APPENDIX C

Milk and Cheese Quality

Tests and Parameters

Appendix C provides an overview of some of the more common tests and how to use the data to your advantage. In addition, we will cover some other avenues for monitoring the production of high-quality milk and cheese. For a more thorough understanding of these tests, please refer to the notes/references section.

Common Laboratory Milk Tests Defined

Standard Plate Count (SPC): Raw milk, total number of aerobic bacteria. Expressed in number of colony-forming units per milliliter of milk (cfu/ml).

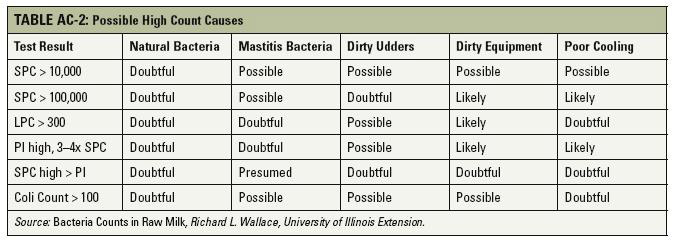

Why it matters for cheese: High bacteria counts in raw milk indicate possible mastitis, poor udder preparation, dirty equipment, and/or inadequate cooling. Coliform bacteria (of which E. coli is one type) are often the dominant microorganism of the SPC. See below.

Preliminary Incubation Count (PIC): Milk sample is held at 55°F (12.8°C) for 18 hours, then an SPC is performed. Bacteria associated with high PICs are generally psychotrophic (cold-loving).

Why it matters for cheese: Many psychotrophic bacteria produce proteolytic (breaks down proteins) and lipolytic (breaks down fats) enzymes that can change the structure of milk during cold storage prior to cheesemaking, leading to poor coagulation, undesirable flavors, and rancidity in the cheese.

Laboratory Pasteurization Count (LPC; also known as thermoduric bacteria count): Milk sample is heated to 145°F (62.9°C) for 30 minutes, then an SPC is performed. Counts bacteria that survive pasteurization. No legal limit for raw milk.

Why it matters for cheese: High LPCs are associated with poor udder cleaning and/or dirty equipment, practices that reduce the quality of milk.

Coliform Bacteria Count: Milk sample is plated on growth medium and incubated at 90°F (32°C) for 24 hours. If total coliform count is high, a separate E. coli culture is done to detect pathogenic strains.

Why it matters for cheese: Coliforms from fecal contamination can be pathogenic, causing severe illness and death in certain cases. Coliforms also cause early gas blowing in cheese.

Somatic Cell Count (SCC): Counts leukocytes (white blood cells) and other body-tissue cells in milk. Indicative of udder health—injury or infection, and/or stage of lactation.

Why it matters for cheese: The increase of SCC correlates with the increase of proteolytic enzymes in the milk, leading to lower cheese yield, poor coagulation, and off-flavors in cheese.

Milk Urea Nitrogen (MUN): Excess protein in diet leads to high blood and milk urea nitrogen levels, which affects cheese quality, as well as contributing to excess nitrogen in manure and ammonia in urine. Acceptable levels for cows average 10–14 mg/dl. Goat and sheep norms have not been established. Small sampling has suggested normal levels for goats to be higher than that of cows.

Why it matters for cheese: High MUN levels are associated with poor coagulation, early fermentation, and excessive proteolysis in aging cheese.

Testing Frequency

The frequency at which your milk will be tested by regulatory officials will vary. I recommend augmenting the state’s testing to keep the frequency to every six to eight weeks, minimum. More frequent testing should occur if the results are less than favorable. The important thing is to establish baseline numbers that you understand, accept, and can maintain. By watching results closely, you will be able to see any changes that indicate a flaw in your sanitation and practices and then remedy that flaw before it becomes a hazard and/or violation.

Most states perform only the minimum tests required to ensure safe milk. For cheesemaking quality (beyond safety), you may want to have other tests performed on a routine basis or when needed. See appendix A for a list of laboratories.

On-Farm and Creamery Tests and Observations

Tests for SCC (Somatic Cell Count) and Mastitis in Milk

Several immediate tests can be done on milk either during milking or prior to cheesemaking that will indicate the presence of somatic cells (SCs) and/or mastitic milk. The California Mastitis Test (CMT) uses a reagent combined with an equal amount of milk swirled in the provided paddle to detect the presence of SCs. The paddle is swirled for 15 seconds and then tilted back and forth. Thickening is judged in degrees that correlate with the amount of SCs present.

• Trace gelling = 300,000

• Thickening but not clumping = 500,000–1,000,000

• Thickening and clumping =>1,000,000

• Clumping and sticking to paddle = >2,000,000

Mastitic milk will be more alkaline than healthy milk. (Some on-farm SCC tests are actually checking pH.) If the pH of milk at the start of cheesemaking is higher than normal, perform a CMT and compare.

Dairy Herd Improvement Programs

Herds enrolled in dairy herd improvement programs have milk samples pulled and weights recorded monthly on each animal. Data collected includes (this can vary by lab and program) butterfat, protein, solids-not-fat, cheese yield (based on butterfat-to-protein ratio and solids), and somatic cell count. This can greatly help the farmer-cheesemaker track seasonal changes in milk and milk quality as they relate to cheesemaking. Many new programs allow for owners to collect samples and data without needing an outside trained test person.

Appearance, Odor, and Flavor

Many flaws and problems can be detected in milk using your senses. I greatly encourage artisan cheesemakers to train their eyes, noses, and taste buds to be their first line of defense in ensuring day-to-day quality.

Tips for Analyzing Milk

1. For maximum aroma analysis, pour sample into a jar, leave a head-space, close tightly, and warm to about 60°F (in water bath). Open jar directly under your nose and inhale deeply.

2. Compare fresh milk to that which has been stored for several days to help pinpoint cause.

3. If necessary, compare samples from each animal to rule out individual variation in flavor.

4. Official advice encourages the pasteurization of all milk samples prior to tasting.

Spoiled or unclean (dirty, animal taste, spoiled, fruity): Contamination and/or bacterial growth during storage. Causes: dirty equipment or udders, psychotrophic bacteria.

Rancid, bitter (soapy, baby vomit, blue cheese): Breakdown of fat. Causes: excess agitation or foaming of milk during milking, late lactation (high SCC), fluctuation of temperature during cold storage.

Malty, acidic (malt cereal and/or sour): Bacterial growth during storage. Causes: poor cooling of milk.

Oxidized (cardboardy, old oil): Oxidation of butterfat. Causes: Excessive high-fat feeds, low levels of vitamin E, presence of certain metals (copper contamination, rust).

Feedy (aromatic, unnaturally sweet): Odors and flavors absorbed by animal and transmitted to milk.

Common Lab Tests for Cheese

These tests are just the tip of the iceberg in regard to understanding the safe manufacture of cheese. I recommend further study through cheesemaking books, classes, and the Dairy Practices Council’s Guideline No. 100: “Food Safety in Farmstead Cheesemaking.”

In-House Observations and Tips

1. Product testing can be infrequent as compared to milk and environmental testing. Good manufacturing practices and quality assurance are more important than testing for ensured quality.

2. Test more “dangerous” cheeses—high-moisture cheeses, such as Brie, Camembert, washed-rind types—more frequently.

3. Suspect any finished product that deviates from flavor, aroma, and appearance profiles.

4. During production, flag any batches where the make deviates from normal production standards. Test prior to selling.