B

Balers

Up to the 1940s, balers were generally called “hay presses.” Apparently, the change in terminology came about together with the advent of the automatic pick-up balers. These were completely mobile machines intended for direct baling in the field. By comparison, hay presses were generally a portable unit that could be moved from farm to farm, with the hay or straw being brought to the hay press vis-à-vis the baler. Since the majority of the machines included in this book are portable hay presses and to avoid redundancy, balers are also included in this section.

Barn Equipment

A great many items could rightfully be placed within this category, although this book separates various categories, such as Dairy Equipment, Haying Equipment and the like. Until about 1900, the average barn was about the same as it had been for hundreds of years, containing ample room for hay storage, stalls for livestock, harness, milk stools and little else. With the coming of farm mechanization came the introduction of great labor-saving devices such as litter carriers, carts and other devices intended to lessen work for the farmer.

Lightning rod equipment had become quite popular by 1900, particularly in those areas in which thunderstorms were frequent and oftentimes severe. Curiously, many early manufacturers advertised their wares in the farm equipment journals of the day. One of these was the Des Moines, Iowa, firm of Dodd & Struthers. Its 1905 advertisement illustrates a static generator that it furnished to all of its retailers. It was intended to demonstrate the proclivities of lightning and also how it could be tamed with the use of lightning rods.

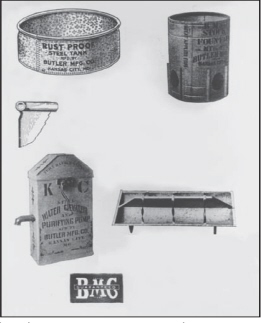

Butler Mfg., Co., Kansas City, was one of many companies offering an extensive line of galvanized tanks and other equipment. A 1907 advertisement demonstrates stock fountains, galvanized hog troughs and its Improved K.C. Water Elevator. The latter has acquired collectible status, with good examples fetching more than $100 by antique dealers.

Firms like J.E. Porter Co., Ottawa, Ill., specialized in barn and farmstead equipment. This 1907 offering for the Porter Litter Carrier was one example. The carrier was mounted on an iron track and featured a raising and lowering device to make work easier for the farmer.

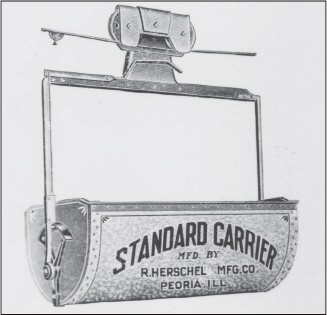

Litter carriers became quite popular with the advent of large barns, particularly the dairy barn. The majority of Midwestern farms of 1900 had at least a small herd of milk cows. R. Herschel Manufacturing Co., Peoria, Ill., offered its Standard Carrier in 1909. It used a solid wire cable from which the carrier was suspended.

C.A. Libbey Co., Oshkosh, Wis., offered its version of the ideal litter carrier in the 1920s. It featured a simple chain-operated device for raising and lowering the carrier. Track systems were available for almost any situation and included accessories, such as right angle curves, switches and other configurations to permit travel to all portions of a barn.

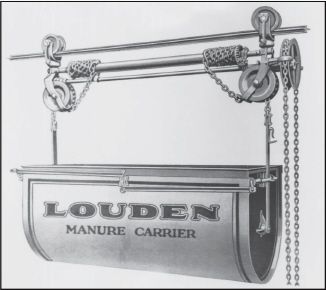

Louden Machinery Co., Fairfield, Iowa, offered a huge line of barn and dairy equipment, including cattle stalls, stanchions, hay carriers and several different styles of litter carriers. The model shown here from a catalog of the 1920s was typical of the line. Most carriers were designed with a track system extending outdoors for dumping the loaded unit, either onto a dung heap or into a waiting manure spreader. Either way, the savings in labor was well worth the investment.

Bean Harvesters

By the 1890s, several companies were offering bean harvesters as a means of mechanizing what was otherwise a back-breaking job. The plants were cut just under the soil and the vines were gently windrowed. Usually, the cut beans were then cocked by forking them into small stacks for drying. After a suitable time, they were threshed. In most instances, the early offerings were intended for use with edible beans, since soybeans had not yet become an important crop. Very few bean harvesters are still in existence, so those still left should rank some value in the farm antiques market, but we have found no indication of their value.

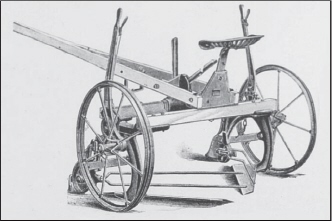

Gale Manufacturing Co., Albion, Mich., offered its Albion Bean Harvester in 1894. It was designed to straddle two rows, cutting them and leaving them in windrows to be loaded onto a wagon. As previously noted, some farmers preferred cocking the beans first for better drying, while others hauled them directly to a waiting bean thresher.

Caledonia Bean Harvester Works, Caledonia, N.Y., announced its New Caledonian Bean Harvester to the 1889 implement trade, noting that it was the result of “Twenty-three Year’s Experience.” That would put the beginnings of this machine back to 1866. Edible bean production was centered primarily in the Eastern states, gaining little prominence in the Western and Midwestern areas.

Miller’s Bean Harvester, as advertised in 1898, was the product of F.W. Miller Manufacturing Co., LeRoy, N.Y. Advertising of the day noted it to be the “oldest and best and beyond competition.” The company also made numerous other implements, including plows, cultivators and land rollers.

Wiard Plow Co., Batavia, N.Y., offered its Universal Bean Harvester as late as 1916. It could be purchased with an all-steel frame or a wooden frame, as desired, and could also be supplied with cast-iron or steel wheels, again at the whim of the purchaser. Eventually, the combine took over the job of harvesting edible beans, as well as soybeans, and the bean harvester became obsolete.

Trade Names

Bee Hives & Supplies

Although bee-keeping is ordinarily considered to be a very specialized industry, farmers often kept a few hives of bees to help pollinate their crops, as well as providing an in-expensive source of delicious honey. Rather than depend on the chances of finding a “honey tree,” commercially made bee hives were a method of harvesting a valuable product. In addition to hives, a few companies manufactured the other necessities, such as supers, smokers, honey extractors and other supplies.

Kretchmer Manufacturing Co., Council Bluffs, Iowa, was established in 1864. This firm pioneered many different farm-related items, including its Iowa seed-corn sorters. However, a 1910 advertisement indicates that the company was ready to supply virtually any need for bee culture.

Trade Names

Bob Sleds & Sleighs

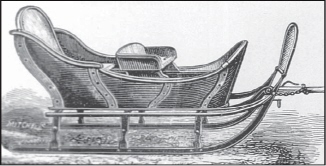

By definition, a bob sled or bob sleigh consists of two sets of runners, one behind the other. These are connected with a reach, built in such a way that the two sections can oscillate independently of each other. Sleighs, on the other hand, are simply a pair of runners mounted to a solid frame. Generally, sleighs were used for transporting people and bob sleds were used for transporting goods of every sort.

Sleighs are highly valued today, especially those built along fancy lines, with upholstered seats and other niceties. It is not uncommon for a nicely restored sleigh to bring more than $1,000, but, as with many antique items, the value depends somewhat on the region. Items commonly used in an area are more plentiful, thus keeping the price somewhat lower. Bob sleds or bob sleighs in good condition commonly bring $500 or more. Establishing a general price figure is difficult, since these are seldom seen on the antique market.

From my collection comes an 1877 circular for James Goold & Co., Albany, N.Y. Established in 1813, this company illustrated its 1816 model on the front of its brochure. The 1816 model looks little different than those built some 60 years later! A sleigh of this vintage would certainly be a valuable piece today, since only a handful of sleighs of its age still exists.

This Portland Cutter from the 1877 catalog of James Goold & Co., illustrates the state-of-the-art in sleighs. Sleighs were generally of the same basic design, with subtle cosmetic changes that could dramatically alter the appearance of the finished product. Relatively few Midwestern farmers of the 1870s were wealthy enough to own a cutter such as this. Most of those who could afford one didn’t buy one. It was either a buggy, if the roads were permissible, or a bob sled, if they weren’t.

Recognizing the reluctance of many farmers to invest in a cutter or sleigh, various firms offered a conversion kit. By removing the wheels from the buggy and replacing them with runners, the conversion was made from summer to winter. Pioneer Manufacturing Co., Columbus, Ohio, offered this conversion kit, “adjustable to fit any buggy, carriage, light delivery or express wagon…not too heavy for a light buggy or too light for a moderately heavy vehicle.” In 1888, this kit sold for $5, plus freight.

Castree-Mallery Co., Flint, Mich., offered various implements for 1887, including the bob sleigh pictured here. Usually, these were designed so that the front runners could turn beneath the reach, enabling the sled to make short turns. The length could be varied by moving the back set of runners ahead or back on the reach pole.

Numerous companies offered carriage-runner conversions for buggies and light wagons. Lansing Wagon Works, Lansing, Mich., was one such firm, offering three different styles for 1910. The same company also made Lansing wagons and Clark buggies. Despite the low cost, compared to a factory-built sleigh, conversion kits never gained great popularity.

Pioneer Implement Company, Council Bluffs, Iowa

Loosely defined, a cutter is a one-horse sleigh. Pioneer, like numerous other wagon makers, offered various cutter styles. Their 1903 dealer catalog notes, “You can sell cutters the first day it snows.”

Bob sleds or bob sleighs were built by many different wagon makers. Some of these were then jobbed to other companies, such as Frost & Wood at Smiths Falls, Ontario, Canada. The latter offered several styles in its 1910 catalog, each designed for a specific purpose. The Ontario Sloop was the most common style, followed by the heavy teaming and logging sled. For extra heavy work, especially for logging, the Midland style was available. It used a wide track design to provide better stability.

Moline Plow Co., Moline, Ill., bought out the T.G. Mandt Co., Stoughton, Wis., in 1906. Mandt vehicles dated back to 1865— and at least into the early 1920s, this wholly owned subsidiary was known as the Mandt Wagon Branch of Moline Plow Co. Its offerings of 1920 included several styles of the Mandt oscillator sleds as shown. In addition, there were at least two styles of anti-tip sleds using a wider track pattern.

Evans Manufacturing Co., Hammond, N.Y., was producing several styles of bob sleighs at the turn of the century. Included was this flexible lumbering version. Instead of the usual bolster mountings for a standard wagon box, the lumbering style was furnished with heavy rings at each end of the bolsters for securing logs and other items.

Over time, certain standards developed in all phases of the farm implement industry. For instance, this Evans bob sleigh of 1905 was built with the track in New York Standard-style or 35 inches from center to center of the runners. However, the standard style was sometimes a disadvantage. If the runners broke through the snow pack on one side, the sled would upset. Then, there was nothing to do but tip the sled back to its proper orientation, reload the cargo and make another attempt. Wide-track sleds had the advantage of providing greater stability.

Boilers

By the 1880s, leading agriculturists were promoting the concept of cooking livestock feed to make it more palatable and more nutritious. The idea had been around for centuries but gained new impetus at this time. Numerous companies emerged with their own ideas of the ideal boiler, cooker or steam generator. Eventually, farmers decided that the advantages were heavily outweighed by the investment in time and labor.

The Austin Steam Generator of 1889 was designed as a multi-purpose unit. It could be used for cooking feed, slaughtering hogs, heating water for laundry and bath use and various other purposes. This company built many different products in its long history, eventually concentrating on the manufacture of road building machinery. The manufacturer, F.C. Austin Co., was located in Chicago.

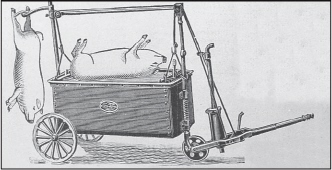

Crippen’s Agricultural Boiler was patented in 1899; this 1903 advertisement shows it in use for scalding hogs as part of the slaughtering and butchering process. Its advertising notes that “the above boiler is a revolution of the old sled for butchering, as one person can butcher and hang a hog weighing 400 pounds.” This combination outfit could also be used for smoking meat, drying fruit and, with its attached pump, and also served as a hand-operated orchard sprayer. It was built by H.M. Crippen, Athens, Ohio.

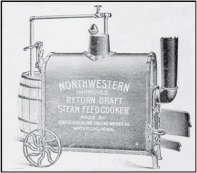

Davis Gasoline Engine Works Co., Waterloo, Iowa, offered this Northwestern Improved Return Draft Steam Feed Cooker in 1906. By that time, W.F. Davis, the company’s founder, left for other endeavors; the company was then in control of the Cas-caden interests at Waterloo. Like other feed cookers of its time, this one consisted of a small boiler that was intended to be portable, although it probably took Dad, the boys and the hired man working in unison to move it any distance.

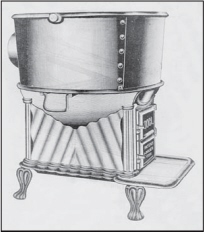

The Hartman Co., Chicago, offered this Majestic Feed Cooker as late as 1919. This one was on the order of a large cast-iron cauldron set inside of a metal jacket; the latter being attached to a rather ordinary box heater. The whole outfit was very simple and buyers were instructed to specify whether they would be burning wood or coal, so that the proper grates would be included. In 1919, this complete outfit sold for $20, plus freight.

Bone Cutters

The grinding of bones is of early origin. The ground material was often returned to the soil as fertilizer; commercially, it was then reduced to bone-black. Farmers and farm wives of the late 1800s were aware that ground bones were an excellent supplement to the diet of their laying hens, since the extra calcium meant better eggs with harder shells. Thus, these machines enjoyed brief popularity until oyster shells and similar products became available on a commercial basis. Bone cutters are seldom found, and, despite many queries and research, we were unable to find a current market value. However, it can be presumed that, due to their scarcity, bone cutters can now fetch $100 and perhaps much more, depending on the machine, its complexity, age and overall condition.

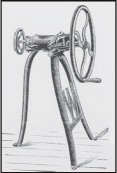

The Webster & Hannum bone cutter was a tabletop variety, with the processed material dropping from the table above into a waiting basket. This one had patents dating back to 1892 and was made by E.C. Stearns & Co., Syracuse, N.Y. The adjustable handle is an interesting feature. It could be removed entirely if any sort of belt power was available.

Webster & Hannum bone cutters, like most other makes, were available in several sizes. The larger units featured an automatic feed mechanism, and this was a great advantage. The crank handle was adjustable and could be removed entirely for use with a belted power. Unfortunately, the average farm of 1895, the year that this mill was advertised, had no power except a strong arm.

In an 1897 advertisement, P.A. Webster, Cazevonia, N.Y., noted that his Premier Green Bone Cutter was “a great revolution in bone cutters…” It had been personally tested and recommended by individuals, as well as by some popular magazines of the day. According to its maker, “not only a woman but a child can cut bones with ease…”

Curiously, Detroit Engine Works, Detroit, added bone cutters to its line about 1910, continuing with them for a few years. This one could be operated by hand or could be powered by an engine. For the latter, three bolts were removed and the crank wheel could be slid off the belt pulley. The company noted that it wasn’t necessary to sharpen the knives every week and, further, that there was no need “for your neighbor to have a better [cutter] than you.”

The majority of the bone cutters were for green bones, but Enterprise Manufacturing Co., Philadelphia, also offered a series of Dry Bone Mills, with this one being of 1910 vintage. In addition to dry bones, this mill could reduce corn, roots, bark and other materials as desired. Even though it is small in physical size, this hand-operated model weighed some 60 pounds

Trade Names

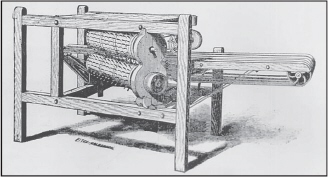

Broom Corn Equipment

Before factory-made brooms were widely available, some farmers raised broom corn, cut it, dried it and did all those special things to make it suitable for durable brooms. All of the equipment was very specialized, so it is not often found today. Since it is virtually worthless for anything but its very specialized purpose, the value of this equipment is not usually as high as might be thought. For instance, a broom vise, used to compress and form the head of the broom might bring anywhere from $75 and up; a broom cutter to trim the bottom end of the broom might bring $50 or more, and the actual broom-making machine might not bring more than $200.

Since the broom-making business was and is very specialized, some of the machines used in this process give little clue as to their actual purpose. This 1884 illustration shows a broom corn scraper, apparently used in the early stages of the preparation process to clean the fibers of leaves and other undesirable debris. More than likely, this device was limited mainly to larger broom-making operations than ordinarily found in a farm broom-making shop.

Trade Names

Bunchers

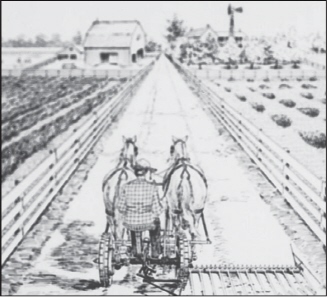

Originally, the buncher was intended to bunch or windrow seed clover and seed alfalfa for its trip to the threshing machine. Eventually, the buncher was used for other purposes, including the flax harvest and the pea harvest. It could also be used in down grain that was flattened by a wind or due to adverse soil and weather conditions. Use of these devices was rather limited, so they are now found only on rare occasions.

It took me considerable time to get a satisfactory image of this illustration, since the original left much to be desired. However, even this rather poor-quality image shows a heavy crop wind-rowed on the left, but a light crop on the right has been bunched. This device was made by the Side Delivery Buncher Co., Toledo, Ohio; the illustration is from a 1903 advertisement.

A 1905 advertisement of the Side Delivery Buncher Co., shows its Clover Buncher and Hay Windrower as attached to a mower. This unit could be attached to virtually any mowing machine. The cut material gathered on the buncher until full; the operator then raised the vertical fingers to the left, allowing the “bunch” to slide off behind the mower.

Did You Know?

Cast-iron lids from seed boxes are a rarity; on average, they sell from $20 to $30.

Port Huron Engine &Thresher Co., Port Huron, Mich., was a well-known manufacturer of traction engines, threshers and other farm machinery. Its 1907 announcement of a buncher was somewhat afield of its usual endeavors; it is not believed that Port Huron continued with bunchers for any length of time. This one was especially designed for harvesting peas, but could also be used with other crops.

While most bunchers were of a side-delivery design, the American buncher (shown in this 1903 advertisement) used a rear delivery system. The company offered two varieties—the American and the Improved Prairie Buncher. These units were designed particularly for the harvest of seed clover or seed alfalfa and were used primarily in areas amenable to these seed crops. American Buncher Manufacturing Co., was located in Indianapolis.

Did You Know?

Today, vintage flour mills often sell at a considerable figure; a nicely restored small mill might bring up to $1,000. However, a mill with a poor framework or a broken stone will bring but a fraction of that figure.