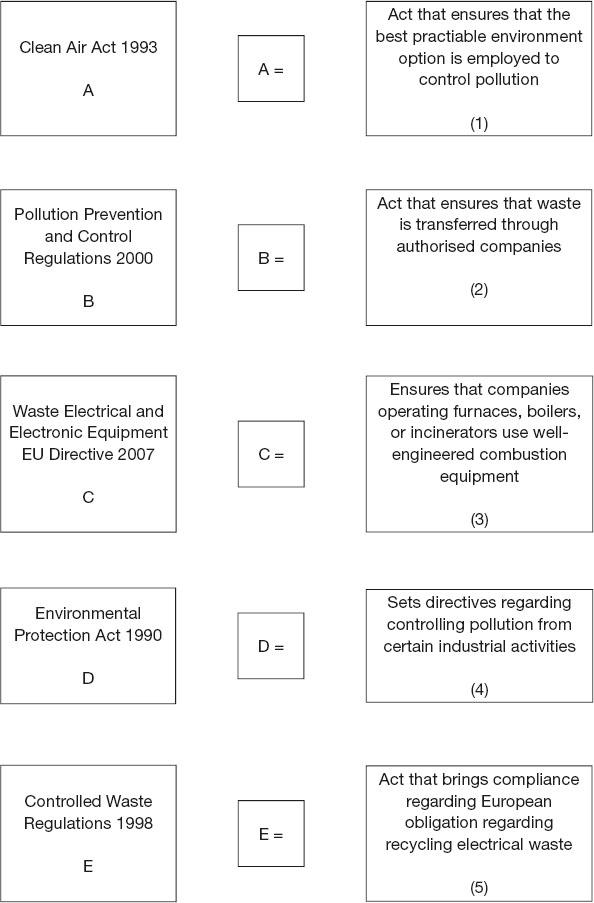

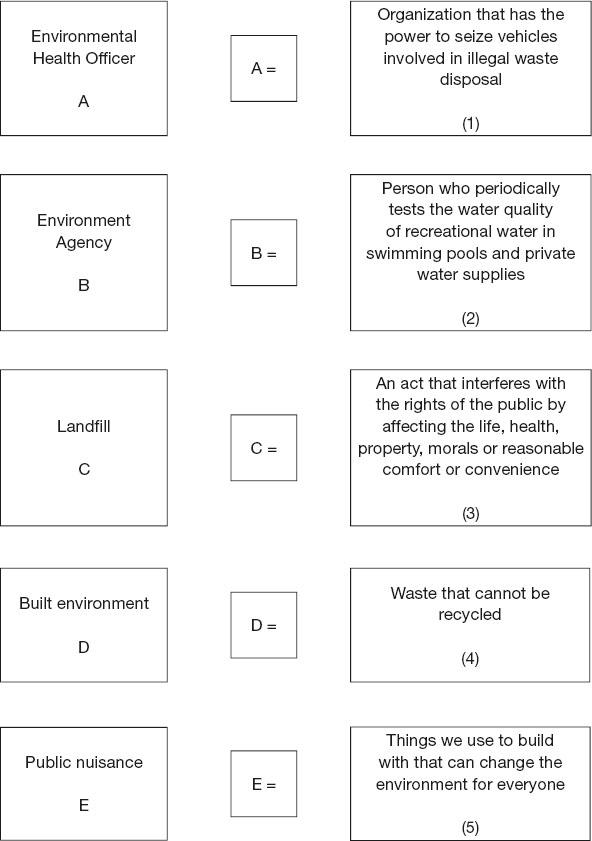

Assessment criteria 1.1

Specify the current, relevant legislation for processing waste

Assessment criteria 1.2

Describe what is meant by the term environment

Environmental laws and regulations

The environment describes the world in which we live, work and play; it relates to our neighbourhood and surroundings and the situation in which we find ourselves.

Definition

Definition

The environment describes the world in which we live, work and play. It relates to our neighbourhood, surroundings and the situation in which we find ourselves.

Environmental laws protect the natural environment in which we all live, including: plants, forests and mountains among other elements.

If an offence is identified in the area in which we now think of as ‘environmental’ it can be of two kinds:

1 An offence in common law, which means damage to property, nuisance or negligence leading to a claim for damages.

2 A statutory offence against one of the laws dealing with the protection of the environment. These offences are nearly always ‘crimes’ and punished by fines or imprisonment rather than by compensating any individual.

Built environment

Everything we do affects other people or other elements, for instance creating new houses creates jobs but this also impacts the environment given the new amount of materials that have to be provided. We therefore define the materials and resources we use to build things that impact on the environment as the ‘built environment’.

Figure 1.1 Eco buildings such as this one are becoming more and more common today.

However, we also impact on the environment in other ways, which is why we have developed laws and legislation to deal with the environment but devolving responsibility for each part such as: air, water, land noise, radioactive substances. Where organizations’ activities impact upon the environmental laws they are increasingly adopting environmental management systems that comply with ISO 14001. Let us now look at some of the regulations and try to see the present picture at the beginning of the new millennium.

Environmental Protection Act 1990

In the context of environmental law, the Environmental Protection Act 1990 was a major piece of legislation. The main sections of the Act are:

The Royal Commission of 1976 identified that a reduction of pollutant to one medium, air, water or land, then led to an increase of pollutant in another. The need to take an integrated approach to pollution control is therefore stressed.

The processes subject to an integrated pollution control are:

• Air emissions.

• Processes that give rise to significant quantities of special waste, that is, waste defined in law in terms of its toxicity or flammability.

• Processes giving rise to emissions to sewers or ‘Red List’ substances. These are 23 substances including mercury, cadmium and many pesticides that are subject to discharge consent to the satisfaction of the Environment Agency.

The Inspectorate is empowered to set conditions to ensure that the best practicable environmental option (BPEO) is employed to control pollution. This is the cornerstone of the Environmental Protection Act.

Hazardous Waste Regulations 2005

New Hazardous Waste Regulations were introduced in July 2005 and under these regulations electric discharge lamps and tubes such as fluorescent, sodium, metal halide and mercury vapour are classified as hazardous waste. While each lamp only contains a very small amount of mercury, vast numbers are used and disposed of each year, resulting in a significant environmental threat. The environmentally responsible way to dispose of lamps and tubes is to recycle them and this process is now available through electrical wholesalers. Electrical companies produce relatively small amounts of waste and even smaller amounts of special waste. Most companies buy in the expertise of specialist waste companies these days and build these costs into the contract.

Safety first

Safety first

Disposal of batteries and old fluorescent tubes is regulated through the Hazardous Waste Regulations 2005.

Pollution Prevention and Control Regulations 2000

The system of Pollution Prevention and Control replaced that of Integrated Pollution Control established by the Environmental Protection Act 1990, thus bringing environmental law into the new millennium and implementing the European Directive (EC/96/61) on integrated pollution prevention and control. The new system was fully implemented in 2007.

Pollution Prevention and Control is a regime for controlling pollution from certain industrial activities. This regime introduces the concept of Best Available Technique (BAT) for reducing and preventing pollution to an acceptable level. Industrial activities are graded according to their potential to pollute the environment:

Definition

Definition

Remember that there are two basic forms of plastic: thermoplastic and thermosetting. Only thermoplastic can be reheated and reshaped.

• A(1) installations are regulated by the Environment Agency.

• A(2) installations are regulated by Local Authorities.

• Part B installations are also regulated by Local Authorities.

All three systems require the operators of certain industrial installations to obtain a permit to operate. Once an operator has submitted a permit application, the regulator then decides whether to issue a permit. If one is issued it will include conditions aimed at reducing and preventing pollution to acceptable levels. A(1) installations are generally perceived as having the greatest potential to pollute the environment. A(2) installations and Part B installations would have the least potential to pollute.

The industries affected by these regulations are those dealing with petrol vapour recovery, incineration of waste, mercury emissions from crematoria, animal rendering, non-ferrous foundry processes, surface treating of metals and plastic materials by powder coating, galvanizing of metals and the manufacture of certain specified composite wood-based boards.

Definition

Definition

Burning waste material on site could contravene the Control of Pollution Act 1989.

This Act specifically extends to prosecuting any person including the seizure/disposal of vehicles involved in:

• Knowingly permitting the use of any plant or equipment for the purpose of disposing of controlled waste including sewerage regarding pollution of any relevant water systems such as streams.

Control of Pollution Act 1989

This Act concerns making provision with regard to depositing controlled waste, and requires carriers of controlled waste to register with either the Environment Agency in England and Wales or the Scottish Environment Protection Agency (SEPA).

Noise at Work Regulations 1989

The Noise at Work Regulations, unlike the previous vague or limited provisions, apply to all work places and require employers to carry out assessments of the noise levels within their premises and to take appropriate action where necessary. The 1989 Regulations came into force on 1 January 1990 implementing in the United Kingdom the EC Directive 86/188/EEC ‘The Protection of Workers from Noise’.

Safety first

Safety first

The Noise at Work Regulations are intended to reduce hearing damage caused by loud noise.

Three action levels are defined by the regulations:

1 The first action level is a daily personal noise exposure of 85 dB, expressed as 85 dB(A).

2 The second action level is a daily personal noise exposure of 90 dB(A).

3 The third defined level is a peak action level of 140 dB(A) or 200 Pa of pressure, which is likely to be linked to the use of cartridge operated tools, shooting guns or similar loud explosive noises. This action level is likely to be most important where workers are subjected to a small number of loud impulses during an otherwise quiet day.

The Noise at Work Regulations are intended to reduce hearing damage caused by loud noise. So, what is a loud noise? If you cannot hear what someone is saying when they are 2 m away from you or if they have to shout to make themselves heard, then the noise level is probably above 85 dB and should be measured by a competent person.

Figure 1.2 This kind of drilling can cause vibration white finger, and can also damage your hearing if the proper precautions aren’t taken.

At the first action level an employee must be provided with ear protection (earmuffs or earplugs) on request. At the second action level the employer must reduce, so far as is reasonably practicable, other than by providing ear protection, the exposure to noise of that employee.

Hearing damage is cumulative, it builds up, leading eventually to a loss of hearing ability. Young people, in particular, should get into the routine of avoiding noise exposure before their hearing is permanently damaged. The damage can also take the form of permanent tinnitus (ringing noise in the ears) and an inability to distinguish words of similar sound such as bit and tip. Vibration is also associated with noise.

Direct vibration through vibrating floors or from vibrating tools can lead to damage to the bones of the feet or hands. A condition known as ‘vibration white finger’ is caused by an impaired blood supply to the fingers, associated with vibrating hand tools.

Employers and employees should not rely too heavily on ear protectors. In practice, they reduce noise exposure far less than is often claimed, because they may be uncomfortable or inconvenient to wear. To be effective, ear protectors need to be worn all the time when in noisy places. If left off for even a short time, the best protectors cannot reduce noise exposure effectively.

Figure 1.3 Ear defenders protect workers from noise at work.

Protection against noise is best achieved by controlling it at source. Wearing ear protection must be a last resort. Employers should:

• Design machinery and processes to reduce noise and vibration (mounting machines on shock absorbing materials can dampen out vibration).

• When buying new equipment, where possible, choose quiet machines. Ask the supplier to specify noise levels at the operator’s working position.

• Enclose noisy machines in sound-absorbing panels.

• Fit silencers on exhaust systems.

• Install motor drives in a separate room away from the operator.

• Inform workers of the noise hazard and get them to wear ear protection.

• Reduce a worker’s exposure to noise by job rotation or provide a noise refuge. New regulations introduced in 2006 reduced the first action level to 80 dB(A) and the second level to 85 dB(A) with a peak action level of 98 dB(A) or 140 Pa of pressure. Every employer must make a ‘noise’ assessment and provide workers with information about the risks to hearing if the noise level approaches the first action level. They must do all that is reasonably practicable to control the noise exposure of their employees and clearly mark ear protection zones. Employees must wear personal ear protection whilst in such a zone.

Packaging (Essential Requirements) Regulations 2003

The new Packaging Regulations were introduced on 25 August 2003 bringing the UK into harmony with Europe. The regulations deal with the essential requirements of packaging for the storage and transportation of goods. There are two essential elements to the regulations:

1 The packaging should be designed and manufactured so that the volume and weight is the minimum amount required to maintain the necessary level of safety for the packaged product.

2 The packaging should be designed and manufactured in such a way that the packaging used is either reusable or recyclable.

Definition

Definition

The new Packaging Regulations were introduced on 25 August 2003, bringing the UK into harmony with Europe. The regulations deal with the essential requirements of packaging for the storage and transportation of goods.

The regulations are enforced by the Weights and Measures Authority in Great Britain, the Department of Enterprise, Trade and Investment in Northern Ireland and the Procurator Fiscal or Lord Advocate in Scotland.

Environmental Act 1975

This Act was necessary in order to create specific regulatory bodies to police and protect the environment through proper measures such as pollution control and any element that impacts against water in general. These bodies have already been mentioned and are the EA and SEPA but their responsibilities will also extend to specific codes of practice for recreational duties areas and sites of special scientific interests and repair of contaminated land.

Waste Electrical and Electronic Equipment EU Directive 2007

The Waste Electrical and Electronic Equipment (WEEE) Directive will ensure that Britain complies with its EU obligation to recycle waste from electrical products. The regulations came into effect in July 2007 and from that date any company that makes, distributes or trades in electrical or electronic goods such as household appliances, sports equipment and even torches and toothbrushes has to make arrangements for recycling these goods at the end of their useful life. Batteries will be covered separately by yet another forthcoming EU directive. Some sectors are better prepared for the new regulations than others. Mobile phone operators, O2, Orange, Virgin and Vodafone, along with retailers such as Currys and Dixons, have already joined together to recycle their mobile phones collectively. In Holland the price of a new car now includes a charge for the recycling costs.

Figure 1.4 Mobile phones contain precious metals and expensive components that can be recycled even if the phones themselves can’t be repaired.

Further information is available on the DTI and DEFRA website under WEEE.

Safety first

Safety first

Hazardous waste needs to be disposed of through licensed recycle operators.

Assessment criteria 1.3

Describe the ways in which the environment may be affected by work activities

A safe attitude towards health and safety, working conscientiously and neatly, keeping passageways clear and regularly tidying up the workplace is the sign of a good and competent craftsman.

However, the same kind of premise must be levied at those who work in industry in order to reduce the effect on the environment, in particular ensuring that some substances are afforded special consideration and therefore need to be disposed of through licensed operators. Such consideration and applied process is also necessary when burning materials or dealing with contaminated water since, for instance, the use of industrial drains will ensure that any water that contains chemicals is filtered accordingly and does not enter ground water drains. Consideration is also needed to plan any on-going works so as not to affect watercourses as well as implementing pollution action plans and response protocols.

Failure to manage or adopt such systems can lead to, for example, land being affected by contamination, the introduction of damaging and harmful particulates into the Earth’s atmosphere, and contamination and pollution of water resources. What happens thereafter is that people can be subjected to disease directly through the environment or indirectly through animals and food crops.

Assessment criteria 1.4

Identify and interpret the requirement for electrical installations as outlined in relevant sections of the Building Regulations and the Code for Sustainable Homes

Building Regulations – Part P 2013 and the self-certification scheme

The Building Regulations (2010 as amended) are one of the most important pieces of legislation controling the installation of environmental technology systems. Part P of the Building Regulations was published on 22 July 2004, bringing domestic electrical installations in England and Wales under Building Regulations control. An amended document was published in an attempt at greater clarity and this came into effect on 6 April 2006. A further amendment occurred in 2013, but it is important to note that this only applies to England.

Part A structure

Part B fire safety

Part C site preparation and resistance to moisture

Part D toxic substances

Part E resistance to the passage of sound

Part F ventilation

Part G hygiene

Part H drainage and waste disposal

Part J combustion appliances and fuel storage systems

Part K protection from falling, collision and impact

Part L conservation of fuel and power

Part M access and facilities for disabled people

Part N glazing – safety in relation to impact, opening and cleaning

Part P electrical safety.

Part Q security – dwellings (England only)

Anyone carrying out domestic electrical installation work must comply with Part P of the Building Regulations. If the electrical installation meets the requirements of the IET Regulations BS 7671, then it will also meet the requirements of Part P of the Building Regulations, so no change there. However, a major change occurred through the concept of ‘notification’ to carry out electrical work.

Notifiable electrical work

Any work to be undertaken by a firm or individual who is not registered under an ‘approved competent person scheme’ must be notified to the Local Authority Building Control Body before work commences. That is, work that involves:

• the provision of at least one new circuit;

• work carried out in kitchens;

• work carried out in bathrooms;

• work carried out in special locations such as swimming pools and hot-air saunas.

Upon completion of the work, the Local Authority Building Control Body will test and inspect the electrical work for compliance with Part P of the Building Regulations.

Figure 1.5 The Local Authority Building Control Body should be notified before carrying out electrical work within bathrooms.

Non-notifiable electrical work

This is work carried out by a person or firm registered under an authorized Competent Persons Self-Certification Scheme or electrical installation work that does not include the provision of a new circuit. This includes work such as:

• replacing accessories such as socket outlets, control switches and ceiling roses;

• replacing a like for like cable for a single circuit that has become damaged by, for example, impact, fire or rodent;

• refixing or replacing the enclosure of an existing installation component provided the circuit’s protective measures are unaffected;

• providing mechanical protection to existing fixed installations;

• adding lighting points (light fittings and switches) to an existing circuit, provided that the work is not in a kitchen, bathroom or special location;

• installing or upgrading the main or supplementary equipotential;

• bonding provided that the work is not in a kitchen, bathroom or special location.

All replacement work is non-notifiable even when carried out in kitchens, bathrooms and special locations, but certain work carried out in kitchens, bathrooms and special locations may be notifiable, even when carried out by an authorized skilled or instructed person. The IET have published a guide called The Electricians’ Guide to the Building Regulations that brings clarity to this subject. In specific cases the Local Authority building control officer or an approved inspector will be able to confirm whether Building Regulations apply.

Failure to comply with the Building Regulations is a criminal offence and Local Authorities have the power to require the removal or alteration of work that does not comply with these requirements. Electrical work carried out by DIY homeowners will still be permitted after the introduction of Part P. Those carrying out notifiable DIY work must first submit a building notice to the Local Authority before the work begins. The work must then be carried out to the standards set by the IET Wiring Regulations BS 7671 and a building control fee paid for such work to be inspected and tested by the Local Authority.

Top tip

Top tip

Part P requirements in England have recently changed and no longer recognize kitchens as special locations. This is in contrast to Wales which still recognizes kitchens as well as bathrooms as special locations.

Competent Persons Scheme

The Competent Persons Self-Certification Scheme is aimed at those who carry out electrical installation work as the primary activity of their business. The government has approved schemes to be operated by BRE Certification Ltd, British Standards Institution, ELECSA Ltd, NICEIC Certification Services Ltd (see http://certsure.com), and Napit Certification Services Ltd. All the different bodies will operate the scheme to the same criteria and will be monitored by the Department for Communities and Local Government, formerly called the Office of the Deputy Prime Minister.

Top tip

Top tip

ELECSA and the NICEIC are now part of CERTSURE, a joint venture created by the partnership between the Electrical Contractors’ Association and the Electrical Safety Council.

Installers of environmental technology systems must also be registered under the scheme. Those individuals or firms wishing to join the Competent Persons Scheme will need to demonstrate their competence, if necessary, by first undergoing training. The work of members will then be inspected at least once each year. There will be an initial registration and assessment fee and then an annual membership and inspection fee.

Code for sustainable homes

The use of energy to provide heat for central heating and hot water in our homes is responsible for 60% of a typical family’s energy bill. Heating accounts for over half of Britain’s entire use of energy and carbon emissions. If Britain is to reduce its carbon footprint and achieve energy security, we must revolutionize the way we keep warm in the home.

At present 69% of our home heating comes from burning gas, 11% from oil, 3% from solid fuels such as coal and 14% from electricity, which is mainly generated from these same three fossil fuels. Only 4% is currently provided by renewable sources. If Britain is to meet its clean energy targets, renewable sources will have to increase, and the revolution will have to start in the home because the country’s dwellings currently provide more than half of the total demand, almost entirely for hot water and central heating.

Key fact

Key fact

Heating accounts for over half of Britain’s entire use of energy and carbon emissions.

There are about 20 million homes in the UK and a review of present buildings has found that about six million homes have inadequately lagged lofts, eight million have uninsulated cavity walls and a further seven million homes with solid walls would benefit from better insulation. If the country is to achieve its reduced carbon emissions targets, these existing homes must be heavily insulated to reduce energy demand and then supplied with renewable heat.

We cannot sustain the present level of carbon emissions without disastrous ecological consequences in the future. Low carbon homes are sustainable homes. HRH The Prince of Wales has entered the debate saying

becoming more sustainable is possibly the greatest challenge humanity has faced and I am convinced that it is therefore, the most remarkable chance to secure a prosperous future for everyone. We must strive harder than ever before to convince people that by living sustainably we will improve our quality of life and our health; that by living in harmony with nature we will protect the intricate, delicate balance of the natural systems that ultimately sustain us.

(Daily Telegraph, 31 July 2010)

Definition

Definition

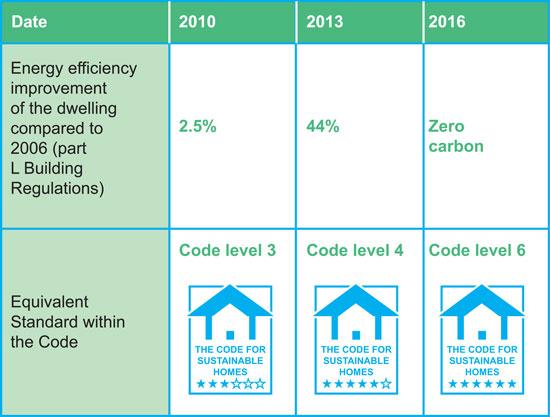

The Code for Sustainable Homes, see Fig. 1.6, measures the sustainability of a home against categories of sustainable design, rating the whole home as a complete package, including building materials and services within the building.

The Code for Sustainable Homes, see Fig. 1.6, measures the sustainability of a home against categories of sustainable design, rating the whole home as a complete package, including building materials and services within the building. The Code uses a one to six star rating to communicate the overall sustainability performance of a new home and sets minimum standards for energy and water use at each level.

Definition

Definition

Code 6 equates to zero carbon emissions.

Since May 2008 all new homes are required to have a Code Rating and a Code Certificate. By 2016 all new homes must be built to zero-carbon standards, which will be achieved through step by step tightening of the Building Regulations. If we look at sustainability from a manufacturing point of view, sustainable manufacture is based on the principle of meeting the needs of the current generation without compromising the ability of future generations to meet their needs.

The topics that we will consider in this chapter, together with improved levels of insulation, would all help our homes to be more sustainable.

Figure 1.6 Code for Sustainable Homes.

Assessment criteria 1.5

State materials and products that are classed as hazardous to the environment or recyclable

Assessment criteria 1.6

Describe the organizational procedures for processing materials that are classed as hazardous to the environment or recyclable

New Hazardous Waste Regulations were introduced in July 2005 and all waste material is now coded but any hazardous waste material is marked with an asterisk in order to highlight the danger. Furthermore, the Environment Agency emphasize what are termed as hazardous outright and are coloured red accordingly.

Under these regulations lamps and tubes are classified as hazardous. While each lamp contains only a small amount of mercury and phosphorous, vast numbers of lamps and tubes are disposed of in the UK every year, resulting in a significant environmental threat.

Safety first

Safety first

• Clean up before you leave the job.

• Put waste in the correct skip.

• Recycle used lamps and tubes.

• Get rid of all waste responsibly.

The environmentally responsible way to dispose of fluorescent lamps and tubes is to recycle them. The process usually goes like this:

• Your employer arranges for the local electrical wholesaler to deliver a plastic used lamp waste container of an appropriate size for the job.

• Expired lamps and tubes are placed whole into the container, which often has a grating inside to prevent the tubes from breaking when being transported.

• When the container is full of used lamps and tubes, you telephone the electrical wholesaler and ask them to pick up the filled container and deliver it to one of the specialist recycling centres.

• Your electrical company will receive a ‘Duty of Care Note’ and full recycling documents, which should be filed safely as proof that the hazardous waste was recycled safely.

• The charge is approximately 50p for each 1800 mm tube and this cost is passed on to the customer through the final account.

Batteries would also come within this category due to the possibility of leakage from the electrolyte inside.

Controlled Waste Regulations 2012

Under these regulations we have a ‘duty of care to handle, recover and dispose of all waste responsibly’. This means that all waste must be handled, recovered and disposed of by individuals or businesses that are authorized to do so under a system of signed Waste Transfer Notes. The Environmental Protection (Duty of Care) Regulations 1991 state that as a business you have a duty to ensure that any waste you produce is handled safely and in accordance with the law. This is the duty of care and applies to anyone who produces, keeps, carries, treats or disposes of waste from business or industry.

You are responsible for the waste that you produce, even after you have passed it on to another party such as a skip hire company, a scrap metal merchant, recycling company or local council. The duty of care has no time limit and extends until the waste has either been finally and properly disposed of or fully recovered. So what does this mean for your company?

• Make sure that waste is only transferred to an authorized company.

• Make sure that waste being transferred is accompanied by the appropriate paperwork showing what was taken, where it was to be taken and by whom.

• Segregate the different types of waste that your work creates.

• Label waste skips and waste containers so that it is clear to everyone what type of waste goes into that skip.

• Minimize the waste that you produce and do not leave waste behind for someone else to clear away.

Remember, there is no time limit on your duty of care for waste. Occupiers of domestic properties are exempt from the duty of care for the household waste that they produce. However, they do have a duty of care for the waste produced by, for example, a tradesperson working at a domestic property.

Special waste is covered by the Special Waste Regulations 1996 and is waste that is potentially hazardous or dangerous and which may, therefore, require special precautions during handling, storage, treatment or disposal. Examples of special waste are asbestos, lead-acid batteries, used engine oil, solvent based paint, solvents, chemical waste and pesticides. The disposal of special waste must be carried out by a competent person, with special equipment and a licence.

Definition

Definition

Special waste is any potentially infectious substance that is harmful to human health or the environment.

Figure 1.7 In order to work with such hazardous materials asbestos removal workers must have a licence.

Assessment criteria 2.1

State installation methods that can help to reduce material wastage

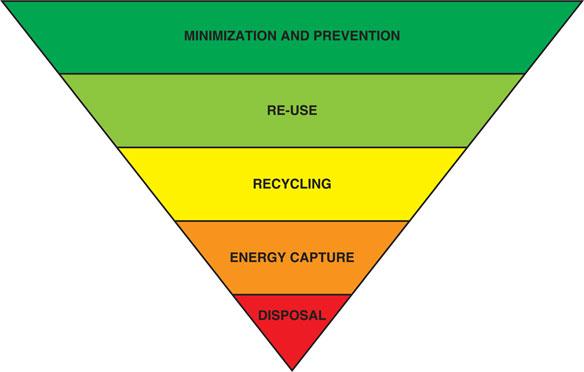

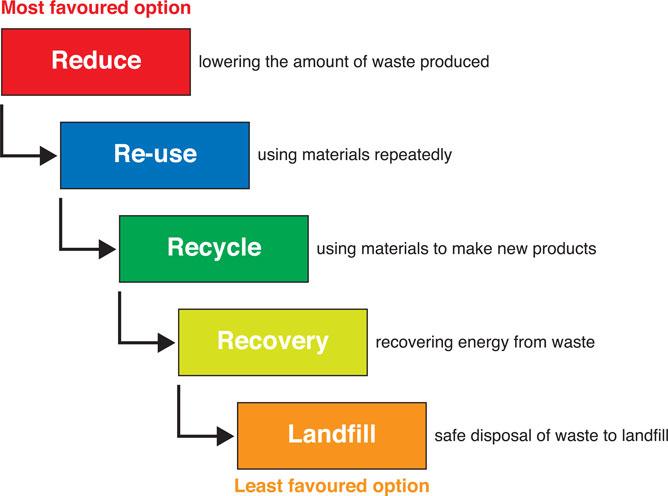

Current government incentives endorse the view that waste should be reduced if possible, but if this is not achievable: reusing it. Consequently, a waste policy looks to protect human health and the impact on the environment and as such a hierarchy of waste management has been produced, which can be seen below.

Waste prevention

The best practice approach to reducing waste is a step-by-step approach and includes the actual design of a building, since judicious use and selection of materials can reduce the waste stream. The process of buying materials is also important and whilst insufficient material stock is never ideal, stock levels should be managed in a way that does not permit excess waste allowance.

Figure 1.8 Remember that landfill is a last resort.

Re-use or recycle

Re-use

The part coils of cable and any other re-usable left-over lengths of conduit, trunking or tray should be taken back to your employer’s stores area. Here it will be stored for future use and the returned quantities deducted from the costs allocated to that job.

Recycle

Recycling involves everyone in all environments including all households in recycling white goods such as microwaves and fridges to plastic bottles and cans.

Energy capture

Traditionally, energy has been generated through waste by burning it, however this has led to phenomena such as acid gases, acid rain and ash. A modern alternative is to create massive ‘district heating’ systems in use in cities such as Newcastle.

Disposal

But what do you do with the rubbish that the working environment produces? Well, all the packaging material for electrical fittings and accessories usually goes into either your employer’s skip or the skip on-site designated for that purpose. All the off-cuts of conduit, trunking and tray also go into the skip. In fact, most of the general site debris will probably go into the skip and the waste disposal company will take the skip contents to a designated local council landfill area for safe disposal.

What goes into the skip for normal disposal into a landfill site is usually a matter of common sense but it is also the least favoured option.

Figure 1.9 Materials should only be sent to landfill as a last resort.

Assessment criteria 2.2

Explain why it is important to report any hazards to the environment that arise from work procedures

If you suspect that an incident or accident has or might affect the environment then it must be reported to your immediate supervisor. The consequences of not reporting such issues could have serious implications, especially when considering exposure to asbestos since it is cumulative – every exposure builds upon the previous ones.

Assessment criteria 2.3

Specify environmentally friendly materials, products and procedures that can be used in the installation and maintenance of electrotechnical systems and equipment

We all have a collective responsibility when it comes to the environment and not just to our families or employer but also to protect future generations through a shift in mindset. There are other benefits, however, since it can reduce both domestic and industrial bills.

Measures include:

• fitting thermostatic control in order to turn down room or working temperature;

• fitting energy efficient replacement items such as compact fluorescent light bulbs or LED fittings;

• installing water meters or smart gas/electricity meters;

• installing insulation;

• repairing leaking taps and pipes;

• fitting light motion sensors in lighting systems or switching off unused rooms, corridors and working areas.

Further development has stemmed from Part L of the Building Regulations and specifically the introduction of Energy Performance Certificates, which grade the environmental efficiency of a building from A being recognized as peak efficiency to G the least efficient. In the electrical installation industry more and more use is being made of installing modular assemblies that have been assembled and tested at the factory. There is therefore less fabrication required on site, which offers a means of waste reduction.

Key fact

Key fact

Modular or pre-made equipment offers a means of reducing waste.

Assessment criteria 3.1

Describe the fundamental operating principles of environmental technology systems

Assessment criteria 3.2

State the applications and limitations of environmental technology systems

Assessment criteria 3.3

State the Local Authority Building Control requirements that apply to the installation of environmental technology systems

Environmental technology systems and renewable energy

Energy is vital to the modern industrial economy in the UK and Europe. We also need energy in almost every aspect of our lives, to heat and light our homes and offices, to enable us to travel on business or for pleasure, and to power our business and industrial machines.

In the past the UK has benefited from its fossil fuel resources of coal, oil and gas but respectable scientific sources indicate that the fossil fuel era is drawing to a close. Popular estimates suggest that gas and oil will reach peak production in the year 2060 with British coal reserves lasting only a little longer. Therefore we must look to different ways of generating electricity so that:

• the remaining fossil fuel is conserved;

• our CO2 emissions are reduced to avoid the consequences of climate change;

• we ensure that our energy supplies are secure, and not dependent upon supplies from other countries.

Following the introduction of the Climate Change Act in 2008 the UK and other Member States agreed an EU-wide target of 20% renewable energy by the year 2020 and 60% by 2050. Meeting these targets will mean basing much of the new energy infrastructure around renewable energy, particularly offshore wind power.

The ‘Energy Hierarchy’ states that organizations and individuals should address energy issues in the following order so as to achieve the agreed targets:

1 Reduce the need for energy – reducing energy demand is cost saving, reduces greenhouse gas emissions and contributes to the security of supply. Reducing the energy loss from buildings by better insulation and switching off equipment when not in use is one way of achieving this target.

2 Use energy more efficiently – use energy-efficient lamps and ‘A’-rated equipment.

3 Use renewable energy – renewable energy refers to the energy that occurs naturally and repeatedly in the environment. This energy may come from wind, waves or water, the sun, or heat from the ground or air.

4 Any continuing use of fossil fuels should use clean and efficient technology. Power stations generating electricity from coal and oil (fossil fuel) release a lot of CO2 in the generating process. New-build power stations must now be fitted with carbon capture filters to reduce the bad environmental effects.

Key fact

Key fact

Renewable energy is no less reliable than energy generated from more traditional sources.

Funding for environmental technology systems

Renewable energy is no less reliable than energy generated from more traditional sources. Using renewable energy does not mean that you have to change your lifestyle or your domestic appliances. There has never been a better time to consider generating energy from renewable technology than now because grants and funding are available to help individuals and companies.

The Low Carbon Building Programme implemented by the Department of Energy and Climate Change (DECC) provides grants towards the installation of renewable technologies that are available to householders, public non-profit-making organizations and commercial organizations across the UK.

The government’s ‘Feed-in Tariff’ pays a tax-free sum which is guaranteed for 25 years. It is called ‘Clean energy cash back’ and has been introduced to promote the uptake of small-scale renewable and low-carbon electricity generation technologies. The customer receives a generation tariff from the electricity supplier, whether or not any electricity generated is exported to the national grid, and an additional export tariff when electricity is transported to the electricity grid through a smart meter.

Key fact

Key fact

The government’s ‘Feed-in Tariff’ pays a tax-free sum which is guaranteed for 25 years.

From April 2010, clean energy generators were paid 41.3p for each kWh of electricity generated. Surplus energy fed back into the national grid earns an extra 3p per unit. However, the scheme has been very popular so the feedback tariffs were reduced to 21p, and from 1 August 2012 the fee fell to only 16p for each kWh. Current rates are 4.32p for each kWh for systems with a capacity of less than 10kW. If you add to this the electricity bill savings, a normal householder could still make some savings. Savings vary according to energy use and type of system used. The Energy Saving Trust at www.energysavingtrust.org.uk, British Gas at www.britishgas.co.uk and Ofgem at www.ofgem.gov.uk/fits provide an online calculator to determine the cost, size of system and CO2 savings for PV systems.

Microgeneration technologies

Microgeneration is defined in the Energy Act 2004 Section 82 as the generation of heat energy up to 45 kW and electricity up to 50 kW.

Today, microgeneration systems generate relatively small amounts of energy at the site of a domestic or commercial building. However, it is estimated that by 2050, 30 to 40% of the UK’s electricity demand could be met by installing microgeneration equipment to all types of building.

Key fact

Key fact

Microgeneration technologies include small wind turbines, solar photovoltaic (PV) systems, small-scale hydro and micro-CHP (combined heat and power) systems.

In the USA, the EU and the UK buildings consume more than 70% of the nation’s electricity and contribute almost 40% of the polluting CO2 greenhouse gases. Any reductions which can be made to these figures will be good for the planet, and hence the great interest today in the microgeneration systems. Microgeneration technologies include small wind turbines, solar photovoltaic (PV) systems, small-scale hydro and micro-CHP (combined heat and power) systems. Microgenerators that produce electricity may be used as stand-alone systems, or may be run in parallel with the low-voltage distribution network; that is, the a.c. mains supply.

The April 2008 amendments to the Town and Country Planning Act 1990 brought in ‘permitted development’ to allow the installation of microgeneration systems within the boundary of domestic premises without obtaining planning permission. However, size limitations have been set to reduce the impact upon neighbours. For example, solar panels attached to a building must not protrude more than 200 mm from the roof slope, and stand-alone panels must be no higher than four metres above ground level and no nearer than five metres from the property boundary. See the Electrical Safety Council site for advice on connecting microgeneration systems at www.esc.org.uk/bestpracticeguides.html.

Smart electricity meters

Smart electricity meters are designed to be used in conjunction with microgenerators. Electricity generated by the consumer’s microgenerator can be sold back to the energy supplier using the ‘smart’ two-way meter.

Key fact

Key fact

Smart electricity meters are designed to be used in conjunction with microgenerators.

From 2012 the Department of Energy and Climate Change began introducing smart meters into consumers’ homes, and this is expected to run until 2020, with the aim being to help consumers reduce their energy bills.

When introducing the proposal Edward Davey, the Energy and Climate Change Secretary, said, ‘the meters which most of us have in our homes were designed for a different age, before climate change. Now we need to get smarter with our energy. This is a big project affecting 26 million homes and several million businesses. The project will lead to extra work for electrical contractors through installing the meters on behalf of the utility companies and implementing more energy-efficient devices once customers can see how much energy they are using.’

Figure 1.10 Smart electricity meter.

Already available is the Real Time Display (RTD) wireless monitor which enables consumers to see exactly how many units of electricity they are using through an easy to read portable display unit. By seeing the immediate impact in pence per hour of replacing existing lamps with low-energy ones or switching off unnecessary devices throughout the home or office, consumers are naturally motivated to consider saving energy. RTD monitors use a clip-on sensor on the meter tails and include desktop software for PC and USB links.

Figure 1.11 Solar photovoltaic (PV array).

Let us now look at some of these microgeneration technologies.

Microgeneration technologies

Electricity-producing technologies

1 Solar photovoltaic (PV) microgenerators

2 Wind energy microgenerators

3 Hydro microgenerators

Heat-producing technologies

4 Solar thermal (hot water) microgenerators

5 Ground source heat pump microgenerators

6 Air source heat pump microgenerators

7 Water source heat pump microgenerators

8 Biomass microgenerators

Co-generation technologies

9 Combined heat and power (CHP) microgenerators

Water conservation technologies

10 Rainwater harvesting

11 Grey water recycling

1. Solar photovoltaic (PV) microgenerators

A solar photovoltaic (PV) system is a collection of PV cells known as a PV string, that forms a PV array and collectively are called a PV generator which turns sunlight directly into electricity. PV systems may be ‘stand-alone’ power supplies or be designed to operate in parallel with the public low-voltage distribution network; that is, the a.c. mains supply.

Definition

Definition

A solar photovoltaic (PV) system is a collection of PV cells known as a PV string, that forms a PV array and collectively are called a PV generator which turns sunlight directly into electricity.

Stand-alone PV systems are typically a small PV panel of maybe 300 mm by 300 mm tilted to face the southern sky, where it receives the maximum amount of sunlight. They typically generate 12 to 15 volts and are used to charge battery supplies on boats, weather stations, road signs and any situation where electronic equipment is used in remote areas away from a reliable electrical supply.

The developing nations are beginning to see stand-alone PV systems as the way forward for electrification of rural areas beyond the National Grid rather than continuing with expensive diesel generators and polluting kerosine lamps.

The cost of PV generators is falling. The period 2009 to 2010 saw PV cells fall by 30% and with new ‘thin-film’ cells being developed, the cost is expected to continue downward. In the rural areas of the developing nations they see PV systems linked to batteries bringing information technology, radio and television to community schools. This will give knowledge and information to the next generation which will help these countries to develop a better economy, a better way of life and to have a voice in the developed world.

Stand-alone systems are not connected to the electricity supply system and are therefore exempt from much of BS 7671, the IET Regulations. However, Regulation 134.1.1, ‘good workmanship by skilled or instructed persons and proper materials shall be used in all electrical installations,’ will apply to any work done by an electrician who must also pay careful attention to the manufacturer’s installation instructions.

PV systems designed to operate in parallel with the public low-voltage distribution network are the type of microgenerator used on commercial and domestic buildings. The PV cells operate in exactly the same way as the standalone system described above, but will cover a much greater area. The PV cells are available in square panels which are clipped together and laid over the existing roof tiles as shown in Fig. 1.12, or the PV cells may be manufactured to look just like the existing roof tiles which are integrated into the existing roof.

Figure 1.12 PV system in a domestic situation.

A solar PV system for a domestic three-bedroom house will require approximately 15 to 20 square metres generating 2 to 3 kilowatts of power. To install a 4KWh system, the average costs involved would range between £6000–£7000. On the positive side, a PV system for a three-bedroom house will save around 1,200 kg of CO2 per year.

These bigger microgeneration systems are designed to be connected to the power supply system and the installation must therefore comply with Section 712 of BS 7671: 2008. Section 712 contains the requirements for protective measures comprising automatic disconnection of the supply wiring systems, isolation, switching and control, earthing arrangements and labelling. In addition, the installation must meet the requirements of the Electricity Safety Quality and Continuity Regulations 2006. This is a mandatory requirement. However, where the output does not exceed 16A per line, they are exempt from some of the requirements, provided that:

• the equipment is type tested and approved by a recognized body;

• the installation complies with the requirements of BS 7671, the IET Regulations;

• the PV equipment must disconnect from the distributor’s network in the event of a network fault;

• the distributor must be advised of the installation before or at the time of commissioning.

Installations of less than 16A per phase but up to 5 kilowatt peak (kWp) will also be required to meet the requirements of the Energy Network Assciation’s Engineering Recommendation G83/1 for small-scale embedded generators in parallel with public low-voltage distribution networks. Installations generating more than 16A must meet the requirements of G59/1 which requires approval from the distributor before any work commences. The installer must be MCS-accredited if the client is to receive the feedback tariff from the energy supplier.

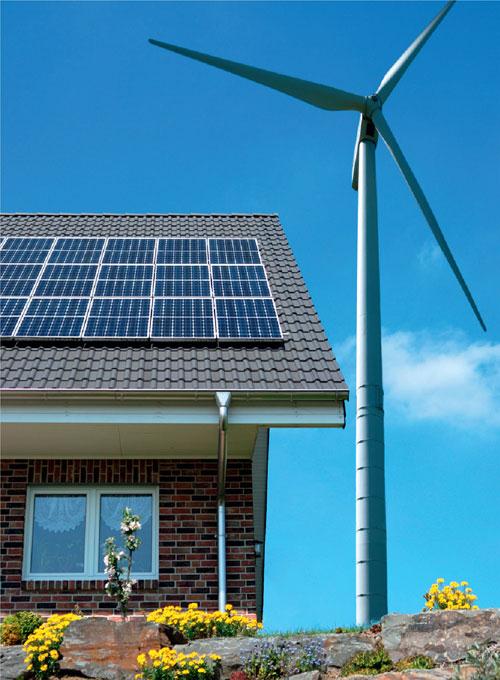

2. Wind energy microgenerators

Modern large-scale wind machines are very different from the traditional windmill of the last century which gave no more power than a small car engine. Very large structures are needed to extract worthwhile amounts of energy from the wind. Modern large-scale wind generators are taller than electricity pylons, with a three-blade aeroplane-type propeller to catch the wind and turn the generator. If a wind turbine was laid down on the ground, it would be longer and wider than a football pitch. They are usually sited together in groups in what has become known as ‘wind energy farms,’ as shown in Fig. 1.13.

Each modern grid-connected wind turbine generates about 600 kW of electricity. A wind energy farm of 20 generators will therefore generate 12 MW, a useful contribution to the national grid, using a naturally occurring, renewable, nonpolluting source of energy. The Department of Energy and Climate Change considers wind energy to be the most promising of the renewable energy sources.

In 2016 there are approximately 5,220 onshore turbines and 1,465 offshore turbines. Combined they generate 33,940,073 MWh, which in turn powers 8,247,891 homes and reduces Co2 yearly emissions by 14,594,232 tonnes.

Figure 1.13 Offshore wind farm energy generators

At one time, the Countryside Commission, the government’s adviser on land use, had calculated that to achieve a target of generating 10% of the total electricity supply by wind power will require 40,000 generators of the present size. In 2018 it was reported that wind power contributes approximately 8% of the total of the electricity generated in the UK.

Wind power is an endless renewable source of energy, is safer than nuclear power and provides none of the polluting emissions associated with fossil fuel. If there was such a thing as a morally pure form of energy, then wind energy would be it. However, wind farms are, by necessity, sited in some of the most beautiful landscapes in the UK. Building wind energy farms in these areas of outstanding natural beauty has outraged conservationists. Prince Charles has reluctantly joined the debate saying that he was in favour of renewable energy sources but believed that ‘wind farms are an horrendous blot on the landscape’. He believes that if they are to be built at all they should be constructed well out to sea.

Definition

Definition

Wind power Is an endless renewable source of energy, Is safer than nuclear power and provides none of the polluting emissions associated with fossil fuel.

The next generation of wind farms will mostly be built offshore, where there is more space and more wind, but the proposed size of these turbines creates considerable engineering problems. From the sea bed foundations to the top of the turbine blade will be up to a staggering 250 metres, three times the height of the Statue of Liberty. Each offshore turbine, generating between 5 and 7 MW, will weigh between 200 and 300 tonnes. When you put large wind forces onto that structure you will create a very big cantilever effect which creates a major engineering challenge.

Key fact

Key fact

The UK Government announced in March 2019 that they would double the present capacity of off shore wind farms in order to meet a new target of generating 30% of energy from renewable sources by the year 2030.

The 100 turbine ‘Thanet’ wind farm just off the Kent coast generates enough power to supply 200,000 homes. The Thanet project cost £780 million to build and was the world’s largest, when it opened in 2010. The turbines are up to 380 feet high and cover an area as large as 4,000 football pitches. The Thanet project did not retain its title as the world’s largest wind farm for long though, because the ‘Greater Gabbard’ wind farm, off the north-east coast with 140 turbines, opened in 2013. These projects bring Britain’s total wind energy capacity above 5,000 megawatts for the first time and more are being built.

The Department of Energy and Climate Change has calculated that 10,000 wind turbines could provide the energy equivalent of eight million tonnes of coal per year and reduce CO2 emissions. While this is a worthwhile saving of fossil fuel, opponents point out the obvious disadvantages of wind machines, among them the need to maintain the energy supply during periods of calm, which means that wind machines can only ever supplement a more conventional electricity supply.

Key fact

Key fact

The Department of Energy and Climate Change has calculated that 10,000 wind turbines could provide the energy equivalent of eight million tonnes of coal per year and reduce CO2 emissions.

Small wind microgenerators can be used to make a useful contribution to a domestic property or a commercial building. They can be stand-alone about the size of a tall street lamp. A 12 m-high turbine costs about £24,000 and, with a good wind, will generate 10,000 kWh per year enough for three small domestic homes. However, if you live in a village, town or city you are unlikely to obtain the the Local Authority Building and Planning permissions to install a wind generator because your neighbours will object.

Small wind generators of the type shown in Fig. 1.14 typically generate between 1.5A and 15A in wind speeds of 10 mph to 40 mph.

Figure 1.14 Small wind generator on a domestic property.

Hydroelectric power generation

The UK is a small island surrounded by water. Surely we could harness some of the energy contained in tides, waves, lakes and rivers? Many different schemes have been considered in the past 20 years and a dozen or more experimental schemes are currently being tested.

Water power makes a useful contribution to the energy needs of Scotland but the possibility of building similar hydroelectric schemes in England is unlikely chiefly due to the topographical nature of the country.

The Severn Estuary has a tidal range of 15 m, the largest in Europe, and a reasonable shape for building a dam across the estuary. This would allow the basin to fill with water as the tide rises, and then allow the impounded water to flow out through electricity-generating turbines as the tide falls. However, such a tidal barrier might have disastrous ecological consequences upon the many wildfowl and wading bird species by the submerging of the mudflats which now provide winter shelter for these birds. Therefore, the value of the power which might be produced must be balanced against the possible ecological consequences.

Key fact

Key fact

Future developments include the Swansea tidal lagoon project which aims to harness the power within tidal surges in the sea in order to drive specialised turbines to generate electricity, The Swansea lagoon could potentially be the first of six installed around Britain’s coastline, which potentially could generate 8% of the UK’s electricity.

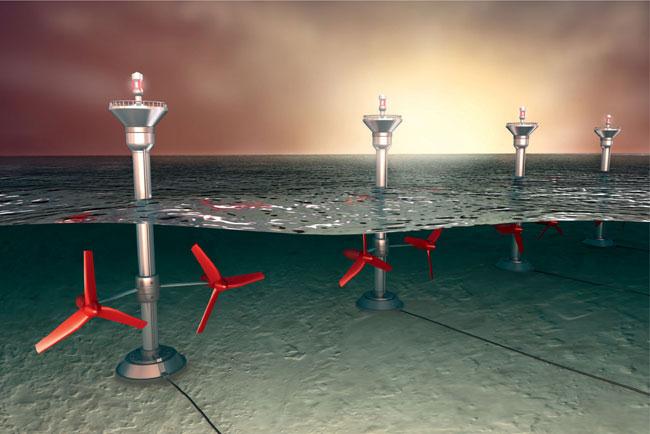

Figure 1.15 Tidal flow water turbines.

France has successfully operated a 240 MW tidal power station at Rance in Brittany for the past 25 years.

Marine Current Turbines Ltd are carrying out research and development on submerged turbines which will rotate by exploiting the principle of flowing water in general and tidal streams in particular. The general principle is that an 11m diameter water turbine is lowered into the sea down a steel column drilled in the sea bed. The tidal movement of the water then rotates the turbine and generates electricity.

The prototype machines were submerged in the sea off Lynmouth in Devon. In May 2008 they installed the world’s first tidal turbine in the Strangford Narrows in Northern Ireland where it is now grid-connected and generating 1.2 MW.

All the above technologies are geared to providing hydroelectric power connected to the national grid, but other micro-hydro schemes are at the planning and development stage.

3. Hydro microgenerators

The use of small hydropower (SHP) or micro-hydropower has grown over recent decades led by continuous technical developments, brought about partly in the UK by the 2010 coalition government’s ‘feed-in tariff’ where green electricity producers are paid a premium to produce electricity from renewable sources.

The normal perception of hydropower is of huge dams, but there is a much bigger use of hydropower in smaller installations. Asia, and especially China, is set to become a leader in hydroelectric generation. Australia and New Zealand are focusing on small hydro plants. Canada, a country with a long tradition of hydropower, is developing small hydropower as a replacement for expensive diesel generation in remote off-grid communities.

Small hydropower schemes generate electricity by converting the power available in rivers, canals and streams. The object of a hydropower scheme is to convert the potential energy of a mass of water flowing in a stream with a certain fall, called the head, into electrical energy at the lower end of the stream where the powerhouse is located. The power generated is proportional to the flow, called the discharge, and to the head of water available. The fundamental asset of hydropower is that it is a clean and a renewable energy source and the fuel used, water, is not consumed in the electricity-generating process.

Definition

Definition

Small hydropower schemes generate electricity by converting the power available in rivers, canals and streams.

In the Derbyshire Peak District along the fast-flowing River Goyt there were once 16 textile mills driven by waterwheels. The last textile mill closed in the year 2000 but the Old Torr Mill has been saved. Where once the waterwheel stood is now a gigantic 12-tonne steel screw, 2.4 metres in diameter. The water now drives the Reverse Archimedian Screw, affectionately called ‘Archie’, to produce 130,000 kWh per year, enough electricity for 40 homes. The electricity-generating project is owned by the residents of New Mills in a sharing cooperative in which surplus electricity is sold back to the grid. The installation cost was £300,000 in 2008. See Fig. 1.16. See also torreshydro new mills website and manpower for info and an interesting video of fish swimming through the turbine.

Figure 1.16 An example of an Archimedian Screw at the River Dart country park, Devon. Credit: WRE Limited.

The type of turbine chosen for any hydro scheme will depend upon the discharge rate of the water and the head of water available. A Pelton Wheel is a water turbine in which specially shaped buckets attached to the periphery of the wheel are struck by a jet of water. The kinetic energy of the water turns the wheel which is coupled to the generator.

Axial turbines comprise a large cylinder in which a propeller-type water turbine is fixed at its centre. The water moving through the cylinder causes the turbine blade to rotate and generate electricity.

A Francis Turbine or Kaplan Turbine is also an axial turbine but the pitch of the blades can be varied according to the load and discharge rate of the water.

Small water turbines will reach a mechanical efficiency at the coupling of 90%.

Up and down the country, riverside communities must be looking at the relics of our industrial past and wondering if they might provide a modern solution for clean, green, electrical energy. However, despite the many successes and obvious potential, there are many barriers to using waterways for electricity generation in the European countries. It is very difficult in this country to obtain permission from the Waterways Commission to extract water from rivers, even though, once the water has passed through the turbine, it is put back into the river. Environmental pressure groups are opposed to microhydro generation because of its perceived local environmental impact on the river ecosystem and the disturbance to fishing. Therefore, once again, the value of the power produced would have to be balanced against the possible consequences.

Key fact

Key fact

The type of turbine chosen for any hydro scheme will depend upon the discharge rate of the water and the head of water available.

4. Solar thermal (hot water) microgenerators

Solar thermal hot water heating systems are recognized as a reliable way to use the energy of the sun to heat water. The technology is straightforward and solar thermal panels for a three-bedroomed house cost at the time of going to press between £3,000 and £6,000 for a 3 to 6 m2 panel and they will save about 260 kg of CO2 annually.

Definition

Definition

Solar thermal hot water heating systems are recognized as a reliable way to use the energy of the sun to heat water.

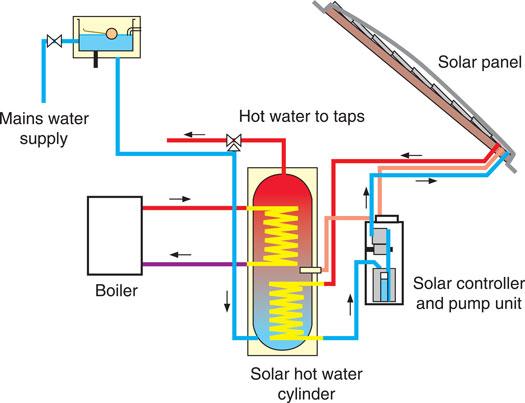

The solar panel comprises a series of tubes containing water that is pumped around the panel and a heat exchanger in the domestic water cylinder as shown in Fig. 1.17. Solar energy heats up the domestic hot water. A solar panel of about 4 m2 will deliver about 1,000 kWh per year which is about half the annual water demand of a domestic dwelling. However, most of the heat energy is generated during the summer and so it is necessary to supplement the solar system with a boiler in the winter months. Figure 1.18 shows a photo of an installed solar hot water panel.

If you travel to Germany, you will see a lot of PV and solar thermal panels on the roofs there. In the UK, planning requirements for solar thermal and PV installations have already been made much easier by ‘permitted development’. A website detailing planning requirements for solar and wind may be found at www.planningportal.gov.uk/planning.

Figure 1.17 Solar-powered hot water system.

Figure 1.18 Solar hot water panel.

Heat pumps

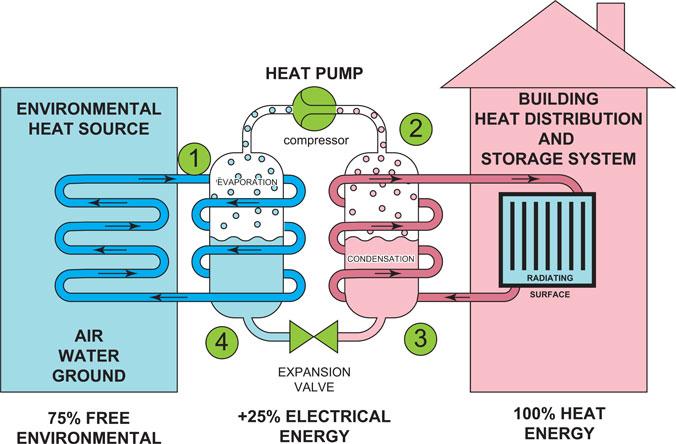

In applications where heat must be upgraded to a higher temperature so that it can be usefully employed, a heat pump must be used. Energy from a low-temperature source such as the earth, the air, a lake or river is absorbed by a gas or liquid contained in pipes, which is then mechanically compressed by an electric pump to produce a temperature increase. The high-temperature energy is then transferred to a heat exchanger so that it might do useful work, such as providing heat to a building. For every 1 kWh of electricity used to power the heat pump compressor, approximately 3 to 4 kWh of heating are produced.

Definition

Definition

In applications where heat must be upgraded to a higher temperature so that it can be usefully employed, a heat pump must be used.

How a heat pump works

1 A large quantity of low-grade energy is absorbed from the environment and transferred to the refrigerant inside the heat pump (called the evaporator). This causes the refrigerant temperature to rise, causing it to change from liquid to a gas.

2 The refrigerant is then compressed, using an electrically driven compressor, reducing its volume but causing its temperature to rise significantly.

3 A heat exchanger (condenser) extracts the heat from the refrigerant to heat the domestic hot water or heating system.

4 After giving up its heat energy, the refrigerant turns back into a liquid, and, after passing through an expansion valve, is once more ready to absorb energy from the environment and the cycle is repeated as shown in Fig. 1.19.

A refrigerator works on this principle. Heat is taken out of the food cabinet, compressed and passed onto the heat exchanger or radiator at the back of the fridge. This warm air then radiates by air convection currents into the room. Thus the heat from inside the cabinet is moved into the room, leaving the sealed refrigerator cabinet cold.

5. Ground source heat pump microgenerators

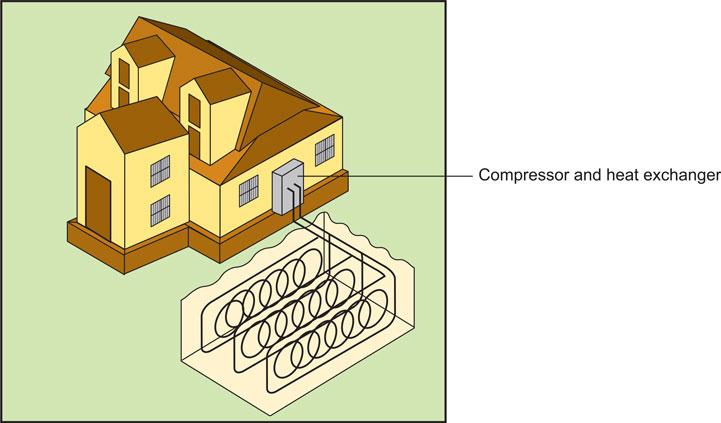

Ground source heat pumps extract heat from the ground by circulating a fluid through polythene pipes buried in the ground in trenches or in vertical boreholes as shown in Fig. 1.20. The fluid in the pipes extracts heat from the ground and a heat exchanger within the pump extracts heat from the fluid. These systems are most effectively used to provide underfloor radiant heating or water heating.

Definition

Definition

Ground source heat pumps extract heat from the ground by circulating a fluid through polythene pipes buried in the ground in trenches or in vertical boreholes.

Calculations show that the length of pipe buried at a depth of 1.5 m required to produce 1.2 kW of heat will vary between 150 m in dry soil and 50 m in wet soil. The average heat output can be taken as 28 watts per metre of pipe. A rule of thumb guideline is that the surface area required for the ground heat exchanger should be about 2.5 times the area of the building to be heated.

This type of installation is only suitable for a new-build project and the ground heat exchanger will require considerable excavation and installation. The installer must seek Local Authority Building Control permissions before work commences.

Figure 1.19 Heat pump working principle.

Figure 1.20 Ground source heating system.

6. Air source heat pump microgenerators

The performance and economics of heat pumps are largely determined by the temperature of the heat source and so we seek to use a high-temperature source. The heat sources used by heat pumps may be soil, the air, ground or surface water. Unfortunately all these sources follow the external temperature, being lower in winter when demand is highest. Normal atmosphere is an ideal heat source in that it can supply an almost unlimited amount of heat although unfortunately at varying temperatures, but relatively mild winter temperatures in the UK mean excellent levels of efficiency and performance throughout the year. For every 1 kWh of electricity used to power the heat pump compressor, between 3 and 4 kWh of heating energy is produced. They also have the advantage over ground source heat pumps of lower installation costs because they do not require any groundwork. Figure 1.21 shows a commercial air source heat pump.

Figure 1.21 Air source heat pump unit.

If the air heat pump is designed to provide full heating with an outside temperature of 2 to 4 degrees centigrade, then the heat pump will provide approximately 80% of the total heating requirement with high performance and efficiency.

The point at which the output of a given heat pump meets the building heat demand is known as the ‘balance point’. In the example described above, the 20% shortfall of heating capacity below the balance point must be provided by some supplementary heat. However, an air-to-air heat pump can also be operated in the reverse cycle which then acts as a cooling device, discharging cold air into the building during the summer months. So here we have a system which could be used for air conditioning in a commercial building.

7. Water source heat pump microgenerators

When we looked at the ground source heat pump at number 5 we said that heat was extracted from the ground by circulating a glycol fluid through polythene pipes buried in the ground. The wetter the soil the more conductive it is to the glycol. Water is an ideal conductor and therefore most suitable as a heat source. Connecting the polythene pipe work together to form a raft-type system will hold the collector together. It is then floated out onto the lake using a small dinghy. When in position the collector is filled with glycol which makes it sink to the bottom of the lake. The feeder pipes are connected to the heat pump at the adjacent building and over time the collector becomes covered with silt.

The lake must be close to the building and large enough to provide a stable temperature throughout the seasons so that the pipes do not freeze at the bottom of the lake.

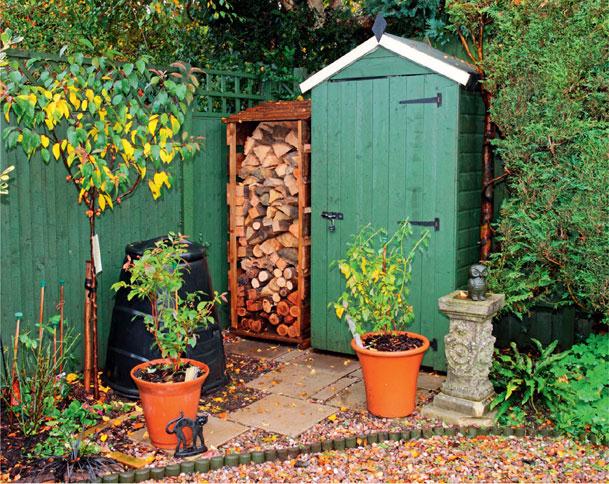

8. Biomass microgenerators

Biomass is derived from plant materials and animal waste. It can be used to generate heat and to produce fuel for transportation. The biomass material may be straw and crop residues, crops grown specially for energy production such as trees or rape seed oil and waste from a range of sources including food production. The nature of the fuel will determine the way that energy can best be recovered from it.

Definition

Definition

Biomass is derived from plant materials and animal waste. It can be used to generate heat and to produce fuel for transportation.

There is a great deal of scientific research being carried out at the moment into ‘biomass renewables’; that is, energy from crops. This area of research is at an early stage, but is expected to flourish in the next decade. The first renewable energy plant, which is to be located at Teesport on the River Tees in the northeast of England, has received approval from the Department of Energy and Climate Change for building to commence.

Definition

Definition

‘Biomass renewables’ is energy from crops.

The facility will be one of the largest biomass plants to be built in the world and is scheduled to enter commercial operation in 2020. Young trees will be grown as a crop to produce wood chips. The plant will use 2.5 million tonnes of wood chips each year to produce 300 MW of electrical energy. The plant will operate 24 hours a day, all year round to meet some of the national grid base load. The USA have over 200 biomass plants operating which meet approximately 4% of the total US energy consumption.

Figure 1.22 Wood pellets being burned in a domestic biomass stove.

Domestic biomass heating can today be found in the increasing popularity of wood stoves. A wide variety of wood-burning appliances are used by households, particularly in rural areas of countries with traditional forest cultures such as Canada, Austria, Finland and Sweden. Since wood fuel was classified as a carbon-neutral fuel under the Kyoto Protocol, most countries that require winter space heating have begun to look again at wood.

Domestic and commercial boilers fuelled by wood logs, wood chips or wood pellets are available. Boiler designs and controls mean that modern boilers can be highly automated. With a water-based heat distribution system already in place, it is relatively simple for any household or commercial operation to remove an existing boiler and replace it with a wood-fuelled one that will do much the same job.

As long as they are locally and sustainably sourced, dry and well-seasoned logs are arguably the greenest of all wood fuels. Apart from drying, they require less processing, and therefore less energy than wood chips or wood pellets.

9. Combined heat and power (CHP) microgenerators

CHP is the simultaneous generation of usable heat and power in a single process. That is, heat is produced as a by-product of the power-generation process. A chemical manufacturing company close to where I live has a small power station which meets some of their electricity requirements using the smart meter principle. They use high-pressure steam in some of their processes and so their 100 MW turbine is driven by high-pressure steam. When the steam condenses after giving up its energy to the turbine, there remains a lot of very hot water which is then piped around the offices and some production plant buildings for space heating. Combining heat and power in this way can increase the overall efficiency of the fuel used because it is performing two operations.

Definition

Definition

CHP is the simultaneous generation of usable heat and power in a single process. That is, heat is produced as a by-product of the power-generation process.

CHP can also use the heat from incinerating refuse to heat a nearby school or block of flats. This is called ‘district heating’, or ‘community heating’.

Water conservation

Conservation is the preservation of something important, especially of the natural environment. Available stored water is a scarce resource in England and Wales where there are only 1,400 cubic metres per person per year; very little compared with France, which has 3,100 cubic metres per person per year, Italy which has 2,900 and Spain 2,800. About half of the water used by an average home is used to shower, bathe and wash the laundry, and another third is used to flush the toilet.

Definition

Definition

Conservation is the preservation of something important, especially of the natural environment.

At a time when most domestic and commercial properties have water meters installed, it saves money to harvest and re-use water.

The examination board has asked us to look at two methods of water conservation: rainwater harvesting and grey water recycling.

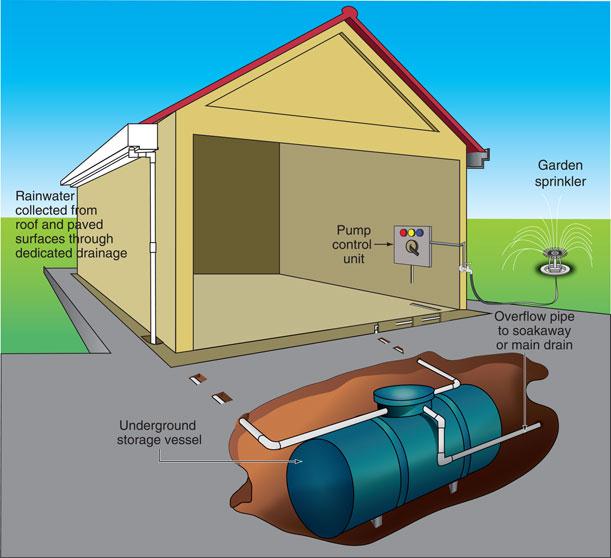

10. Rainwater harvesting

Rainwater harvesting is the collection and storage of rainwater for future use. Rainwater has in the past been used for drinking, water for livestock and water for irrigation. It is now also being used to provide water for car cleaning and garden irrigation in domestic and commercial buildings.

Definition

Definition

Rainwater harvesting is the collection and storage of rainwater for future use.

Many gardeners already harvest rainwater for garden use by collecting runoff from a roof or greenhouse and storing it in a water butt or water barrel. However, a 200-litre water butt does not give much drought protection although garden plants much prefer rainwater to fluoridated tap water. To make a useful contribution the rainwater storage tank should be between 2,000 and 7,000 litre capacity. The rainwater-collecting surfaces will be the roof of the building and any hard-paved surfaces such as patios. Downpipes and drainage pipes then route the water to the storage tank situated, perhaps, under the lawn. An electric pump lifts the water from the storage tank to the point of use, possibly a dedicated outdoor tap. The water is then distributed through a hosepipe or sprinkler system to the garden in the normal way.

With a little extra investment, rainwater can be filtered and used inside the house to supply washing machines and WCs. Domestic pipes and interior plumbing can be added to existing homes although it is more straightforward in a new-build home.

With the move towards more sustainable homes UK architects are becoming more likely to specify rainwater harvesting in their design to support alternatives to a mains water supply. In Germany, rainwater harvesting systems are now installed as standard in all new commercial buildings.

Figure 1.23 Underground rainwater storage vessel.

Figure 1.24 Rainwater harvesting can save a significant amount of water in domestic situations.

11. Grey water recycling

Grey water is tap water which has already performed one operation and is then made available to be used again instead of flushing it down the drain. Grey water recycling offers a way of getting double the use out of the world’s most precious resource.

Definition

Definition

Grey water is tap water which has already performed one operation and is then made available to be used again instead of flushing it down the drain.

There are many products on the market such as the BRAC system which takes in water used in the shower, bath and laundry, cleans it by filtering and then re-uses it for toilet flushing. It is only a matter of routing the grey waste water drainpipe from the bath, shower and laundry to the filter unit and then plumbing the sanitized grey water to the toilet tank.

These systems are easy to install, particularly in a new-build property. It is only a matter of re-routing the drainpipes. Another option for your grey water is to route it into the rainwater storage tank for further use in the garden.

Planning permission and permitted development

The Town and Country Planning Act 1990 effects control over all building development, its appearance and the layout of the building. The Public Health Acts limit the development of buildings with regard to noise, pollution and public nuisance. The Highways Act 1980 determines the layout and construction of roads and pavements. The Building Act 1984 affects the Building Regulations 2000 which enforce minimum material and design standards.

If you are considering building a new home, office or factory you will definitely require Local Authority planning permission before any work begins. However, under permitted development, small extensions to an existing building may be exempt from a formal planning application. The General Permitted Developments Amendment 2, 2008 said, for example, that porches are exempt from planning permission providing that the floor area was no more than three square metres, the height was no more than three metres high and the porch was more than two metres from the boundary wall of the property.

This same permitted developments amendment also lifted the requirements for planning permission for most domestic microgeneration technologies. However, as with the porch example given above, size limitations have been set to reduce the impact upon neighbours. For example, solar panels attached to a building must not protrude more than 200mm from the roof slope and stand-alone panels must be no higher than four metres above ground level and no nearer than five metres from the property boundary. A website detailing planning requirements may be found at www.planningportal.gov.uk/uploads/hhghouseguide.html.

Installing Microgenerators – the Regulations

Let us look at the regulation requirements for each of the technologies discussed earlier in this chapter.

1. Solar PV. This is probably one of the most popular forms of microgeneration in the UK. Planning permission is not required because the fitting of solar panels comes within permitted development unless the building is listed or in a conservation area.