4

RUNNING THE FACTORY

The automotive assembly plant dominates its landscape, wherever in the world it’s located. From a distance, it is a vast windowless mass surrounded by acres of storage areas and railway yards. The complex shape of the building and the lack of a facade often make it hard to know just where to enter. Once inside, the scene is initially bewildering.

Thousands of workers in one vast building tend to streams of vehicles moving across the floor, while a complex network of conveyors and belts in the lofty ceiling carries parts to and fro. The scene is dense, hectic, noisy. On first exposure, it’s like finding oneself inside a Swiss watch—fascinating but incomprehensible and a little frightening, as well.

In 1986, at the outset of the IMVP, we set out to contrast lean production with mass production by carefully surveying as many of the world’s motor-vehicle assembly plants as possible. In the end, we visited and systematically gathered information on more than ninety plants in seventeen countries, or about half of the assembly capacity of the entire world. Ours would prove one of the most comprehensive international surveys ever undertaken in the automobile or any other industry.

This chapter is based on the IMVP World Assembly Plant Survey. The survey was initiated by John Krafcik, who was later joined by John Paul MacDuffie. Haruo Shimada also assisted.

Why did we choose the assembly plant for study? Why not the engine plant, say, or the brake plant or the alternator factory? And why so many plants in so many countries? Surely, the best lean-production plant in Japan and the worst mass-production plant in North America or Europe would have sufficiently demonstrated the differences between lean and mass production.

Three factors convinced us that the assembly plant was the most useful activity in the motor-vehicle production system to study.

First, a large part of the work in the auto industry involves assembly. This is so simply because of the large number of parts in a car. Much of this assembly occurs in components plants. For example, an alternator plant will gather from suppliers or fabricate the 100 or so discrete parts in an alternator, then assemble them into a complete unit. However, it’s hard to understand assembly in such a plant, because the final activity usually makes up only a small part of the total. In the final assembly plant, by contrast, the sole activity is assembly—welding and screwing several thousand simple parts and complex components into a finished vehicle.

Second, assembly plants all over the world do almost exactly the same things, because practically all of today’s cars and light trucks are built with very similar fabrication techniques. In almost every assembly plant, about 300 stamped steel panels are spot-welded into a complete body. Then the body is dipped and sprayed to protect it from corrosion. Next, it is painted. Finally, thousands of mechanical parts, electrical items, and bits of upholstery are installed inside the painted body to produce the complete automobile. Because these tasks are so uniform, we can meaningfully compare a plant in Japan with one in Canada, another in West Germany, and still another in China, even though they are making cars that look very different as they emerge from the factory.

Finally, we chose the assembly plant for study, because Japanese efforts to spread lean production by building plants in North America and Europe initially involved assembly plants. When we began our survey in 1986, three Japanese-managed assembly plants were already in operation in the United States and one was ready to open in England.

By contrast, Japanese plants for engines, brakes, alternators, and other components, though publicly announced for North America and Europe, were still in the planning stage. We knew from experience that it’s pointless to examine a company’s blueprints for a new plant or to look at a plant just as it starts production. To see the full difference between lean and mass production at the plant level, we had to compare plants operating at full volume.

What about the second question we are often asked: “Why study so many plants in so many countries?” The answer is simple. Lean production is now spreading from Japan to practically every nation. Directly in its path are the giant mass-production plants of the previous industrial era.

In every country and every company—including, we might add, in the less accomplished companies in Japan—we have found an intense, even desperate, desire to know the answer to two simple questions: “Where do we stand?” and “What must we do to match the new competitive level required by lean production?” Now we know the answers.

CLASSIC MASS PRODUCTION: GM FRAMINGHAM

We began our survey in 1986 at General Motors’ Framingham, Massachusetts, assembly plant, just a few miles south of our home base in Boston. We chose Framingham, not because it was nearby, but because we strongly suspected it embodied all the elements of classic mass production.

Our first interview with the plant’s senior managers was not promising. They had just returned from a tour of the Toyota-GM joint-venture plant (NUMMI) where John Krafcik, our assembly-plant survey leader, formerly worked. One reported that secret repair areas and secret inventories had to exist behind the NUMMI plant, because he hadn’t seen enough of either for a “real” plant. Another manager wondered what all the fuss was about. “They build cars just like we do.” A third warned that “all that NUMMI talk [about lean production] is not welcome around here.”

Despite this cold beginning, we found the plant management enormously helpful. All over the world, as we have since discovered again and again, managers and workers badly want to learn where they stand and how to improve. Their fear of just how bad things might be is in fact what often creates initial hostility.

On the plant floor, we found about what we had expected: a classic mass-production environment with its many dysfunctions. We began by looking down the aisles next to the assembly line. They were crammed with what we term indirect workers—workers on their way to relieve a fellow employee, machine repairers en route to troubleshoot a problem, housekeepers, inventory runners. None of these workers actually add value, and companies can find other ways to get their jobs done.

Next, we looked at the line itself. Next to each work station were piles—in some cases weeks’ worth—of inventory. Littered about were discarded boxes and other temporary wrapping material. On the line itself the work was unevenly distributed, with some workers running madly to keep up and others finding time to smoke or even read a newspaper. In addition, at a number of points the workers seemed to be struggling to attach poorly fitting parts to the Oldsmobile Ciera models they were building. The parts that wouldn’t fit at all were unceremoniously chucked in trash cans.

At the end of the line we found what is perhaps the best evidence of old-fashioned mass production: an enormous work area full of finished cars riddled with defects. All these cars needed further repair before shipment, a task that can prove enormously time-consuming and often fails to fix fully the problems now buried under layers of parts and upholstery.

On our way back through the plant to discuss our findings with the senior managers, we found two final signs of mass production: large buffers of finished bodies awaiting their trip through the paint booth and from the paint booth to the final assembly line, and massive stores of parts, many still in the railway cars in which they had been shipped from General Motors’ components plants in the Detroit area.

Finally, a word on the workforce. Dispirited is the only label that would fit. Framingham workers had been laid off a half-dozen times since the beginning of the American industry’s crisis in 1979, and they seemed to have little hope that the plant could long hold out against the lean-production facilities locating in the American Midwest.

CLASSIC LEAN PRODUCTION: TOYOTA TAKAOKA

Our next stop was the Toyota assembly plant at Takaoka in Toyota City. Like Framingham (built in 1948), this is a middle-aged facility (from 1966). It had a much larger number of welding and painting robots in 1986 but was hardly a high-tech facility of the sort General Motors was then building for its new GM-10 models, in which computer-guided carriers replaced the final assembly line.

The differences between Takaoka and Framingham are striking to anyone who understands the logic of lean production. For a start, hardly anyone was in the aisles. The armies of indirect workers so visible at GM were missing, and practically every worker in sight was actually adding value to the car. This fact was even more apparent because Takaoka’s aisles are so narrow.

Toyota’s philosophy about the amount of plant space needed for a given production volume is just the opposite of GM’s at Framingham: Toyota believes in having as little space as possible so that face-to-face communication among workers is easier, and there is no room to store inventories. GM, by contrast, has believed that extra space is necessary to work on vehicles needing repairs and to store the large inventories needed to ensure smooth production.

The final assembly line revealed further differences. Less than an hour’s worth of inventory was next to each worker at Takaoka. The parts went on more smoothly and the work tasks were better balanced, so that every worker worked at about the same pace. When a worker found a defective part, he—there are no women working in Toyota plants in Japan—carefully tagged it and sent it to the quality-control area in order to obtain a replacement part. Once in quality control, employees subjected the part to what Toyota calls “the five why’s” in which, as we explained in Chapter 2, the reason for the defect is traced back to its ultimate cause so that it will not recur.

As we noted, each worker along the line can pull a cord just above the work station to stop the line if any problem is found; at GM only senior managers can stop the line for any reason other than safety—but it stops frequently due to problems with machinery or materials delivery. At Takaoka, every worker can stop the line but the line is almost never stopped, because problems are solved in advance and the same problem never occurs twice. Clearly, paying relentless attention to preventing defects has removed most of the reasons for the line to stop.

At the end of the line, the difference between lean and mass production was even more striking. At Takaoka, we observed almost no rework area at all. Almost every car was driven directly from the line to the boat or the trucks taking cars to the buyer.

On the way back through the plant, we observed yet other differences between this plant and Framingham. There were practically no buffers between the welding shop and paint booth and between paint and final assembly. And there were no parts warehouses at all. Instead parts were delivered directly to the line at hourly intervals from the supplier plants where they had just been made. (Indeed, our initial plant survey form asked how many days of inventory were in the plant. A Toyota manager politely asked whether there was an error in translation. Surely we meant minutes of inventory.)

A final and striking difference with Framingham was the morale of the workforce. The work pace was clearly harder at Takaoka, and yet there was a sense of purposefulness, not simply of workers going through the motions with their minds elsewhere under the watchful eye of the foreman. No doubt this was in considerable part due to the fact that all of the Takaoka workers were lifetime employees of Toyota, with fully secure jobs in return for a full commitment to their work.1

A BOX SCORE: MASS PRODUCTION VERSUS LEAN

When the team had surveyed both plants, we began to construct a simple box score to tell us how productive and accurate each plant was (“accurate” here means the number of assembly defects in cars as subsequently reported by buyers).2 It was easy to calculate a gross productivity comparison, dividing the number of hours worked by all plant employees by the number of vehicles produced, as shown in the top line of Figure 4.13 However, we had to make sure that each plant was performing exactly the same tasks. Otherwise, we wouldn’t be comparing apples with apples.

So we devised a list of standard activities for both plants—welding of all body panels, application of three coats of paint, installation of all parts, final inspection, and rework—and noted any task one plant was doing that the other wasn’t. For example, Framingham did only half its own welding and obtained many prewelded assemblies from outside contractors. We made an adjustment to reflect this fact.

We also knew it would make little sense to compare plants assembling vehicles of grossly different sizes and with differing amounts of optional equipment, so we adjusted the amount of effort in each plant as if a standard vehicle of a specified size and option content were being assembled.4

FIGURE 4.1

When our task was completed, an extraordinary finding emerged, as shown in Figure 4.1. Takaoka was almost twice as productive and three times as accurate as Framingham in performing the same set of standard activities on our standard car. In terms of manufacturing space, it was 40 percent more efficient, and its inventories were a tiny fraction of those at Framingham.

If you remember Figure 2.1 from Chapter 2, you might wonder whether this leap in performance from classic mass production, as practiced by GM, to classic lean production, as performed by Toyota, really deserves the term revolution. After all, Ford managed to reduce direct assembly effort by a factor of nine at Highland Park.

In fact, Takaoka is in some ways an even more impressive achievement than Ford’s at Highland Park, because it represents an advance on so many dimensions. Not only is effort cut in half and defects reduced by a factor of three, Takaoka also slashes inventories and manufacturing space. (That is, it is both capital-and labor-saving compared with Framingham-style mass production.) What’s more, Takaoka is able to change over in a few days from one type of vehicle to the next generation of product, while Highland Park, with its vast array of dedicated tools, was closed for months in 1927 when Ford switched from the Model T to the new Model A. Mass-production plants continue to close for months while switching to new products.

DIFFUSING LEAN PRODUCTION

Revolutions in manufacture are useful only if they are available to everyone. We were therefore vitally interested in learning if the new transplant facilities being opened in North America and Europe could actually institute lean production in a different environment.

We knew one of the Japanese transplants in North America very well, of course, because of IMVP research affiliate John Krafcik’s tenure there. The New United Motor Manufacturing Inc. (NUMMI) plant in Fremont, California, is a joint venture between the classic mass producer, GM, and the classic lean producer, Toyota.

NUMMI uses an old General Motors plant built in the 1960s to assemble GM cars and pickup trucks for the U.S. West Coast. As GM’s market share along the Pacific Coast slipped steadily, the plant had less and less work. It finally closed its doors for good in 1982. By 1984 GM had decided that it needed to learn about lean production from the master. So it convinced Toyota to provide the management for a reopened plant, which would produce small Toyota-designed passenger cars for the U.S. market.

NUMMI was to make no compromises on lean production. The senior managers were all from Toyota and quickly implemented an exact copy of the Toyota Production System. A key action toward this end was the construction of a new stamping plant adjacent to the body-welding area, so that body panels could be stamped in small lots just as they were needed. By contrast, the old Fremont plant had depended on panels supplied by rail from GM’s centralized stamping plants in the Midwest. There they were stamped out by the million on dedicated presses.

The United Automobile Workers Union also cooperated to make lean production possible. Eighty percent of the NUMMI workforce consisted of workers formerly employed by GM at Fremont. However, in place of the usual union contract with thousands of pages of fine print defining narrow job categories and other job-control issues, the NUMMI contract provided for only two categories of workers—assemblers and technicians. The union agreed as well that all its members should work in small teams to get the job done with the least effort and highest quality.

By the fall of 1986, NUMMI was running full blast. And we were ready to compare it with Takaoka and Framingham, as shown in Figure 4.2.

We found that NUMMI matched Takaoka’s quality and nearly matched its productivity. Space utilization was not as efficient because of the old GM plant’s poor layout. Inventory was also considerably higher than at Takaoka, because almost all the parts were transported 5,000 miles across the Pacific rather than five or ten miles from neighboring supplier plants in Toyota City. (Even so, NUMMI was able to run with a two-day supply of parts, while Framingham needed two weeks’ worth.)

It was clear to us by the end of 1986 that Toyota had truly achieved a revolution in manufacturing, that old mass-production plants could not compete, and that the new best way—lean production—could be transplanted successfully to new environments, such as NUMMI. Given these findings, we were hardly surprised by subsequent events: Takaoka continues to improve, now with much additional automation. NUMMI is also getting continually better and a second line is being added to assemble Toyota pickup trucks. Framingham was closed forever in the summer of 1989.

FIGURE 4.2

SURVEYING THE WORLD

Once we finished our initial survey, we were determined to press ahead on a survey of the entire world. We were motivated partly by the fact that the companies and governments sponsoring us wanted to know where they stood and partly by the knowledge that a survey of three plants could not answer a number of questions about what roles automation, manufacturability, product variety, and management practices play in the success of manufacturing.

However, we soon realized that we would have to conceal company and plant names when we reported our findings. Many companies were willing to grant us access to their plants only on the condition that we would not reveal plant names in our results. We have respected their wishes and in this book identify plants only when the company has agreed.

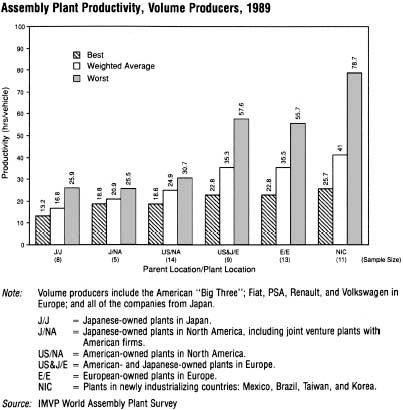

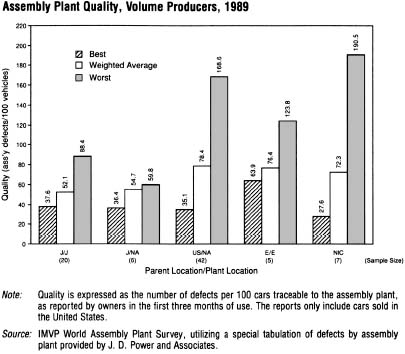

After four more years of research, we have found the following about productivity and quality (or accuracy) across the world, as summarized in figures 4.3 and 4.4.

These findings are not at all what we had expected. We had anticipated all of the Japanese firms in Japan to be roughly comparable in performance—that is, equally lean. Further, we had expected all of the American plants in North America and the American-and European-owned plants in Europe to perform at about the same level with little variation and to trail the average Japanese plant by about the same degree that Framingham trailed Takaoka in 1986. Finally, we expected the assembly plants in developing countries to be marked by low productivity and low quality. The reality is different.

What we find instead is that there is a considerable range of productivity performance in Japan, indeed a difference of two to one between the best plant and the worst in both productivity and quality. The differences along other dimensions—space utilization, level of inventories, percentage of the factory devoted to rework area—are much less, but there is still variation.

FIGURE 4.3

In North America, we quickly discovered that Framingham was in fact the worst American-owned plant. Average Big Three performance in late 1989 was much better—48 percent more effort and 50 percent more defects, compared with the Framingham/Takaoka gap in 1986 of nearly twice the effort and three times the defects. Even more striking, Ford, the originator of mass production seventy-five years ago, is now practically as lean in its North American assembly plants as the average Japanese transplant in North America.5 The best U.S.-owned plants in North America are now nearly as productive as the average Japanese plant—and are very nearly equal in quality.

FIGURE 4.4

Perhaps most striking was our finding about Europe. Framingham, the North American plant that fared so poorly in comparison with Takaoka and which has now been closed, in fact had considerably better productivity in 1986 than the average European plant had achieved by 1989. Indeed, as we marched through plant after plant we came to a remarkable conclusion: Europe, once the cradle of craft production in the motor industry, is now truly the home of classic mass production. Average American performance—under unrelenting pressure from the Japanese transplants in North America—has improved dramatically, partly by closing the worst plants, such as Framingham, and partly by adopting lean production techniques at others. Europe, by contrast, has not yet begun to close the competitive gap.

Regarding the Japanese transplants in North America, we found about what we expected. Their average performance is about comparable to the average Japanese plant in terms of quality but lags about 25 percent in terms of productivity. We believe these differences are partly due to the fact that the transplants are still at an early point in the learning curve with respect to lean production. The differences are also due to different methods of obtaining supplies that necessitate extra work, a point we will return to in Chapter 6.6

However, there is important variation among the transplants as well. For example, one of the transplants has the least efficient utilization of manufacturing space in the entire world sample. In general, we found that the best-performing companies in Japan run the best-performing transplants in North America, suggesting that most of the variation observed is due to differences in management.

Finally, the assembly plants in the developing countries, notably Brazil, Korea, Mexico, and Taiwan, show an extraordinary range of performance. The best plant in terms of quality, Ford at Hermosillo, Mexico, in fact had the best assembly-plant quality in the entire volume plant sample, better than that of the best Japanese plants and the best North American transplants. The best developing country plant was also surprisingly efficient, particularly given its modest level of automation. By contrast, the worst developing country plants were very poor performers, with poor quality and abysmal productivity.

What accounts for the difference? We believe it can be traced to the assembly of a product from a lean-development process (as at Hermosillo, where the car assembled was a variant of a Mazda 323) and doing so with management assistance from a firm mastering lean production. (In the case of Hermosillo, this was directly from Ford, but in several other cases an independent firm had received significant and continuing Japanese management assistance, effectively becoming a transplant.)

These findings require a dramatic reordering of our mental map of the industrial world, which we believe many readers will find very difficult: We must now stop equating “Japanese” with “lean” production and “Western” with “mass” production. In fact, some plants in Japan are not particularly lean, and a number of Japanese-owned plants in North America are now demonstrating that lean production can be practiced far away from Japan. At the same time, the best American-owned plants in North America show that lean production can be implemented fully by Western companies, and the best plants in the developing countries show that lean production can be introduced anywhere in the world.

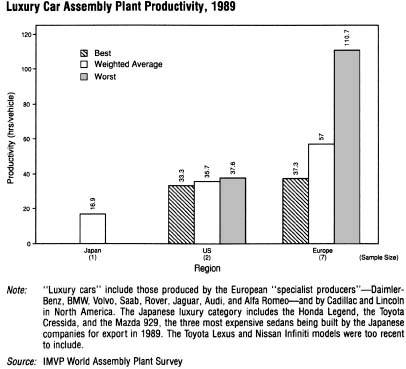

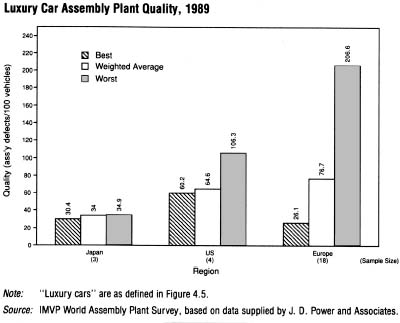

THE STRANGE CASE OF THE “CRAFT” PRODUCERS

The productivity and quality data in figures 4.3 and 4.4 are only for mass-market cars, that is, Fords but not Lincolns, Toyotas but not Lexus, Volkswagens but not Mercedes. From the outset, we believed that assembly plants are all pretty much the same in what they actually do, no matter how prestigious the brand they’re putting together. The same type of robots, indeed often identical models from the same manufacturer, make both the Volkswagen and the Mercedes body welds. Paint is applied in practically identical paint booths, and final assembly involves the installation, largely by hand, of thousands of parts as the vehicle moves along a lengthy assembly line. The real difference between the mass-market and the luxury car is that the latter may have a thicker gauge of steel in its body, extra coats of paint, thicker insulation, and many more luxury add-on features.

While obvious to us, this idea is not universally accepted even in the auto industry and is certainly not the view of the broader public. Repeatedly, executives told us that our productivity and quality findings might be correct for the average car and light truck, but “luxury cars are different.”

We set out to find out for certain by conducting a special world survey of assembly plants making luxury cars. We went to the Japanese large-car plant that we believe, based on our survey of the same company’s mass-market car plants, to be the best in the world. In North America, we looked at the Lincoln and Cadillac plants. In Europe we visited Audi, BMW, Mercedes, Volvo, Rover, Saab, and Jaguar. In each case, we carefully standardized the tasks being undertaken and the specifications of the vehicle, so that we were in fact asking how much effort each plant would need to perform standard assembly steps on the smaller and less elaborate standard car and how many errors it would make in the process. So the actual amount of effort expended in each plant is actually much greater than that shown in figures 4.5 and 4.6. In addition, we adjusted for absenteeism, which runs at 25 percent in many of these European plants compared with 5 percent or less in Japan. The hours in our table represent hours actually worked, not hours on the payroll.

FIGURE 4.5

Our findings were eye-opening. The Japanese plant requires one-half the effort of the American luxury-car plants, half the effort of the best European plant, a quarter of the effort of the average European plant, and one-sixth the effort of the worst European luxury-car producer. At the same time, the Japanese plant greatly exceeds the quality level of all plants except one in Europe—and this European plant requires four times the effort of the Japanese plant to assemble a comparable product. No wonder the Western luxury-car producers are terrified by the arrival of Lexus, Infiniti, Acura, and the Japanese luxury brands still to come.

FIGURE 4.6

In reviewing these data, many readers may wonder if the difference lies in greater product variety and lower production scale in Europe. Certainly our mental image of these companies is that of low-volume craft production. In fact, this is simply not true. The European plants, with one exception, produce at the same volume as the mass producers we looked at earlier, and in most cases produce a less complex mix of products than the Japanese luxury-car plant we surveyed.

When we visited the high-quality but low-productivity European plant we just mentioned, we didn’t have to go far to find the basic problem: a widespread conviction among managers and workers that they were craftsmen. At the end of the assembly line was an enormous rework and rectification area where armies of technicians in white laboratory jackets labored to bring the finished vehicles up to the company’s fabled quality standard. We found that a third of the total effort involved in assembly occurred in this area. In other words, the German plant was expending more effort to fix the problems it had just created than the Japanese plant required to make a nearly perfect car the first time.

We politely inquired of these white-smocked workers exactly what they were doing. “We’re craftsmen, proof of our company’s dedication to quality,” they replied. These “craftsmen” would have been surprised to learn that they were actually doing the work of Henry Ford’s fitters in 1905—adjusting off-standard parts, fine-tuning parts designed so as to need adjustment, and rectifying incorrect previous assembly work so that everything would work properly in the end.

Certainly, these workers are highly skilled and the work they do is no doubt challenging, since every problem is different. However, from the standpoint of the lean producer this is pure muda—waste. Its cause: the failure to design easy-to-assemble parts and failure to track down defects as soon as they are discovered so that they never recur. When employees don’t take this important last step, subsequent assembly work compounds the initial problem and it’s necessary to call for the craftsman to put things right.

Our advice to any company practicing “craftsmanship” of this sort in any manufacturing activity, automotive or otherwise, is simple and emphatic: Stamp it out. Institute lean production as quickly as possible and eliminate the need for all craftsmanship at the source. Otherwise lean competitors will overwhelm you in the 1990s.

THE IMVP WORLD ASSEMBLY PLANT SURVEY IN SUMMARY

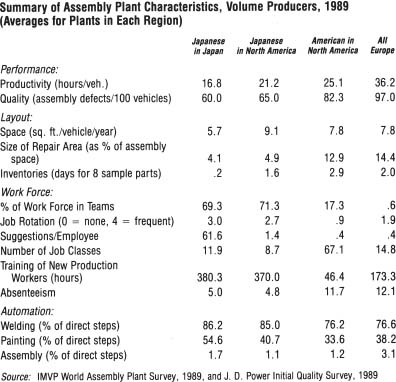

Figure 4.7 summarizes a number of dimensions of current worldwide performance of the volume producers at the assembly-plant level in addition to productivity and quality. In particular, it is striking to note the difference between average Japanese performance and the average in North America and Europe in terms of the size of repair area needed, the fraction of workers organized into teams, the number of suggestions received (and the lack so far of suggestion systems in the Japanese transplants), and the amount of training given new assembly workers.

FIGURE 4.7

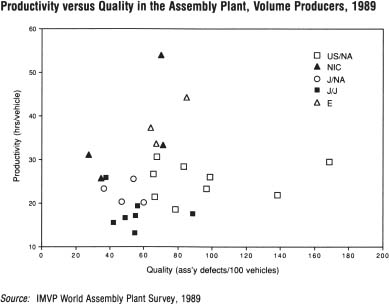

One additional and very important finding of the survey bears note: the relation between productivity and quality. When we first began the survey and correlated productivity with quality in all plants, we found almost no relationship. What’s more, this did not change over time. In Figure 4.8, showing the relationship across the world at the end of 1989, the correlation between productivity and quality is .15.

FIGURE 4.8

This seemed puzzling. We thought it should either be negatively correlated—plants with high quality should require more effort to achieve this, as Western factory managers had long thought—or it should be positively correlated—quality should be “free,” as many writers on Japanese manufacturing had suggested. The answer to the puzzle, as a moment’s examination of Figure 4.8 will show, is that both trends are in evidence and they cancel each other out. The Japanese domestic and transplant facilities are all concentrated in the lower left corner of the figure. For these lean plants, quality really is free. Removing these plants leaves a pattern in which plants tend to have high quality or high productivity but not both. For these mass producers, quality is expensive when it can be achieved at all.

GETTING TO LEAN

We have periodically reviewed our survey findings with practically all the world’s motor-vehicle producers, the main sponsors of the IMVP. So the figures we report here don’t come as a surprise to these companies and are now generally accepted as an accurate summary of the general state of competition at the factory level.

However, determining who stands where in world competition differs from explaining precisely what the also-rans need to do to catch up. As we have reviewed our data with these companies, their executives and managers have questioned us on four points in particular.

First, they ask whether automation is the secret. Our answer is that it is and it isn’t. Figure 4.9 shows the relation between the fraction of assembly steps that are automated—either by robotics or more traditional “hard” automation—and the productivity of plants. There is clearly a downward slope to the right—more automation means less effort. (Stated another way, higher levels of automation show a strong negative correlation (-.67) with higher levels of effort.) We estimate that on average automation accounts for about one-third of the total difference in productivity between plants.

However, what is truly striking about Figure 4.9 is that at any level of automation the difference between the most and least efficient plant is enormous. For example, the least automated Japanese domestic plant in the sample (with 34 percent of all steps accomplished automatically), which is also the most efficient plant in the world, needs half the human effort of one comparably automated European plant and a third the effort of another. Looking farther to the right in Figure 4.9, we can see that the European plant that is the most automated in the world (with 48 percent of all assembly steps done by automation) requires 70 percent more effort to perform our standard set of assembly tasks on our standard car than is needed by the most efficient plant with only 34 percent automation.

The obvious question is, how can this be? From our survey findings and plant tours, we’ve concluded that high-tech plants that are improperly organized end up adding about as many indirect technical and service workers as they remove unskilled direct workers from manual assembly tasks.

FIGURE 4.9

What’s more, they have a hard time maintaining high yield, because breakdowns in the complex machinery reduce the fraction of the total operating time that a plant is actually producing vehicles. From observing advanced robotics technology in many plants, we’ve devised the simple axiom that lean organization must come before high-tech process automation if a company is to gain the full benefit.7

The also-rans’ second question is, Does the manufacturability (ease of assembly) of the product make the difference, rather than the operation of the factory? Understandably, union leaders have often asked us this question as well. Donald Ephlin, now retired from his position as vice-president of the United Auto Workers in the United States, engaged us in a dialogue on this point throughout the life of the IMVP.

How much of the competitive gap between good firms and bad, he wanted to know, lies with the unionized workers in the plant and how much with engineers and managers far away in the corporate development offices. His argument has been simple: “The workers I represent in American plants are getting the blame for problems they are helpless to correct.” Ephlin argued that putting in place organizational improvements—just-in-time inventory, a cord that allowed the worker to stop the line, and so forth—would make a difference, but that none of those improvements could make a plant fully competitive if the product design was defective.

Answering the manufacturability question definitively is difficult, because we would need to perform what auto makers call a tear-down analysis on every car being assembled in every plant we surveyed. Only then could we see how many parts the car has and how easily they can be assembled. This analysis would be staggeringly expensive and time-consuming. So we can report only some interesting but partial evidence that manufacturability is indeed very important.

One piece of evidence is a survey we conducted in the spring of 1990 of the world’s auto makers.8 We asked them to rank all the other auto makers in terms of how manufacturable their products are at the assembly plant. They were to base their ranking on tear-down studies that car companies conduct as part of their competitive assessment programs. (Strange as it may seem, the first production models of any new car are unlikely to reach consumers. Instead, competitors buy them, then immediately tear them apart for competitive assessment.) The results the manufacturers reported are shown in Figure 4.10.

We can’t confirm the accuracy of these findings, because we don’t know how much tear-down analysis companies do or how well they do it. When we began our assembly-plant survey, we were amazed to discover that very few car companies conducted systematic benchmarking studies of their competitors. Nevertheless, the companies responding were in close agreement on which producers design the most manufacturable designs, and the findings correlate nicely with company performance on our productivity and quality indices. This suggests that manufacturability is conducive to high performance in the factory.

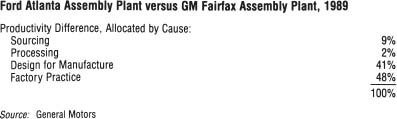

Further evidence comes from a recent comparison General Motors made between its new assembly plant at Fairfax, Kansas, which makes the Pontiac Grand Prix version of its GM-10 model, and Ford’s assembly plant for its Taurus and Mercury Sable models near Atlanta. This comparison was based on tearing down both cars, then using shop manuals to reconstruct the assembly process.

FIGURE 4.10

GM found a large productivity gap between its plant and the Ford plant—both make cars in the same size class, with similar levels of optional equipment and selling in the same market segment. After careful investigation, GM concluded that 41 percent of the productivity gap could be traced to the manufacturability of the two designs, as shown in Figure 4.11. For example, the Ford car has many fewer parts—ten in its front bumper compared with 100 in the GM Pontiac—and the Ford parts fit together more easily. (The other major cause of the productivity gap was plant organizational practices of the type we have just discussed. The GM study found that the level of automation—which was actually much higher in the GM plant—was not a factor in explaining the productivity gap.)

FIGURE 4.11

Ease of manufacture is not an accident. Rather, it’s one of the most important results of a lean-design process. We’ll look at this point more carefully in Chapter 5.

A third question that often crops up when we review our survey findings with companies is product variety and complexity. The factory manager we encountered in Chapter 3, who maintained he could compete with anyone if he could only focus his factory on a single standardized product, is typical of many Western managers. This is certainly an interesting idea and it has a simple logic to commend it.

However, in our survey we could find no correlation at all between the number of models and body styles being run down a production line and either productivity or product quality. We tried a different approach by comparing what was being built in plants around the world in terms of “under-the-skin” complexity. This was a composite measure composed of the number of main body wire harnesses, exterior paint colors, and engine/transmission combinations being installed on a production line, plus the number of different parts being installed and the number of different suppliers to an assembly plant. The results were even less assuring to those thinking that a focused factory is the solution to their competitive problems: The plants in our survey with the highest under-the-skin complexity also had the highest productivity and quality. These of course were the Japanese plants in Japan.9

LEAN ORGANIZATION AT THE PLANT LEVEL

Those company executives, plant managers, and union leaders accepting our conclusion that automation and manufacturability are both important to high performance plants, but that gaining the full potential of either requires superior plant management, usually raise a final question that we find most interesting: What are the truly important organizational features of a lean plant—the specific aspects of plant operations that account for up to half of the overall performance difference among plants across the world? And how can these be introduced?

The truly lean plant has two key organizational features: It transfers the maximum number of tasks and responsibilities to those workers actually adding value to the car on the line, and it has in place a system for detecting defects that quickly traces every problem, once discovered, to its ultimate cause.

This, in turn, means teamwork among line workers and a simple but comprehensive information display system that makes it possible for everyone in the plant to respond quickly to problems and to understand the plant’s overall situation. In old-fashioned mass-production plants, managers jealously guard information about conditions in the plant, thinking this knowledge is the key to their power. In a lean plant, such as Takaoka, all information—daily production targets, cars produced so far that day, equipment breakdowns, personnel shortages, overtime requirements, and so forth—are displayed on andon boards (lighted electronic displays) that are visible from every work station. Every time anything goes wrong anywhere in the plant, any employee who knows how to help runs to lend a hand.

So in the end, it is the dynamic work team that emerges as the heart of the lean factory. Building these efficient teams is not simple. First, workers need to be taught a wide variety of skills—in fact, all the jobs in their work group so that tasks can be rotated and workers can fill in for each other. Workers then need to acquire many additional skills: simple machine repair, quality-checking, housekeeping, and materials-ordering. Then they need encouragement to think actively, indeed proactively, so they can devise solutions before problems become serious.

Our studies of plants trying to adopt lean production reveal that workers respond only when there exists some sense of reciprocal obligation, a sense that management actually values skilled workers, will make sacrifices to retain them, and is willing to delegate responsibility to the team. Merely changing the organization chart to show “teams” and introducing quality circles to find ways to improve production processes are unlikely to make much difference.

This simple fact was brought home to us by one of our early studies of Ford and General Motors plants in the United States. In the Ford plants we found that the basic union-management contract had not been changed since 1938, when Ford was finally forced to sign a job control contract with the UAW. Workers continued to have narrow job assignments and no formal team structure was in place. Yet, as we walked through plant after plant we observed that teamwork was actually alive and well. Workers were ignoring the technical details of the contract on a massive scale in order to cooperate and get the job done.10

By contrast, in a number of General Motors showcase plants we found a new team contract in place and all the formal apparatus of lean production. Yet, a few moments’ observation revealed that very little teamwork was taking place and that morale on the plant foor was very low.

How do we account for these seeming contradictions? The answer is simple. The workers in the Ford plants had great confidence in the operating management, who worked very hard in the early 1980s to understand the principles of lean production. They also strongly believed that if all employees worked together to get the job done in the best way the company could protect their jobs. At the GM plants, by contrast, we found that workers had very little confidence that management knew how to manage lean production. No wonder, since GM’s focus in the early 1980s was on devising advanced technology to get rid of the workers. The GM workers also had a fatalistic sense that many plants were doomed anyway. In these circumstances, it is hardly surprising that a commitment to lean production from the top levels of the corporation and the union had never translated into progress on the plant floor.

We’ll return to the thorny question of how lean production can be introduced into existing mass-production factories in Chapter 9.

IS LEAN PRODUCTION HUMANLY FULFILLING?

As we noted in Chapter 2, Henry Ford’s sword was double-edged. Mass production made mass consumption possible, while it made factory work barren. Does lean production restore the satisfaction of work while raising living standards, or is it a sword even more double-edged than Ford’s?

Opinions are certainly divided. Two members of the United Automobile Workers Union in the United States have recently argued that lean production is even worse for the worker than mass production.11 They go so far as to label the lean-production system instituted at NUMMI in California management by stress, because managers continually try to identify slack in the system—unused work time, excess workers, excess inventories—and remove them. Critics argue that this approach makes Modern Times look like a picnic. In Charlie Chaplin’s widget factory at least the workers didn’t have to think about what they were doing and try to improve it.

A second critique of lean production comes in the form of what might be called “neocraftsmanship.” This has been put in operation in only a few plants in Sweden, but it draws wide attention across the world because it appeals to a seemingly unshakable public faith in craftsmanship.

Let’s take Volvo’s new Udevalla plant in western Sweden as an example. At Udevalla, teams of Volvo workers assemble Volvo’s 740 and 760 models on stationary assembly platforms in small work cells. Each team of ten workers is responsible for putting together an entire vehicle from the point it emerges from the paint oven. Looked at in one way, this system is a return full circle to Henry Ford’s assembly hall of 1903, which we and the rest of the world left behind in Chapter 2. The cycle time—the interval before the worker begins to repeat his or her actions—increases at Udevalla to several hours, from about one minute in a mass-or lean-production assembly plant. In addition, workers in the assembly team can set their own pace, so long as they complete four cars each day. They can also rotate jobs within the teams as they desire. Automated materials-handling delivers the parts needed for each car to the work team. Proponents of the Udevalla system argue that it can match the efficiency of lean-production plants while providing a working environment that is much more humane.

We strongly disagree with both points. We believe that a vital, but often misunderstood, difference exists between tension and a continuing challenge and between neocraftsmanship and lean production.

To take the first point, we agree that a properly organized lean-production system does indeed remove all slack—that’s why it’s lean. But it also provides workers with the skills they need to control their work environment and the continuing challenge of making the work go more smoothly. While the mass-production plant is often filled with mind-numbing stress, as workers struggle to assemble unmanufacturable products and have no way to improve their working environment, lean production offers a creative tension in which workers have many ways to address challenges. This creative tension involved in solving complex problems is precisely what has separated manual factory work from professional “think” work in the age of mass production.

To make this system work, of course, management must offer its full support to the factory workforce and, when the auto market slumps, make the sacrifices to ensure job security that has historically been offered only to valued professionals. It truly is a system of reciprocal obligation.

What’s more, we believe that once lean-production principles are fully instituted, companies will be able to move rapidly in the 1990s to automate most of the remaining repetitive tasks in auto assembly—and more. Thus by the end of the century we expect that lean-assembly plants will be populated almost entirely by highly skilled problem solvers whose task will be to think continually of ways to make the system run more smoothly and productively.

The great flaw of neocraftsmanship is that it will never reach this goal, since it aspires to go in the other direction, back toward an era of handcrafting as an end in itself.

We are very skeptical that this form of organization can ever be as challenging or fulfilling as lean production. Simply bolting and screwing together a large number of parts in a long cycle rather than a small number in a short cycle is a very limited vision of job enrichment. The real satisfaction presumably comes in reworking and adjusting every little part so that it fits properly. In the properly organized lean-production system, this activity is totally unnecessary.

Finally, the productivity of the Udevalla system is almost certain to be uncompetitive even with mass production, much less lean production. We have not audited Udevalla or Kalmar, the two Volvo plants operated on the neocraft model, but some simple arithmetic suggests that if ten workers require 8 hours simply to assemble four vehicles (not including welding the body, painting it, and gathering necessary materials)—for a total of 20 assembly hours per vehicle—Udevalla can hardly hope to compete with our survey’s leading lean-production plant, which requires only 13.3 hours to weld, paint, and assemble a slightly smaller and less elaborate vehicle.

Before leaving this point, we offer one final reason why lean production is unlikely to prove more oppressive than mass production. Simply put, lean production is fragile. Mass production is designed with buffers everywhere—extra inventory, extra space, extra workers—in order to make it function. Even when parts don’t arrive on time or many workers call in sick or other workers fail to detect a problem before the product is mass-produced, the system still runs.

However, to make a lean system with no slack—no safety net—work at all, it is essential that every worker try very hard. Simply going through the motions of mass production with one’s head down and mind elsewhere quickly leads to disaster with lean production. So if management fails to lead and the workforce feels that no reciprocal obligations are in force, it is quite predictable that lean production will revert to mass production. As one lean-production manager remarked during a plant tour: “Mass production is simply lean production run by the rule book, so that no one takes initiative and responsibility to continually improve the system.”

This last point raises some profound questions about the spread of lean production across the whole world, a topic that occupies our attention in Chapter 9. However, at this point, we need to follow the logic of lean production from the assembly plant back to product development. As we’ll see, the nature of the modern motorcar—a highly complex product with more than 10,000 parts—requires a highly complex design and engineering system. And, as in every other aspect of production, the lean approach to coordinating this system is fundamentally different from that of mass production.