F

Fanning Mills

Whether called a fanning mill or a grain cleaner is mostly a matter of semantics; both terms mean essentially the same thing. With the coming of intensive agriculture, farmers wanted to plant clean grain without replanting weeds harvested with the previous crop-there were enough of those already. Thus, there were many companies offering grain cleaners or fanning mills by the 1880s; this industry saw its peak in the 1920s. By that time, the market was fairly saturated and most of these little machines were so well built that it was nearly impossible to wear them out. In fact, a great many fanning mills used today saw first light in the 1920s or even earlier. Despite their age, they are used every season for cleaning oats and other grains.

Usually, a fanning mill will have a reasonable market value; it is not uncommon for a good machine to bring $100 or perhaps much more, depending on age and condition. Quite often, they are purchased for farm use, rather than as a farm antique.

Bergman Manufacturing Co., Newton, Iowa, offered its Newton Grain Grader and Cleaner in this form for 1913. It was built for several years. Although there were probably other models designed for belt power, this one was purely a hand-powered outfit, as evidenced in the illustration.

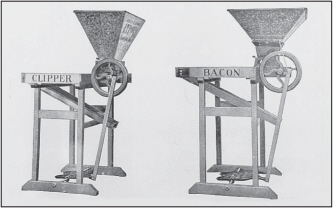

Clipper Grain Cleaners from A.T. Ferrell & Co., Saginaw, Mich., were and remain the most popular of all fanning mills. Its fanning mills, such as this No. 1-B of the 1920s, were sold by the thousands and many are still in use. This one could be operated by hand power or could be belted. In the 1920s, this one was priced at $35.

A.T. Ferrell & Co., built several styles of Clipper bean sorters, with the two examples shown here coming from a catalog of the 1920s. They were specialized machines designed for picking and sorting edible beans, as well as soybeans. The Clipper shown at the left sold for $9.

Fosston Manufacturing Co., St. Paul, Minn., offered its Fosston Automatic No. 24 in 1910, shown here. This one was somewhat larger than the ordinary, even including a sacking elevator.

A large commercial warehouse fanning mill was offered by Grant-Ferris & Co., Troy, N.Y. at the turn of the century. Despite its size, this one was a hand-powered outfit, although it seems that a unit of this size might have been capable of belt power.

An 1897 catalog from Grant-Ferris & Co., illustrates its double-blast fanning mill of the time. As with most such mills, it not only cleaned the grain but also graded it so that small or broken seeds were discarded and only the best seed was saved for planting the new crop.

From 1909 comes this illustration of the Handicap Seed Cleaner and Grain Separator. It was built by the firm of Gunther & Lyman, Wapakoneta, Ohio. Various companies entered this business in the early 1900s, but most of them only continued for a few years.

A very popular and widely advertised fanning mill came from Johnson & Field Manufacturing Co., Racine, Wis. This hand-powered outfit was even available with a separate sacking elevator, enabling the farmer to sack the cleaned grain for the new crop. Oftentimes, the grain cleaning was done in the winter, so cranking the mill probably wasn’t a bad job after all-at least one could keep warm! Shown here is the No. 1 Racine Farm Mill of 1915.

Manson Campbell Co., Ltd., Detroit, offered this model of its Chatham Fanning Mill in 1904. It is shown with its patented sacking attachment. For reasons unknown, fanning mills were usually decorated with extensive pin-striping, plus stencils or decals, even when most farm machinery was losing that special appearance.

About 1910, One Minute Manufacturing Co., Newton, Iowa, offered its One Minute Grain Grader and Seed Cleaner. Its Model No. 1 shown here is equipped with a hand-crank, but it was removable and the machine could be powered with a special drive attachment as shown in this engraving.

J.L. Owens Co., Minneapolis, specialized in large grain cleaners for elevators and mills, but also offered its New Superior Fanning Mills. Built in two different sizes for farm use, they could be powered by hand or belt and could be furnished with or without a bagging elevator. This one is of about 1910 vintage.

For a time, this Hawkeye Grain Grader was offered by Parsons-Hawkeye Co., Newton, Iowa. Eventually, the same machine appears under the auspices of Maytag Co., Newton. The Hawkeye carried as its slogan the Biblical expression, “Whatsoever a man soweth, that shall he also reap.”

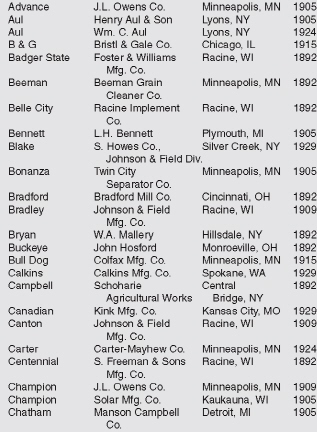

Trade Names

Farmstead Tools & Equipment

Under this heading one could (and we probably will) write a complete book. The variety of farm tools and appliances is simply amazing. While the frontiersmen had little more than a plow, a spade and an ax, farmers of 1900 were equipping themselves with numerous tools and gadgets to make their work easier. For the purposes of this book, it has seemed the better course to provide a brief outline of farmstead tools and equipment rather than give the impression they were not an important part of the scene. Yet, to provide a comprehensive display would minimize other important areas of discussion.

By the 1880s, many farmers were convinced that cooked feed was more nutritious and more palatable than uncooked. Numerous companies sprang forth with feed cooking apparatus; some, like this one from Goulds & Austin, could be used for almost anything requiring hot water or steam

Dozens of iron foundries made the huge cauldrons or kettles as shown here from D.R. Sperry & Co. The company called them farm boilers, as compared to steam boilers. In other words, the farm boiler was capable of boiling water, as in a kettle, but could not generate steam. Large iron cauldrons as shown often bring $100 or more.

Feed cookers or farm boilers were often built on a regional basis, coming from iron foundries in a certain area, rather than being shipped hundreds of miles (with additional freight costs). Such was the case with Swift’s Feed Cooker, made in sizes from 20 to 60 gallons. Swift Manufacturing Co., Waterloo, Iowa, offered this one in 1907; the company also made carts, feed grinders and other equipment.

Farm boilers, such as this one from F. Thurman & Co., Plymouth, Wis., were used for everything from cooking feed to scalding hogs or making soap. Sometimes, they were simply used for boiling large quantities of water. As noted, large cast-iron cauldrons like this one often bring $100 or more.

Heider Manufacturing Co., Carroll, Iowa, was a major manufacturer of eveners as shown. In fact, this illustration shows but one of its line, since the company made literally dozens of different styles. Today, wooden eveners sell sometimes for very little, while in other instances, they may bring $30 to $50.

Heider Manufacturing Co. also made various sorts of singletrees, each for a specific purpose. For those unfamiliar with the terminology, eveners were used to hitch a specific number of horses to, for instance, a plow. If the evener was for four horses, then four singletrees as shown, were needed, one for each horse. Singletrees today sell for anywhere from $5 to $20.

In cold weather climates, keeping a water supply available to livestock necessitated the use of a tank heater. These were usually of cast iron, heavy enough to sink to the bottom by their own weight. In cold weather it was necessary to tend the fire on a regular basis, usually several times every day. This one was made by Stover Manufacturing Co., Freeport, Ill.

A very popular tank heater was the Cow Boy from Wills Manufacturing Co., Mendota, Ill. This sectional view shows the inside construction, particularly demonstrating the adaptability of this unit to either wood or coal. While this advertisement is from 1914, the company made the Cow Boy Tank Heater for many years.

Dayton-Dowd Co., Quincy, Ill., made the Economy tank heaters for a number of years. The Economy of the late 1920s was offered in three sizes (as shown in the specifications). The largest unit sold for $23.

The early settlers used oxen as draft animals; doing so required that the farmer have an ox-yoke. For the benefit of blacksmiths and enterprising farmers, the Feb. 22, 1851, Boston Cultivator ran this engraving and description of a new ox-yoke design. Although a few ox-yokes were “factory-made,” the great majority were the product of localized blacksmith or millwright shops. Ox-yokes sometimes bring $100 or more; excellent examples might bring several times that figure.

Most farmers had a small box on their corn wagon; when they came across an extra nice ear of corn, it was saved to be used for next year’s seed. These ears were carefully dried and many different kinds of drying racks were devised. This one of 1923 is from Bain Bros. Manufacturing Co., Cedar Rapids, Iowa. It would hold from 625 to 700 ears of corn.

Once the seed corn was dried and shelled, it was time to see how well it would germinate. To this end, many companies sold special corn testers. Bain Bros. Manufacturing Co., Cedar Rapids, Iowa, offered this Ideal Corn Tester in the 1920s. Samples were placed in individual cells; with the use of artificial heat from a kerosene lamp, the seed would germinate in a few days.

While coaster wagons may not have been essential to getting the farm work accomplished, they filled an important role for the youngsters. Having one of these 1907 Star Coaster Wagons must have indeed been a thrill in a day when toys were the exception rather than the rule. This line came from Hunt, Helm, Ferris & Co., Harvard, Ill.

One of the necessities on a farm was the grindstone. Treadle units like this one from Whitman & Barnes Manufacturing Co., Akron, Ohio, were sold by the thousands. A small vessel above the stone kept it wet while the farmer sharpened the scythe, ax or other cutlery. Curiously, most old grindstones have a relatively low antique value.

In 1915, Peerless Machine Works at Freeport, Ill., offered its No. 1 Peerless grinder. Instead of the old-fashioned sandstone wheel, this one used a vitrified wheel that was easily replaceable and was much more aggressive than earlier designs. The grinding wheel is shown on one end of the spindle, while the other end could be fitted with a polishing wheel.

Old sickle grinders sometimes have a substantial antique value, occasionally selling for $50 or more. Shown here is the Star Sickle Grinder of 1898; unfortunately, the magazine article does not give the name of the manufacturer, nor have we found it in subsequent research. Numerous companies made sickle grinders; oftentimes, they were made by the firms making the mowers or grain binders.

By the 1880s, enterprising farmers could buy a complete shop outfit from Foos Manufacturing Co., Springfield, Ohio. This 1888 catalog illustration displays the complete outfit for home blacksmithing and horse shoeing. Each of the items shown here is now in the antique tool category.

Did You Know?

Antique corn shellers are a popular farm collectible; small one- and two-hole designs usually bring $50 or more, while larger four- and six-hole versions fall in the $250 to $500 range.

Did You Know?

Old cream separators are highly sought after by a specialized group of collectors, but the separators usually do not fetch high figures on auction (less than $100).

An early advertisement from The New London Vise Works gives the post office box number but fails to give the city and state where the company was located. However, a copy of this unique horse shoer’s foot vise would likely be a highly prized item for tool collectors. Its action is easily seen in the engraving. This interesting vise sold for $15.

By 1920, many farmers had equipped themselves with a post drill. This was usually their first introduction to a machine that permitted them to drill a hole through a piece of iron; without it, the only choices were to journey to a local blacksmith or to heat the iron and punch a hole through the steel. This one is from Champion Blower & Forge Co., Lancaster, Pa.

Did You Know?

Workable grain binders are becoming a scarcity today; thus a grain binder in excellent operating condition may bring $200 to $300 or more.

When this advertisement appeared in 1903, very few farmers or blacksmiths, had a lathe of any kind. Many were overjoyed to have a simple foot-operated lathe like this one from W.F. &John Barnes Co., Rockford, Ill. This 7-inch lathe sold for $40; today, its value as a collectible could be 10 times that figure.

An 1887 advertisement from A.S. Todd, Sterling, Ill., shows its Dandy Barrel Cart, a great labor-saver on the farm. This particular style involved fitting the hardware to a wooden barrel in a permanent manner. Dozens of companies made barrel carts.

One of the major implement manufacturers to include hand carts in its line was Roderick Lean Manufacturing Co., Mansfield, Ohio. Its Butler hand carts could be fitted with a barrel, a box or for whatever purpose might be desired.

By the early 1900s, farmers in many areas were anxious to install lightning rod equipment. Few things were as devastating to a farmer as the loss of a barn, a crib or even the home to fire, and many of these fires were caused by lightning. Usually, the lightning rods were installed by people qualified in this business; the 1903 list of manufacturers included The Martin Co., Sac City, Iowa.

Almost every farm had a lantern or two on hand. These so-called Cold Blast lanterns could be safely used in the barn and could also light up a dark night. Numerous styles were made by several different companies, with three different sizes shown here. Pricing varies; the reader is directed to various antique price guides for further information.

For the farmer of 1900 and before, a macadam road was a rarity and paved roads didn’t exist. Farmers in each township often banded together to look after their own roads. To this end, Pitts Thresher Works at Marseilles, Ill., offered its Pitts Patent Road Worker in 1889. The complete outfit shown here sold for $95.

Feed Cutters

By the turn of the century, the term “feed cutters” generally implied a hand or power-operated device that would cut corn, hay or straw into small pieces for use as livestock feed. By comparison, the term “feed grinders” usually implied a machine for reducing grain to a palatable feed. Many of these machines were forerunners of ensilage cutters and an overlap is obvious when comparing these machines to feed cutters. Generally, though, ensilage cutters were machines designed to cut the forage crop into small pieces and either elevate it or blow it into a silo.

Today, relatively few feed cutters exist. Even so, they seem to have a limited value to vintage machinery collectors. Quite often they can be secured for a relatively low price of less than $50. As with all vintage equipment, the condition and the rarity of the particular item have a dramatic effect on the value.

Appleton Manufacturing Co., Appleton, Wisc.

This 1888 advertisement shows Peck’s Improved Shelling, Cleaning and Threshing Attachment on an Appleton Fodder Cutter. All this is somehow tied together as Goddard’s Process with a patent date of Dec. 18, 1883. Little is known of this unusual machine; although the side of the machine plainly states the address at Appleton, Wis., the accompanying article notes that the company is at Chicago. Is this the same Appleton Manufacturing Co., as at Batavia, Ill.? Our research has not indicated the answer.

Appleton Manufacturing Co., Batavia, Ill.

A 1917 catalog from Appleton Manufacturing Co., illustrates various of its fodder cutters, although the term might also be feed cutters. This one is shown with a hand-crank and one can only imagine the work it was to keep this machine in operation. Presumably, it could also be fitted with a belt pulley.

Challenge Co., Batavia, Ill.

Several different styles of fodder cutters are shown in the 1910 catalog of Challenge Co., Batavia, Ill. This small machine is a hand-cranked style, and the company has added substantial cast-iron guards over the open gears. As with most of these machines, the framework is entirely of hardwood.

A.B. Farquhar Co., Limited, York, Pa.

Another approach to the feed cutter was the hand-lever style. With this device, the feed was advanced on the table and the curved knife was brought down. The inherent dangers of this machine are hard to describe. In those days, however, owners of machinery were presumed to know better than to get fingers or other body parts in the way.

G.S. Garth, Mill Hall, Pa.

In 1887, Garth’s Jumbo and Try Me feed cutters were available to the farmer. They were built along the same pattern, with the Jumbo being substantially heavier and larger. Aside from this early illustration, nothing further is known of the firm.

W.R. Harrison & Co., Canton, Ohio

When this 1888 advertisement appeared, W.R. Harrison & Co., was located in Canton, Ohio. Shown here is its Tornado Feed Cutter No. 18. This unit was large for its time and was strictly a belt-powered machine. Although the elevator was probably optional, it would have been nearly imperative for a machine of this size.

At some point, now unknown, W.R. Harrison & Co., moved from Canton to Massillon, Ohio. A 1919 advertisement shows its Tornado Feed Cutter; it varied little from the one built at Canton back in 1888. While this one is shown with a hand-crank, it seems likely that a belt pulley was another option.

Hartman Co., Chicago, Ill.

Hartman Co., was a large catalog mail-order house that thrived into the 1930s. During the 1920s, the company offered its Majestic feed cutter, noting that it was made with a heavy hardwood frame. Hartman likely contracted with another manufacturer for this machine—the actual builder is now unknown.

Hocking Valley Manufacturing Co., Lancaster, Ohio

Hocking Valley was a leader in manufacturing various kinds of feed mills, corn shellers and other farm equipment. Its designs were always very substantial, as is evident on this 1890 version of the Improved Giant Feed Mill. Due to the size of the machine, it was furnished with a belt pulley; in the absence of a motive power, the hand-crank is obvious on the large flywheel.

Long, Black & Alstatter, Hamilton, Ohio

With a patent date of Nov. 2, 1858, this small feed cutter ranks among the earliest designs. This unique cutter used a v-shaped trough to feed material under the knife. Presumably, it could have been operated by one person, although one to feed and one to cut would have been a more likely scenario.

From the turn of the century comes an advertisement for the Hamilton Hay, Straw and Fodder Cutter from Long, Black & Al-statter. This one was equipped with a belt pulley, and, in case power was available, the hand-crank was easily removed. With the coming of small gasoline engines, mainly after 1910, farmers quickly added one of these to their farm power arsenal.

Did You Know?

The Appleton No. 19 Cyclone Corn and Cob Breaker sold for $25 in 1917.

Geo. K. Oyler Manufacturing Co., St. Louis, Mo.

When this 1884 advertisement appeared, Geo. K. Oyler’s company was building a wide range of farm equipment. Its Feed &Straw Cutter shown here was of heavy all-wood construction. Little is known of this firm after the 1880s.

Plymouth Foundry & Machine Co., Plymouth, Wisc.

About 1910, Plymouth was offering its Emperor Cylinder Feed Cutter (this one has an unusual power-jack attachment). By its use, the cutter could be coupled through tumbling rods to a horsepower. For farmers without a gas engine or other power, this left the horse do the work while the farmer fed roughage into the cutter.

Did You Know?

Since so few threshing machines remain, especially the early wooden designs, they have now acquired collector status. Late model, all-steel machines of the 1920s and later, often bring $500 or more in good condition and some of the earliest wooden designs have acquired museum status.

Silver Manufacturing Co., Salem, Ohio

An 1888 advertisement notes the name of Silver & Deming on this No. 24 Ohio Special Ensilage Cutter. An 1892 advertisement notes Silver Manufacturing Co., and also refers to the Ohio Special as a feed cutter. The size of this machine precluded it from hand operation; a belt pulley is obvious on the far side of the main shaft.

Smalley Manufacturing Co., Manitowoc, Wisc.

From 1888 comes this advertisement for a big Smalley feed cutter. As shown here, farmers are taking baled hay or straw and converting it to fodder through the cutter; the latter is being operated by a portable steam engine. Smalley also built numerous other farm machines.

By 1915, Smalley was offering this No. 10 Force Feed Cutter and Blower. This small outfit was capable of blowing the cut material to a barn or a small silo. While not intended to compete with the big silo fillers on the market, this small machine found its niche with the small farmer.

Stover Manufacturing Co., Freeport, Ill.

Long before Stover became famous for its gasoline engines, the company was building windmills, feed grinders and many other farm implements. From 1887 comes this illustration of a Stover Ideal Feed Mill. The protective cover is removed from the cutter, demonstrating an early version of the flywheel cutter design.

U.S. Wind Engine & Pump Co., Batavia, Ill.

This firm, well known among farmers for its windmills and its other equipment, met with a good reception on the farm. In 1887, the company offered this IXL Feed Cutter, a large machine designed for power use. This one was extraordinary for its time because it included a power-feed mechanism and other advanced features.

Did You Know?

Antique corn shellers are a popular farm collectible; small one- and two-hole designs usually bring $50 or more, while larger four- and six-hole versions fall in the $250 to $500 range.

Whitman Agricultural Co., St. Louis, Mo.

For 1887, Whitman offered this heavy feed cutter to the farmer. It included a power-feed mechanism and the length of cut could be varied by substituting various change gears (as shown beneath the machine). Whitman was a well-known and respected manufacturer for many years.

Trade Names

Feed Grinders

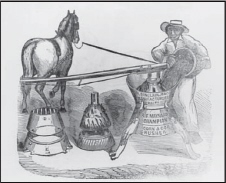

By the 1860s, farmers were aware of the benefits derived from grinding the grain fed to their livestock. It was more palatable and nutritious. But even better, livestock gained better with ground feed. Unfortunately, there were few farmers of the time who had a source of power to operate a grinder, except for those lucky enough to have a horsepower and willing horses.

Progress moved forward; by the 1880s, several companies made feed grinders with a built-in sweep so that one or two horses could walk in a circle around the mill, all the while grinding the feed. By the 1890s, steam power was available to a few. Not until 1900 did the gasoline engine begin to make itself known to the average farmer. Combining all the factors, feed grinders gained great popularity by 1900. Within a few years, almost every farm had one.

Within this section are included feed grinders or burr grinders, along with the hammer mill. The latter did not gain popularity until the 1920s and subsequent. Many farmers opted for the hammermill in the 1930s—by then, tractor power was abundantly available. Eventually, the burr mill lost in the popularity contest, with the hammermill becoming the most widely used method of grinding feed. In this section, only a few examples are shown of what were literally thousands of different models from several hundred manufacturers. Also of note, a separate section entitled Grinding Mills is included. It includes primarily the stone buhr mill or flour mill. The latter was used primarily for grinding flour and other edibles, while the feed grinder, with its iron burrs, was limited mainly to use for livestock feed.

Old feed grinders have appreciated in value considerably over the years. Sometimes, a rare model, or one that is especially popular, will bring well more than $100, while one that is quite common might sell for $25 or less.

American Well Works, Aurora, Ill.

An 1887 catalog from American Well Works illustrates its IXL Iron Feed Grinder. It had been in use since the early 1870s and was made entirely of iron, except for the hopper. The IXL on the left is set up for use with a horsepower, while the one on the right could be belted to a steam engine, gas engine, windmill, or water wheel.

Appleton Manufacturing Co., Batavia, Ill.

Appleton began building feed grinders in the 1880s, with its Appleton, Hero and American feed grinders gaining wide popularity. Shown here is its No. 22 Appleton General Purpose mill, a belt-powered model that was suitable for the average farm.

Appleton’s No. 1 Special Grinder of 1917 was a small mill with a capacity of five to 12 bushels per hour. This one, like most burr grinders, used safety shear pins so that if a foreign object made its way between the burrs, the pin would break and prevent serious damage to the grinder. This one could be successfully operated with a gas engine of only 1 or 2 horsepower.

The Appleton No. 19 Cyclone Corn and Cob Breaker is shown here. It really wasn’t a grinder but was designed specifically for breaking or crushing ear corn into small pieces. With a 6-horsepower engine, this machine could crush up to 15 bushels of corn per hour. In 1917, it sold for $25.

Associated Manufacturers, Waterloo, Iowa

Associated was a well-known engine manufacturer. It augmented its extensive engine line with various machines, including a series of grinders.Shown here is its 1917 version of the Amanco Feed Grinder. The smaller No. 8 machine used 8-inch burrs; without a sacking elevator, it sold for $23. The larger No. 10 shown here, is equipped with a sacking elevator. This 10-inch grinder retailed at $45.

In addition to larger models, Associated also offered small mills. Its No. 18 (left) was a plain mill having 8-inch burrs and capable of 10 to 30 bushels per hour, depending on the fineness of the feed and the availablepower. To the right is the little No. 16 mill, a small bench-mounted grinder with 5-1/2 inch burrs. It weighed but 70 pounds.

F.C. Austin Co., Chicago, Ill.

While this company would later become a well-known manufacturer of construction machinery, an 1889 advertisement illustrates its Austin Clipper Pulley Mill No. 1. Small mills like this abounded and a surprising number still exist, some of them coming from small manufacturers that are rarely known outside of their local area. Austin offered several sizes and styles of mills, with the largest being capable of 75 bushels per hour.

Bauer Bros. Co., Springfield, Ohio

At some point, now uncertain, Bauer Bros. took over the Feed Grinder Business Co., also of Springfield. This Scientific No. 1 Mill was extremely heavy, utilizing almost all cast iron except for the hopper and the sills. Although small and slow by contemporary standards, mills like this one were very popular in the 1900-1940 period.

C.S. Bell Co., Hillsboro, Ohio

By the 1920s, several companies were offering mills designed especially for use with small tractors. Numerous feed grinders and other machines were “Designed Especially for the Fordson.” Such was the case with the Bell No. 80 grinder. Bell called it “A Real Grain Grinder for Tractors.”

Blue Valley Manufacturing Co., Manhattan, Kan.

Numerous companies were manufacturing feed mills in the 1890s, among them being the Blue Valley firm, as pictured in this 1898 advertisement. All that was needed was the mill; the horses were already on the farm and they provided the power. Nothing is known of this company.

N.P. Bowsher Co., South Bend, Ind.

This 1893 model of the Globe Feed Mill is listed in various implement directories as still being available from Bowsher as late as 1948. Like other sweep mills, it was very simple in design. Bowsher also gained a high reputation for various other feed grinders offered during the years.

Bowsher’s Combination Feed Mill of 1913 was a very popular model, with this one even including a sacking elevator. In addition to handling small grains, this model could also grind ear corn successfully. At the time, this was a major selling point since cattlemen, especially, saw the benefits of feeding ground ear corn to their livestock.

Carley Bros., Colfax, Wash.

In some areas of the country, barley was grown, at least occasionally, while for other areas it was an important annual crop. This roller machine, while technically not a feed grinder, was difficult to classify in any other section of the book; of interest is the legend on the sacking elevator denoting Carley’s Roller Feed Mill. The concept of a roller mill as compared to the ordinary burr mill was dramatic indeed and gained rather poor acceptance for some years.

Cascaden Manufacturing Co., Waterloo, Iowa

In 1903, numerous advertisements appeared concerning Cas-caden’s Giant Killer Geared Grinder. Within a year or so, the identical mill is advertised by Davis Gasoline Engine Works Co., also of Waterloo, and also owned by Cascaden. Tangling things even further, see the Corn King Feed Mill Co. entry for a mill that is virtually identical. It likewise was made at Waterloo, Iowa.

Challenge Wind Mill & Feed Mill Co., Batavia, Ill.

By 1899, Challenge was offering this example of a sweep mill. Patented in 1897, this was one of the first such mills in the Challenge line, but it remained for decades to come. Challenge was a well-known manufacturer of windmills, gasoline engines and other items.

A 1910 catalog illustrates the Challenge Belt Power Grinder. This small feed mill was made in three different sizes, all of the same pattern and differing mainly in physical size. Like most burr mills, this series was furnished with one set of coarse burrs and a set of fine burrs. Other styles were available for special purposes.

Shown here is the 1910 version of the Challenge No. 5 Grinder, complete with a sacking elevator. At the time, sacking was a preferred method of storage for many farmers, either because of personal preference or because that was the only method available on a given farm.

Initially, many burr mills were incapable of grinding ear corn; by 1910, the problem had been solved with the introduction of special crushing attachments built as a part of the mill. This No. 27 Challenge mill was furnished with 10-inch burrs.

Chicago Tubular Well Works, Chicago, Ill.

An 1887 advertisement illustrates the Clipper Feed Mill from Chicago Tubular Well Works. The interesting company title resulted from its development of a well-drilling machine that used round steel casing to line the shaft. Very little is known of the company.

C.D. Colton & Co., Galesburg, Ill.

From 1906 comes this advertisement of the Corn Belt No. 5 Power Mill. Colton claimed this one would grind the corn and the cob, and this was indeed an important point for farmers wishing to feed ground ear corn. The extra set of burrs furnished with the grinder are shown on the sill in the foreground.

Common Sense Engine Co., Springfield, Ohio

In 1890, Common Sense Engine Co., offered its combination of a steam engine and the Common Sense grinder. In reality, the engine was probably belted to overhead line-shafting so that it could operate several different machines including the feed grinder.

Did You Know?

A nicely restored sleigh can bring more than $1,000.

Corn King Feed Mill Co., Waterloo, Iowa

Corn King mills were advertised in 1903 and were virtually identical to the Giant Killer mills from Cascaden Manufacturing Co., which is listed in this section. In the 1920s, repair parts for both were available from Swift Manufacturing Co., also at Waterloo. This Corn King advertisement notes that the company had sold more than 2,000 mills the previous season.

Dain Manufacturing Co., Ottumwa, Iowa

By 1900, Dain Manufacturing Co. was offering this Dain Double Geared Mill, a very popular design that remained on the market for some years. After Dain came into the fold of Deere & Co., the latter continued to build this mill. Very few sweep mills like this still remain, so they are now a scarce collector’s item.

J.A. Field & Co., St. Louis, Mo.

Field’s Favorite Corn Mill and Power Combine was the title of this attractive horse-powered outfit. Note also the unique system of using a tumbling rod to operate a small corn sheller. Nothing further is known of the company, save for this 1884 advertisement.

Foos Manufacturing Co., Springfield, Ohio

Foos began building its Scientific line of farm equipment at least by the mid-1880s. Its Scientific mill of 1888, as shown here, was virtually unchanged when an advertisement of 1900 appeared. Since the mill was built almost entirely of cast iron, there was little to wear out. Because of this, many of these mills were used for decades with almost nothing spent for repairs.

Hartman Co., Chicago, Ill.

Hartman Co. was a major mail-order house for the farmer of the 1920s. Its line of Majestic equipment included several different feed grinders. Among them was this small Majestic Power Mill, a little bench-top model intended for small farm or household needs.

Harvey Manufacturing Co., Racine, Wisc.

By the 1940s, the hammer mill had become an important equipment item for the livestock farmer. Newer and larger tractors were capable of the power needed for efficient operation. Numerous companies manufactured hammer mills, among them being the Harvey Red Hed line. This company also made Red Hed corn shellers.

Hocking Valley Manufacturing Co., Lancaster, Ohio

This interesting feed mill design was available from Hocking Valley in 1890. The special gearing is for direct attachment to the tumbling rod from a horsepower. Thus a farmer could hitch up a team to the power and grind feed with this Style B mill.

International Harvester Co., Chicago, Ill.

International Harvester Co. offered a wide variety of feed grinders to the farmer. One of its most popular mills up to the 1930s was this Type C grinder. These were sold by the thousands, along with several other IHC models. The Type C was very simple, being made entirely of steel and cast iron components.

Iowa Grinder & Steamer Works, Waterloo, Iowa

From an 1898 advertisement comes this notice of the Four Burr Mill from Iowa Grinder & Steamer Works. With its two sets of burrs, this mill was claimed to have twice the capacity of its competitors. The company also made the Bovee Western Steamer, a device for cooking livestock feed.

Kelly & Taneyhill, Waterloo, Iowa

The Farmer’s Friend Feed Grinder was a sweep grinder of somewhat the same design as its contemporaries. The company was one of several operating at Waterloo in 1898, all of them manufacturing feed grinders. Virtually nothing is known of the company’s activities outside of this single illustration.

Lamb & Company, Freeport, Ill.

The business connection between Lamb & Co. and the Stover Mfg. Co., both of Freeport, Illinois, is unknown. At times, the two appear to be associated. In other instances, they appeared to compete. In the early 1890s, Lamb & Co. offered an extensive line of grinding mills. These included the buhr stone mills for edible flour and meal, along with the steel-plate burr mills used for grinding livestock feed.

Letz Manufacturing Co., Crown Point, Ind.

In 1917, Letz promoted its Letz Dixie feed mills. The No. 77 used 8-inch burrs; the No. 88 had 10-inch burrs; and the big No. 22 had 12-inch burrs. The latter size required up to 30 horsepower for efficient operation. Letz claimed that this mill could “grind anything that’s grindable.”

Letz burr mills of 1920 were an immediate success, being very popular with farmers. The design was simple, yet the mill was sturdy enough to stand up to heavy, daily usage. Steel and cast-iron components were used throughout.

By 1930, the Letz stationary burr mills had taken on the same general form they would follow throughout the remaining decades of production. Built in 8- or 10-inch sizes, the No. 80 was immensely popular, especially for grinding ear corn. A small tractor was sufficient to operate this mill.

Marseilles Manufacturing Co., Marseilles, Ill.

An 1895 advertisement illustrates a rather unique feed grinder design from Marseilles Manufacturing Co. This Universal Feed Grinder was said to be capable of handling everything from ear corn to small grain. This one is furnished with the necessary gearing to operate from an overhead line-shaft.

Martin Manufacturing Co., Anoka, Minn.

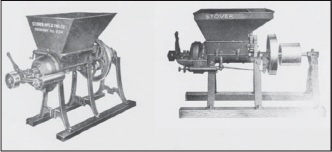

The Martin grinders were small-sized units, with the two models shown here being of the bench-mounted type. The Junior B on the left used 4-1/2 inch grinding plates and only needed a 1 horsepower engine, while the No. 4 on the right used 5-1/4 inch plates and required about 2 horsepower.

New Holland Manufacturing Co., New Holland, Pa.

Feed grinders were often adorned with fancy striping and ornamentation; the New Holland was probably the epitome of this practice. Beyond its fancy appearance, the New Holland mills were very popular, even though they continued using a wooden frame long after most companies had opted for steel and cast iron.

Nordyke & Marmon Co., Indianapolis, Ind.

While Nordyke & Marmon is perhaps better known for its stone buhr mills, the company produced a number of small feed grinders; this Diamond King Double Grinder is from an 1889 advertisement. Little else is known of this unique design, except that it weighed some 400 pounds.

An 1889 advertisement of Nordyke & Marmon illustrates its No. 8 Feed Grinder, a heavy machine capable of grinding 60 bushels per hour. This large grinder was probably better suited to a commercial elevator than to a farm of the time, since very few had any method of powering the machine.

Geo. K. Oyler Manufacturing Co., St. Louis, Mo.

During the 1880s, the sweep mill became very popular, with this Excelsior Mill from Geo. K. Oyler being an example. By the time this 1884 advertisement appeared, Oyler was offering feed mills, corn shellers, fanning mills and many other farm equipment from its St. Louis factory.

Papec Machine Co., Shortsville, N.Y.

Papec was a well-known manufacturer of feed grinders, ensilage cutters and other farm machinery. In 1930, the company offered this farm-type feed mixer. With the coming of feed concentrates and the need for feed additives, thorough mixing of the ground feed was virtually impossible, outside of a commercial establishment. The Papec unit sought to remedy this shortfall, but it would be another 20 years or more before the mobile grinder-mixer came to the farm.

Red Chief Manufacturing Co., Louisville, Kty.

In 1919, Red Chief offered this small hand mill, noting that it would meet the farmer’s needs for grinding his own corn meal, graham flour, grits and other necessities. Red Chief also built several other sizes of hand- and power-operated mills.

Root-Heath Manufacturing Co., Plymouth, Ohio

Root-Heath offered its small Korn King Grist Mills in several sizes for hand or power use. As noted in this 1915 engraving, the pulley could be easily added or detached with four small bolts. The company also made several styles of small corn shellers.

Racine-Sattley Co., Springfield, Ill.

For 1903, Sattley offered its Royal sweep mills; this one had an impressive and ornate iron base. In this engraving, the horses are shown with the mill in operation. Occasionally, one can see a mill like this at a thresher’s show or vintage machinery exhibition.

J.B. Sedberry Inc., Utica, N.Y.

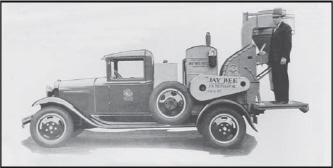

When the Jay Bee portable feed grinder appeared in the early 1930s, it created a sensation. Equipped with a large engine, the Jay Bee hammermill quickly converted grain to wholesome feed. A substantial number of custom operators thrived for some years, traveling from farm to farm, some having a regular “route” each week.

R. Sinclair Jr. & Co., Baltimore, Md.

An 1866 advertisement illustrates the Young American Corn and Cob Mill, also known as the R.F. Maynard Champion Mill. To the left is shown an extra set of burrs for this mill. If one is any judge at all of cast iron, the burrs must have been extremely heavy. Nothing at all is known of this firm, outside of the engraving shown here.

Springfield Engine & Thresher Co., Springfield, Ohio

An 1888 advertisement of the Kelly Duplex mill illustrates it in use. A caption with the engraving reads, “Kelly Duplex No. 2 Feed Mill in operation on the model farm of W.K. Thompson, near Springfield, Ohio.” The mill is being operated by a Springfield engine.

From 1888 comes this illustration of the Kelly Duplex mill being driven by a stationary sawmill engine. This company later was renamed as O.S. Kelly Manufacturing Co., even moving for a time to Iowa City, Iowa, and operating as O.S. Kelly Western Manufacturing Co.

Springfield Engine & Thresher Co. was an early promoter of steam power for the farm, whether as a stationary engine pictured here or with its newly developed traction engine. The artist’s conception illustrates the general form of a stationary setup, together with overhead line-shafting. Very few farms were thus equipped; it was an expensive proposition to set up a complete operation like this.

Star Manufacturing Co., New Lexington, Ohio

Star Manufacturing Co., advertised heavily in the American Thresherman, Gas Review and other titles that would be read by people interested in gas and steam power. For a time, the company even built its own gas engines to power its feed grinders. However, by the 1920s, parts only were available from Perry Manufacturing Co., at New Lexington. Eventually, the Star line faded from the scene.

Staver & Abbott Manufacturing Co., Chicago, Ill.

An 1894 advertisement illustrates the Buckeye Feed Mill, as built by Staver & Abbott. This one differed somewhat in its design, as can be seen by a comparison with others in this section. It also appears that the sweep power could be fitted with a tumbling rod and applied to other uses when not needed for grinding.

Stover Manufacturing Co., Freeport, Ill.

As early as 1887, perhaps before, the Stover Ideal Mill was available from Stover Manufacturing. The company advertised extensively in farm magazines such as the American Agriculturist. The latter was also published in a German-language edition; this 1895 illustration is from one of these magazines. Stover also built the Ideal Double Geared Sweep Mill for ear corn and shelled grain.

By 1889, Stover was offering its Ideal Duplex Grinding Mill in sizes ranging from 10 to 150 bushels per hour, requiring anywhere from 2 to 40 horsepower for efficient operation. Stover was already a famous name in the windmill business; within a few years, it would attain permanent fame as a gasoline engine manufacturer.

In addition to its Ideal grinding mills, Stover also offered a series of small, hand- or belt-powered grinders for bench or table mounting. These small mills were available until the company finally ceased business in 1942. Only the largest model to the far right of the illustration could be fitted for belt power the other three were hand-powered.

Numerous models of Stover feed grinders were built up to 1942. However, one of the most popular was the 40-series, including the No. 42 shown here. It could handle ear corn, small grain or almost anything grindable. Like the Stover engines, these mills were very popular with farmers.

In the 1930s, Stover began offering a series of hammermills to take advantage of the available tractor power. The hammermill was becoming very popular by this time, and Stover was a leader in its design. Production of all Stover equipment ended when the factory closed in 1942.

Western Land Roller Co., Hastings, Neb.

In the 1930s, the Western Bear-Cat hammermill became very popular. This heavy-duty mill used a frame of cast iron, the terminus of the feeder table was a cutter head for cutting up ear corn, grinding fodder and the like. A small hopper was furnished for adding small grain directly into the hammer chamber. These mills were very popular and enjoyed a long production run.

Winona Manufacturing Co., Winona, Minn.

From the German-language edition of the American Agriculturist comes this 1895 illustration of the Diamond Mill from Winona Manufacturing Co. The open gears are of massive size. The entire machine, except for the hopper, is made of cast iron. Virtually nothing is known of this company outside of the illustration shown here.

Trade Names

Did You Know?

Since so few threshing machines remain, especially the early wooden designs, they have now acquired collector status. Late model, all-steel machines of the 1920s and later, often bring $500 or more in good condition and some of the earliest wooden designs have acquired museum status.

Fence-Making Machinery

Up to about 1915, several companies offered fence-making machinery for use on the farm. Most of this equipment was intended for use right in the fence row; once the fence was completed, the equipment could be used on another fence in a different location.

During the years, though, various steel companies developed galvanized steel wire; a few, such as the Page Woven Wire Fence Co., Adrian, Mich., specialized in making woven wire. To this day, some farmers still speak of woven wire as “Page wire.” The manufactured product was superior to the home-made styles, so the demand for on-the-farm fence making equipment vanished. Today, these machines are a rarity, but so few of them appear that there is no established market.

In 1887, M.C. Henley, Richmond, Ind., offered Henley’s Monarch Fence Machine, a device obviously intended to manufacture picket fences. Outside of this illustration, nothing at all is known of the company or its activities.

Perhaps by coincidence, the Richmond Check Rower Co., Richmond, Ind., offered its Little Giant Fence Loom in 1887, possibly in competition with the Henley machine, also made at Richmond. This one was patented in 1884, so it had been on the market for only a short time prior to this illustration. Presumably the company also made check-row corn planters, but nothing has been found regarding this endeavor.

Did You Know?

Vintage corn graders in nice shape are valued at $100 or more.

The Norwalk Lock Stay Fence Co., Norwalk, Ohio, offered this interesting fence-making machine in 1897. It claimed it would make anywhere from 50 to 65 rods of fence per day at a cost of only 16 to 24 cents per rod. It could use smooth or barbed wire; turning the crank twisted the stay cables from top to bottom, along with crimping the main wires. The latter was necessary to accommodate expansion and contraction of the fence with changing temperatures.

From an unknown source comes this 1914 illustration of the Empire Fence Building Machine. This engine-powered outfit was capable of building 200 different styles of fence and as shown is using barbed wire for the top and bottom. Unfortunately, we have found no address for this company, nor do we have any further information regarding the Empire fence machinery.

By 1900, thousands of miles of barbed wire were already in place. Recognizing the difficulty of rolling and unrolling barbed wire, the Cosey Barb Wire Reel Co. was organized at Sterling, Ill., to mechanize the job. Shown here mounted to the back of a wagon, the Cosey Reel was an automatic outfit. This illustration goes back to 1905.

Various methods were developed for stretching barbed wire and woven wire, with the Matthews Woven Wire Fence Stretcher shown here. A wooden clamp was attached to the wire and, in this instance, a heavy screw did the job of stretching. This outfit was made by Bain Bros., Manufacturing Co., Cedar Rapids, Iowa, in the 1920s.

Already in 1887, a “comealong” was devised for stretching smooth or barbed-wire fencing. This one was made by Cortez V. Pugh at Bowling Green, Mo. Over the years, farmers used various methods, although a small tackle block with specially designed wire grips was probably the most common device.

Various devices were made to dig post holes; this one from 1914 ranks among the most unusual of the era. Built by Ohio Cultivator Co., Bellevue, Ohio, the Cyclone auger used an anchor chain to automatically space the hole from the previous one. After the anchor chain was set, a 50-foot rope was wound at the top, the other end hitched to the horse, with the hole being dug in less than a minute. It should have been an interesting sight if the horse became frightened by the neighbor’s dog!

Looking somewhat like today’s so-called “screw anchors” this device was actually Lee’s Patent Post Hole Auger; it was patented in 1883. Shown here in an 1884 advertisement, this device was made by Branch, Crookes & Co., St. Louis.

Among the tools in the farmer’s arsenal were a variety of fence-making devices, most of them having to do with ways to dig a post hole. Some farmers preferred the Iawn auger in the center of this illustration, while other preferred the post hole diggers shown to the right. Late in the 1930s, a few companies began making some heavy and cumbersome augers for mounting on a tractor; until the 1950s, however, most post holes were dug with equipment similar to that shown here and available from numerous manufacturers.

Trade Names

Fertilizer Spreaders

This section only includes devices for spreading commercial fertilizers. Sometimes, in polite company, a manure spreader was referred to as a fertilizer distributor, but most commonly it was called what it was—a manure spreader. Thus there is a separate section for manure spreaders, as distinguished from the fertilizer spreader machines.

By the 1890s, commercial fertilizers were available on a limited basis, being primarily used by truck gardens and certain other crops. The average farmer of the 1890s did not use commercial fertilizer. Shown here is the 1892 version of the McSherry Dandy Fertilizer Distributor made by McSherry Manufacturing Co., Dayton, Ohio.

Truck gardeners, cotton and tobacco growers could purchase this model of the Spangler Fertilizer Distributor in 1892. The company also made other products at the time, including grain drills, corn planters, corn shellers, feed cutters and other items. Span-gler Manufacturing Co. was located in York, Pa.

In the 1920s, the Nonpareil Lime & Fertilizer Sower, as shown, made its appearance. Nonpareil Manufacturing Co., Cochranton, Pa., was the manufacturer. By this time, many farmers were anxious to add lime to their fields as a means of controlling soil acidity. This popular line was taken over by Ohio Cultivator Co., Bellevue, Ohio, in 1927. Nonpareil spreaders were available in various forms at least into the 1940s.

A random photograph of the 1930s illustrates one of numerous special machines designed for truck gardeners. This special fertilizer distributor was designed especially for vegetables and featured variable row spacings and application rates. Unfortunately, this photograph gives no indication of the manufacturer.

By the 1930s, Portable Elevator Manufacturing Co., Bloomington, Ill., began marketing its Little Giant Lime Stone and Fertilizer Spreader. This little device attached to the rear of a wagon, with the farmer keeping the hopper filled as he went through the fields. This small spreader was very popular.

Late in the 1930s came Flink’s Self-Feeding Spreader, made by The Flink Co., Streator, Ill. This was a truck-mounted unit that practically eliminated the hand work involved with previous devices. Eventually, lime and fertilizer spreading would become a mechanized process using specially designed trucks and equipment.

Trade Names

Did You Know?

Challenge’s 1910 model of its Dandy one-hole sheller had a base price of $8.