D

Dairy Equipment

Under this general heading will be found various items used in a dairy. Included are churns, butter workers and other items. Further information will be found under Churns, Cream Separators and various other headings.

By the 1880s, dairying had become a well-established industry in the United States. Prior to that, commercial dairying was practiced around the larger cities, with daily deliveries of fresh milk. Many people in small towns had a cow of their own or shared milk from a neighbor’s cow. As pointed out in the Churns section, some of the old butter churns, particularly the square-box variety, can easily fetch $500 or more in good condition. Butter workers, butter paddles and similar items also can be quite expensive. A decent butter worker might bring $200 to $300 or more; butter paddles in nice condition often retail for $20 or more. Old cream cans, sometimes known as shipping cans, can often bring $20 to $40 or much more for an unusual or unique design. Establishing anything more than general guidelines for this equipment is very difficult, due to an ever changing market, uniqueness of the item, condition and local demand.

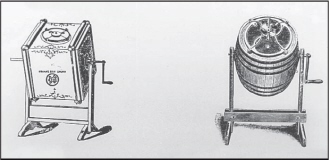

A 1910 Baker & Hamilton hardware catalog illustrates the two most common barrel and box churns. Both styles shown here were available in several sizes, ranging from a small 7-gallon model up to a big 60-gallon churn. At the time, the smaller ones sold for $5.50 to $8; the largest models sold for $26 to $28.

For quality butter, a butter worker was a necessity. It took much of the labor out of working the butter by hand to remove all traces of the buttermilk and bringing the butter to an even consistency. This one is from a 1910 Baker & Hamilton hardware catalog, although there were many others available.

Cream cans, also known as shipping cans, were available in many different styles, sizes and patterns. Shown here from a 1910 Baker & Hamilton hardware catalog are the Ohio Pattern, Pioneer Pattern and Texas Pattern. There were many others. All had the purpose of providing a sanitary leak-proof container with which to haul milk or cream from the farm to a local dairy. Oftentimes, the product was hauled to the local railroad depot and picked up by a passing train and off-loaded at a nearby town.

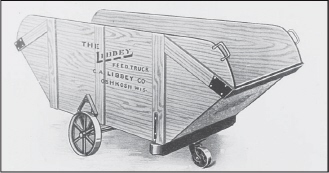

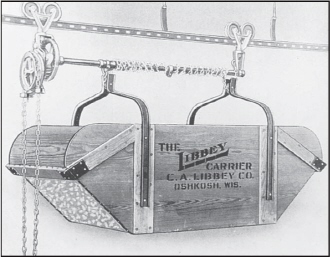

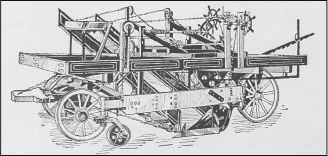

Within a dairy was also the need for equipment to feed the milk cows. To minimize the hand labor, modern barns of the 1920s had concrete floors throughout. This permitted the use of feed trucks like the one shown here. It was made by C.A. Libbey Co., Oshkosh, Wisconsin.

By the 1920s, there were numerous dairy barns equipped with a track system for delivering feed and grain to the livestock. This one, from C.A. Libbey Co., Oshkosh, Wis., had a simple lift system to enable the farmer to raise and lower the carrier at will. Compared to earlier hand methods, these appliances greatly reduced the hand work of an earlier time.

Disc Harrows

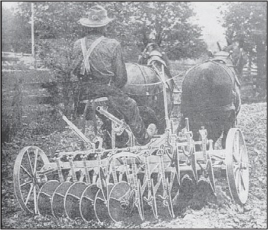

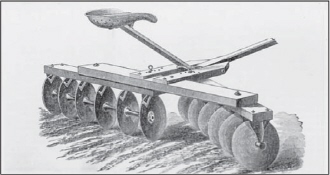

Although some development work was done in the 1850s, it was not until the 1870s that the disc harrow became a reality; generalized manufacturing of disc harrows only began in the 1880s. As with other implements, there were generalities and there were specialties. In general, the disc harrow consisted of a series of curved blades. When set on an angle to the direction of travel, the rolling blades sheared and crumbled the soil over which they passed, doing so in a much more aggressive manner than anything previously invented. Specialties were various types of blades, all intended to the same duty of pulverizing the soil. Then there were disc harrows that threw all the soil one way, there were tandem disc harrows and a variety of other designs. Coincidentally, some manufacturers used “disk harrow” as the proper term, but most companies used “disc harrow.”

Curiously, the disc harrow underwent such major developments over the years that eventually it all but replaced the mold-board plows. Beginning with the first hydraulically controlled models of the 1940s, the disc harrow has undergone a continuing transformation into a primary tillage implement, a role once reserved solely for the plow.

Much of the development work on disk harrows came from small manufacturers, notable exceptions being Deere and the P&O line. Deere began as a plow maker, so the disk harrow fit into its plans; likewise, for P&O. Oliver Chilled Plow Works also was an early entrant into the disc harrow business. International Harvester was not formed until the turn of the century; some of its early tillage implements had been developed by Osborne, with the line taking on major dimensions with the purchase of P&O. J.I. Case was primarily a tractor and threshing machine builder, so it did not get into tillage implements for some years. Allis-Chalmers sold the LaCrosse line for a time, finally buying the company. Thus it is seen that much of the developmental work was carried on by smaller firms that eventually came into the fold of the developing major companies.

Regarding the antique value to collectors of old farm machinery, disc harrows generally are not a highly prized item, so their value is not usually much more than their scrap value. Restored and repainted examples, however, might bring $200 to $300.

American Seeding Machine Co., Springfield, Ohio

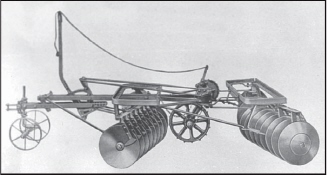

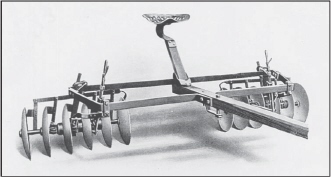

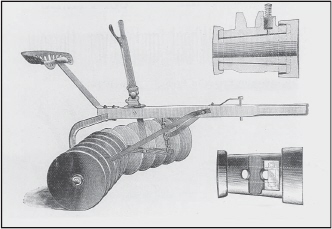

In 1903, American Seeding Machine Co. offered this interesting disc harrow with individually controlled spring-loaded blades. The entire unit was carried on its own chassis. This rear view shows the action of the blades when encountering a stump as shown to the right. No further information has been found concerning this unique design.

B.F. Avery & Sons, Louisville, Ky.

B.F. Avery was a longtime manufacturer of tillage implements; its 1916 catalog illustrates the Avery Volcano and Volcano Jr., Disc Harrows. Shown here in transport position, the two gangs could be angled as desired by use of the hand levers. B.F. Avery & Sons had no connection with Avery Co., Peoria, Ill.

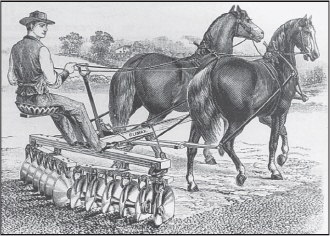

By 1916, B.F. Avery had developed a line of tractor disc harrows, noting that its disc was the only one that had a ground-driven power mechanism to change the gangs from transport to working position. No sooner had manufacturers begun perfecting the disc harrow for use with horse power than the coming of the small tractor necessitated a complete redesign for use with the farm tractor.

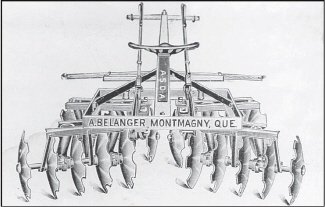

A. Belanger, Montmagny, Quebec

About 1910, Belanger was offering this interesting disc harrow with notched blades, the latter making the disc much more aggressive. In a curious aside, the Belanger was designed for two, three or four horses and could also be furnished with a tractor hitch. In most instances, though, the horse-drawn disc and the tractor disc were separate entities.

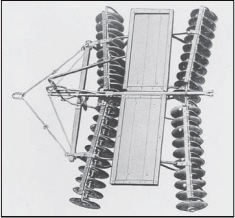

Belle City Manufacturing Co., Racine, Wisc.

By 1903, Belle City was offering its version of the ultimate disc harrow, with the engraving showing its extreme flexibility, even under the most adverse circumstances. Eventually, Belle City concentrated its efforts on threshing machines and other farm equipment, but opted out of the tillage equipment lines.

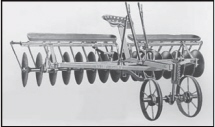

Brown Manufacturing Co., Zanesville, Ohio

Brown was a well-known manufacturer of hay loaders and other hay equipment; the company also had an extensive line of cultivators and tillage equipment. For 1928, the firm offered this tractor disc harrow; shortly after, trade directories note that parts for the Brown equipment line were available from Brown-Manly Plow Co., Malta, Ohio.

Bryan Plow Co., Bryan, Ohio

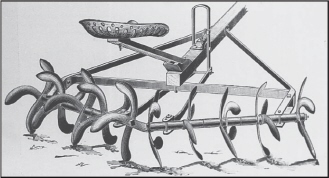

Little is known of Bryan Plow Co., outside of this 1893 advertisement of “Drader’s New Reversible and Adjustable Harrow.” This one was designed to be very aggressive in its work; it also featured changeable gangs so that it could be used as a cultivator. Bryan Plow Co., disappeared from the trade directories in the 1920s.

Bucher & Gibbs Plow Co., Canton, Ohio

A 1908 advertisement called this the Imperial Foretruck Double Disc Harrow. The notched blades were quite effective in pulverizing the soil; anything escaping the first gangs was certain to be encountered by the rear gangs. Bucher & Gibbs appears in the implement directories at least into the late 1950s, but no specific information has been found.

Cutaway Harrow Co., Higganum, Conn.

By 1903, Clark’s Cutaway Harrow had already made a name for itself as a bush plow. The original design was intended for the heavy work required in uprooting heavy brush and grasses. This 1920 photograph shows a tandem harrow or as the company termed it, a Double Action Tractor Harrow. This one is being pulled in conjunction with a Cletrac crawler from Cleveland Tractor Co.

Deere & Co., Moline, Ill.

Deere was a major developer of the disc harrow; by the time this 1908 advertisement appeared, the company had made major strides toward perfection of this very important tillage implement. Shown here is its popular Model B Disk Harrow, available in 7- and 8-foot sizes. An important feature was the oscillating scraper system that enabled the driver to scrape the disc blades clean with a simple foot lever.

By 1935, the Deere line included several different tractor disc harrows; the unique design shown here could be used with only the front gang, since the rear gang could be easily disconnected. At this point in time, the tractor disc harrow was assuming a prominent role, while the sales of horse-drawn models languished, all but ending with the coming of World War II.

De Kalb Implement Works, De Kalb, Ill.

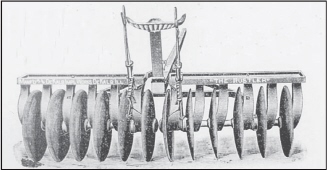

Virtually nothing is known of this company except for this 1895 illustration of the Rustler Disc Harrow. The company made plows and various kinds of harrows, claiming that its Rustler design “has no competitor.”

Emerson-Brantingham Co., Rockford, Ill.

Although the earliest products of Emerson consisted mainly of mowers and haying equipment, the 1907 line included an extensive offering of tillage implements. Included was The New Emerson disc harrow, available in 6-, 7- and 8-foot sizes and available with blades having a diameter of 16-, 18- or 20-inches. The latter was unique at the time, since the majority of disc harrow in 1907 used 16-inch or smaller blades.

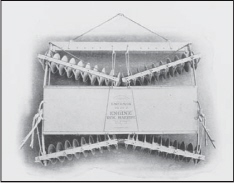

A 1919 catalog from Emerson-Brantingham shows a top view of its No. 60C tractor disc harrow. Emerson-Brantingham was an industry leader in designing farm equipment specifically for tractor power; many competing companies attempted to adapt its horse-drawn designs to tractor power, but with poor results much of the time. J.I. Case bought the company in 1928.

Empire Manufacturing Co., Rock Falls, Ill.

From the 1895 edition of the Germania Kalendar comes this advertisement for the Empire Steel Frame Disc Harrow. Outside of this advertisement, nothing whatever is known of Empire Manufacturing Co.

A.C. Evans Co., Springfield, Ohio

By the time this 1905 advertisement appeared, Evans was actually a part of American Seeding Machine Co., but is shown separately since the company had developed an extensive line of tillage implements prior to the merger. Evidence of the numerous options in disc harrows is shown by this extension-reversible orchard model, made especially for the needs of the nurseryman and the orchardist.

The 1905 Evans disc harrow line included its well-known Thomson In-Throw Disc Harrow. While most disc harrows threw the soil outward, this design was especially useful for certain farming practices. Note how the gangs are offset to permit the soil to be thrown inward.

Farm Tools, Inc., Mansfield, Ohio

Emerging about 1940, this hydraulically controlled disc harrow was an exclusive from Farm Tools, Inc. With this, the farmer could simply raise and lower the disc with a hand lever while turning at the ends of the field or for moving down the road to the next field. It is unlikely that anyone at the time fully grasped the idea that this would be the design to emulate; within a few years, almost all companies were making disc harrows that followed this concept.

A.B. Farquhar Co., York, Pa.

Farquhar was an early entrant into the tillage equipment business, with its Pennsylvania Agricultural Works. Shown here is an early example, probably from the 1890s. The company would later change its emphasis to include various other farm equipment, with sawmills and stationary steam engines always being a particular favorite.

Hapgood Plow Co., Alton, Ill.

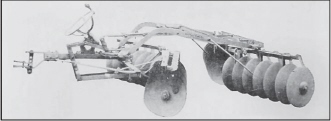

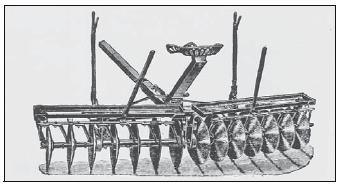

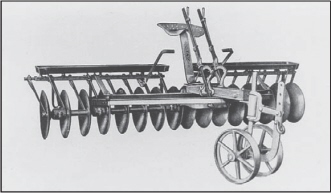

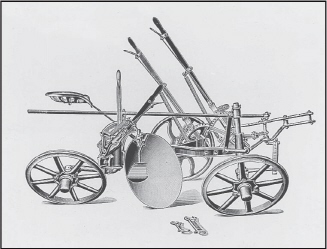

About 1887, Hapgood announced this new disc harrow, complete with a drill attachment. It offered several unique features, among them being the ability to carry the entire unit on wheels for transport or for turning at the ends of the field. This design remained on the market for some years; an identical design appears as late as 1906.

International Harvester Co., Chicago, Ill.

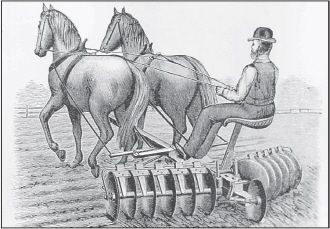

International Harvester initially gained much of its tillage implement line from the 1905 acquisition of D.M. Osborne & Co. By 1910, the company was offering this Osborne disc harrow with an attached tongue truck. Most farmers preferred this design, since the tongue truck or foretruck, carried the weight of the machine rather than placing it forward on the necks of the horses.

By 1920, the IHC line hadbeen greatly enhanced with the purchase of Parlin & Orendorff. The latter was a greatly experienced manufacturer of tillage implements and had a very good reputation with farmers. Shown here is an International 8-foot disc harrow. IHC was developing a row-crop tractor at the time, ultimately coming out with the famous Farmall in a few short years. At the same time, the company was developing an entirely new series of implements designed specifically for tractor power.

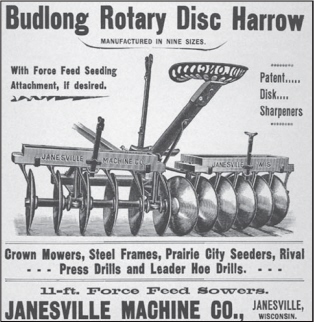

Janesville Machine Co., Janesville, Wisconsin

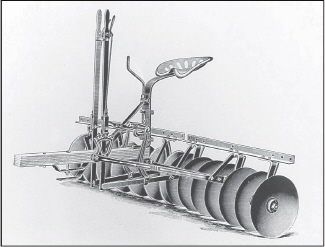

By the early 1890s, J. J. Budlong Company, Aurora, Illinois, had become a part of the Janesville Machine Co., Janesville, Wisconsin. The 1892 Budlong disc harrow was manufactured in nine sizes. Note the cast iron seat on this model. Janesville was bought out by Samson Tractor Co., a subsidiary of General Motors, about 1920.

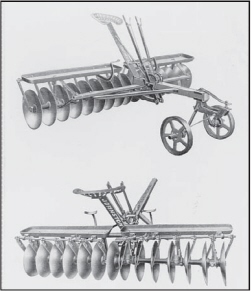

Johnston Harvester Co., Batavia, N.Y.

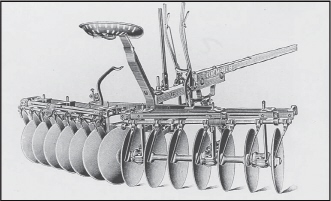

Johnston Harvester Co., began already in 1847 as a manufacturer of harvesting machines. Subsequently, the company expanded the line to include tillage implements. This advertisement of about 1910 shows the Johnston Continental disc harrow in two different views. Johnston came under stock control of Massey-Harris in 1910 and became a direct subsidiary in 1917.

Keystone Manufacturing Co., Sterling, Ill.

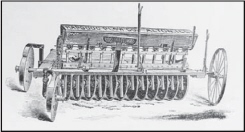

Keystone Manufacturing Co., became a part of International Harvester Co., in 1905. This well-known company had an established line of tillage implements, plus many other farm equipment items. An 1887 illustration depicts the Keystone Combined Disk Harrow and Seed Sower. Note the unique drive for the drill mechanism from the disc shaft.

LaCrosse Plow Co., LaCrosse, Wisc.

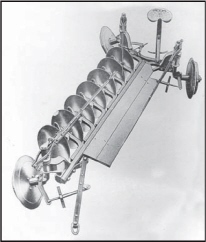

LaCrosse became a part of Allis-Chalmers in 1929, forming the basis of the Allis-Chalmers tillage equipment line. In the 1920s, LaCrosse was offering this impressive tractor disc harrow as one of many different styles and sizes. This model was furnished with a heavy platform that could be used as a weight box to provide better penetration of the disc blades.

Massey-Harris Co., Ltd., Toronto, Ontario

Massey-Harris was originally a Canadian company but established a major manufacturing base in the United States with its 1910 stock control of Johnston Harvester Co., Batavia, N.Y. Included in the extensive Massey-Harris line was this No. 28 disc harrow, a horse-drawn model of the 1920s. The 8-foot model is shown here, but it was also available in 4-, 5-, 6-, 9- and 10-foot sizes.

D.S. Morgan & Co., Brockport, N.Y.

D.S. Morgan & Co., was an early manufacturer of reapers, but eventually its line was diversified to include numerous tillage implements. An 1890 advertisement shows its rather unusual disc harrow; it appears to have been designed for a spading action, compared to the pulverizing action of most disc harrows.

D.M. Osborne Co., Auburn, N.Y.

When established in 1856, Osborne manufactured mowers and other harvesting machines. In the 1880s, tillage implements were added to the line, with this Osborne Rival Disc Harrow appearing by 1900. Osborne became a part of International Harvester Co., in 1905.

Geo. K. Oyler Manufacturing Co., St. Louis, Mo.

Although this company manufactured an extensive line of implements, by the time of the 1887 disc harrow pictured here, the company disappeared from advertising in the 1890s, for reasons now unknown. Its 1887 model featured a unique leveling disc behind the gangs to level the ridge normally created.

Parlin & Orendorff Co., Canton, Ill.

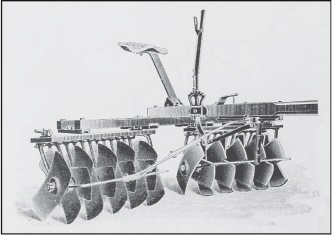

The history of P&O is well known; this company was a major manufacturer of tillage implements, as well as other machines. In 1919, P&O came under ownership of International Harvester. In 1887, the company offered the Rose Disc Harrow shown here. In evidence are the heavy wooden weight boxes that could be filled with dirt, rocks or iron to provide greater penetration of the soil.

Racine-Sattley Company, Springfield, Ill.

About 1907, Sattley Mfg. Co. of Springfield, Illinois, merged with Racine Wagon Co., Racine, Wisconsin. This circa-1910 engraving shows the Sattley Harrow Transporter. The harrow gangs were lifted over the standards of this device. The ironclad runners provided a long working life on a device rarely found today.

S.G. Randall, Providence, R.I.

S.G. Randall was the first to receive a patent for a combined grain seeder and disc harrow. When this patent was issued in 1859, Randall was shown residing at New Braintree, Mass. An 1874 illustration shows the Randall Pulverizing Harrow, as built at that time. Despite the qualities of this machine, compared to its peers, little reference can be found to Randall or his subsequent developments.

Roderick Lean Co., Springfield, Ohio

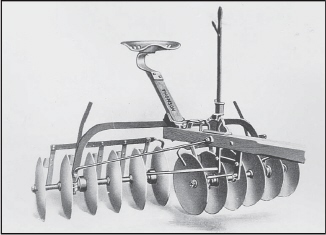

Roderick Lean established a tillage implement factory at Springfield in about 1865. The company thrived and sold all it wanted to, not seeming to be especially interested in growing beyond a certain point. The quality of the Roderick Lean line was undisputed. In 1930, this company joined with others to form Farm Tools, Inc. Shown here is a 1917 example of the New Century “H” Series disc harrow.

Stoddard Manufacturing Co., Dayton, Ohio

By 1887, Stoddard was offering its Climax pulverizing disc harrow. At the time, wood engraving had developed into a major art form; curiously, most engravers depicted light boned, rather fancy horses pulling one machine or another. In contrast, draft horses, as generally used, were heavy boned and not nearly so concerned with high stepping as with exerting power enough to do the job at hand.

Zeller, Phelps & Swift, Rock Falls, Ill.

An 1887 advertisement illustrates the Empire Disc Harrow from the company. This one used a wooden framework with built-in weight boxes for better penetration of the disc blades. Beyond this illustration, nothing at all has been found regarding this company.

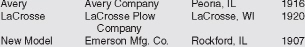

Trade Names

Disc Plows

The disc plow is a comparatively recent development; the classic title American Agricultural Implements by R.L. Ar-drey and first published in 1894, makes no mention of the disc plow. Farm Machinery & Farm Motors written by Chase and Davidson in 1915, makes scant mention of the disc plow, noting that they were an alternative to the mold-board plow in very sticky soil or in soils that were too hard for moldboard plowing. Thus, the disc plow, while important in certain areas, has not generally been used in vast portions of the United States; Midwestern farmers, for example, have little knowledge of this important farm implement.

One example of a disc plow is that built by Emerson Manufacturing Co., Rockford, Ill., in 1907. Its New Model was available with one, two or three discs, with the No. 1 Single shown here. Emerson designed the frame so that right hand turns were possible without the front wheel running interference with the disc.

Available in lever or power-lift styles, the Avery Multiple Disc Plow as shown was listed in the company’s 1916 catalog. Since Avery was located in Louisville, the company was much closer to Texas and other areas having a need for this type of plow. When set to turn 9 inches, this six-disc model plowed 54 inches at each pass.

LaCrosse Plow Co., LaCrosse, Wis., offered a variety of disc plows by the 1920s, including this Montana Disc Plow, an obvious reference for its intended area of use. By the 1920s, most of the major plow makers were offering at least a limited number of disc plows; for most, however, their major manufacturing efforts were still aimed at the time-honored moldboard plow.

Trade Names

Ditching Machines

While technically, at least, not a farm implement, a great many ditching machines were used on farms. Usually, such a machine was owned by someone in a neighborhood, the latter then doing custom work for local farmers. All styles, sizes and designs appeared. Some were small horse-drawn affairs, while others required a sizable steam-traction engine or tractor.

H. W. Beldsmeyer & Co., St. Louis, Mo.

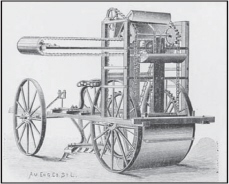

An 1887 advertisement illustrates Beldsmeyer’s Patent Ditching Machine. This rather simple design plowed up the earth, with the loose soil being carried by elevator buckets up to a cross conveyor. The latter then dropped the soil off to one side of the machine. The advertising claimed that this machine could move 1,000 cubic yards of earth in 10 hours.

Standard Ditching Machine Co., St. Louis, Mo.

This 1892 Mogul Grader and Dieter claimed it could move up to 1,000 cubic yards of earth in a 10-hour day. Although it could be pulled by a sizable number of horses, probably 12 or more, it could also be pulled by a steam-traction engine, since, by 1892, there were a few of these capable of heavy traction work.

Owensboro Ditcher & Grader Co., Owensboro, Kty.

By the 1920s, this company was offering a variety of ditching machines. The Martin All-Steel Ditcher shown here was a small outfit designed to build ditches, particularly on farms and on rural roads. The company also made road graders and other earth-moving equipment.

Trade Names