Wind Power

Clean, Cheap Power From an Old Idea And a New Technology

Wind power has been used for hundreds of years to pump water and grind grain. Its use in milling grain was once so common, in fact, that all machines with blades turned by the wind became known as windmills, even though they were and are used for other purposes than milling. Traditional windmills of the type associated with Holland were ponderous and inefficient. As a result, wind power did not become popular in this country until mills with multiple metal blades were developed. Such mills performed admirably at pumping water from wells and proliferated rapidly after 1850, particularly across the Plains States. Millions of them were erected on farms and placed along railroad rights-of-way to supply water for the boilers of steam locomotives.

In the 1930s it became possible to buy a windmill that could generate electricity. This was a new development based on a mill using two or three propellerlike blades turning at high speed. The best of these wind-electric systems were made by Marcellus Jacobs, whose product is still admired today. Many of these depression era wind-powered generators, along with their water-pumping brethren, have fallen into disuse or been sold for scrap. But with the steady rise in the cost of electricity, wind generators may yet become a competitive alternative in areas of the country where the average yearly wind speed is high. However, it takes a very large wind plant to supply the entire power needs of a typical modern home, so unless the family is willing to budget its household electricity usage stringently, a wind plant can only act as a supplement or serve as an emergency backup during utility blackouts.

Water-pumping windmills, with rotor diameters ranging from 6 ft. to 16 ft., are still manufactured. Because of their many blades, only a gentle breeze is necessary to start and run them. Though they cannot take advantage of the large amounts of power in heavy winds (they do not spin fast enough), they are quite adequate for supplying the water needs for a small farm—500 to 5,000 gal. a day; depending on the size of the unit and depth of the well. Protection against extreme winds is provided in various ways: the tail vane automatically turns sideways to keep the rotor facing at right angles to the wind, brakes are automatically applied, or the mill may be automatically decoupled from the pump shaft. The only attention the windmill needs is replacement of the oil in the gear case once a year.

Modern Windmills

Turning speeds of greater than 1,500 revolutions per minute are necessary to generate electricity. To attain these speeds, propellers with only two or three blades must be used. Traditional multibladed windmills do not work because they operate well only at relatively low speeds. At higher rates of rotation the blades spin so fast that the air cannot pass between them, and as a result the whirling blades act like a solid disc.

High-speed wind generators are subject to stresses that can quickly destroy them if they are not carefully designed and built. Exhaustive testing of a variety of prototypes has led to several key discoveries. The most important was that the propeller blades should have an aerodynamic design similar (although not identical) to that of airplane propellers. In addition, it was found that the blades should be constructed from a durable lightweight material such as Sitka spruce or carbon fiber. Finally, engineers determined that either two or three blades will work well. Wind generators in both styles are being produced in sizes over 1000 kilowatts—electricity for more than 400 U.S. homes.

High-speed windmills behave like gyroscopes. When the wind changes its direction and pushes at the tail vane to swing the mill around, the windmill balks and exerts a gyroscopic counterforce that can either break the blades or tear the entire propeller-generator unit off its base unless it is sturdily moored to the tower and cushioned at critical points by shock absorbers.

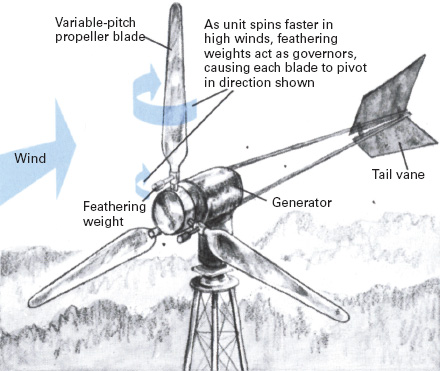

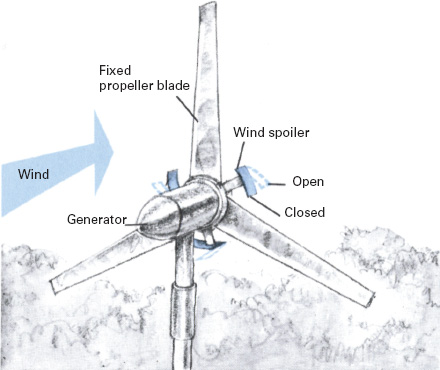

Windmills for residential installations that meet these requirements can be obtained from manufacturers in the United States, Europe, and Australia. The propeller diameters of the units (diameters of circles swept by the blade tips) range in size from 3 feet up to 30 feet, corresponding roughly to power outputs of 25 watts to 6,000 watts at a 25-mile-per-hour wind speed. Most of the plants are designed to run for 20 or more years with little or no attention. Lubrication is relatively permanent, parts are moisture-proof and noncorrosive, and some means is built into each unit to keep the windmill from running wild and destroying itself in extreme winds. Two such safety devices are illustrated below.

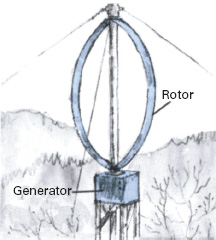

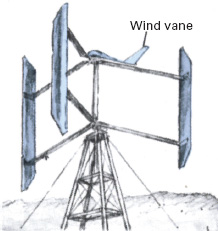

Wind-electric technology is no longer in its infancy, yet a variety of ways to tap the wind continue to be investigated. The Darrieus rotor shown at the right solves the problem of twisting stresses since it does not have to swivel its axis with each change in wind direction. A virtue of sailwing plants is that extreme winds are likely to do no more damage than rip the sails—a considerably safer consequence than a broken propeller blade flying downwind. They are also easier to repair.

Wind-powered generators are manufactured in two configurations: with a tail vane and without one. Generators without a vane pivot on an off-center support point so that the force of the wind keeps them oriented toward the wind on the downwind side of the pivot. In heavy winds the generator shown with a vane has weights on each propeller shaft that turn outward like governor weights and “feather” the blades. (Feathered blades are edged into the wind; in this way they lose their propulsive power and keep the unit from overspeeding.) The wind spoilers shown on the downwind generator serve the same purpose, but instead of feathering the blades, the spoilers spread centrifugally outward in rising winds to act as a brake.

Experimental designs

Darrieus rotor resembles a two- or three-bladed eggbeater. Because it spins on a vertical axis, it does not have to swivel into the wind to catch it every time the wind shifts direction. It does not start by itself, however, so a small motor is usually built on to get the unit going after each spell of no wind.

Variable-pitch blades on this type of Darrieus rotor give the unit a means to start by itself. A small wind vane on top of the rotor shaft makes starting possible by sensing any new direction from which the wind may be rising and altering the angle that the blades make with respect to the new direction.

Sailwing windmills use blades made of nylon. The cloth is kept taut by a framework of aluminum poles and takes on the airfoil profile of a sail on a sailboat whenever the wind blows. Since the cloth is flexible, the blades bend with the wind and so are less likely than solid blades to break.

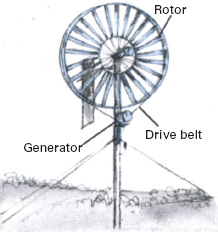

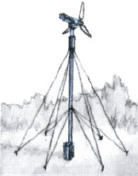

Bicycle-wheel rotor is a modern cousin to the old multibladed windmills. The rotors weigh very little. To operate a generator, the rotor perimeter is employed as a drive wheel in a pulley system with a large step-up ratio. Fair amounts of power can be produced in this way in the low wind-speed range within which these mills are most effective.

Measuring the Wind In Order to Reap It

Although the most accurate way to calculate the power potential of the wind in your area is to measure it yourself, a fair estimate can be obtained by using wind data accumulated by the government at over 270 locations around the country. It can be obtained by writing the National Climatic Data Center, Federal Building, Asheville, North Carolina 28801; ask for data collected by the station nearest you. Also check with your local newspaper and television and radio stations—they frequently maintain files on wind and weather dating back many years. The most useful information you can get is the average wind speed for each month of the year as well as for the year as a whole. For most parts of the United States the average falls between 8 and 12 miles per hour. Localities that have an average wind speed of more than 12 miles per hour are definitely worth considering for a wind power installation; areas with an average below 8 miles per hour are marginal at best.

What the Wind's Power Can Do

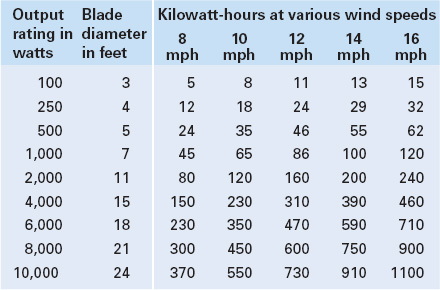

After an optimum location has been selected, use the wind speed measured at that location and the monthly power output chart (far right) to determine the number of kilowatt-hours available if a wind-powered generator is installed. The output will depend, of course, on the wind-plant model planned for the site. The manufacturer will probably specify a power rating that is the maximum power the wind plant will deliver—usually it will be the power generated when the wind speed is 25 miles per hour. Use this rating in the chart.

Having determined the expected monthly output in kilowatt-hours, you can estimate what value it can have for you. One way to do this is to compare the kilowatt-hours on your electric bill with the expected output of the wind generator. This will tell you how much of your electric power needs the wind plant will satisfy. For the comparison, use a bill that is typical of the year.

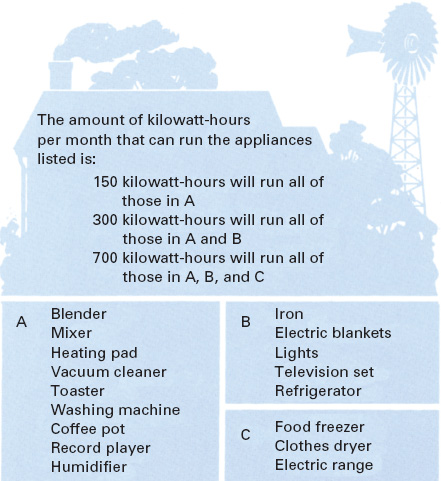

Alternatively, use a power capability chart like the one at the right for the estimate. The chart indicates in an approximate way the number and type of appliances that various monthly power outputs can handle. It is expected that the use of these appliances will be fairly evenly distributed over each month and that batteries are used to store power and absorb peak power demands.

If you make your own wind speed measurements, you should obtain periodic readings at a number of locations around your property, particularly at higher elevations, to find the optimum site. One shortcut is to measure for a week or two only; if the ups and downs of the data over this period are similar to those reported by the nearest weather station, you can assume that the station's readings for the remaining 11 months will also be similar. For example, if your measurements consistently turn out to be 10 percent higher than the station's reported wind speeds, augment the remaining reported figures by 10 percent to achieve a year-round estimate.

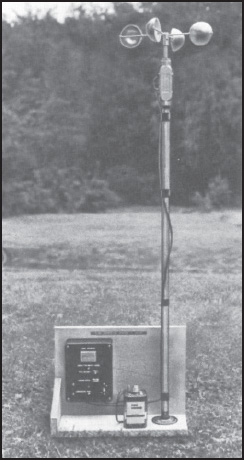

A variety of instruments are available for measuring wind speed. Some, costing only a few dollars, simply measure the speed at a given moment. To obtain a reliable average over a period of time with these devices requires that you make many observations, a chore that can quickly become tedious. At the other end of the spectrum are sophisticated instruments costing hundreds of dollars that automatically provide a complete printout of wind data over an extended period. The best choice for the individual homeowner may be a compromise, such as the semiautomatic anemometer-odometer arrangement shown at the right.

Power capability

Low cost system to measure wind speed uses anemometer wired to odometer. Cups of anemometer are spun by wind; odometer (black box at base of mast) counts each revolution of the anemometer. To measure wind, set odometer counter to zero and note the time. After several hours, read number tallied by odometer and recheck time. Divide odometer reading by 60 and by number of hours elapsed to obtain average wind speed in miles per hour. For example, if odometer tally is 1,500 after an interval of 2½ hours, the tally divided by 60 and then by 2½ gives an average wind speed of 10 miles per hour.

Average monthly power output

Chart shows the output you can expect for a variety of generator sizes and wind speeds. To use the chart, locate the wind speed column most closely matching the average in your area, and read down the column. Each entry shows the kilowatt-hours (kwh) per month that will be developed by a particular generator-blade combination. For instance, if the average wind speed at a potential site is about 12 miles per hour, a 100-watt wind generator will turn out 11 kwh (scarcely worthwhile), but a 2,000-watt generator will produce 160 kwh and a 10,000-watt generator, 730 kwh.

Preferred Sites for Windmills

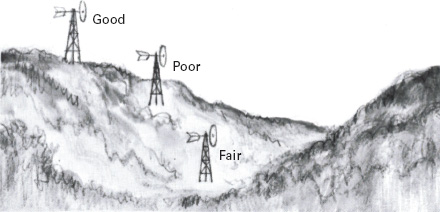

In hilly areas average wind speed can differ markedly according to location. As a guide when checking, hilltops are the best sites, hillsides are the poorest, while valley bottoms can do very well provided the direction of local prevailing winds is up and down the valley. But test each site to make sure.

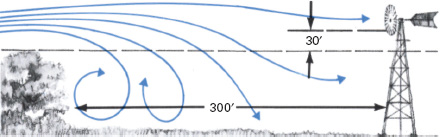

Nearby obstacles can be very detrimental to windmill power output. Even when a barrier is situated downwind from the mill it can produce enough turbulence in the area to interfere with the windmill's efficient performance. For best results, a windmill should be at least 30 ft. higher than any obstruction within a circle of a 300-ft. radius out from the windmill.

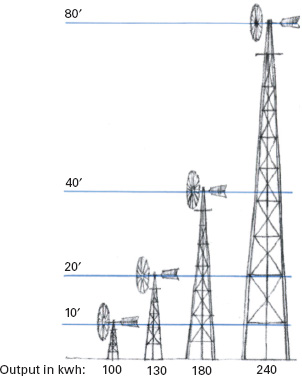

Height of windmill above the ground makes a substantial difference in power output, since wind speed in general increases with altitude. Also, windmills respond in exaggerated fashion to small changes in wind speed, their power output climbing 33 percent for each 10 percent increase in wind speed. The net effect is shown in the illustration. A wind plant that generates 100 kwh per month on a 10-ft. tower, for instance, will generate 240 kwh per month on an 80-ft. tower.

Selecting and Putting Up Towers

As towers rise in height, they also rise in cost, and eventually a point of diminishing returns is reached where added tower expense is not appreciably offset by added power output. Where to draw the line will depend on your power needs and the nature of the site. Factors to consider include average available wind speed, the type of tower used, and the cost of the windmill. For example, if a pole-type tower is to be erected, an array of at least five guy wires fanned out in different directions is preferable, an arrangement that requires more and more space as tower height increases.

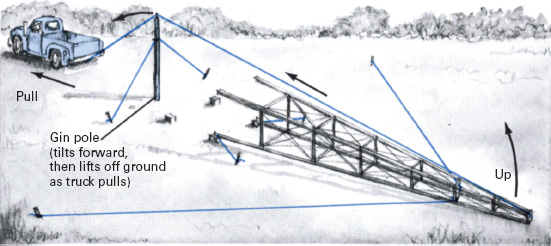

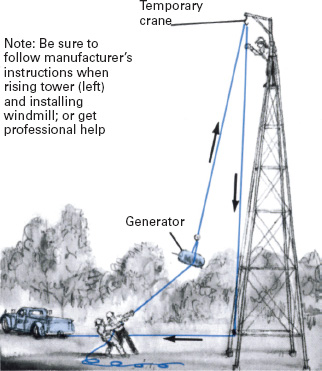

It is easy to underestimate the twisting forces that a wind plant will exert in extreme winds, so it is best to use a commercial tower specifically engineered to support a windmill, especially for heights greater than 30 feet. The manufacturer will provide instructions concerning assembly and erection. You will need at least two helpers to put up the tower and install the windmill on it. The usual procedure is to prepare the foundation, assemble the tower on its side, and erect it by the gin-pole method (below). The mill is then installed part by part at the top. (Do not attach the generator unit before raising the tower; the added weight increases the tower's likelihood of falling down as it is being pulled up.) Towers can also be built vertically, section by section, but this is more hazardous. In general, erecting a tower or climbing one to install equipment can be dangerous work. Never work alone and always wear strong boots, gloves, sturdy clothing, and a hard hat—tools or construction debris falling from a structure can cause serious injury.

Pole-type tower must either be deeply anchored in concrete or supported by guy wires. Use a minimum of three guy-wire anchors (five are preferable). Set anchors at least one-half of tower height away from base of tower and use turnbuckles in the guy wires so that their tension can be adjusted. Some pole towers are hinged at the bottom to permit lowering for servicing and during gales.

Self-supporting tower does not need additional bracing but must have an adequate foundation—usually concrete piers in which the tower's legs are embedded or to which they are bolted. Self-supporting towers are delivered in segments by the manufacturer and must be assembled on location. They are about twice as expensive as pole-type towers of equivalent height but require no guy wires.

Homemade towers up to 30 ft. high, such as the wooden structure shown here, can be built by experienced do-it-yourselfers. They can be quite attractive (this one includes a small picnic platform in the base) but are more apt to be blown down in high winds. If you plan on building one, consult a structural engineer and site the tower in an area where danger to life and property due to the tower falling will be negligible.

Gin-pole method for raising a tower depends for its success on carefully placed temporary guy wires that keep pole and tower from falling sideways during lifting. Wires at base of tower prevent it from sliding forward as vehicle pulls.

Temporary crane attached to top of tower is used to raise windmill parts—first the generator, then tail vane and blades. Man on ground guides each part with guy, helping it into place at tower top, where assistant installs it.

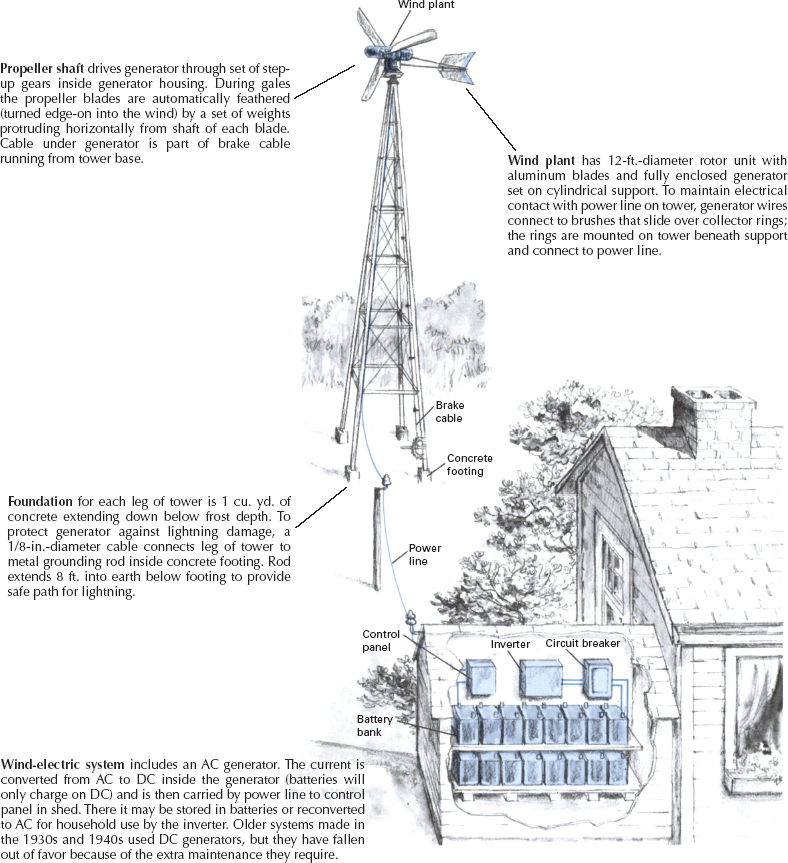

A Wind-Electric System For Household Needs

A system such as the one shown at right can supply a significant portion of the electrical needs of a one-family home. A bank of batteries installed in a well-ventilated shed (or basement of a house) stores excess power that the wind plant generates during low demand periods and releases during windless periods or times of peak demand. Operation is automatic. When the wind blows strongly and few appliances are on, or when the wind is down, the battery current reverses, sending just enough to the house system to make up the difference between windmill output and appliance demand.

Wind plants are generally rated according to their maximum output. The one illustrated here is rated at 2,000 watts, the rating corresponding to its power output when the wind is 25 miles per hour. Its actual output is considerably lower—in the 50- to 150-watt range for most places in the United States—since there are very few locations where wind speeds average 25 miles per hour.

The wind plant is built to stand up in winds of up to 120 miles per hour, but the propeller should be braked whenever winds above 80 miles per hour are anticipated. The brake, which is also useful for stopping the windmill for inspection and servicing, can be operated from the base of the windmill tower.

Sources and resources

Books and pamphlets

Bailey, Donna. Energy from Wind and Water. Chatham, N.J.: Raintree Steck-Vaughn, 1990.

Gipe, Paul. Wind Energy Comes of Age. New York: John Wiley & Sons, 1995.

Rickard, Graham. Wind Energy. Milwaukee, Ind.: Gareth Stevens, 1991. Wind Energy Technical Information Guide. New York: Gordon Press, 1991.

Wind Power: A Source Guide. New York: Gordon Press, 1991.

Periodicals

Wind Power Digest, P.O. Box 700, Bascom, Ohio 44809.

Equipment

Northern Power Systems. 1 North Wind Rd., Moretown, Vt. 05660.

Omnion Power Engineering Corp. 2010 Energy Dr., East Troy, Wisc. 53120

Pease Windamatic Systems Inc., Huntertown, Ind. 46748.

Zephyr Wind Dynamo Co. 107 Bowery St., Bath, Maine 04530.

Organizations

The American Wind Energy Association. 1516 King St., Alexandria, Va. 22314.

Electrical Equipment

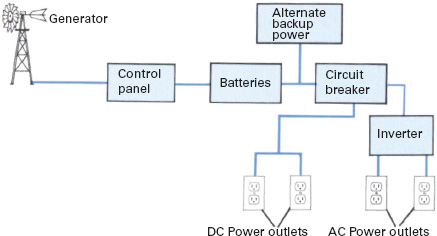

The amount of electrical energy that can be stored by a wind-electric system depends on the capacity of its batteries. A typical home system will store enough to carry a family through two or three windless days after which some type of alternate backup supply must be switched on. If more batteries were used, more windless days could be handled, but batteries are expensive, and it is generally cheaper to use an occasional backup.

Batteries come in various storage ratings and are priced accordingly. Those shown below have a rating of 270 ampere-hours. This means, for example, if an appliance draws 10 amperes of current from such a battery, the battery will become discharged after 27 hours (10 amperes times 27 hours equals 270 ampere-hours). Appliances such as electric irons and toasters each draw about 10 amperes. This calculation can be extended to any amount of current drawn provided it is not excessive. (For instance, the batteries will not deliver 270 amperes for one hour; they are not built for it.)

Properly maintained and operated, a battery will last about 10 years. Water should be added periodically, usually every one to six months, the battery terminals should be kept clear of corrosion, and the batteries must not be permitted to become more than 90 percent discharged. Maintain the batteries at room temperature or above, since cold reduces battery effectiveness. However, be sure to ventilate the room in which the batteries are placed; they can emit hydrogen, a highly flammable and potentially explosive gas.

The public utility or a standby gasoline-fueled generator can be used for backup power. A standby unit requires an engine no larger than a snow thrower's, but it has a limited life span. A better backup option may be photovoltaic (PV) cells. PV cells convert sunlight to electricity and can allow greater daytime electric use.

Bank of 58 batteries produces 116 volts DC. Batteries are like those used in electric golf carts and can provide a steady output over long periods. Inverter is at far right on counter. Above it, on wall, are control panel and circuit breaker (partly hidden).

Inverters are employed to convert DC to AC. The inverter used with the batteries illustrated below has a 2,000-watt capacity and automatically adjusts to changing loads. Such a device is quite expensive, almost as much as the wind plant shown on the facing page. If DC can be used in the house, a mixed system—one that delivers both AC and DC—is preferable; the inverter can then be smaller and less costly.

Typical wind-electric system has control panel to protect batteries from overcharging, an inverter to convert some of the DC output to AC, and a source of standby power. (Alternate systems, similar to some hydroelectric systems, can also be employed. See Power Storage, Regulators, and Inverters, p.101.)

State of charge or discharge is indicated by ball-shaped battery floats. When left ball drops to level shown, battery has become 30 percent discharged; when center ball drops, battery is 60 percent discharged; when right ball drops, battery is 90 percent discharged. Battery water level can also be seen through glass and checked. The water, which must be distilled water, should never be above high mark or below low mark. At top is a capped opening for replenishing water.

Neil Welliver, Painter and Wind Enthusiast

Independence From The Local Power Company

Neil Welliver, of Lincolnville, Maine, is an internationally renowned artist who often paints his giant landscapes under floodlights powered by the two wind plants on his isolated farm. The plants serve his other electrical needs as well and have saved him thousands of dollars in utility costs.

“I suppose I first got interested in wind power as a child when got my first pinwheel. Later I read a little about electricity and wind plants but, really, I was a rank amateur. I put up my first wind plant myself with the help of a local electrician. I sure earned a lot about electricity in a hurry.

“There's no problem in generating enough power for all our household activities from the 2- and 6-kilowatt plants we have. We're conscious of what we're using, but I've never even had a light flicker. I have a backup generator, but we hardly ever need it except for August and September during the doldrums—you know, the period when the wind really dies down. In the winter the wind up here is very strong, and I get more power than the batteries can store.

“There's been an enormous interest in wind plants in the last several years. I was one of the first people in the country to install one and a New York paper did a story on me. People drove from as far away as Louisiana to see the wind plant without so much as a call beforehand.

“Despite the interest, I should say that wind plants are not for everybody. First of all, you have to climb a 50-ft. tower to grease the equipment. And to use a wind plant effectively, you really have to know how the whole thing operates, how to check the machinery and the batteries to see if everything is in good shape. Then, remember, a wind plant produces direct current. That's all right for light bulbs, but for most electronic equipment you have to use an inverter to change that direct current to alternating current.

“Nonetheless, I hope more people will get the information on wind plants. It's madness not to use the wind as power. Look, 90 percent of my electricity I get free. I like to think of myself as a consumer with my own electric company.”