• 7 •

Infrastructure and Efficiency

In chapter 2 we discussed some issues related to dairy waste and wastewater management. In this chapter we will talk about choices you can make for handling both wastewater and fresh water, as well as power usage and building efficiency. As costs for power and water will no doubt continue to rise over time, it behooves the small-business cheesemaker to seriously assess these considerations before beginning construction. The more efficiency that can be built in, the better the return over the life of your business—not to mention the good feeling you will get from knowing you are doing your best to reduce your environmental footprint.

Water

Potable (drinkable) water is used in the creamery for the washing of equipment, hands, etc., and sometimes in the actual making of cheese (such as in washed-curd cheeses like Jack and Gouda).

Quality

One of the most important issues to be considered when addressing water supply for your creamery is quality. Your water source needs to be free of contaminants and any elements that could negatively affect the quality and safety of your cheese. Water enters the processing chain in a number of ways, including as residue on hands and equipment; when diluting cheesemaking ingredients, such as rennet and calcium chloride; and when washing curd in such cheeses as Colby and Gouda.

If you receive your water from a municipal water source treated with chlorine, your main concern will be not pathogens in the water but having chlorine-free water for diluting such things as rennet and other coagulants. This can be accomplished by purchasing distilled water or by de-chlorinating—using a small amount of milk added directly to the water (the chlorine molecules will attach to the organic compounds of the milk and be deactivated). You only need to add enough milk to give the water a faint milky color. This method is used in many mid-size creameries where the purchase of distilled water would not be cost effective.

If you have a well or other private, non-treated water source, it is important to have your water tested regularly for coliform bacteria and/or any other contaminants that might be of concern. Be sure to do this testing well before you begin production so you have extra time to use or install any needed remedies, treatments, or equipment and test the water again. Most states require preliminary testing as well as routine testing after you begin production. But even if they don’t, you are wise to implement your own testing regimen. In addition, you should expect the dairy inspector to inspect your wellhead and any holding tanks, usually just prior to licensing, although this requirement can vary by jurisdiction.

If your water is not considered safe for manufacturing cheese, then various purification systems can be used. One of the most popular choices is an ultraviolet (UV) purification system. These systems utilize UV light to kill Escherichia coli (E. coli), Salmonella, Legionella pneumophilia, Mycobacterium tuberculosis, and Streptococcus bacteria, as well as other pathogens. In addition, the same system can be equipped with various filters to eliminate sediment, odors, or other off-flavors. Whole-house filters and reverse osmosis units are also possibilities. It is important to consult with a plumber and water quality expert to determine your needs based on your water’s test results and issues. Each filtration system has pros and cons and should be analyzed on an individual basis.

Utilization of equipment to its maximum capacity will

increase your efficient use of water and lower your production of

wastewater per pound of cheese produced.

One often-unexplored aspect of water quality is how your water works in conjunction with the cleaning chemicals you use. Water hardness (mineral content) and pH (an indicator of acidity or alkalinity) greatly influence the effectiveness of detergents and sanitizers. You should have your water analyzed for pH and hardness; if the levels deviate from average, you will need special detergents. Be sure to consult with the manufacturer of the cleaning products you use, and/ or a company representative, to select the proper products.

You should also install an anti-siphon device (also known as a backflow prevention device or valve). In order to maintain potable water quality, you must ensure that water pressure never reverses direction and siphons animal drinking water, wash water, or any other contaminated water back into the water pipes. A back-flow prevention device should be installed between the lines running to the creamery and the lines running to the barn. In addition, individual anti-siphon devices should be placed at each hose faucet where the possibility exists that a hose end could be left in standing water (where it could potentially siphon contaminated water back into the main lines). Talk to a plumber or plumbing supply company to choose an appropriate device. Also be sure to consult with your inspector as to placement, as well as any regulatory requirements that might exist.

Calculating Needs

Running a dairy and making cheese requires a lot of water. If your water comes from a municipal source (what we often call “city water”), your increased use will be reflected on your water (or in some cases sewer) bill—and while you might not have to worry about the volume of water available, the likelihood of increasing water costs is something you will need to consider. If you have a private well or other water source, your well pump and any filtration system will be put to greater use and this will be reflected in higher energy bills.

Estimates of water use in the farmstead creamery vary greatly based on cleaning practices and volume of milk processed. The volume of water used goes up in steps based on the potential production capacity of your equipment. For example, if you have a 50-gallon bulk tank and vat but are processing only 20 gallons of milk into cheese, you’re really not using that much less water than if you processed 50 gallons—cleanup of the equipment will use the same amount. Utilization of equipment to its maximum capacity will increase your efficient use of water and lower your production of wastewater per pound of cheese produced.

A common ratio used by cheesemakers states that it takes from 1 to 5 gallons of water to process 1 gallon of milk (from the milking parlor to the finished product). Our own personal experience shows that we use about 4 gallons of water for every gallon of milk, by the time we factor in cleaning the parlor, milkhouse, make room, and equipment. The bigger the batch, the fewer gallons of water used per gallon of milk produced.

A common ratio used by cheesemakers

states that it takes from 1 to 5 gallons of

water to process 1 gallon of milk.

Reducing Use

While water seems like a cheap resource, it should be treated as an endangered one. As human populations grow, the demand on municipal treatment plants and on rural water tables continues to rise. In addition, how a dairy handles its wastewater and how it attempts to conserve and/or reduce waste can become a political tool—to the benefit or detriment (or eventual demise) of the dairy operation. Reducing water use is good from every angle: saving money, saving local resources, and saving your business’s image.

In issue 32 of her quarterly newsletter CreamLine, publisher Vicki Dunaway quotes Kent Rausch and G. Morgan Powell, authors of Dairy Processing Methods to Reduce Water Use and Liquid Waste: “Stop using your water hose as a broom.” The best way to reduce use is to employ a squeegee or broom to assist with cleanup instead of spraying every little piece of curd to move it to the drain. Combine this with efficient sizing of equipment and batches and you will have maximized your water use.

While boilers are not commonly used on very small farms, when an economical fuel sources is available they are quite viable options. This wood-fired boiler with heat storage tank (on right) works in combination with a propane on-demand water heater (in background) to provide hot water at Pholia Farm, Oregon.

Hot Water

You will need a reliable supply of hot water, at about 140–160°F, for cleaning dairy equipment (more on cleaning in chapter 8) and heating the cheesemaking vat. Depending upon your water type (hard or soft) and the type of detergents used, your optimal hot water temperature will vary, but by planning on having it available toward the high end of the range, you will be better prepared for all situations. This seems to be the area where most creameries initially fall short, ourselves included!

Calculating Needs

Base your need calculations on the high estimate for total water usage (mentioned above) and calculate that two-thirds of that will likely be hot water. Remember that if you are sharing a hot water source for domestic use as well, you will need to consider not only volume but also pressure. Ask yourself, “If hot water is running in another part of the building, will I still have enough for cleaning in the creamery?”

Information on Water Heating Systems

The U.S. Department of Energy (DOE) has an up-to-date website that discusses most of the pros and cons of typical residential and small-business water heating systems. Go to www.eere.energy.gov and follow the links. When studying the different options, keep the following questions in mind:

1. What is the maximum volume and maximum temperature required at any given time of use?

2. What is the initial cost versus the long-term operating cost?

3. Are there renewable energy rebates and incentives in my state that will help reduce the initial investment?

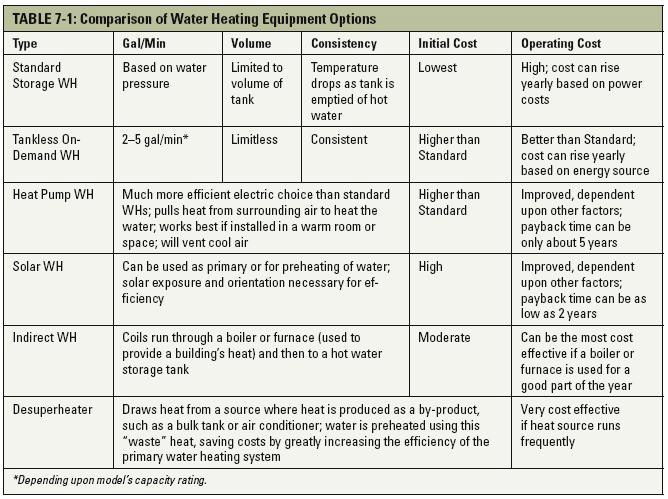

Table 7-1 breaks down the main features of most systems. The only one not included in the USDE’s website is the desuperheater. Desuperheaters harvest “waste heat” from heat pumps, bulk tank compressors, etc., to help heat water.

While not common, they are worth considering.

Reducing Use

Simple solutions apply when considering saving on hot water usage: Using water at the correct temperature for the need, insulating lines to maintain water temperature in the pipes, and reducing overall use whenever possible are all viable options for reducing hot water use.

Wastewater

Wastewater from your creamery can be divided into three categories: parlor wastewater, containing some animal waste as well as chemicals from cleaning; creamery wastewater, containing clear wash water and chemicals along with small amounts of milk, whey, and curd; and blackwater from the toilet/restroom. State and local regulating agencies may differ greatly in how they regulate each of these types of wastewater. You will hear about a great variety of methods that have been approved for dealing with them. Be sure to contact the correct authorities before proceeding with a wastewater management plan.

Calculating Volume

In most states you will need to estimate your wastewater volume as part of your sanitation application for septic, or for the animal waste management plan (AWMP) that some states require for even a very small dairy (see “CAFO and the Dairy Wastewater Management Permit” in chapter 2). You can make this calculation using the same formula as above for fresh water usage, since the same water will be running down your drains as waste.

Management Options

How you manage the wastewater from your creamery will depend upon the regulations of your local jurisdiction as well as your state. For the very small dairy, many states defer to the local agency in regard to wastewater management. Smaller creameries will have very simplified wastewater management plans in comparison to the medium- to large-size dairy. Concentrated Animal Feeding Operation (CAFO) regulations were designed to properly deal with the wastewater and runoff from very large animal facilities where animals are confined, such as feedlots, confinement dairies, and hog or poultry operations. Some states have implemented the same permitting requirements for all commercial livestock operations, regardless of size. You will have to make sure that you are very clear on what your state and local authorities will expect and allow!

Cheese curd being placed into forms for draining on Pholia Farm’s draining table—made from a commercial dishwasher drain rack with stainless steel legs added.

Below are some of the wastewater management options that may be allowed in your state. These options are by no means inclusive: Many other options exist, and exciting new ones are being developed, such as constructed wetlands (Living Machines built an indoor version at Cedar Grove Cheese in Wisconsin that processes 7,000 gallons of dairy wastewater per day), which send wastewater through a series of ponds or holding tanks where plants, microbes, and even fish cleanse the water naturally. For the purposes of this book, though, we will cover the more common systems.

MAKE IT GO A-WHEY!

Whey, a natural by-product of cheesemaking, is considered an effluent if it is dumped down the drain, while in large facilities it can become a value-added product if quickly dried and sold as a food additive, protein powder, etc. When introduced to septic tanks, waterways, and wastewater, however, whey has a high biological (or biochemical) oxidation demand (BOD), making it a pollutant. Substances with a high BOD consume oxygen that is dissolved in the water. In plain terms, whey disposed of in water will create “dead zones”—not something you want in your septic system, stream, or pond.

So what are your options? Most small creameries deal with the whey through two main disposal methods: feeding to animals and/or spreading on fields. If your whey is not too acidic (“sweet whey,” with a pH above 6.0, is produced during the manufacture of cooked/pressed cheeses, such as Cheddar and Gouda), then it can successfully be fed back to your herd. Acid whey, with a pH around 4.6, is the by-product of lactic-fermented, soft cheeses, such as chèvre and ricotta; it can be fed to pigs and chickens but should not be fed to ruminants, as it could upset rumen acid balance. It can be diluted to alleviate some of these concerns and buffers can also be added, but this should be done with care. Some whey (sweet) can be used to create other cheese products, such as whey ricotta and Gjetost, but it is unlikely that you will be utilizing all of your whey for such products. Most creameries will find that the large volume of whey produced will require at least some of it to be disposed of, along with creamery wastewater, and spread on field, crops, or compost heaps.

Direct Diversion

This method is sometimes called “run-to-daylight.” Wastewater basically goes down the drain and runs through a pipe to the ground’s surface. This method, even where allowed, is not one I recommend, as it does not deal properly with the nutrients and chemicals present in the water; nor does it reuse the water as well as it could. Some filtration can occur if the water is run to a gravel and sand pit, but the longevity of this system cannot be predicted.

Septic System

Many jurisdictions allow for the use of a domestic-type septic system (either shared with a bathroom or independent). A grease trap should be included on the tank, and the drain field must be sized properly to deal with the large volume of water generated by the dairy. A properly functioning septic system allows for the disposal of solids (by tank pumping) and for the return of water to the ground.

Holding Tank

Holding tanks are the most common means of dealing with wastewater in newly constructed small dairies. A holding tank for wastewater is any type of cistern, either buried or aboveground, that can receive and hold the wastewater. Periodically the water is distributed to crops and fields or disposed of in other acceptable fashions. A dairy’s holding tank is basically a “dark” greywater system (as it will include small amounts of animal waste from the milking parlor) with a higher concentration of detergents and sanitizers than in a domestic greywater system. In addition, the distribution of the dairy wastewater will most certainly be regulated by CAFO rules. If you are interested in learning more about domestic greywater systems, go to www.greywater.com and www.thenaturalhome.com/greywater.html.

Wastewater holding tank, Fairview Farm, Oregon.

FAIRVIEW FARM

Cheesemaker Laurie Carlson of Fairview Farm in Dallas, Oregon, describes her creamery’s wastewater management system this way:

“We are newly licensed, so I’ll describe our system. We had to put in an aboveground tank—1,550 gallons—to hold wastewater from milking during rainy months, so no water from the milking parlor would run onto wet pastures. We have a sump pump in the ground beside the milking parlor, which the floor drain runs into, then it pumps out to the tank. During dry periods we can run the water out of the tank onto the pasture through a hose. We are permitted with the condition that we do not milk during January through March, when our does are dry. If we planned to milk year-round we would have needed a bigger tank, because the winter months are the rainy ones.

“We had to get a CAFO permit here in Oregon, and we have a permit for 50 goats on the property.

“Our cheese processing building had to have a restroom with its own septic tank (commercial size, of course! For one toilet!). The floor drain in the cheese make room runs about 50 feet underground to a French drain in our orchard.”

Ponds and Lagoons

Think of the dairy pond as an aboveground, open storage tank. Wastewater flows, or is pumped, to the pond, where it is held until it is spread. A lagoon is similar to a pond, but it’s meant for longer-term storage and treatment of the wastewater. While most small dairies will not need the volume of storage space provided by a pond or lagoon, they are often seen on older dairies that have been refurbished. Water spread from a pond will have a higher nitrogen content than that from a lagoon (and consequently more odor). Both ponds and lagoons will require extensive waste management plans (through the CAFO permitting process) and engineering.

Power and Fuel

Too often, the energy needs of the small dairy are not adequately calculated before designing and outfitting the creamery. By not factoring in these costs early in the planning stages, the small business can find itself facing higher power bills than expected and unable to keep costs in line with income. With energy costs being variable, and with long-term forecasts of price increases, it is important to attempt to address energy usage needs not only before opening for business, but before adding any new piece of equipment.

ESTRELLA FAMILY CREAMERY

Kelli and Anthony Estrella of Estrella Family Creamery, Washington, saw their electric power bill go from $50 a month to $500 a month when their creamery came online. The family-run farm produces award-winning raw-milk and cave-aged cheeses from their herd of 19 Normandie cross cows and 50 La Mancha goats that graze the 164-acre restored dairy farm.

Calculating Usage

Don’t be intimidated by such terms as watts, kilowatts, amps, and volts. You don’t have to completely understand electricity to figure out how its use will affect your business. There is a simple formula that can be used to determine the potential energy usage of any appliance:

Formula to Determine Energy Usage

Volts × Amps = Watts

So if you don’t really need to know what all of this means, how do you make it work for you? If you take a look at any electric appliance, you will find a plate or label that states the volts and amps (short for amperes) that the unit uses at peak usage. When you multiply these two numbers together, you will find out how many watts the equipment will use at any given time. To take it one step further, if the equipment runs at that rate for 1 hour, its usage could be measured in kilowatt-hours (KwH). Your electric bill tells you how many kilowatt-hours you use per month and how much those hours cost you. One kilowatt-hour is equal to 1,000 watts. For example, if a 100-watt light bulb runs for 1 hour, it will use 0.1 KwH of electricity. If it runs for 10 hours it will use 1 KwH.

PHOLIA FARM

Before we built our off-grid dairy, creamery, and home, we plugged every appliance we had into a Kill A Watt meter to find out how much power we would have to make. Our example is extreme, but it is an eye-opening experience to find out how much power some things really use!

Here is an example of using the formula of volts × amps = watts for our milking machine:

• 115 volts × 6.6 amps = 759 watts

• 759 watts × 2 hours of use = 1,518 watts or 1.5 KwH

• 1.5 KwH/day = 45 KwH/month • 45 KwH × [cost per KwH] = electricity cost per month

• If the average price per KwH across the U.S. is $0.11, then it will cost you about $5.00 per month to operate this equipment.

Here is another example, using a more power-thirsty appliance—a three-compartment, glass-fronted refrigerator:

• 115 volts × 12 amps = 1,380 watts

• 1,380 watts × 10 hours (as the compressor will not run all of the time) = 13.8 KwH

• 13.8 KwH/day = 414 KwH/month

• 414 Kwh × $0.11/hour = $45.54/month

You can see how this usage might all start adding up to a sharp increase in your power bill!

A very useful tool to get an even more accurate idea of how much electricity a piece of equipment is really using is a neat gadget called an energy usage meter. A popular brand is called the Kill A Watt. You plug the meter into any 110-volt wall socket and then plug an appliance into the unit. A digital readout will display the current usage, as well as usage over time. Wait about 24 hours and you can get a pretty accurate idea of how much power is being consumed—and think about whether adding that second fridge is really worth it!

Reducing Needs

When you design your creamery (as well as your business plan), you can make power-saving choices that will positively impact your future power bills and environmental footprint. The following chapters will discuss options that you can build into your plan for energy efficiency. This can be a greater challenge when you are working with existing buildings and infrastructure, but you can still make choices that will help reduce your energy needs.

If you are considering increasing production in order to increase income, don’t forget to factor in increased energy usage and costs. If you are already using your equipment at its maximum and you need to add additional cold storage, etc., be sure that the increased product will offset the increased costs enough to make the investment worthwhile.

Renewable Energy

Renewable energy (RE) can be expensive to purchase and install, but it can become a cost-saving investment for any size creamery. The USDA Farm Bill often includes grant moneys for farmers who want to use RE. Check its website for updates and links to state officials who can help you research these options: www.rurdev.usda.gov/rbs/farmbill.

Another useful site for monitoring state incentives as well as other funding possibilities is www.dsireusa.org.

Tax credits and state rebates can sometimes cover as much as 50 percent of your initial RE purchase and installation costs, but these vary from year to year and state to state. Finding a reliable RE installer will be your best bet for staying on top of state funding and how to best take advantage of it. Many RE companies now offer financing, as well. Think of it as buying your power in advance—for a set price now, you are guaranteeing a steady source of power for years to come.

Often people focus on the “payback time” for renewable energy (the time it would take, with conventional operational costs, to pay for an RE system). Payback time isn’t usually a consideration when using conventional energy sources, buying groceries, or buying a car—so if you’re considering renewable energy, take the payback time information with a grain of salt and choose what works not only for your pocketbook, but for your philosophy.

GIANACLIS’S “CUPS” FOR MAXIMIZING ENERGY EFFICIENCY IN THE CREAMERY

1. Choose the right-size equipment. For example, don’t buy a 100-gallon bulk tank if you will be storing only 50 gallons of milk.

2. Use equipment to its maximum capacity for its size. In other words, don’t run a large refrigerator only half full of product.

3. Place equipment where it can run efficiently. For instance, don’t place a freezer against a wall that receives full sun exposure and radiates heat. Place cooling units, such as bulk tanks and refrigerators, so that the excess heat they create (as a by-product of cooling) can be exhausted from the room (to increase the efficiency of the compressor).

4. Schedule processing to take advantage of natural conditions. For example, if the make room is so warm in the afternoon that you have to run an air conditioner, make cheese earlier in the day.

A micro-hydroelectric turbine provides additional power to Pholia Farm’s off-grid solar power system.

For a detailed description of renewable energy options for farms, go to the National Renewable Energy Laboratory’s website and visit the page for farmers and ranchers at www.nrel.gov/learning/farmers_ranchers.html. Another great site for farmers considering RE is www.farmenergy.org. While some of the RE options listed, such as methane recovery systems, are currently aimed at the large-scale dairy, others—including wind and solar (photovoltaics)—are viable options for any size farm. Determining your site’s best choice and system size is most likely a job for a licensed installer.

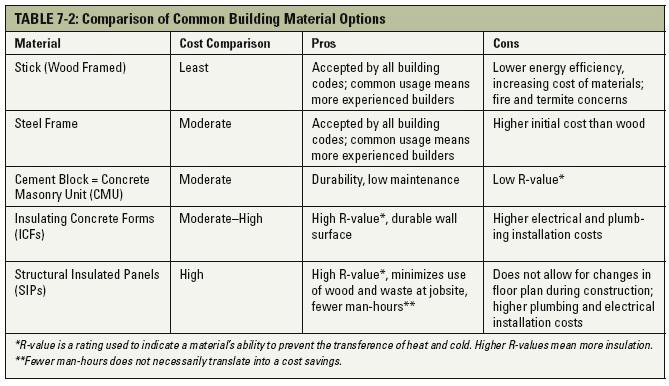

Structure

As you think about building a new barn and creamery, you will have options for choosing designs and materials that can increase your buildings’ efficiency and reduce maintenance. While traditional (conventional) materials, such as wood framing and cement block, are always options, these days it’s becoming easier to find contractors who have experience with some interesting, often more ecologically friendly options—such as structural insulated panels (SIPs) or insulating concrete forms (ICFs). New construction will also give you the opportunity to orient the building and position windows to maximize efficiency. Even if you are remodeling, you might be able to take advantage of some of these options.

Building Material Choices

There are many options available for the construction of a small dairy. Some of these choices may not be available in your area, either due to lack of supplies and construction expertise, or due to building codes that have not evolved to accept some of the newer building choices.

When you choose a building material, it is a good idea to consider the environmental cost (EC). Environmental cost figures attempt to factor in such things as carbon output during production of materials, man-hours of installation, life span of the material, and demolition and disposal costs. Bear in mind that data on these factors is subjective and constantly changing. Depending upon where you live, the intended use of your building, the expected life span of the business, etc., the actual EC will vary greatly.

Here is an example: Concrete has a high up-front environmental cost. One of the key ingredients in concrete is cement, which is made from limestone that is mined and then kiln treated. Much energy is consumed not only during the process of producing concrete but also during its use as a building material—including trucking and often pumping the concrete to, and at, the building site. On the plus side, however, since any building will use far more energy over its life span than during its construction, concrete’s long-term assets—which include thermal mass (the ability of a material to store heat ) and low maintenance (cleaning, upkeep, paint, etc.)—add EC credits. Furthermore, at the end of its life span concrete can be recycled for new uses. In addition, its fire-resistant quality adds sustainable benefits (as well as insurance rate discounts) that can all add up and make it the greenest choice available—in the appropriate application. (If it sounds a bit confusing, it is, but it is still a good idea to learn what you can and make the best choice possible—when options exist.)

Table 7-2 summarizes some of the primary differences in building materials.

Passive Solar Design

Passive solar design optimizes a building’s design to suit its climate and location to help maintain optimal comfortable temperatures year-round. Factors to be considered include the orientation of the building (south-facing usually being ideal); thermal mass of the materials (walls and surfaces that are placed to intentionally retain seasonally desirable temperatures); windows placed and sized to minimize undesirable heat loss or gain; and shading, such as deciduous trees and awnings that keep the building cool in the summer and allow sun exposure for increased warmth in the winter. Existing buildings, geographical limitations, or other factors can limit the use of passive solar design, but if you keep it in mind and incorporate it whenever possible, you will reap a great benefit on your power bill!

Ergonomics and Efficiency of Motion

At this point, you are probably feeling as if there is enough to think about when designing your creamery, but here is one more! Think of sustainability in terms of how you might design your workspace to maximize your efficiency and therefore, in the long run, the sustainability of both your business and your enjoyment of the work. In the beginning, we all just want to do whatever it takes to get our license and start selling cheese, but some of the choices we might make to arrive at this short-term goal as quickly as possible could adversely affect our long-term survival. So, whenever possible, make choices that will reduce your workload and increase your efficiency! This topic will be revisited as you continue reading about designing each room of your creamery.

As you continue reading part 3, I hope you will see how your floor plan design and equipment choices will affect your choices of infrastructure and system options. No one I know who has built a creamery has been able to look back and say, “It’s just right; I wouldn’t change a thing.” But with some thought and consideration, perhaps your creamery will be close to ideal.