Tanks emerged from the Second World War as the pre-eminent component of the ground forces. However, their importance did not remain unchallenged, mainly because of the development during the latter part of the war of weapons firing projectiles or missiles with shaped charges. The very high-velocity metallic jets formed by these charges could perforate very thick armour, and this enabled relatively light weapons, and consequently infantrymen, to knock out tanks and therefore to reduce their effectiveness.

The armour-piercing capabilities of shaped charges had already led Hitler to believe that they would reduce the importance of tanks when they were incorporated in German artillery shells in 1943.1 However, shaped charges did not become a serious threat to tanks until they became the warheads of rockets fired from simple tubular light weight launchers. Their use in this form was pioneered by the 2.36in. (60mm) rocket launchers that the US Army first used in North Africa in 1942. The launchers were called ‘bazookas’ after the pipe-like musical instrument, and this became the popular name for weapons of their kind.

In 1944 the German Army introduced another and simpler shaped charge weapon, the Panzerfaust. Instead of rocket propelled grenades, this fired a grenade from a disposable recoilless launch tube, and in spite of its short range of 30 to 60m was responsible for killing a considerable number of tanks in the closing stages of the war. By the end of the conflict the US Army developed a more powerful 3.5in. (89mm) bazooka that could penetrate 280mm of armour, which was more than the thickness of armour of any contemporary tank. It also developed 75mm and later 105mm recoilless guns or ‘rifles’ that fired shaped charge shells. Unlike the bazookas, they could not be carried by one man but could be mounted on jeeps or other light trucks.

The development of such weapons led to the view, particularly in the United States, that henceforth the armour of tanks could be easily defeated and that their effectiveness was therefore greatly reduced. Such views were advanced, among others, by Dr Vannevar Bush, the head of the US Office of Scientific Research and Development during the war, in his influential book Modern Arms and Free Men published in 1949.2 Similar views were also held by the US Secretary of the Army, F. Pace, who shortly before the outbreak of the war in Korea in 1950 stated at the West Point Military Academy that tanks were obsolescent.3

In contrast to the views held in the United States and elsewhere, the Red Army, which in 1947 was renamed the Soviet Army, continued to regard tanks as a major component of the ground forces. It retained large numbers of them and kept acquiring new tanks, increasing its tank strength well above the 25,400 that it was estimated to have at the end of the war.4 In consequence, Soviet tanks dominated the post-war scene and, given the aggressive stance of the Soviet Union, drove the development of tanks in other countries as a counter to them.

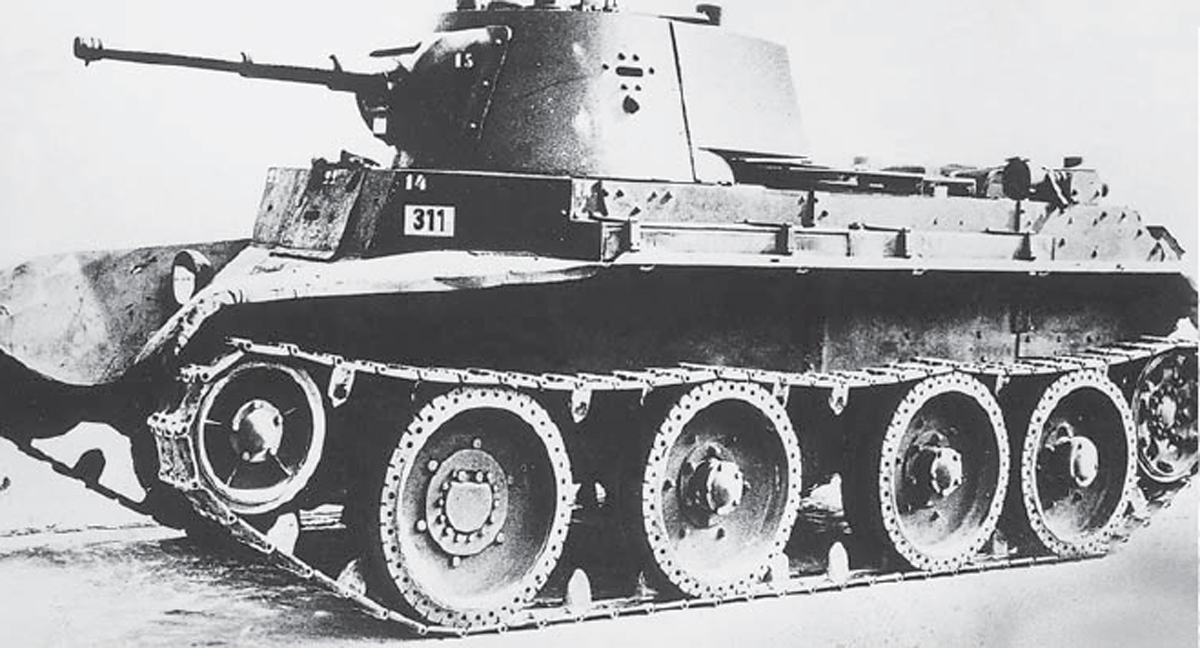

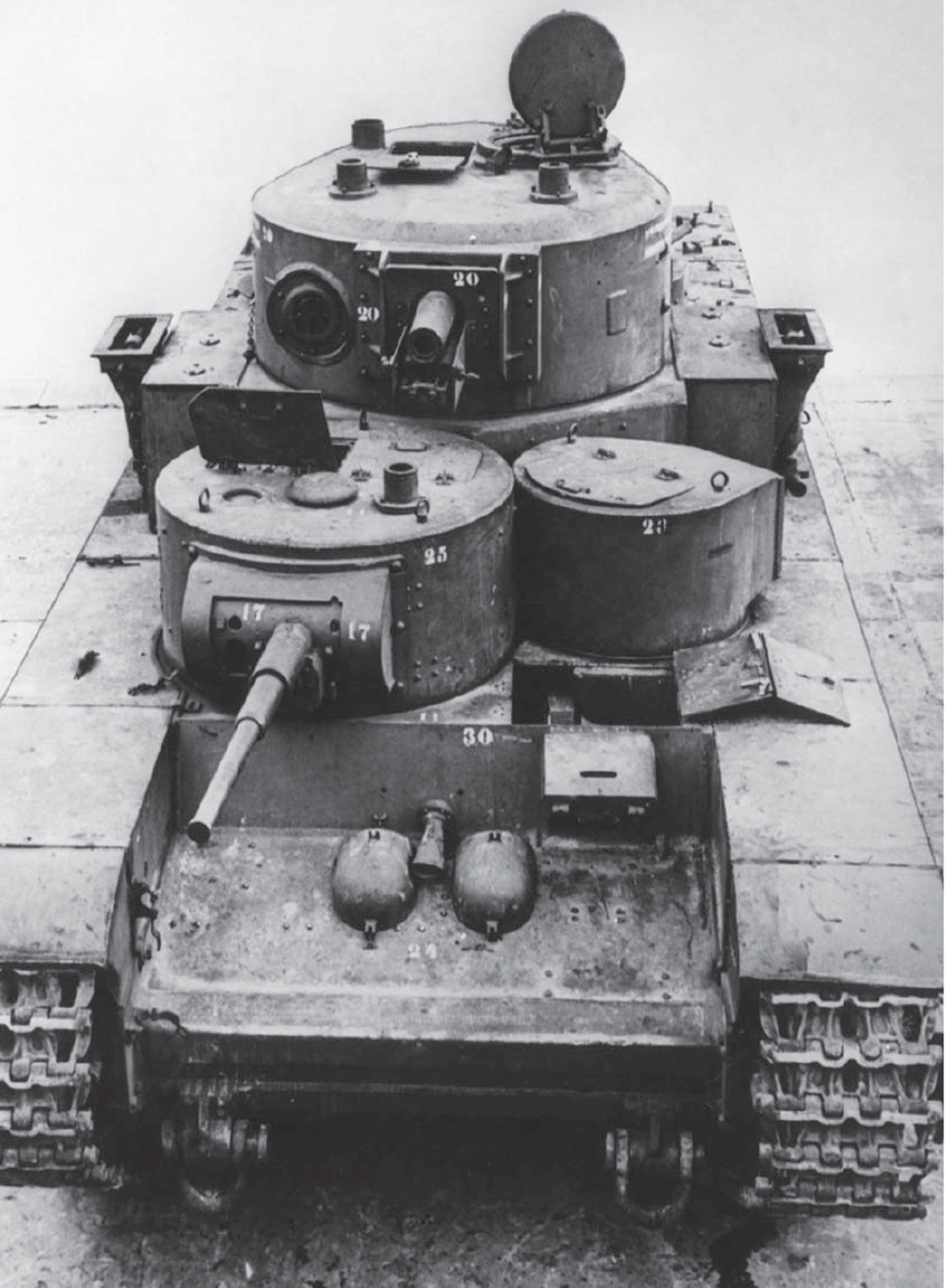

The roots of the development of the new Soviet tanks lay in a number of experimental vehicles built during the war. The earliest of them was the T-43, which was an attempt to revive the development of the improved T-34M version of the T-34 abandoned in 1941 because of the German invasion, as mentioned in Chapter 8. However, by the time the prototype of the T-43 was built in 1943, its 76mm gun was no longer considered adequate. In consequence it was abandoned in favour of the T-44, which was much more heavily armed as well as being superior in several other respects. One of them was the new transverse location of its diesel engine, which made the engine compartment and the hull more compact, although the engine itself was the same as that of the T-34. Like the T-43, it also had a torsion bar suspension instead of the Christie coil spring suspension, and it also abandoned the Christie-type long pitch tracks of the T-34. Anticipating the general trend, the T-44 also dispensed with the hull machine gunner, which reduced its crew to four and contributed further to making the tank compact.

Prototypes of the T-44 were built as early as 1944 and were armed with 122mm as well as 85mm guns, but the larger gun was found to be incompatible with the 32-tonne tank and it was the version armed with the 85mm gun that went into production in 1945. The first batch was produced just in time to be sent to the Far East for the Soviet offensive against the Japanese forces in Manchuria in August 1945.5

Production of the T-44 was not continued for long, but it served as a model for the T-54 that succeeded it and which, with the very similar T-55, became the principal Soviet tank of the mid-20th century. T-54 and T-55 also became the most numerous tanks ever built, the total number produced amounting to about 100,000, including tanks produced in Poland and Czechoslovakia and T-54s built in China as Type 59. They have also been the most widely employed, starting with the use of the T-54 by the Soviet forces that suppressed the Hungarian uprising in 1956, through the Arab-Israeli Six Day War of 1967, the final stages of the war in Vietnam and the 1980s wars in Afghanistan and Angola to the Second Gulf War of 2003.

The first two prototypes of the T-54 were built in 1945 and production of it began two years later. That of the T-55 followed in 1958 and continued until about 1980, although by then solely for export to some of the 40 Soviet client states and neutral countries. The principal difference between these models and their T-44 forerunner was that they were armed with a larger calibre 100mm gun mounted in a ballistically better-shaped hemispherical turret with 200mm thick frontal armour. Yet, in spite of their heavy armour, they only weighed 36 tonnes due to their very compact design, although the latter also resulted in them being cramped inside.

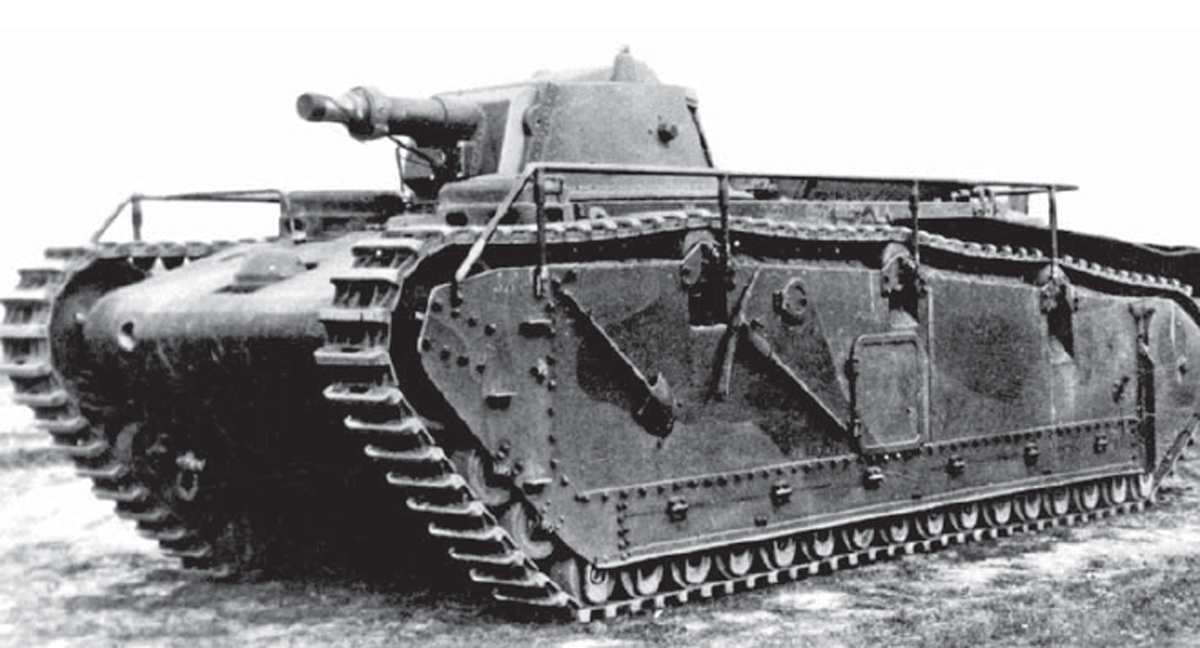

The armour of the T-54 and T-55 was actually thicker than that of the Soviet IS-2 heavy tank and comparable to that of the heaviest wartime tank, the German Tiger II. Nevertheless, the Soviet Army continued to develop heavy tanks with even thicker armour. The most significant of them was the IS-3, which stemmed from the experience of the 1943 Battle of Kursk. This battle emphasized the importance of frontal armour and led to the design of the IS-3, which was in effect an IS-2 but with a ballistically much better shaped turret and hull front. The armour of IS-3 was actually 120mm thick at the front of the hull, but because of the way it was angled it was equivalent to about 330mm against conventional armour-piercing projectiles, which was more than the armour of any tank produced before its appearance.

The development of the IS-3 started in 1944 and it was put into production with remarkable speed at the beginning of 1945. But only a few were completed by the time the war ended and so none saw any action in it. Production of it continued until 1959 and totalled 2,311 tanks.6

The existence of the IS-3 was revealed to the outside world when 52 took part in the Allied Victory Parade in Berlin in September 1945. After the parade Marshal Zhukov, the Soviet commander in Germany, is reported to have told Stalin that IS-3 made a great impression on Western observers.7 In fact, the IS-3 came to be considered the principal threat to Western armies during the early days of the Cold War, and as ‘Stalin tanks’ they became something of a bogey. However, they suffered from various shortcomings including cracking of the welded joints between their armour plates, some of which was due to them being rushed into production, and they had to undergo a number of modifications that went on until the late 1950s. When they were eventually used in combat, they also proved less formidable than was expected. This was the case in 1956, when some were destroyed in the streets of Budapest during the Hungarian uprising, and when the Israeli forces destroyed or captured 73 of the 100 IS-3s the Egyptian Army employed during the Six Day War of 1967.

The IS-3 was followed after the Second World War by the development of other heavy tanks. First came the IS-4, which was also armed with a 122mm gun but had thicker frontal armour, as a result of which it weighed 60 tonnes compared with the 46.5 tonnes of the IS-3. It was produced from 1947 to 1949 but only about 200 are believed to have been built. Next came the IS-6, which was essentially an IS-4 but with an electric instead of a mechanical transmission. It proved a failure. The third tank to be built was the IS-7, which was armed with a more powerful 130mm gun based on a naval gun. It weighed 68 tonnes, which made it the heaviest tank built in the Soviet Union. Design of the IS-7 was begun in 1945 and a series of four was completed in 1948, but after accidents during trials further development of it was abandoned.8

There was one more heavy tank that was originally called IS-8 but which after Stalin’s death in 1953 was re-designated T-10, breaking the connection of the heavy tanks with the Soviet dictator. In essence, the T-10 was an improved version of the IS-3, and it was armed with a similar 122mm gun but it had thicker armour as a result of which it was heavier, weighing 50 tonnes. It began to be produced in 1950 and continued to be built until 1957, when it was succeeded by an improved T-10M version that was produced until 1962. By then the number of T-10 and T-10M that were produced amounted to about 8,000 tanks.

Four more heavy tanks were developed by 1957, three of them armed with 130mm guns and all weighing between 55 and 60 tonnes. However, none was adopted and further development of heavy tanks was discontinued as a result of a decision taken against it in 1960 by Nikita Krushchev, who came to power in the mid-1950s and who doubted the future of tanks because of the appearance of anti-tank guided missiles.

Krushchev’s views did not put an end to the development of other types of tanks, but they steered some of it in a new direction. This manifested itself from 1957 onwards in a flurry of designs of tanks armed with missiles instead of guns. The earliest Soviet anti-tank guided missiles did not lend themselves, like those produced elsewhere, to installation in tanks, primarily because of the large span of their fins. They were therefore mounted initially on top of BRDM wheeled reconnaissance vehicles. But as new and less cumbersome missiles were developed, a T-62 tank was retrofitted with a new low profile turret out of which popped a launcher with a 3M7 ‘Draken’ missile. Work on this missile-armed tank began as early as 1952 and a number was produced between 1968 and 1970 as IT or Istrebitel Tank (Tank Destroyer). Two battalions were equipped with it, but it was withdrawn from service in 1970.9

Two more missile tanks were developed by 1961 or 1962, both based on the then newly built T-64 and both with only a two-man crew. In one of them, called Object 287, both crew members were seated in the front of the hull and operated an unmanned turret by remote control, the turret being fitted again with a pop-up launcher, in this case with a 3M15 Taifun missile. In the other tank, called Object 775, both crewmen were in the turret, which mounted a short-barrelled 125mm gun that fired unguided rockets or Rubin guided missiles. In their different ways, objects 287 and 775 embodied major departures from conventional tank designs and the latter was as adventurous in some respects as the US-German MBT-70 that began to be designed in 1964. In particular, it had its driver in a rotating turret, like the MBT-70, but whereas the latter still had three men in the turret Object 775 had only two. It was also one of the first tanks to be fitted with an adjustable hydropneumatic suspension, which, when it squatted, enabled it to reduce its already low overall height of 1.65m to even less.10

The 125mm gun/missile launcher of Object 775 was conceptually similar to the 152mm XM81 gun/launcher adopted at about the same time for the US M551 Sheridan light tank and the M60A2 battle tank, but it was in advance of it in having an automatic loading system. However, it suffered from a number of serious problems, related among others to the radio command link of its missiles and the inevitable complication of driving controls created by the location of the driver in a rotating turret. The problems were not resolved and development of Object 775 was abandoned, but its combination of a gun with missiles launched through the gun tube foreshadowed a system later widely used in Soviet tanks.

In the meantime, Soviet tank development took another major step forward with the design of the T-62 tank, which was a derivative of the T-55 but armed with a 115mm smooth bore gun that fired arrow-like projectiles instead of the traditional, full calibre projectiles that until then were the standard armour-piercing ammunition of the Soviet tanks. Its projectiles, which came to be known as Armour Piercing Fin Stabilized Discarding Sabot or APFSDS projectiles, were fired with a muzzle velocity of 1,680m/s, which was higher than that of any other tank gun ammunition in use at the time, and this, together with the slender shape of the projectiles, resulted in greater armour penetration.

Development of the T-62 began in 1958 and was almost concurrent with that of the 90 and 105mm smooth bore guns firing APFSDS projectiles that were being developed in the United States for the T95 tank.11 But whereas the results obtained in the United States were unsatisfactory and the development of the T95 was terminated in 1961, the T-62 was developed successfully and was accepted for use in that year. It was produced in its original form until 1972 and with modifications until 1983, by which time as many as 20,000 are believed to have been built. Most went to the Soviet Army but a significant number was delivered to the Egyptian and Syrian armies, which first used them in combat during the Arab-Israeli War of 1973. They were also supplied to Iraq and to North Korea, where the T-62 has been developed further.

The T-62 was the first tank to come into use armed with a high pressure smooth bore gun firing APFSDS, and as such ushered in the worldwide adoption of this type of armament, which superseded almost all other types of tank guns and kinetic energy ammunition during the 1980s and 1990s. In spite of having an advanced gun armament, the fire power of the T-62M was augmented in 1983 by the provision of guided missiles that could be launched from its gun. The missiles were the 9M117 Bastion laser beam-riders, which were the same as those launched from the 100mm gun of the T-55M and significantly increased the range at which both tanks could engage targets. However, the T-55M and T-62M were not the first to be provided with gun launched missiles in addition to conventional ammunition. This distinction belonged to the T-64 tank, the T-64B version of which, introduced in 1976, fired 9M112 Kobra missiles out of its 125mm smoothbore gun.

Kobra was also fired by the T-80B tank, which was introduced two years later. Its semi-automatic guidance system incorporated a radio command link, and this potentially vulnerable link was still used in the 9M124 Agona missile system introduced in 1988. But it was superseded by laser beam riding guidance when new tube launched missiles were introduced in the 1980s. These included not only the Bastion but also the 9M119 missile, which was part of the Refleks system installed in T-80U and T-90 and of the Svir system of the T-72B and T-72S, all of which were introduced between 1983 and 1993.12

The T-64, in which gun launched missiles were first installed, was the outcome of a programme initiated in 1954 to develop a new tank with a much more compact power pack. To achieve this objective, the designers of the T-64 took advantage of the resources made available to them by the Soviet system to devise a novel closely integrated engine-transmission assembly, instead of combining separately developed engines and transmissions as other designers generally had to do. The engine chosen by them was a two-stroke opposed-piston diesel similar to the Junkers Jumo diesel developed in Germany in the 1930s for aircraft, which enjoyed a reputation for high thermal efficiency.13 The engine was mounted transversely and, unlike any other, was coupled directly on either side of the cylinder block to a multi-speed epicyclic transmission. This eliminated the need for several shafts and gears required by more conventional installations, and resulted in the engine compartment of the T-64 being little more than one half of that of the T-54. In addition, the engine installation of the T-64 incorporated a novel cooling system that used an exhaust gas ejector to suck cooling air through the radiators and thereby eliminated the need for cooling fans as well as simplifying the engine installation. The original four-cylinder engine of this type developed 580hp, but most of the T-64s were powered by a five-cylinder engine that developed 700hp and in its final form by a six-cylinder engine of 1,000hp.

In spite of its potential advantages the original design, designated Object 430, was not pursued at first beyond the construction of three test vehicles because it did not offer sufficient advantage as a fighting vehicle over the T-55, being armed with the same 100mm gun as the latter. When development was resumed in 1961, the T-64 was armed with a 115mm gun similar to that adopted at the time for the T-62. But because of the smaller size of the T-64’s fighting compartment, its crew could not handle the large one-piece ammunition used in the T-62. The T-64 was therefore provided with two-piece ammunition and an automatic loading system of the carousel type installed under the turret, which not only solved the ammunition handling problem but also eliminated the need for a human loader and consequently reduced the crew of the tank to three men.

T-64 was also provided with an optical rangefinder, which increased its probability of hitting targets, but its most important feature was its novel and greatly improved armour protection. This involved a departure from the traditional solid steel armour and the use instead of a sandwich of steel plates and layers of a glass-fibre plastics composite on the front of the hull and of a ceramic material within cavities of the turret. In consequence the frontal protection of the T-64 rose to the equivalent of about 400mm of steel both against kinetic energy and shaped charge projectiles, which was twice the level of protection possessed by earlier Soviet tanks such as the T-55 and T-62.14 In addition, the T-64 was provided with a liner of a nuclear radiation absorbing material.

The T-64 began to be produced in 1963, but within a year it was followed by the T-64A, which was armed with a new 125mm smooth bore gun. This gun fired APFSDS projectiles with a velocity of 1,715m/s, which was higher than that of other contemporary tank guns. Thus, when the T-64A came into service with the Soviet Army in 1968, it provided it with a tank which was well ahead of others in terms of gun power and was also well armoured, and yet weighed only 38 tonnes.

T-64A and the very similar T-64B became the main tanks of the T-64 series and T-64B continued to be produced until 1987. How many were built is not clear, but in 1990, before the collapse of the Soviet Union, Soviet authorities reported under the terms of the Conventional Forces in Europe (CFE) Treaty that there were 3,982 T-64 series tanks west of the Urals. Whatever the total produced, all T-64s went to the Soviet Army as none was exported, in contrast to other Soviet tanks.

For all its virtues, T-64A was open to criticism, mainly on account of its engine being expensive to produce, difficult to start in cold weather and unreliable. This led to a decision in 1967 to develop an alternative engine for the T-64, which took the form of a 1,000hp gas turbine.15

The use of gas turbines to power tanks began to be considered in the Soviet Union as early as 1949. It may have been prompted, like the contemporary development of gas turbines for tanks in Britain, by the exploratory work on them in Germany towards the end of the Second World War, but nothing came of it until 1955 when development began of a pair of 1,000hp gas turbines that were to power a heavy tank. But the latter was never built as a result of the decision taken by Krushchev to end the development of heavy tanks. However, in 1963 experiments began with helicopter gas turbines installed in T-62 and T-64 tank chassis. The results were discouraging, largely because of the high fuel consumption of the gas turbines, which was to be expected. Nevertheless, a decision was taken to produce a tank powered by a gas turbine, which became the T-80.

Compared with the Avco Lycoming AGT-1500 gas turbine that was being developed at about the same time for the US M1 battle tank, the Soviet GTD-1000T gas turbine was simpler and more robust, having a two-stage centrifugal compressor instead of a multi-stage axial flow compressor, and it was more compact as it had no recuperator, or heat exchanger, to recover some of the heat from the exhaust gases and improve thereby the thermal efficiency of the engine. The use of recuperators has been considered essential for automotive gas turbines to make them viable, but the developers of the T-80 have subsequently claimed in justification of their decision not to use one that recuperators do not work very efficiently when the output of engines fluctuates, as it does when they power tanks. Moreover, they have claimed that the vehicle weight saved by the smaller size of a gas turbine without a recuperator compensates to some extent for its higher fuel consumption, so that the overall fuel consumption of a tank would be much the same whether it had a gas turbine with a recuperator or not.16

Be that as it may, the fuel consumption per mile of the T-80 proved to be twice that of a similar tank powered by a conventional four-stroke diesel. At the same time the cost of producing the GTD-1000T was almost 11 times that of the latter.17 On the other hand, GTD-1000T offered a higher power-to-weight ratio and therefore greater agility than that of the T-64 with the 700hp 5TDF two-stroke diesel, although the latter was eventually replaced by the 6TD of 1,000hp while the gas turbine was developed into the GTD-1250 of 1,250hp. Other advantages of the gas turbines included much more reliable starting at low ambient temperatures, elimination of water cooling and low lubricating oil consumption.

Before it was adopted, the gas turbine was extensively tested under a variety of climatic conditions mounted in more than 60 test vehicles based on the T-64 chassis, and the tank that it powered was finally accepted for service with the Soviet Army in 1976 as the T-80. Production began at the same time and continued until 1987.

Engines apart, the T-80 was very similar to the T-64A on which it was in fact based. It had the same general configuration, a similar 125mm smooth bore gun with a carousel-type automatic loading system, and comparable armour protection. The only major difference between the two was the T-80’s greater agility, but this hardly justified its development, particularly in view of its higher production cost and the additional logistics burden it created.

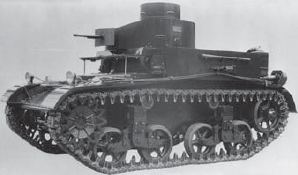

A much more rational move than the production of the T-80 was the development of another variant of the T-64, which was powered by an uprated version of the 12-cylinder diesel that had powered most Soviet tanks from the BT-7M of 1939 onwards. By adding a mechanically driven supercharger, the output of this remarkably durable engine was raised from the 580hp of the naturally aspirated V-55 model that was used in the T-62 to 780hp of the V-46 version, and this made it a potential alternative to the two-stroke engine of the T-64 and the gas turbine of the T-80.

Use of the V-46 as a back-up engine for the T-64 began to be considered as early as 1961 and was pursued between 1966 and 1969, leading to the conclusion that the mobility of the T-64 when powered by it would be as good as that of the standard version.18 After modifications, particularly to its suspension and autoloader, what was basically a T-64 with the V-46 engine was accepted in 1973 as the T-72.19 Once its production began, the T-72 was built on a large scale, the number produced amounting to more than 30,000 according to its manufacturers.20 However, the number reported in 1990 under the terms of the CFE Treaty to be west of the Urals was only 5,092, and of the total produced 6,000 were exported to several countries.21 The T-72 was also built in a number of countries, sometimes under different designations, including India, Iran, Poland, Slovakia and Yugoslavia.

During the course of its production the T-72 was improved in several respects, as were the T-64 and T-80. This included improvements to their protection, the most important of which was the addition of explosive reactive armour or ERA. (For details of this see Appendix II.) Its adoption increased considerably the protection of Soviet tanks against shaped charge anti-tank weapons and because of this caused consternation in NATO, which relied to a large extent on such weapons to counter a possible onslaught by Soviet armoured formations in Central Europe.

ERA was originally put to use by Israeli forces, appearing for the first time on Israeli tanks in 1982 during the operation ‘Peace for Galilee’. This incursion by Israeli forces into the Lebanon involved clashes with the Syrian forces, which are widely believed to have captured an Israeli tank with ERA and to have passed it on to the Soviet Union, where the ERA was copied. In fact, the Russians had been working on ERA for several years prior to this, but because of accidental explosions and other problems decided not to use it until they saw it on Israeli tanks, when they took it up again.22 The decision to use ERA was taken quickly and in 1983 T-64BV began to be produced with it, at the cost of an increase in weight from about 40 to 42.4 tonnes. Two years later ERA also began to be fitted to the T-72 and T-80.

In addition to adopting ERA on a large scale, the Russians developed it further following the original or ‘light’ type, which was effective only against shaped charges, with a ‘heavy’ or Kontact 5 type effective also against the long-rod penetrators of APFSDS projectiles. The essential difference between the two types was that the steel plates of the steel-explosive-steel sandwiches of the original or ‘light’ ERA were only 2 or 3mm thick, whereas those of the ‘heavy’ ERA were considerably thicker, typically of the order of 15mm.

The Russians were also the first to develop a much more sophisticated type of protection against anti-tank guided missiles in the form of the Drozd active protection system. This appeared for the first time in 1983 on a T-55AD and consisted of a millimetre wave radar to detect incoming threats and a cluster of four launchers on each side of the turret with 107mm rockets, one of which would be fired at a threat missile at the appropriate moment determined by the system’s computer to shower it with fragments and thereby damage or destroy it.23 In contrast to other active protection systems developed elsewhere several years later that provided all-round protection, Drozd’s rocket launchers only covered a frontal arc of 80º, but this would have been sufficient for tanks used for frontal assaults. In addition to T-55AD, Drozd was also installed on some T-62D tanks, but its use has been limited, other Soviet tanks continuing to rely on ERA to augment their built-in passive armour protection.

When the last of the trio of Soviet tanks, the T-80, was adopted in 1976, the T-72 was already in production and so, even more, was the T-64. This created a bizarre situation, as it meant that the Soviet Army had three tanks armed with the same 125mm gun and with basically much the same combat capabilities but powered by different engines and having different hulls, running gear and fire control systems. These differences were bound to create operational as well as logistics problems, and there were also considerable differences in the production costs, that of the T-80 being almost twice the cost of the T-72. Rationalization was inevitable and very sensibly resulted in concentration on the tank that cost least to produce and to operate, which was the T-72. But concentration on the T-72 was not implemented for some time.

The T-80U continued to be built on a small scale, partly to provide work for the factory in Omsk that produced it, and a new, T-80UD version powered by a more powerful 1,000hp 6TD diesel instead of the gas turbine was adopted in 1985. However, it ceased to be available to the Russian Army after the collapse of the Soviet Union because it was built in the Ukraine.

The collapse of the Soviet Union also created a problem of disposal of the large fleet of armoured vehicles belonging to the Soviet Army. On the eve of its collapse, the Soviet Union reported to the United Nations that on 1 January 1990 it had 63,900 tanks and in 1990, under the terms of the CFE Treaty, 21,296 tanks were declared to be west of the Urals. By 1997 the Russian Army was reported to have been left with a total of 5,546 tanks there. What happened to the rest is not clear, except that negotiations held in Tashkent in 1992 allocated 6,400 of the former Soviet tanks to Russia, 4,080 to the Ukraine, 1,800 to Belarus and 200-odd to each of the four newly independent republics.24 But this accounted for only 13,150 tanks. Some of the older vehicles, which included T-34-85, were no doubt scrapped, but many others must have been retained east of the Urals, and in 2006 the Russian Army was still stated to have about 20,000 tanks.25

Some further development and small scale production of the T-80 and T-72 took place during the period of dissolution of the Soviet Union. In particular, improvements were made to the T-72, which included the installation of a more advanced fire control system already used in the T-80 and of the Shtora infrared jammer or missile decoy system as well as an uprated 840hp V-84 version of the venerable V-54 engine. While it was still being tested, the improved T-72BU was accepted in 1992 for service by the Russian Army as the T-90, and four years later it was confirmed that it would be the only tank produced for it, although the T-80U continued to be offered for export and a small number was actually sold to Cyprus and to South Korea.

Production of the T-90 for the Russian Army has been at a low rate and only about 300 are believed to have been built by 2006.26 However, in 2001 the Indian Army ordered 310 of the T-90S export version, deliveries of which commenced in 2004. Subsequently a licence agreement was reached for the production of 1,000 T-90S in India, and in 2007 a contract was signed for 347 additional T-90S to be supplied in kit form. Thus, when all the tanks are built, the Indian Army should have 1,657 T-90S.

T-90S tanks of the Indian Army retain the 9M119 Refleks system with guided missiles launched out of their 125mm smooth bore guns, but they are powered by an uprated turbo-charged V-92S development of the V-46 engine that develops 1,000hp and consequently increases the agility of the 46.5 tonnes tank.

By a quirk of fate, the procurement by India of T-90S tanks was driven by the acquisition of another tank of Soviet origin, the T-80UD, by its traditional enemy, Pakistan. Both tanks were derived from the T-64 and were very similar except for their engines, but the T-90S was produced at Nizhny Tagil in Russia whereas the T-80UD was built in Kharkov in the Ukraine. As a result, after the break-up of the Soviet Union the production of T-80UD became separated from that of tanks in the Russian Federation, and this helped Pakistan to order it. The order, issued in 1996, was for 320 tanks, all of which were delivered by 2002.

T-80UD was developed further in Kharkov by its designers, the Morozov design bureau, into the 46-tonne T-84, which was basically similar but had improved protection and a more powerful 1,200hp 6TD-2 version of their two-stroke diesel. The Morozov bureau then developed the T-84 into the T-84-120, which departed from what had been the two standard features of Soviet/Russian/Ukrainian tanks for more than 30 years. One of them was the use of a Soviet-designed 125mm gun, which was replaced by a 120mm smooth bore gun that fired NATO standard ammunition. The other standard feature of Soviet designed tanks was a carousel-type autoloader located under the turret, which was abandoned in the T-84-120 in favour of a bustle autoloader. This was an inevitable consequence of the adoption of the 120mm gun, as its one-piece ammunition could not be accommodated in the carousel. But it also made the tank less vulnerable, because it relocated most of its ammunition in the turret bustle and separated it from the crew by a bulkhead that protected it in the event of an ammunition explosion, as the bustle compartment did in US M1 tanks.

A similar change was made in the mid-1990s in Russia, where the experimental T-80UM2 Black Eagle tank was also fitted with a bustle autoloader instead of the carousel type, although it retained the 125mm gun of its predecessors. Another and much more advanced tank, called the T-95, had been worked on in Russia since the mid-1990s, but its development was abandoned in 2010.

The importance that the Soviet Army consistently attached to tanks stood in marked contrast to the fluctuating attitude towards them by the US Army. Thus at the end of the Second World War the US Army had 16 armoured divisions incorporating 52 tank battalions and 65 independent non-divisional tank battalions. But within three years of the end of hostilities, hasty demobilisation and doubts about the future of tanks reduced US armoured forces to a single division.27 This represented a sweeping reduction not only in absolute but also in relative terms, as the rest of the Army consisted at the time of nine infantry divisions, while during the war the ratio of armoured to infantry divisions was approximately one to five. In contrast, the Soviet Army not only maintained large armoured forces, estimated at the time at 35 to 70 divisions, but increased considerably their number in relation to the rest of its forces.28

The one US armoured division had a nominal strength of 373 tanks. The only other tanks the US Army had were in the divisional tank battalions and the regimental tank companies of the infantry divisions, each of which had a nominal total of 147 tanks. There were no independent tank battalions and no battalions of tank destroyers, the number of which had grown to 106 during the war but which disappeared in its aftermath with the abolition of the Tank Destroyer Command. The disappearance of the latter was in itself unlamented because of the harmful influence its existence had on US tank development during the war.

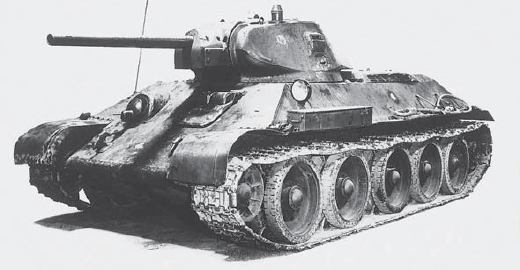

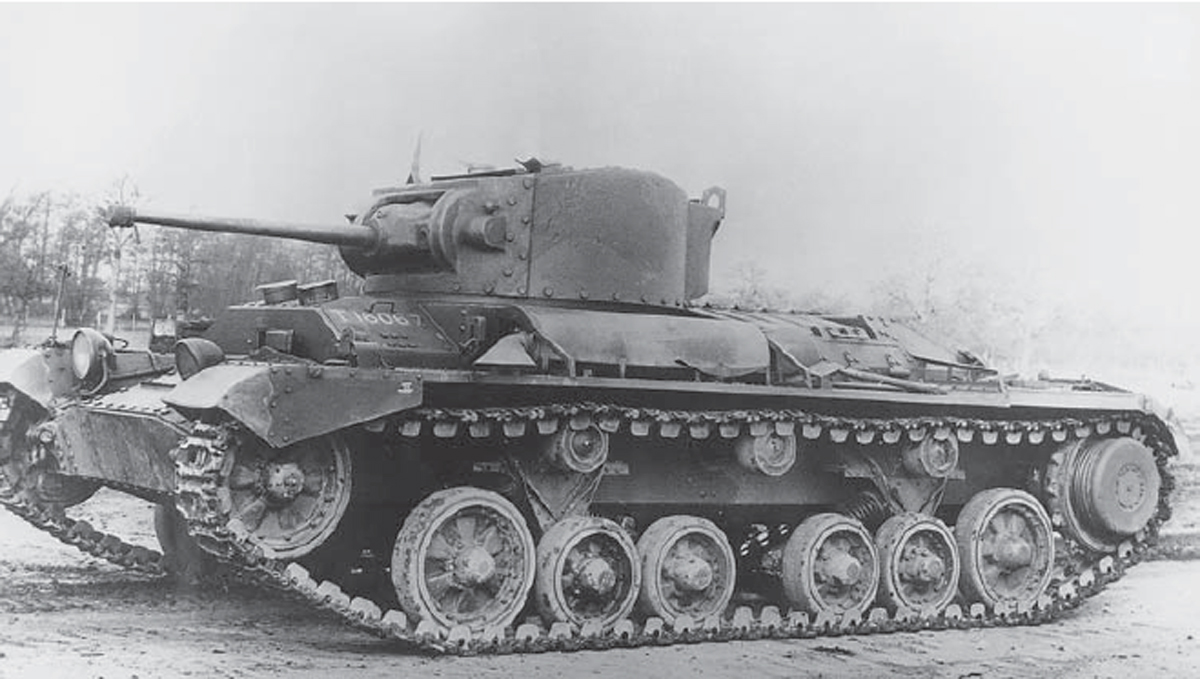

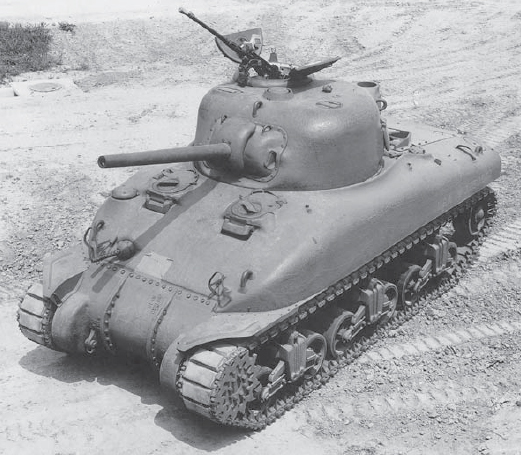

The situation changed dramatically in June 1950 when North Korean troops led by about 140 Soviet-built T-34-85 tanks almost overran South Korea, which altered radically the perception of tanks in the United States. The immediate reaction consisted of the deployment of US tanks available in the area, but they were confined to four companies of M24 light tanks that were part of the US infantry divisions on occupation duty in Japan. Moreover, the M24 tanks with their medium-velocity 75mm guns were no match for the T-34-85, and the balance was not redressed until the arrival in August from the United States of five tank battalions equipped with Shermans and M26 Pershings.

At about the same time the number of armoured divisions was raised to six, although four of them were only training formations, and one of the two that was combat-ready was sent in 1951 to Germany to counter a possible Soviet threat in Europe. Until then the only mobile US forces in Germany consisted of three constabulary brigades, which had some light tanks.

The outbreak of the war in Korea also accelerated the development of new tanks. Equipment boards convened just before the end of the Second World War and immediately after it called for the development of three categories of light, medium and heavy tanks. However, funds available to the US Army were limited, defence budgets being dominated by nuclear weapons and their delivery systems. In the circumstances it was considered more productive to develop new components rather than new tanks. This policy resulted in the production of new engines, transmissions and other components, and when the threat posed by the Soviet Union was belatedly recognized these were used to improve the capabilities of the most effective of the available US tanks, which were the M26 Pershings. When re-engined these became M46 Pattons, and in 1949 there were already enough of them to equip one of the five battalions sent a year later to bolster US forces in Korea.

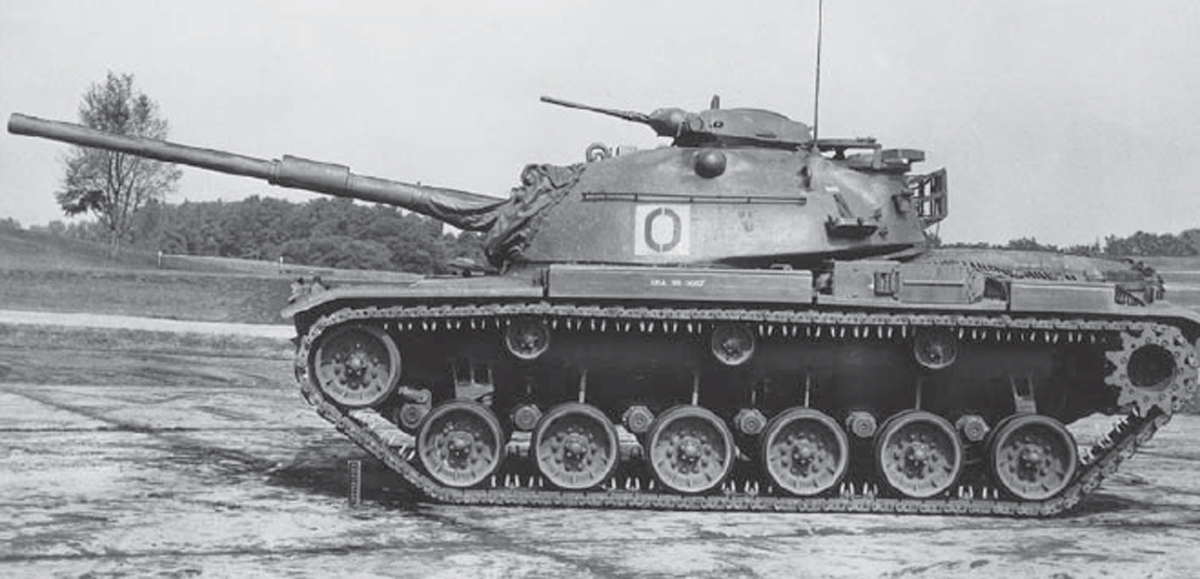

As the number of Pershings available for conversion was limited some new M46s were produced, but once the war in Korea broke out more modern tanks were demanded. The design of a new T42 medium tank had actually begun in 1949, but it had not advanced sufficiently by 1950 for it to go into production. This led to an emergency programme that resulted in the combination of the new turret of the T42 with the proven chassis of the M46. The first of the M47 tanks that came out of this was produced in 1951. Its general characteristics were not very different from those of the M46, but its 90mm gun was somewhat more powerful and it was the first US tank to have an optical (stereoscopic) range finder, which increased the gun’s probability of hitting targets. At 45.5 tonnes it was 2 tonnes heavier, but it was powered by a similar 810hp V-12 air-cooled gasoline engine and had the same maximum road speed of 30mph.

Production of the M47 continued at a high rate until 1953, when it reached a total of 8,576 tanks.29 It was criticized for its extremely short operating range of 70 miles, even on roads, and for problems with its stereoscopic rangefinder, which was difficult to use. However, the US Army did not have to use it for long as after a few years most M47s were passed on to Allied armies when a new US medium tank became available. The principal recipients of the M47 were the German Army, which received the first in 1956, and the French Army. When others followed, the M47 became almost the standard Western European tank of the late 1950s and early 1960s.

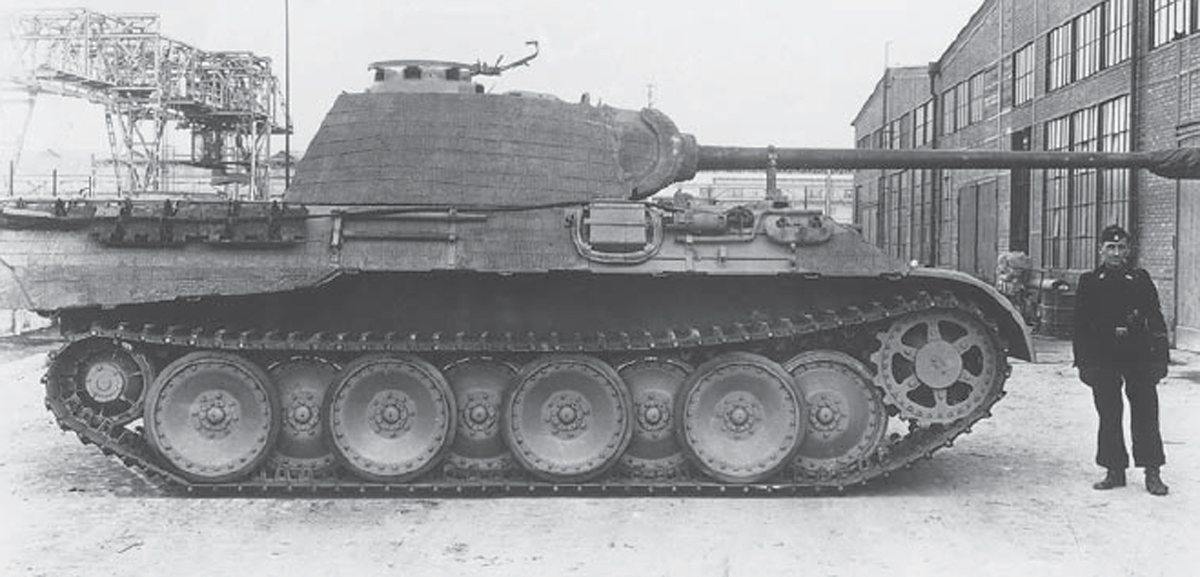

The new US medium tank was the M48, which had much the same automotive characteristics as the M47 and was armed with a 90mm gun similar to that of its predecessor. But it dispensed with the hull machine gunner, which reduced its crew to four and contributed to it having a ballistically better-shaped elipsoidal hull. It also had an almost hemispherical turret and a lower silhouette. Production of it began in 1952, only two years after its design was started, and continued until 1959, by which time 11,703 had been built. Most went to the US Army but, once again, a significant number was supplied to Allied armies and in particular to the German Army, which received the first of 1,666 M48 tanks at the end of 1957.30 Eight years later some of them were passed on to Israel.

Because they were rushed into production, early M48s suffered from a number of problems and many had to be rebuilt before they could be issued to the armoured units. But once the problems were rectified, M48 proved to be a good and robust tank that matched its potential adversary, the Soviet T-54, although it was armed with a 90mm rather than a 100mm gun.

So far as the gun power of US tank units was concerned, the M48 was to be backed by a more powerfully armed heavy tank. A tank of this kind, the 56.5-tonne M6, armed with a 3in and then 105m gun was designed in 1940, but although 43 were built none was sent to the fighting fronts because the US Army preferred to have medium tanks, two of which could be shipped for each heavy tank.31

Nevertheless, other heavy tanks began to be developed towards the end of the Second World War. The first was the turretless T28 assault tank, which had frontal armour 305mm thick and weighed as much as 84.8 tonnes. However, only two were completed after the war. Other experimental heavy tanks were turreted. Their general configuration was similar to that of the M26 Pershing and they shared some of their components with it. But two of them, designated T29, were armed with 105mm guns, while two T30s were armed with 155mm guns, and the T34 that followed was armed with a modified 120mm anti-aircraft gun whose armour-piercing performance was superior to that of the other guns. In all cases the weight of the tanks was much the same, being in the range of 63 to 64 tonnes.

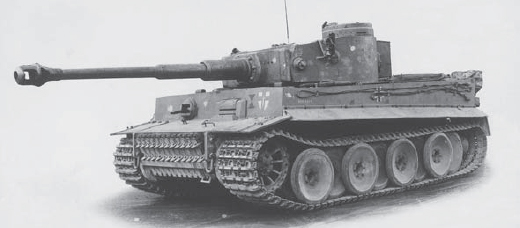

The development of the US heavy tanks was inspired by the appearance of the German Tiger II heavy tank, and at one stage the procurement of as many as 1,200 T29s was contemplated.32 However, only eight T29s were eventually built, two or three years after the war. By then a new threat had emerged in the shape of the Soviet IS-3 heavy tank, and this spurred further development of heavy tanks in the United States.

The only available design was that of the T34, but the Army objected to its 64-tonne weight. A lighter 56-tonne version was therefore devised and was adopted as the T43 and later M103 heavy tank. Prototypes of it were built in 1951 and 300 were produced between 1953 and 1954, but, oddly enough, only 80 went to the US Army, which in 1958 deployed a single battalion of 72 tanks in Germany. The rest went to the US Marine Corps, which used them until 1973.33

An unusual feature of the M103 heavy tank was its large turret, which had a crew of four as it included two loaders to handle the heavy ammunition of the tank’s 120mm gun, one round of which weighed 48.8 kg. In contrast, the Soviet IS-3 heavy tank retained the customary turret crew of three, in spite of having a 122mm gun, by using ammunition with separate projectiles and propellant charges and accepting a slower rate of fire.

A solution to the problem of handling heavy ammunition was sought in the use of the oscillating or trunion mounted turret pioneered by the French AMX 13 light tank, a prototype of which was tested in the United States in 1950. Two experimental heavy tanks with oscillating turrets on T43 tank chassis were consequently built between 1951 and 1957, the T57 with a 120mm gun and the T58 with a 155mm gun. In both cases the guns were automatically loaded, but neither tank was accepted and they were the last of the separate category of heavy tanks to be built in the United States.

The third type of tank envisaged by the US Army after the war was the M41 light tank, a 22.9-tonne vehicle with a crew of four and a 76mm gun. It was the first of the post-war generation of US tanks and it began to be developed as early as 1946. But its development proceeded slowly until the outbreak of the war in Korea, when it was rushed into production, continuing until 1954 when 3,729 had been completed.34 The haste with which it was produced led initially to problems, but its general design was sound. However, it was too large for a reconnaissance vehicle and not powerful enough to be an effective combat vehicle, even though its 76mm gun fired projectiles with a higher muzzle velocity than that of the guns of the wartime M4 medium tanks. It was not therefore very profitable for the US Army to devote some of the limited amount of money it had in the immediate post-Second World War period to the development of what was originally designated the T37 and then M41 light tank.

Medium tanks were certainly a better investment, but to remain effective over a number of years they required continuous development. By the mid-1950s this was focused on the M48, which was gradually improved by being retrofitted with a diesel derivative of its gasoline engine that increased its operating range on roads from about 70 to 300 miles. Its stereoscopic rangefinder was also replaced by one of an easier to operate coincidence type. Finally, by about 1959, its 90mm gun was replaced by a much more effective 105mm gun. Yet its weight only increased from the 44 tonnes of the original M48 to the 48 tonnes of the final M48A5.

Attempts to increase the gun power of the M48 started as early as 1951, and led initially to two experimental T54 versions with 105mm guns. One of them had an oscillating turret and automatic loading of its gun, but neither was adopted. Another attempt made later resulted in the T77 armed with an automatically loaded 120mm gun, but this was also abandoned in 1957.35

In 1954, instead of trying to make the M48 more powerful, the US Army decided to develop an entirely new tank, the T95. This was to be armed with a 90 or 105mm smooth bore gun firing what was then a new APFSDS type of projectile capable of perforating thicker armour than the traditional kinetic energy ammunition. In consequence, the T95 was considered to be a successor to heavy as well as medium tanks. The first of nine experimental T95s was built in 1957, but problems were encountered with the smooth bore guns, which included a high dispersion of their fin-stabilized projectiles, and in 1958 a group of senior US Army officers concluded that the T95 offered only a marginal improvement over the M48A5 and that the desired increases in firepower and mobility could be achieved at less cost by upgunning the M48A2 and replacing its gasoline engine by a diesel.36 This was accepted and work on the T95 and the smooth bore guns was terminated. Had it been pursued, the US Army might have been the first to field a smooth bore tank gun. As it was, this was left to the Soviet Army, which was developing smooth bore tank guns at about the same time and produced the first tank armed with one, the T-62, in 1961, as mentioned earlier in this chapter.

The place of the T95 was taken by an ‘interim main battle tank’, which became the M60, and was in effect an M48A2 armed with a US M68 version of the British 105mm L7 gun and powered by an AVDS-1790 diesel engine. The M60 was adopted in 1959 and began to be produced a year later, after which it continued to be built, with modifications, until 1987 when a total of 15,221 had been produced for the US Army and a number of friendly countries.

The adoption of the 105mm M68 gun for the M60 was well justified, as the L7 gun from which it was derived was probably the best gun that was available in 1959 because of the performance of its APDS ammunition. However, the concurrent US Army decision to abandon the development of smooth bore guns was short sighted, as they were to prove superior in the long run to rifled tank guns. In fact, in 1960 the US Army was on the verge of successfully developing one, the 120mm Delta gun. This gun fired APFSDS projectiles with a velocity of 1,615m/s, which was higher than that achieved with APDS ammunition fired from any rifled gun.37 Fortunately the example of the Delta gun was taken up in Germany, where the Rheinmetall company successfully developed a similar 120mm smooth bore gun for the Leopard 2 tank, and some 20 years later this gun was also adopted by the US Army for its M1 tank.

One reason why the US Army did not pursue the development of the Delta gun was that those in charge of US tank development became beguiled by the perceived performance of guided missiles. This manifested itself in 1957 when the ARCOV (Armament for Future Tanks and Similar Combat Vehicles) committee established by the US Army Chief of Staff to review the development of tanks recommended that future tanks should be armed with guided missiles. The recommendation was accepted and in 1959 the Aeronutronics Division of the Ford Motor Company started to develop the Shillelagh, a semi-automatic command-to-line-of-sight or SACLOS missile, and a short-barrelled 152mm gun launcher from which the missile could be fired and which could also fire conventional medium-velocity projectiles.

The 152mm gun launcher was envisaged to be the main armament of battle tanks as well as that of an air-transportable light armoured reconnaissance vehicle that was expected to take the place of more conventional light tanks. To start with, it was decided to install it in some of the M60 tanks. The latter were modified by being provided with a novel low frontal area turret, which was meant to reduce the area they exposed to enemy fire. But their silhouette was ruined by the addition of an exceptionally large commander’s cupola that increased their overall height to 3.3m, or one metre more than the overall height of the contemporary Soviet tanks.

The installation of the 152mm gun launcher in the M60 was originally thought to be a relatively simple matter of upgunning an existing well-established tank. But it proved to be problematic and this delayed the deployment of the resulting M60A2, of which 540 were produced. A prototype of the M60A2 was built in 1967, but the first of six battalions, each equipped with 59 tanks, was only deployed in Europe in 1975. When it finally came into use, the M60A2 was not popular because it was complicated and difficult to maintain, and it was taken out of service after a few years.38

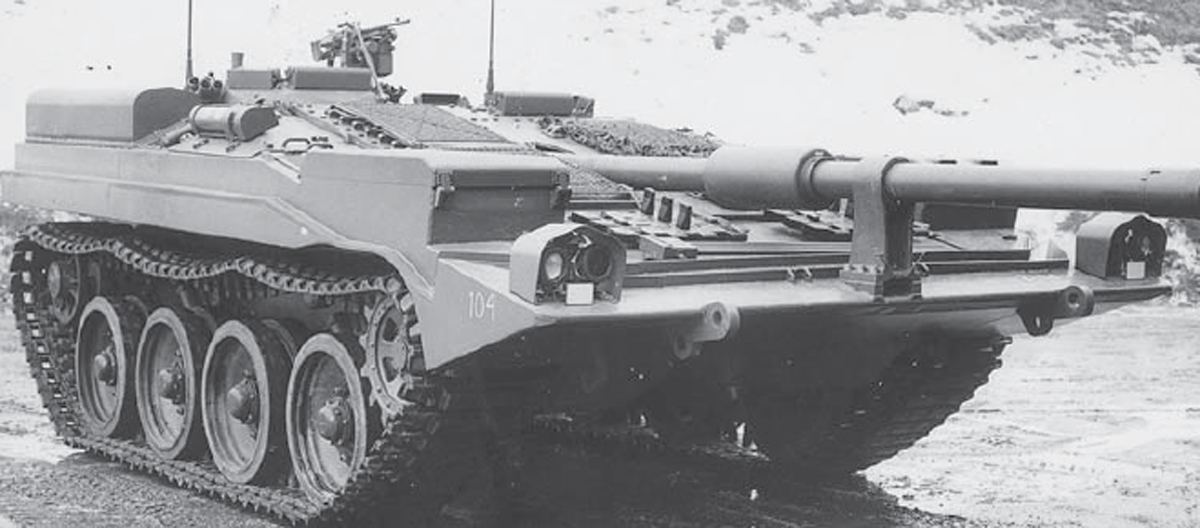

In addition to being used as battle tank armament, the 152mm gun launcher appeared to be a solution to the problem of combining low vehicle weight with powerful armament. It was therefore adopted as the armament of the Armored Reconnaissance/Airborne Assault Vehicle, which began to be studied in 1959 and which became the M551 Sheridan. The armament of this light tank made it remarkably powerful in relation to its weight of 15.8 tonnes, but it suffered from a number of problems, which included smouldering debris left in the gun by the combustible cases of its conventional ammunition and the jolt this ammunition gave to the vehicle on firing, which made the missile system inoperable as well as threatening injury to the crew. Nevertheless, Sheridans began to be produced in 1966, and in 1969 two squadrons with 64 of them, stripped of their missile systems, were sent to Vietnam, where they proved vulnerable to mines because of their light armour and where they were less popular than M48 tanks. Others were then sent to the US forces in Europe where they replaced M41 light tanks. But in 1978 most were withdrawn from service.39 Of the 1,662 that were produced, only one battalion was retained as part of the 82nd Airborne Division. During the First Gulf War of 1991, this battalion with its 56 Sheridans was flown to Saudi Arabia in C-5 Galaxy transport aircraft and was then deployed within the theatre by a shuttle of six C-130 Hercules aircraft, but in the course of the operations against the Iraqi forces fired only one Shillelagh in anger.40

Soon after the US Army decided that future tanks should be armed with guided missiles, the United States entered into discussions with Germany about the joint development of a new battle tank. This was promoted by the US Secretary of Defense, R. S. McNamara, as a means of saving money by sharing costs, and was agreed to by the two countries in 1963. Concept studies began a year later and the first of six prototypes of the selected design, which was called MBT 70, was built in 1967.41

The 50-tonne MBT 70 was expected to advance the state of the art in almost every respect, which resulted in it incorporating several components and features that were new and relatively untried. The most novel of them was the turret, which contained the whole of its three-man crew, including the driver. Within the turret the crew would be protected against nuclear radiation and chemical contamination, and the driver’s location in the turret helped to lower the silhouette of the tank but required providing him with a counter-rotating capsule that complicated controls and did not entirely prevent disorientation.

In keeping with the contemporary adoption of the 152mm gun launcher and the Shillelagh missiles for the M60A2 and the Sheridan, the US Army wanted the MBT 70 to have a similar armament, but the German Army preferred, wisely, a gun firing high-velocity kinetic energy projectiles. The difference was resolved by the development of a new version of the 152mm gun launcher with a barrel 30.5 instead of 17.5 calibres long, which could fire APFSDS projectiles with a muzzle velocity of 1,478m/s but that could still also fire Shillelagh missiles.

Development of the various new components and their integration into the MBT 70 created problems that considerably increased its cost. By 1969 this was estimated to have risen to one million dollars or four times the cost of an M60A1. The high cost drew the attention of the US Congress, which forced the US Army to terminate the development of MBT 70. At the same time Germany withdrew from the joint programme. The US Army tried to continue the development by itself of an ‘austere version’ designated XM 803, which it claimed would cost 600,000 dollars. But Congress considered that each might still cost more than one million dollars and declared that MBT 70/XM 803 was ‘unnecessarily complex, excessively sophisticated and too expensive’.42 In consequence Congress put an end to its further development in 1971 – an ironic end to a tank programme that was touted by McNamara as a cost saver.

Although Congress withheld funds for further development of the MBT 70/XM 803, it recognized that the US Army needed a new tank and in 1972 authorized the design of one that would cost no more than 500,000 dollars. An Army task force then drew up a set of design criteria, and in 1973 Chrysler and General Motors were awarded contracts for the construction of prototypes for competitive evaluation. One prototype of each competing XM1 tank was completed in 1976, and later that year the Chrysler design was selected for further development, ostensibly because it was offered at a lower price.

Both XM1 prototypes had the same conventional configuration and four-man crew, and both were armed with the same 105mm M68 rifled gun as that already used for several years in the M60. However, the 105mm gun had been given a new lease of life by the development of ammunition with a slipping driving band that prevented it being spun by the rifling. This enabled it to fire fin-stabilized projectiles, including APFSDS, which perforated thicker armour than the APDS projectiles on which it previously relied. The improved performance made the 105mm gun competitive with larger calibre British and German guns, but although it was adopted in preference to them it was decided that the XM1 would be armed at a later stage with the 120mm smooth bore gun developed in Germany by Rheinmetall.

In contrast to the MBT 70, in the specification of which firepower and mobility preceded survivability in the order of importance, the latter became a priority in the design of XM1 and a critical issue, since it was being designed in the aftermath of the Arab-Israeli War of 1973, which gave rise to doubts about the future of tanks because of their perceived vulnerability to anti-tank guided missiles. But, fortunately for the XM1, the head of the task force set up to define its characteristics, General W. R. Desobry, happened to visit in 1972 the British Fighting Vehicles Research and Development Establishment (FVRDE) and learnt of the development there of a new type of armour, called Chobham armour after its location, which was much more effective against shaped charge weapons than steel armour.43 This led to the adoption of Chobham armour by the US Army and a visit to FVRDE in 1973 by Chrysler and General Motors engineers, who subsequently modified their prototypes of the XM1 to incorporate the new type of armour in them instead of the simple spaced armour or the arrays of several separated steel plates that they were originally meant to have and that represented the best form of protection devised until then against shaped charges.

The principal difference between the two prototypes was their engines. That of the General Motors prototype was a 1,500hp Teledyne Continental AVCR-1360 similar to one of the engines of the MBT 70. It was an unconventional variable compression ratio air-cooled diesel based on some research in Britain, which delivered more power in relation to its capacity than conventional diesel engines. But it was more complicated and had difficulty in achieving good combustion over the whole of its operating range, which manifested itself at times in clouds of black exhaust smoke. The Chrysler prototype was powered by a 1,500hp Avco Lycoming AGT-1500 gas turbine which was originally designed for the MBT 70 but was never tested in it.44 The available evidence indicated that its fuel consumption would be significantly higher than that of a diesel and it was considerably more expensive to produce, which forced Chrysler engineers to economize on the fire control system and other components of their tank in order to remain within the overall cost target. However, the gas turbine had its proponents in the US tank community, who claimed that its fuel consumption would be only slightly higher than that of the diesel.45 The writer was drawn into the ensuing debate and estimated that the fuel consumption of a tank powered by the AGT-1500 would actually be 60 to 70 per cent higher than that of a tank powered by a good diesel, which the AVCR-1360 unfortunately was not.46 In fact, the situation proved to be even worse, as demonstrated several years later when the gas turbine powered M1 tank competed unsuccessfully with the German diesel-powered Leopard 2 for a Swedish Army order, and over the same extensive mileage used twice as much fuel.47

Nevertheless, the Chrysler design was approved for production in 1979 and began to be built in the following year as the M1 Abrams. But in 1982 Chrysler Defense Division was sold to the General Dynamics Corporation, who then produced most of the M1s. After 2,374 of the original 105mm gun-armed version were completed in 1985 production switched to the M1A1, which was armed with the US version of the 120mm smooth bore Rheinmetall gun. The M1A1 version began to be issued to US armoured and infantry divisions in Germany in 1988 and its production continued until 1993, when a total of 8,141 M1 series tanks was completed for the US Army. In addition, 221 M1A1s were produced for the US Marine Corps and 315 and 218 were also built respectively for Saudi Arabia and Kuwait, while Egypt ordered 555 M1A1s and partly produced them itself, eventually raising the total of M1A1 tanks it had to 1,055.

M1 tanks were first used in action in 1991 during the First Gulf War, for which as many as 3,113 were transported from the United States to the Middle East.48 During the 100-hour land campaign they destroyed a number of Soviet-built T-72s while avoiding destruction themselves, partly because of the advantage of having thermal imaging sights that enabled them to detect targets when their opponents could not. A much smaller number was used during the invasion of Iraq in 2003, when they again outgunned the opposing T-72 as well as T-55 tanks but proved vulnerable to attack at close quarters by RPG-7 rocket propelled anti-tank grenades. The massive fuel demands of the M1 tanks were met on both occasions by a very extensive logistics support organization, but in 1997, when trying to sell more M1 tanks, General Dynamics recognized the objections to their gas turbine and replaced it by the German-developed Europack based on a MTU MT 883 diesel. This reduced the fuel consumption significantly, but its use did not advance beyond a prototype.

Studies of a potential successor to the M1 started soon after its production began, but only led to a series of abortive development programmes. The first of them, called the Future Close Combat Vehicle Program, came into being in 1981 and was aimed at a family of armoured vehicles based on a common chassis which meant, among other things, that an infantry fighting vehicle would use the same chassis as a battle tank. However, the programme only led to further studies under the Heavy Forces Modernization and Armored Systems Modernization programmes, the last of which was reduced to the upgrading of the M1 by 1993 when the Soviet threat had receded.

Development of subsystems and components that was pursued in parallel with the vehicle programmes produced more concrete results. One of them was the Tank Test Bed, which consisted of an M1 tank chassis with an automatically loaded 120mm gun mounted in an unmanned low frontal area turret remotely operated by a crew of three located in the front of the hull. Work on this experimental vehicle began in 1981 and was completed five years later, but, surprisingly, it was abandoned without being fully developed. Another significant development was that of a 140mm smooth bore gun, which started in 1985 and led to its installation, together with a bustle autoloader, in a modified M1 tank. Guns of a similar 145mm calibre were already specified for tanks under the Future Close Combat System Vehicle Program, and the 140mm XM 291 gun became part of the Future Tank Main Armament Programme set up in collaboration with Britain, France and Germany. The gun began to be tested in 1987 and its APFSDS projectiles had twice the muzzle energy of 120mm gun projectiles, but it came to be considered unnecessary for the defeat of enemy tanks and was not adopted.

An entirely different series of developments was initiated in 1973 by the Defense Advanced Research Projects Agency (DARPA), which was prompted by two events.49 One of them was the progress being made at the time with smooth bore guns firing APFSDS, which were becoming more effective than the standard 105mm tank guns using APDS ammunition and looked like being able to replace the latter when of smaller 75mm or even 60mm calibre, in which size they could be mounted in lighter vehicles. The other happening was the contemporary concern about the survivability of tanks, which gave rise to the belief that this could be improved by making tanks much more agile. All this led to the construction and tests of the High Mobility Agility (HIMAG) experimental vehicle armed with a high-velocity automatic 75mm ARES gun firing APFSDS ammunition. The HIMAG vehicle was based on a M1 tank chassis and its weight could be varied from 29.5 to 38.1 tonnes, so that its power-to-weight ratio could be as high as 50.8hp per tonne compared with 26hp per tonne of the M1A1, and it was consequently more agile than other contemporary tracked armoured vehicles.

Tests of the HIMAG vehicle, which the writer was able to follow closely as a member of a DARPA advisory group, began in 1977 and continued until 1981 but without resolving the power-to-weight issue, while the 75mm ARES gun was overtaken by the development in Germany by Rheinmetall of a low recoil impulse version of the 105mm L7 tank gun, which could be fired from vehicles weighing only 14 tonnes. At the same time, APFSDS ammunition was developed for 105mm guns, which made the Rheinmetall gun more effective than the 75mm ARES gun. In fact, it became a model for the armament of other gun-armed light armoured vehicles.

Changes in the political situation in the Middle East that followed the fall of the shah in 1978 created a need for rapid deployment forces, which led the US Army to formulate a requirement for an air-transportable Mobile Protected Gun System, subsequently renamed the Armored Gun System. Several companies responded to it but the requirement was not funded and none of the vehicles proposed in the mid-1980s was adopted. All were armed with 105mm guns on the Rheinmetall model except for a light tank built by the AAI Corporation, which was an offshoot of the HIMAG programme and was still armed with a 75mm gun.

The requirement for an air-transportable gun system was revived in 1992, and after another competition the vehicle proposed by United Defense LP, which was a modified version of the one built in 1985 for the previous competition, was adopted as the M8 Armored Gun System or AGS. It was a vehicle with a crew of three and an automatically loaded 105mm gun that weighed 18 to 23.6 tonnes depending on the amount of add-on armour it carried and, like all the other AGS candidates, it was transportable in Lockheed C-130 aircraft. The first was completed in 1994 and there were plans to produce 237, but a year later, when only six prototypes had been built, development of the M8 AGS was terminated, which deprived the US Army of having an armoured vehicle suitable for airborne operations.

In the meantime studies were restarted of a potential replacement of the M1 tank in 1993, which was called the Future Main Battle Tank or FMBT. They envisaged a tank with a 120mm gun in an unmanned remotely operated turret and with a crew of three located in the hull, a configuration which was anticipated ten years earlier by the Tank Test Bed, except that FMBT was to have its engine at the front. By 1997 studies of FMBT gave way to the Future Combat System concept, which reached the stage of a full-size mock-up. This showed it to be another tank with an unmanned remotely operated turret, but with a crew of only two men at the front of the hull and an engine at the rear. It was to weigh 36 tonnes and, in spite of all the evidence against it, a gas turbine was again considered for it as an alternative to a diesel.50

All these tentative moves towards a new battle tank came to nothing in 1999 when the then Chief of Staff of the US Army, General E. K. Shinseki, announced his plans to transform the Army into a force that would be more mobile strategically. This involved the adoption of armoured vehicles that were considerably lighter than the M1 tanks and that were wheeled, as the latter were mistakenly assumed to be more mobile overall than tracked vehicles. Initially these were to be off-the-shelf Interim Armoured Vehicles, but they were to be followed by the development of a family of sophisticated wheeled armoured vehicles that would form part of the Future Combat Systems and all of which would be transportable in Hercules C-130 aircraft.

The vehicle ultimately chosen as the basic Interim Armoured Vehicle was the eight-wheeled Piranha armoured carrier designed in Switzerland by Mowag and produced under licence in Canada by General Motors as the Light Armoured Vehicle or LAV. It was chosen in preference to a tracked vehicle partly because General Shinseki and others in the US Army had become mesmerized by the operational mobility of wheeled vehicles, which was undoubtedly greater than that of tracked vehicles and which was vividly demonstrated during the 1999 Kosovo crisis when a Russian unit equipped with eight-wheeled armoured carriers drove at high speed from Bosnia and seized control of Pristina airport ahead of the slower moving NATO troops. In fact, an ‘operational march to Pristina’ became the criterion by which wheeled vehicles were chosen, which ignored the greater tactical mobility of tracked vehicles and their inherently lighter weight and smaller size than that of comparable multi-wheeled armoured vehicles.

The LAV was adopted in 2000 and was named the Stryker. Soon after the invasion of Iraq in 2003, Strykers began to be deployed there and became involved in urban counter-insurgency operations for which they were not designed and in which their light armour made them vulnerable. To improve their protection they were hastily fitted with slat armour, which provided a partial answer to the rocket propelled RPG-7 anti-tank grenades used extensively by the insurgents, and with thick underbelly plates against the explosions of improvised mines. But the improvements to their protection increased their weight to well over 17 tonnes, which was the most they could weigh if they were to be transportable in C-130 aircraft over operationally useful distances.

Studies of the Future Combat Systems vehicles that were to follow the Strykers started in 2000 and their development was formally launched three years later. At first they were to be wheeled, but once their development began in earnest common sense prevailed and they became tracked. The most challenging of them was the Mounted Combat System, which was to take the place of tanks. Like the contemporary versions of the latter, MCS was to be armed with a 120mm gun while its general configuration was a mixture of concepts that had already been proposed since the Tank Test Bed of the early 1980s. Thus, it had an unmanned remotely controlled turret and the crew located behind the engine, like the FMBT, but the crew consisted of only two men, as in the FCS of the late 1990s.

As MCS and the other FCS vehicles were to be C-130 transportable, they could not have much armour. Instead, they were to rely for their survivability on being part of a networked system, which, through information dominance, would enable threats to be detected and defeated before they could act. However, fighting in Iraq demonstrated once again that combat at close quarters could not be avoided, and that situation awareness, no matter how good, was no substitute for armour protection. In consequence, the armour of MCS was increased, in spite of the resulting increase in its weight, to more than the 18 tonnes originally specified. The need for such an increase was actually recognized at an early stage of the development, when it was considered necessary to allow the weight of the MCS to rise to 22 tonnes and virtually give up the idea of transporting it in C-130 aircraft. By 2008 the armour of the MCS was increased further and its weight rose to 24.5 tonnes. However, even this further increase in armour protection was not considered sufficient, and in 2009 the development of MCS and of the other Manned Ground Vehicles that formed part of the Future Combat Systems was abandoned in favour of a more realistic and inevitably heavier Ground Combat Vehicle.

When the Second World War came to an end, the British Army, like the US Army, reduced its armoured forces to a single armoured division but stationed it in Germany where the threat of Soviet aggression was greatest. Moreover, it continued with little interruption the development of tanks initiated in the closing stages of the war.

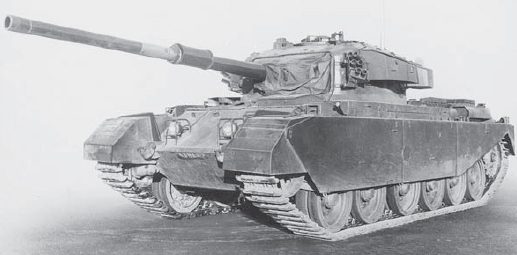

However, the ideas underlying the development of British tanks were changing, moving away from the unrealistic and harmful division into infantry and cruiser tanks towards the concept of a single type of battle tank. The most important protagonist of this concept was General, later Field Marshal, B. Montgomery who, according to his principal critic on this issue General G. Martel, came to favour it as early as 1943 on the basis of his observations of the successful advance across North Africa by the Eighth Army, which he commanded.51 Montgomery subsequently outlined his views on the single type of what he called a ‘capital tank’ in a lecture given in London in 1945 and when he became Chief of the Imperial General Staff development of such a tank became official policy.52

The changes were not, of course, immediately or generally accepted. Just before the end of the hostilities, War Office studies still saw the need for separate infantry and cruiser tanks, and as late as 1950 generals Fuller as well as Martel were writing letters to The Times in support of two types of tanks with different functions. The General Staff also needed time to come to terms with the concept of a ‘dual purpose’ tank gun, agonizing over how tanks should be divided between those armed with what were primarily anti-tank weapons and others intended principally to fire high explosive ammunition – as if high-velocity tank guns could not fire high-explosive shells as well as armour-piercing projectiles.53

The actual development of a single type of tank started, oddly enough, in 1944 with the design of the A.45, a 55-tonne infantry support tank that was to complement the A.41 Centurion, which was originally regarded as a cruiser tank. A.45 was never built, but it was transformed in 1946 into a ‘universal tank’, which, apart from its basic role of a gun tank, was to be readily adaptable to or could be modified to perform a variety of specialized roles inspired for most part by the special purpose tanks of the 79th Armoured Division created for the 1944 landings in Normandy. A prototype of the basic FV 201 gun tank began to be tested in 1948, but the idea of incorporating in it a wide variety of specialist features proved impracticable and they were, in any case, superfluous so far as its main function was concerned. In consequence, the concept of a multi-functional ‘universal tank’ was abandoned in 1949.54

What was left was the basic FV 201. It was to be armed with the newly developed 83.8mm 20-pounder, but this quickly came to be considered insufficiently powerful to defeat the IS-3 and other heavy tanks that were expected to be fielded by the Soviet Army. A larger calibre 120mm gun, which was considered necessary for this purpose, was too heavy to be installed in the Centurion and it was decided therefore to mount it on the FV 201, which was modified consequently into FV 214. As no 120mm tank gun had yet been developed in Britain, it was decided to use an American gun of this calibre, which had been developed from an anti-aircraft gun for the US T34 heavy tank designed in 1945. However, the British version of this gun was provided with two new types of ammunition. One was the tungsten-cored APDS, which took the place of the traditional full calibre armour-piercing shot; the other was HESH, or high explosive squash head, which took the place of conventional high explosive ammunition.

FV 214 came to weigh 65 tonnes and was called Conqueror. Trials of its prototype began in 1952, and three years later it started to be delivered to British armoured units to serve as a heavy gun complement of the Centurions. However, a total of only about 180 was produced, and although it remained in service until 1966 it was made redundant well before this by the re-arming of the Centurions with the 105mm L7 gun.

While the Conqueror was still being developed studies began in 1950 of an even more heavily armed tank called FV 215. This tank was to be armed with a 183mm gun that fired massive, 160kg HESH projectiles and became the world’s largest calibre tank gun. FV 215 did not advance beyond a full-size wooden mock-up and its development was discontinued in 1957. However, the 183mm gun was not only built but was successfully fired from a Centurion chassis and is preserved at the Tank Museum at Bovington.55

In the meantime, Centurion became almost the only tank of the British Army. Although it was conceived during the war as a ‘heavy cruiser’ and was later designated a medium gun tank it was, for most of its life, a very well armed universal tank. The first few were still armed with the wartime 76mm 17-pounder, but in 1948 the Mark III version was armed with the much more powerful 83.8mm gun, or 20-pounder, as it was called under the archaic system of gun designation still used by the War Office. Design of the 83.8mm gun was strongly influenced by that of the German 8.8cm KwK 43, which armed Tiger II heavy tanks and was probably the most effective tank gun of the Second World War. Like the latter, the 83.8mm gun was still designed to fire conventional full calibre armour-piercing projectiles, but it was also provided with APDS ammunition fired with a muzzle velocity of 1,465m/s, which was higher than that of other types of tank gun ammunition produced until then and which greatly increased the armour-piercing capabilities of the gun, making it the most effective of its day.

Armed with the 83.8mm gun, Centurion performed with credit when it was first used in 1951 during the Korean War, and the three Centurion-equipped British armoured divisions stationed in Germany during the 1950s formed the most effective counter to the Soviet armour massed in what was at the time East Germany. The capabilities of the Centurions came to be highly regarded and led to their acquisition during the 1950s and 1960s by no fewer than 16 different countries, either by direct purchase, like Sweden, Switzerland and Israel, or under US military aid programmes, like the Netherlands and Denmark. In fact, more than half of the total production of 4,423 tanks was exported.

The successful development of the 83.8mm gun and its APDS ammunition was followed by its evolution into a 105mm gun, which proved even more successful. The original experimental version of this gun was actually made in 1954 by simply boring out an 83.8mm gun barrel to 105mm, and with new APDS ammunition developed in the 1960s it could penetrate 120mm of steel armour inclined at 60º at a range of 1,830m, which was about twice what the earlier type of full calibre armour-piercing projectiles fired from a gun of the same calibre could penetrate.

On the strength of its performance, the 105mm L7 gun began to replace the 83.8mm gun in the Centurions of the British Army in 1959, and in 1958 it was adopted by the US Army in preference to two American guns as the main armament of the US battle tank of the 1960s and 1970s, the M60. It was also adopted, with or without modifications, for several other tanks including the German Leopard 1, Swedish S-tank, Swiss Pz 61, Indian Vijayanta, Japanese Type 74, Israeli Merkava and even the original version of the US M1 tank designed in the mid-1970s, as well as the South Korean K 1 designed still later and the Chinese Type 80. Altogether about 35,000 different tanks have been armed with the 105mm L7 and its derivatives, making it the most widely used tank gun outside the Soviet bloc since the Second World War.

In Britain the development of the Centurion was followed by that of the Chieftain, which originally was to be another medium gun tank but became a main battle tank after the Tripartite – American, British and Canadian – conference in Quebec in 1957 decided to adopt the concept of such a tank in place of the earlier policy of developing medium and heavy tanks. Studies leading to it started in 1951, but a prototype was not built until 1959. It embodied a number of novel features, one of which was a supine position for the driver that reduced the height of the hull and consequently of the whole tank, making it a more difficult target for enemy guns. The lower hull also helped to keep the weight of the Chieftain down to 55 tonnes compared with 65 tonnes of the Conqueror in spite of having thicker frontal armour. In fact, the horizontal shot line thickness of Chieftain’s frontal armour was 388mm compared with 258mm of the Conqueror and was greater than that of any other tank available to the NATO forces until the 1980s.