Dining & Entertaining Projects

Perhaps the most popular backyard activities are cooking and eating. In fact, throwing backyard barbecues and preparing summertime meals for the family are the primary reasons we acquire most of our yard furnishings. Picnic tables and patio tables are the heart of your outdoor entertaining accommodations, and you’ll find several interpretations here. The Cedar Patio table offers sturdiness, a spacious top, and rich wood tones. The trestle-type table with a pair of matching benches is flexible, comfortable, and low-maintenance, thanks to the composite decking used. The outdoor tea table and chairs sets an Eastern tone that is at once contemporary and classic. For ambitious outdoor cooks, investigate the rolling Patio Prep Cart with built-in refrigerator compartment, or the Pitmaster’s Locker—a vertical cabinet with a locking door for fuel and grilling accessory storage.

In this chapter:

Trestle Table and Benches

Trestle Table and Benches

This modified picnic table-and-bench set combines the tried-and-true dimensions and durability of a classic picnic table with the style and structure of a traditional trestle dining table. It is built with common exterior lumber. The version seen here uses pressure-treated pine to do the structural work of the base frames, but it has a modern twist. For the tabletop and seat tops it employs low-maintenance composite deck boards. The composite deck boards provide a surface that’s easy to clean and requires little long-term maintenance. Composite boards are quite a bit heavier than wood, so you might not want to use them if you foresee a need to move your table frequently.

Trestle tables share one principal defining feature: a pair of end leg frames that support a horizontal beam (the trestle). Today, the most common trestle leg tables are the manufactured metal leg folding tables found in almost all schools, hotel banquet rooms, and other commercial settings. But trestle leg construction isn’t new; it has been used in table designs for centuries. Early versions were built with large, solid slab-wood legs that were braced with a center stretcher. The stretcher and trestle legs were typically joined by a through-mortise-and-tenon joint that was secured with a pin or key that fit through the tenon.

This outdoor table design reflects the style of those early wood trestle tables. The legs are made from multiple boards instead of a single slab, and the stretcher locks to the leg boards in notches instead of with a through-mortise-and-tenon joint.

A classic picnic table gets a modern makeover by replacing the wood tabletop and seat boards with low-maintenance composite decking.

Trestle Table and Benches

Trestle Table and Benches

CUT THE TABLE PARTS

Cut four 27"-long pieces of 2 × 10 and then trim off the edges to make the four 71/4"-wide inside legs. Use a table saw or circular saw to rip-cut these pieces to width. Clamp the four inner legs together face to face with the ends and edges flush. Draw lines to designate the top and bottom of the notches that hold the middle and side stretchers. Use a router and straight bit to cut out the waste material inside the notch outlines. Clamp a straightedge on each side of the notch layout lines at a distance that is equal to the distance between the edge of the bit and the edge of the router base (photo 1 and photo 2). These guides will function as stops for the router base. Cut the notches for the middle stretcher 1/2" deep by 63/4" long and the notches for the side stretchers 11/2" deep by 3" long. The tops of both notches should be 3" down from the top of the leg. Cut the notches by making multiple passes with the router, lowering the bit after each pass (photo 3). Do not attempt to remove more than 1/4" of material (in thickness) in a single pass.

Measure the router bit setback. So you know where to place the straightedge cutting guides to cut the notches with your router, measure the distance from the edge of the straight bit to the outside edge of the base plate.

Gang-cut the stretcher notches into the legs. Clamp a straightedge guide on each side of the notch layout lines so the distance from the blocks to the notch layout line equals the router bit setback distance.

Finish clearing the notches. Don’t try to remove all of the waste material from the notches in one pass. Start with a 1/4" bit depth and then lower the bit 1/4" after each pass.

Cut four 283/4" long pieces of 2 × 4 and then trim approximately 1/2" off the long edges 1/2" per edge to make the four 21/2"-wide outer legs. Cut the two bottom leg rails to length. Cut one 52" long piece of 2 × 10 and then trim approximately 1/4" off the long edges to make the 83/4"-wide middle stretcher. Use a miter saw or jigsaw to cut each corner to a 30° miter. Make the cuts 1" in from the ends (photo 4).

Trim the middle stretcher. Use a miter saw to trim off each corner at a 30° angle. Make the cuts 1" in from the ends.

Cut two 48"-long pieces of 2 × 4 and then trim approximately 1/4" off the long edges to make the 3"-wide side stretchers. Cut three 30"-long pieces of 2 × 4 and then trim approximately 1/4" off the long edges to make the 3"-wide cross supports. Cut 30° miters in the ends of the crosspieces (photo 4).

Sand all of the wood parts to prepare for finishing. Apply an exterior finish to all of the frame parts. In this case a solid-color deck and siding stain was used. Solid color stains are available in a wide range of colors. It looks almost like paint after it is applied, but it doesn’t peel as it ages so it is easier to reapply and maintain than paint. Finally, cut the tabletop planks to length. Cut 12-foot deck boards in half to make the 6-foot tabletop and seat top planks.

ASSEMBLE THE TABLE

Begin the assembly of the table by attaching one of the inside legs to the middle stretcher using two 21/2" screws. Attach one of the cross supports to the inner leg with two 21/2" screws (photo 5). Attach the second inside leg to the cross support with two 21/2" screws and toe-screw it into the middle stretcher with one screw (photo 6). Repeat the inside leg and cross support assembly sequence to build the other leg assembly. Fit the side stretchers into the notches on the sides of the inside legs and secure them with two 21/2" screws at each joint.

Join the supports and legs. Attach one of the cross supports to the inner leg that has already been attached to the middle stretcher.

Secure the middle stretcher to the leg assemblies. Attach the second inner leg to the cross support and toe-screw this leg into the middle stretcher.

Attach the outside legs to the inside legs with three 21/2" screws each (photo 7). Attach the bottom leg rail to the bottom of the inside legs with four 2" screws. Clamp the middle cross support in position on the middle stretcher and side stretchers. Drill a 3/8"-diameter × 11/2"-deep counterbored hole in the top of the cross support and over the center of the stretchers. Then, drill a 3/16" pilot hole the rest of the way through the cross support. Attach the cross support to the stretchers by using an extended driver bit or a hand screwdriver to drive a 21/2" screw through each pilot hole and into the side stretcher (photo 8).

Add outside legs to the leg assemblies. Attach an outside leg to the outer edge of each inside leg. The tops of the inside and outside legs must be flush.

Attach the middle cross support. Drill a deep counterbored hole halfway through the middle cross support and drill a pilot hole through the rest of the cross support. Secure with screws.

Attach the composite tabletop planks to the cross supports with 2" composite decking screws (these are specially designed to minimize "mushrooming" of the composite material around the screw head). Drive two screws in each board, centered over the cross supports.

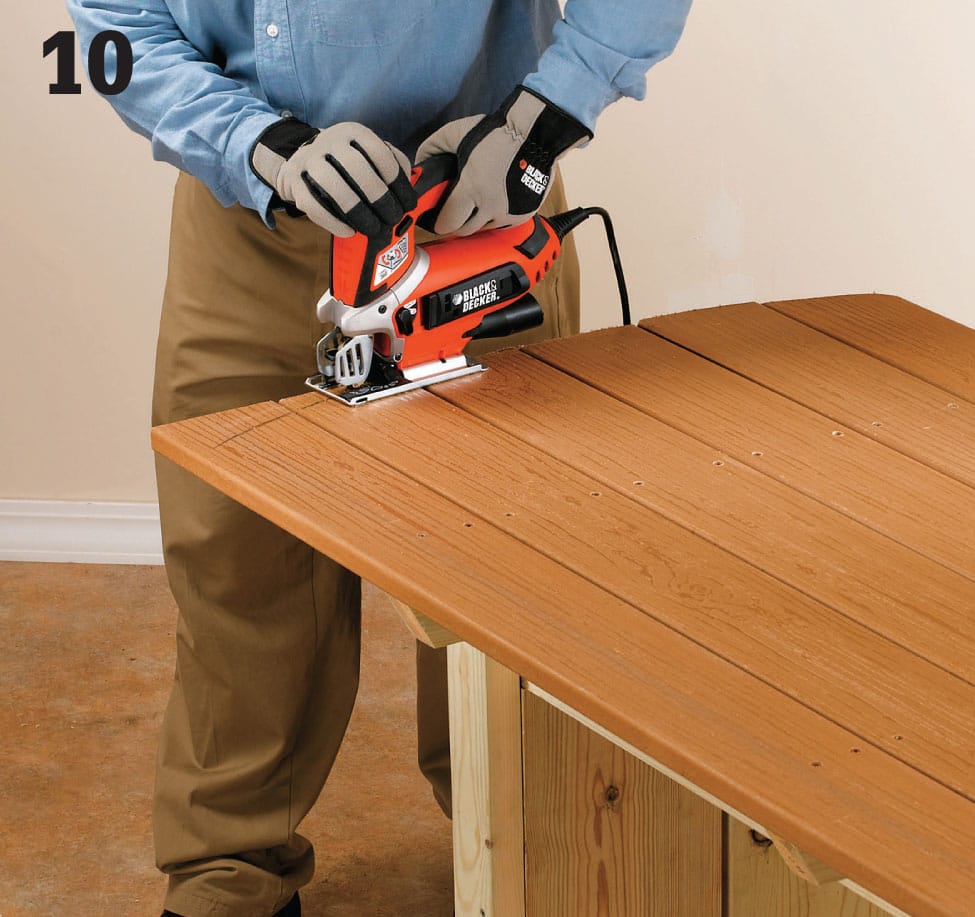

To make arcs for trimming lines on the ends of the tabletops, measure and mark a point 45" in from each end of the table and centered from side to side. These marks will act as the pivot points for drawing the radius curves on the tabletop ends. Tie a string to a pencil or marker and then measure 45" of string out from the writing utensil. Hold the string on each pivot point and sweep the pencil or marker across the tabletop, keeping it perpendicular at all times. This will create a radius line (photo 9). Cut carefully along the trim lines with a jigsaw and 12-tooth-per-inch blade (photo 10). Also draw 3"-radius lines at each corner and then cut along the radius lines. Use a router and 1/4" roundover bit to ease the radius edges on the ends of the top boards.

Mark the end curves on the tabletop. Use a 45"-long string or wood strip as a compass (more accurately, as a trammel) and a pencil to mark the 45" radius cutting lines on the ends of the tabletop boards.

Cut the curves. Use a jigsaw and 12-TPI blade to cut the arc at the ends of the tabletop. Be careful to make clean cuts, as composite material is virtually impossible to sand.

BUILD THE BENCHES

The bench part dimensions are different than the table part dimensions, but the construction process is basically the same. The only notable difference is that the benches do not have a middle stretcher. Cut the bench parts and build the benches using the same steps and techniques that were used to build the table (photo 11).

Build the benches. Make the trestle benches using the same procedure you used for building the trestle table. The benches do not have a middle stretcher.

Cedar Patio Table

Cedar Patio Table

In these days of plastic-resin or aluminum-and-bubble-glass patio furniture, it is refreshing to encounter a nice beefy patio table made of solid wood. With a massive base of 4× 4 cedar, this square patio table definitely has a surplus of sturdiness. Also boasting warm wood tones, this all-cedar patio table is roomy enough to seat six and strong enough to support a large patio umbrella. The construction process for this table is very straightforward. The legs and cross braces are cut from solid 4× 4 cedar posts and then they are lag-screwed together. The lag screw heads are countersunk below the wood surface. If you can find them at your local building center, buy heartwood cedar posts. Heartwood, cut from the center of the tree, is valued for its density, straightness, and resistance to decay. Also, take care when selecting the 1× 4 cedar boards used to make the tabletop. Look for boards that are free of large knots and fairly consistent in tone. Most dimensioned cedar sold at building centers is rough on one face. Either plane the rough faces smooth or face them inward when you install them in this project. Because it’s used for an eating surface, apply a natural, clear linseed-oil finish.

This patio table blends sturdy construction with rugged style to offer many years of steady service.

Cedar Patio Table

Cedar Patio Table

MAKE THE LEG ASSEMBLIES

Cut the legs, stretchers, and spreader to length. Measure and mark 4" up from the bottom edge of each leg to mark the positions of the bottom edges of the lower stretchers. Test-fit the legs and stretchers to make sure they are square. The top stretchers should be flush with the top leg ends. Carefully position the pieces and clamp them together with pipe clamps. The metal jaws on the pipe clamps can damage the wood, so use protective clamping pads.

Drill 7/8"-diameter × 3/8"-deep counterbores positioned diagonally across the bottom end of each leg and opposite the lower stretchers (photo 1). Drill 1/4" pilot holes through the counterbores and into the stretchers. Unclamp the pieces and drill 3/8" guide holes for lag screws through the legs, using the pilot holes as center marks. Apply moisture-resistant glue to the ends of the stretchers. Attach the legs to the stretchers by driving lag screws with washers through the legs and into the stretchers. Use the same procedure to attach the spreader to the stretchers.

Counterbore two sets of holes on each leg to recess the lag screws when you attach the legs to the stretchers.

ATTACH CLEATS & RAILS

Cut the side rails and end rails to length. Drill two evenly spaced, 1/8" pilot holes through the ends of the side rails. Counterbore the holes 1/4" deep to accept plugs using a counterbore bit. Apply glue and fasten the side rails to the end rails with 2" deck screws.

Cut the end cleats, cross cleats, and side cleats to length. Fasten the end cleats to the end rails 3/4" below the top edges of the rails with glue and 2" deck screws (photo 2). Repeat this procedure with the side cleats and side rails.

Attach the end cleats to the inside faces of the end rails. Maintain a 3/4" distance from the top edge of the rails to the top edge of the cleats.

CUT & ATTACH THE TOP SLATS

Cut the top slats to length. Lay the slats into the tabletop frame so they rest on the cleats. Carefully spread the slats apart so they are evenly spaced. Use masking tape to hold the slats in place once you achieve the correct spacing (photo 3). Stand the tabletop frame on one end and fasten the top slats in place by driving two 2" deck screws through the end cleats and into each slat. Hold or clamp each slat firmly while fastening to prevent the screws from pushing the slats away from the frame (photo 4).

Install the tabletop slats. Use pencils or dowels as spacers to set even gaps between top slats. Tape the slats in position with masking tape.

Fasten cross cleats to the tabletop for strength and to provide an anchor for the leg assembly.

CONNECT THE LEGS & TOP

Turn the tabletop over and center the legs on the underside. Make sure the legs are the same distance apart at the top as they are at the bottom. Lay the cross cleats along the insides of the table legs. Fasten the cross cleats to the tabletop with 2" deck screws. Fasten the cross cleats to the legs with 3" deck screws (photo 5).

Attach the tabletop to the table base with 2" deck screws. Do not overdrive the screws.

APPLY FINISHING TOUCHES

Fill screw hole counterbores with cedar plugs or buttons for a more finished appearance. Smooth the edges of the table and legs with a sander or router (photo 6). If you want to fit the table with a patio umbrella, use a 11/2"-diameter hole saw to cut a hole into the center of the tabletop. Use a drill and spade bit to cut the 11/2"-diameter hole through the spreader. Finish the table as desired. Use clear linseed oil for a natural, nontoxic, and protective finish.

Sand the surfaces smooth before you stain or treat the patio table. Use the sander to break sharp edges with a slight roundover.

Teahouse Table Set

Teahouse Table Set

Inspired by low teahouse tables, this table-and-stool set looks great on a small urban patio or in a Japanese-style garden. The table height offers a unique perspective on the rest of the surroundings and creates a more intimate setting for a casual dinner or evening tea. And if the idea of crouching down to sit in these stools doesn’t appeal to you, then you might still consider building it as a child’s table.

This set is relatively easy to build, but it still features several appealing and unique design details. The legs of the table and stools feature reverse tapers, reinforcing the Eastern design influence. The seats are cupped slightly for greater comfort. And, the round tabletop has a chamfered edge.

You can build this table using any exterior grade lumber, and the parts are sized so that you can find all of the materials at most home centers or lumberyards. This version was built out of cedar and stained with a dark brown, solid semitransparent deck stain, giving it the look of dark weathered wood.

A few power tools are needed to build this set. First, you need a saw, such as a miter saw or circular saw, to cut the parts to length. You also need a saw to cut the tapers—a band saw is best for this, but you could also use a jigsaw with a long blade or make two mating cuts with a circular saw. The circular top is easiest to cut with a jigsaw or with a router equipped with a circle-cutting jig. The chamfered edge on the tabletop is an optional detail that requires a router and chamfer bit.

Add a touch of Eastern elegance to your patio or transform your gazebo into a teahouse with this simple-to-make table-and-stool set.

TABLETOP SUPPORT DETAIL

TABLETOP SUPPORT DETAIL

BUILD THE TABLE BASE

Begin building the base of the tea table by cutting the leg pieces to length. A 10" or 12" power miter saw can cut through the 4 × 4 in a single pass, but a circular saw requires two joining cuts from opposite sides. Set the saw’s cutting depth so it is slightly deeper than one-half the thickness. Cutting with the blade at full depth increases the possibility of uneven cuts.

The table legs are created with reverse tapers—they’re wider at the bottom than the top. If you are an experienced woodworker and have a table saw, use a tapering jig to make the parts. A band saw is the next best bet for making taper cuts. Mark the taper lines on two adjacent sides of each leg (photo 1). Cut the tapers with a band saw. Cut the first taper (photo 2) and then reattach the taper to the leg with tape, flip the leg, and cut the second taper (photo 3). Repeat the taper cuts on all four legs and sand the blade marks smooth.

One edge of a straightedge should be on the corner of the leg blank on one end. The other end of the blank should be marked 2" in from the edge. Connect the points to create the taper cutting line.

Make the first taper cut. Using a band saw, place one hand on the tabletop to act as a guide and use your other hand to push and steer the leg through the cut.

Make the second taper cut. Temporarily reattach the cutoff taper waste piece with masking tape to support the leg on the table. With the leg oriented so the first taper rests on the table, cut the second taper on the adjoining face.

Cut the side supports and middle support to length. Trim off the bottom corners of each support with 30° miter cuts. The miters should end 11/2" in from the ends of the bottom edges (photo 4). The table supports fit together with half-lap joints. There are several ways to cut the half-laps notches. In this case, the notches are all spaced 15" apart so it makes sense to cut them all at the same time—a technique referred to as “gang cutting.” To gang-cut the supports, mark the center on the bottom face of two of the side supports and the middle support. Also mark the center on the top faces of the two remaining side supports. Clamp the supports together with the center marks facing up and aligned. Next, mark the outsides of the notches on the support that is closest to you and then use a try square or combination square to extend that line across all of the supports (photo 5). Set your circular saw blade to a depth of 13/4". Make cuts along the notch edge layout lines. Align the blade inside the notch waste area, with the edge of the blade following the layout line.

Cut off the bottom corners of the supports. Make marks 11/2" in from the ends on the bottom edge of the supports. Align the power miter saw blade with these marks and make 30° miter cuts.

Lay out the notches. Clamp the stretchers together with the centers aligned. Use a square to extend the notch cut lines across all of the stretchers.

After cutting the sides of the notches, clean out the rest of the waste material from the notch by making several overlapping cuts with the circular saw (photo 6). Smooth any remaining blade marks on the bottom of the notch with a sharp wood chisel. The two bottom side supports also require a middle half-lap notch to hold the middle support. Clamp the two bottom side supports together and repeat the notch cutting process for the middle notch.

Cut the notch shoulders. Cut the sides of the notch first. Then clean out the middle by making several overlapping cuts.

Test-fit the parts to make sure everything fits together and then assemble the table base. First, apply exterior-rated glue to the inside faces of the notches. Then, place the top side and middle stretchers in position on the bottom side stretchers. Drive a 21/2" screw through the bottom of each half-lap joint. Then, attach the framework to a flat face of each leg (photo 7).

Assemble the base. The framework of the supports is fastened to the legs with 2" screws.

MAKE THE TABLETOP

Make the teahouse tabletop as a square and then cut it to round after it is assembled. Cut the tabletop planks to length. Then, mark the center of each plank and attach them in succession to the supports using 2" deck screws. Center each plank across the middle support, leaving a 1/8" gap between the boards. Drill a countersunk, 1/8"-diameter pilot hole for each screw.

To lay out the circular shape for the tabletop, make a compass using a scrap piece of 1/4"-thick wood or plywood that is roughly 11/2" wide × 20" long. Drill two 1/8"-diameter holes in the scrap, 183/8" apart. Tap a nail through one of the holes and into the center of the table. TIP: To find the center, draw straight lines across the tabletop from opposite corners. The point where the lines intersect is the center—provided you were careful and made the top square. Place a pencil tip through the other hole in the scrap wood compass and draw the perimeter of the tabletop (photo 8).

Lay out the circular cutting line. Draw the perimeter of the tabletop using an 183/8" long compass. You can also use a piece of string as a compass.

Cut just outside the round tabletop outline with a jigsaw (photo 9). Then, use a belt sander to smooth and shape the wood precisely up to the cutting line. Use a router and 45° chamfer bit to profile the top edge of the table (photo 10). Finally, attach the table legs to the tabletop supports with 21/2" screws. Drill countersunk pilot holes and drive the screws from the inside faces of the supports.

Cut the round tabletop shape. Use a jigsaw to make a rough cut just outside of the cutting line (inset). Then, use a belt sander to remove wood precisely up to the cutting line.

Profile the tabletop edge. Cut a 1/2" chamfer profile in the top edge of the table with a router and 45° chamfering bit.

BUILD THE STOOLS

Make the matching stools. The information shown here lists materials and supplies for four stools. Start by cutting the legs to length. Unlike the table legs, the bench legs are only tapered on one side. Make a mark 11/2" in from the outside edge of one of the wide faces of the leg. Draw a line from that mark across the wide face down to a point that is 2" up from the opposite bottom corner of the leg (photo 11). Cut the tapers with a band saw or jigsaw. Cut the seat supports and seat rails to length. Trim off the bottom corners of the supports with 30° miter cuts. The miters should end 11/2" in from the ends of the bottom edge.

Lay out the bench legs. Draw a taper line across one of the wide faces of each leg. Cut along the taper line with a band saw or jigsaw.

Mark and cut the 11/2" wide by 13/4" deep notches using the same gang-cutting techniques used to cut the table support notches. Cut the notches in the seat supports as one group and the seat rails as another group. The bottom of the seat arc profile that is cut in the seat supports is located 1" down from the top edge and is centered across the support side. Tap a finish nail in the bottom point and bend a flexible piece of scrap stock to form the arc profile template. Trace the arc profile on the support (photo 12). Cut along the arc line on the first support and then use that support as a template to trace the arc on the other supports.

Plot the seat support profile. Use a finish nail as a bending point and flex a piece of scrap stock to create an arc template. Clamp the template and trace the profile on the supports.

ASSEMBLE THE LEGS

Attach the supports and rails with glue and screws in the same way that you assembled the table supports. First, cut the seat planks to length. Clamp the seat boards to a flat work surface in groups of five. The boards should be edge to edge with the ends flush. Cut a chamfer profile on both ends of all five boards. Unclamp the boards and rout a chamfer onto the outside edge of each outer board using a piloted chamfer bit (photo 13). Space each set of five seat boards evenly across a seat assembly and attach them to the seat supports with 2" screws. Drill a countersunk pilot hole for each screw. Attach the legs to the supports and rails with 21/2" screws.

Cut chamfers in the seat boards. With the workpieces for one complete stool clamped together edge to edge, rout the chamfer profile across the end grain on both ends. The chamfer matches the tabletop edge profile and eliminates sharp edges on the seat.

Folding Table

Folding Table

Sturdy, simple, and portable, this table is the go-everywhere solution for outdoor events that lack stable surfaces on which to place drinks, food, or other essentials. The beauty of this table is that, once folded up, it can be stored in a slim space. You can even keep it under an overhang or in a tool shed outside, although don’t be surprised if you become so enamored with it that you bring it indoors.

For an operable folding structure, the construction could not be simpler. You’ll find that this doesn’t take expert skills and you’ll probably only need about a day to construct the table. You also won’t have to break the bank; made of ubiquitous pine, the table is relatively inexpensive to put together. Of course, you don’t necessarily have to use the wood we’ve specified. You can always make the table out of cedar and let it age naturally for a wonderfully changeable appearance over time.

Otherwise, you might want to paint or finish the table. Because it doesn’t have to be in your yard all the time, a nice coat of your favorite bold hue can add a splash of fun color to your outdoor festivities. A dark stain can help the table blend into a more complex landscape and a clear finish will let the naturally warm look of plain pine shine through.

Sturdy and spacious when set up, this portable table folds up into a small package for convenient storage.

Folding Table

Folding Table

MAKE THE SIDE SECTIONS

Start by cutting the side rails and skirts. These will create a sturdy support for the slats and, ultimately, for the table. Position a side skirt against each side rail, so that the skirts overhang the rails by 3/4" on the long edge. This creates a healthy lip for the slats to sit on.

Center the side skirts on the side rails so that 3/4" of the skirt extends at each end (this will be the location of the overlap joints for each end). Clamp the side skirts to the side rails, ensuring that they are perfectly aligned—do not use a skirt or rail that has any bow along its length on edge. Attach the skirts with 11/4" deck screws (you don’t need to countersink the holes).

Leave the middle of side skirts and side rails free of screws. Cut these two side assemblies into two equal lengths, sawing at the center of the span. Connect the halves with 6" brass or galvanized strap hinges attached to the bottom edges of the side rail halves, then remove the hinges and unscrew the parts before proceeding.

ATTACH THE END SECTIONS

Cut the end rails and skirts. Position the end rails between the side rails, flush with the side rail ends to create a butt joint with the side rail faces overlapping the end rail ends. Apply glue and drive 21/2" deck screws through the side rail faces into the end rails.

Position an end skirt against each end rail, maintaining the 3/4"-deep ledge for the slats. With the ends of the end skirts flush with the side rails, drive 11/4" deck screws through the end skirts and into the side rails and end rails. Reattach the side skirts and strap hinges.

ATTACH THE SLATS

Cut the slats to length. Rip-cut one slat in half lengthwise. Position one half of the ripped slat on each side of center cut of the side rail, with no gap (the two parts of the slat will separate when the table is folded).

Attach the slats to the side rails, using glue on the face-to-edge contact area, and securing the slats with 2" deck screws (photo 1). Glue and screw the remaining slats evenly spaced down the side rail.

Once the frame is built with the side rails and skirts attached, glue and drill the two halves of the split slat on either side of the center cut through the rail, which allows the table to fold.

Drill 3/8"-diameter counterbored holes for carriage bolts through each end of the side skirts and side rails for the legs. Center the holes 41/4" in from the ends of the side skirts and 13/4" up from the bottoms of the side rails.

MAKE THE LEGS

Cut the legs and stretchers. Cut a 10° miter across the broad face of each leg at one end. At the other end of each leg, use a compass to draw a centered, 13/4"-radius semicircle. Mark the center of the semicircle and drill a 3/8"-diameter hole.

Draw a line across one face of each leg, 14" down from the top. Position the legs in pairs on the work surface. Slide a stretcher between each leg pair with the top faces on the reference lines. Glue and screw the stretchers between the legs with 21/2" deck screws.

MAKE THE CLEATS

Cut the cleats. The cleats have 1" notches on one long edge to allow folding. To mark the notches, draw reference lines across one edge of each cleat, 31/2", 71/4", and 181/2" from one end.

Cut the notches 1" deep from the 31/2" line to the 71/4" line, and from the 181/2" line to the ends. Cut each cleat in half. Attach the cleat halves with strap hinges.

ATTACH THE SWEEPS AND GUIDES

The sweeps and guides attach to the cleats to form a locking mechanism. Cut the sweeps and guides. Position the guides on the cleats, flush with edges of notches. Attach with glue and 21/2" deck screws (photo 2).

Align the ends of the guides with the outside edges of the sweeps. These need to be perfectly aligned for the opening mechanism to lock correctly. Glue and screw the guides in place.

Turn the tabletop upside down. Position the cleats and guides inside the tabletop so the hinged centers align. Use 13/4"-thick spacers to center the cleats between the side rails. Fasten them to the bottom of the table with glue and 2" deck screws (photo 3). Attach 3" brass butt hinges to one end of each sweep, then use the hinges to attach a sweep to one end of each cleat.

With the cleats centered between the side rails, it’s an easy task to screw them in place.

APPLY FINISHING TOUCHES

Fasten the legs inside the tabletop, using carriage bolts, washers, and lock nuts (photo 4). Check for smooth operation and make any adjustments as necessary for the legs to open smooth and the table to lock in the open position.

Secure the legs in place with carriage bolts, washers, and lock nuts.

Cover the screwheads with wood putty. Sand with 100- or 120-grit sandpaper, and paint or finish as desired.

Occasional Table

Occasional Table

When it comes to outdoor furniture, most of the attention is usually given to big, splashy tables that will seat lots of people or provide abundant space for food next to a grill. But, while there is certainly a need for expansive tabletop space, it’s the rare yard or outdoor seating area that can’t benefit from at least one more modest accent table. Put a side table next to a lounge or in between two Adirondack chairs and you add a place for drinks, snacks, or the book you’re reading.

The table in this project is amazingly simple, but with a few special touches, it’s also a stylish accent for your porch, deck, or patio. It is a nicely proportioned structure that will complement patio or deck seating, and is light enough to be moved wherever you need a small table. It is also stable enough to be placed on grass or gravel—so it can go just about anywhere in the yard it might be needed.

The table is made out of cedar so it can be left outdoors all year long, and cedar not only tolerates exposure to the elements, it also ages with a very nice gray patina. Cedar can also be finished clear to maintain the lovely fresh appearance of the wood.

However, you can save some money and craft it out of pine, an especially good choice if you plan on painting the table. If your area of the country experiences harsh weather and you don’t intend on moving the table into a garage or shed during winter, you might choose pressure-treated pine.

This sturdy accent table is an easy-to-build addition to your deck furniture. As stylish as it is simple, the design pairs nicely with an Adirondack chair.

Occasional Table

Occasional Table

MAKE THE STRINGERS, APRONS & LEGS

Cut the end aprons and side aprons to length. Because the end aprons overlap the side aprons to form butt joints, the side aprons must be shorter. Mark them on the inside face so that you don’t confuse them during construction.

Cut the end stringers and middle stringer to length. Note that these two are different lengths. The middle stringer will provide support that keeps the table sturdy and durable over the long run.

Each leg is formed of two pieces—one narrow and one wide—cut at a taper. The taper adds a bit of visual flair to the table, but the tapers have to be cut correctly or the effect will be ruined. Start by cutting the narrow and wide leg sides to length.

On one wide leg, measure 83/4" down along one edge of the leg side and make a mark. Measure across the bottom end of the leg side 11/2" and make another mark. Use a straightedge to connect the two marks to create a leg taper cutting line. Mark cutting lines for tapers on all four wide leg sides (photo 1).

Carefully measure and mark the taper cutting lines for both the wide and the narrow sides of the legs. Work on the wide sides first, and then the narrow, to avoid mixing them up and mis-measuring the cut lines.

For the tapers on the narrow legs, measure 83/4" down along one edge and make a mark as before. Then measure 3/4" across the bottom end and make a mark. Connect the marks to make the taper cutting lines.

Clamp each leg side to the work surface. Cut along the line using a jigsaw or circular saw (photo 2).

A jigsaw is ideal for cutting the taper lines in the legs, although you can also use a circular saw.

ASSEMBLE THE LEGS

The legs must be assembled precisely to maintain the illusion of solid tapered legs in each corner. Apply a 1/2"-wide bead of moisture-resistant glue on the face of a wide leg side, down along the untapered edge (the mating edge for the other leg piece). Repeat on the untapered edge of a narrow leg side. Join the leg sides together at a right angle to form a leg pair.

Drill and countersink pilot holes for screws to reinforce the joint between the leg pieces. Use three 11/4" deck screws. Glue and screw the rest of the leg pairs in the same manner (photo 3). Be careful not to use too much glue or mismatch the legs.

Work on a perfectly flat surface to ensure the leg sides are exactly aligned. Apply a bead of glue where the inside face overlaps the edge of the smaller leg piece, and then drill three countersunk holes and screw the pieces together.

CONSTRUCT THE FRAME

The table frame will securely hold the tabletop slats in place. Work from the outside in by gluing and screwing the side aprons to leg pairs. Carefully align the aprons and legs so that there are no unsightly overlaps or gaps in the frame construction.

Screw the legs to the aprons from the inside of each leg pair to conceal the screw heads. The narrow leg side should face in toward the center of the side apron, and the outside faces of the wide leg sides flush with the side apron ends. The leg pairs’ tops should be 3/4" down from the side aprons’ tops to create recesses for the tabletop slats.

Glue and screw the end aprons to the leg assemblies with the end aprons’ ends positioned with the outside faces of side aprons.

Glue and screw the end stringers to the end aprons between the leg pairs. Center the middle stringer between the end stringers. Use glue and screws to attach the middle stringer to the side aprons, 3/4" down from tops to maintain the ledge for the slats.

CUT AND INSTALL THE SLATS

Measure the inside dimension between the end aprons to verify the correct slat length. Measure at different points along the aprons to check that the frame is square and all the slats should be the same length. Cut the slats.

Drill countersunk pilot holes at each end of each slat, down into the middle and end stringers. Glue and screw the slats into the tops of the middle and end stringers, leaving a gap of approximately 1/16" between the slats (photo 4).

Drill two pilot holes at each end and in the middle of each slat, down into the end and middle stringers. Attach each slat with glue and screws at each location.

FINISH THE TABLE

A little easy detailing will give this table a lovely look next to your other outdoor furniture. Smooth all sharp edges by using a router with a roundover bit (photo 5) or a power sander with medium-grit (100 to 120) sandpaper. Finish-sand and thoroughly clean the table to remove any sanding residue.

Rounding off the edges of the table gives it a very polished appearance. Cover it with the finish of your choice and the project is complete.

Finish the table with a clear wood sealer or paint it in a color of your choice.

Children’s Picnic Table

Children’s Picnic Table

Picnic tables come in many styles, shapes, and sizes, with one of the sizes being “pint.” This downscaled kids’ picnic table is a wonderful addition to any backyard where children play. Its light weight allows you to move the table around the yard for impromptu tea parties on the deck or dinner under the trees. Yet its wide footprint makes it extremely stable so your rambunctious little ones won’t tip it over.

Constructing this kid-sized picnic table is easy. The trickiest part is probably getting the angles cut correctly at the tops and bottoms of the legs. They should be cut at a relatively shallow 50° angle. If they are cut too steeply the table will be taller and less stable; too shallow and it will be shorter and very difficult to seat oneself in.

With a kids’ project such as this it is important that you eliminate any sharp edges and do a thorough job sanding the surfaces smooth and splinter free. The edges of the boards can be “broken” by sanding them lightly so they are not sharp. Or, you can install a roundover bit in your router or laminate trimmer and shape the edges all to the same profile.

The table seen here is built with cedar and coated with a clear, UV-protective sealant. You could also make it from pressure-treated pine and paint it or finish it with a semitransparent deck stain. If you do use treated lumber, be sure to choose hot-dipped lag bolts that are triple-coated to limit corrosion. Or, better yet, use all stainless steel fasteners.

This kid-scale table with benches makes picnicking in the backyard even more fun for children. And with its broad legs and low top it is very stable.

Children’s Picnic Table

Children’s Picnic Table

CUT THE ANGLED LEGS & SUPPORTS

To make the angled legs, use a saw protractor to mark a 50° angle on one end of a 2 × 6 (photo 1). Cut the angle using a circular saw. Measure 32" from the tip of the angle, then mark and cut another 50° angle parallel to the first. Do this for all four legs, cutting two legs from one piece of lumber.

Use a saw protractor to mark a 50° angle on the end of the table leg, and then cut the angle using a circular saw.

Cut the table supports to length. Measure 11/2" in from each end of both supports and make a mark. Make a 45° angle starting at the mark and going in the direction of the board end. This relieves the sharp end of the board to prevent injuries and also looks more pleasing. Cut the seat supports to length. Measure 21/2" from the ends of both supports, make a mark, and cut a 45° angle to relieve the sharp ends.

ASSEMBLE THE A-FRAMES

Place one of the legs against the tabletop support so the inside edge of the leg is at the centerpoint of the support. Align the top of the leg with the top of the support. Clamp the pieces together. Drill two 3/8" holes through the leg and support. Stagger the holes. To keep the bolts from causing scrapes, recess both the bolt head and nut. Drill 1"-diameter counterbored holes about 1/4" deep into the legs and the tabletop supports. Insert a 3/8 × 3" carriage bolt and washer into each hole. Tighten a washer and nut on the end of the bolt using a ratchet wrench. Repeat these steps to fasten the second leg in place. Note: If your washers are larger than 1 ", drill a larger counterbore.

Measure along the inside edge of each leg and make a mark 121/2" up from the bottom. Center the seat support over the leg assembly, on the same side of the legs as the tabletop support, with the 45° cuts facing down and the bottom flush with the 121/2" marks. Clamp the two pieces together and then drill 3/8" holes with 1"-diameter counterbored holes. Fasten the seat support to the legs using carriage bolts, nuts, and washers (photo 2). Repeat this step to assemble the second A-frame.

Fasten the tabletop and seat supports to the legs with carriage bolts. Do not use washers with carriage bolt heads. The washers and nuts are recessed in counterbored holes to prevent injury.

ATTACH THE TABLETOP & SEATS

Cut the seat boards to length. Stand one of the A-frames upright. Place a seat on the seat support so the seat overhangs the outside of the support by 71/2". Align the back edge of the seat with the end of the support. Drill two 3/32" pilot holes through the seat into the support and then drive 21/2" deck screws. Attach the seat to the second A-frame the same way. Fasten the seat on the other side of the table using the same method.

Cut the brace. Center the brace between the seat supports, making sure they’re flush at the bottom. Drill two 3/32" pilot holes through the supports on each side, then fasten the brace to the supports using 21/2" deck screws. Cut the tabletop boards to length. Place the 2 × 4 tabletop across the center of the tabletop supports, overhanging the supports by 71/2". Drill two 3/32" pilot holes on both ends of the top board where it crosses the supports. Attach it to the supports with 21/2" deck screws.

Place a 2 × 8 tabletop board across the supports, keeping a 1/4" gap from the 2 × 4. Drill pilot holes in the end of the board, then insert 21/2" deck screws (photo 3). Install the remaining top boards the same way, spacing them evenly with a 1/4" gap. Allow the outside boards to overhang the end of the tabletop supports.

Install the tabletop boards by drilling pilot holes and driving 21/2" deck screws. Insert 1/4" spacers between boards.

FINISHING TOUCHES

Sand any rough surfaces and splinters, and round over edges on the seat and tabletop using 150-grit sandpaper. Apply a stain, sealer (foodsafe boiled linseed oil is a good choice), or paint.

Traditional Picnic Table

Traditional Picnic Table

Every backyard needs a picnic table, and this one is a classic. The design, with two long built-in benches attached to the sides of an abundant tabletop, can serve many different purposes. It is ideal for outdoor dining, whether you’re having an intimate dinner for two or a large birthday party meal. Many people can cram in around the table, and the setup allows for easy access to anything on the table, no matter where you happen to be sitting.

This table design is timeless largely because it is so durable. The picnic table is built to last and will take a lot of abuse. Spills, hot plates full of grilled meat, dropped items and more won’t faze this table. But the table remains popular because it is also a handsome form. Simple to build, the look is appealing and seems to fit right in no matter what landscape, patio surface or outdoor area it’s assigned to.

It’s also adaptable. The traditional material for this type of table is redwood, which will resist rot and the elements quite naturally. You can also go with cedar, which has the same properties and looks just as nice as redwood. Of course, if you’d like to save a bit of money, you can use pine. Nicer woods are best finished in a clear sealer or a light wood stain. Pine is often painted. You can make the legs from pressure treated lumber for greater longevity, but usually this isn’t necessary and in any case, PT lumber should not generally be painted.

Few pieces of outdoor furniture are so useful—and have such a classic look—as the traditional picnic table with benches on either side.

Traditional Picnic Table

Traditional Picnic Table

CUT THE LUMBER TO SIZE

The most challenging cuts for the whole table are the legs, which need to be mitered to stand at angles to the table. Make a 25° miter cut across one end of a 2 × 6. Measure 32" from the tip of the angle and cut a second 65° miter parallel to the first (photo 1). This makes one leg. Use the first leg as a template for laying out the other legs.

Use an adjustable square to determine and mark the parallel miter cuts at each end of one leg. Once you’ve cut the first leg you can use it as a template for laying out the parallel ends cuts on the three remaining legs.

Cut three 2 × 4 tabletop supports 26" long. Measure 11/2" from each end of the two end supports, make a mark, and cut a 45° angle. For the flat center support, measure 3/4 × 3/4" and cut this miter at the bottom of each end.

Cut two 2 × 6 seat supports 57" long. Measure 21/2" from the ends of both supports, make a mark, and cut a 45° angle. Cut two 2 × 4 seat stiffeners 10" long.

The bench and tabletop boards don’t need to be cut.

ASSEMBLE THE A-FRAME

Mark the centers of the tabletop supports. Measure 23/4" out from this centerline and make another mark. Place one leg against the tabletop support with the inside leg edge aligned with the second mark. Align the angled cut of the leg with the support tops. Clamp the pieces together.

Align the legs and seat and top support on the 23/4" and 151/2" marks. Fasten the supports to the legs with a 21/2" deck screw at each joint (avoid the bolt locations). Then drill guide holes for the bolts.

Drill two 3/8" holes through the leg and support. Counterbore 1" holes centered over the 3/8" hole about 1/2" deep into the support (photo 2). Insert and tighten a 3/8 × 3" carriage bolt into each hole. Repeat for the second leg.

Drill 1"-dia. counterbore holes for the carriage bolts that connect the legs and the supports. When using a spade bit to drill counterbores it is easier if you drill the counterbore before the guide hole that goes all the way through both workpieces.

Measure along the leg’s outside edge and mark 151/2" from the bottom. Center the seat support over the leg assembly, on the same side of the legs as the tabletop support, with 45° cuts facing down and the top flush with the 151/2" marks. Drill 3/8" guide holes with a 1"-diameter counterbore, and fasten the seat support to the legs using carriage bolts (photo 3). Repeat for the second A-frame.

Attach the leg assemblies using carriage bolts, washers, and locking nuts. The legs on each side are assembled before attaching the tabletop and seat boards.

ATTACH THE TABLETOP & SEATS

To make sure you don’t strip any screws, drill 3/32" countersunk pilot holes for all the screws.

Stand one A-frame upright. Place a 2 × 6 seat board on the seat support, overhanging the outside of the support by 81/2". Align the seat back edge with the end of the support. Attach with 21/2" deck screws. Repeat on the opposite side.

Place 2 × 6 tabletop boards across the tabletop supports, overhanging at the ends 81/2". Space the boards evenly across the tabletop supports, overhanging the supports by 11/2". Fasten the boards with 21/2" deck screws (photo 4).

Drill countersunk pilot holes for the screws that fasten the tabletop and seat tops to the supports.

Turn the table upside down. Attach a seat stiffener to the underside of each seat at its midpoint, using 21/2" deck screws. Attach the tabletop stiffener to the underside of the tabletop at its midpoint, using 21/2" deck screws.

Cut two braces 301/4" long, mitering one end 50° and the other at 40°, at intersecting, not parallel, angles. Test fit the braces with the 50° angle against the seat support, and the 40° against the tabletop brace. The tabletop end needs to have the tip of the angle clipped off. Mark and make this cut.

Drill 3/32" countersunk pilot holes and attach the braces with 3" deck screws.

FINISH THE TABLE

Round over the edges of the tabletop and seat tops, to avoid catching on clothing or hurting anyone who bumps the edges. For best results, use a router with a roundover bit to cut the profiles; alternatively, ease all edges with a power sander and 100 grit sandpaper. Sand all surfaces to 120- or 150 grit and apply a clear sealant or stain or paint the table your choice of colors.

Patio Prep Cart

Patio Prep Cart

This elegant rolling cook’s cart will take your outdoor cooking to a higher level without breaking your bank account.Whether the point is to impress or simply to make your outdoor entertaining a bit more pleasant, setting up an outdoor kitchen that revolves around this clever cart and an ordinary grill is easy. And, because this cart (and most grills) are on wheels, they’re easy to move as needed and to roll away into storage.

This cart features 8 square feet of countertop space, a storage cabinet with shelves, and a dedicated place for a refrigerator. The sides are made from 1 × 4 cedar or a similar exterior-grade lumber. Use corrosion-resistant screws to assemble this cart. The screws that attach the siding are driven from the outside, leaving the heads exposed to act as a design feature.

This outdoor kitchen cart employs eight 12 × 12" tiles for the countertop, minimizing the joints in the countertop surface. To simplify construction the tiles are set with construction adhesive (instead of thinset mortar) and the joints between the tiles are filled with exterior caulk (instead of tile grout).

Both attractive and functional, this rolling cook’s cart with space for a refrigerator will make your deck or patio almost as convenient as your kitchen for entertaining friends and family.

Patio Prep Cart

Patio Prep Cart

BUILD THE FRAME

This outdoor kitchen cart is essentially a skeleton of 2 × 4 cedar wrapped in cedar siding and capped off with large tiles. Start by building the skeleton: that is, the frame. Cut the bottom supports, posts, and top rails to length. Cut the bottom panel and center panel to length and width. Attach two of the posts to the center panel with 11/4" screws. Place the center panel and bottom panel on their sides and attach the bottom panel to the posts with 21/2" screws (photo 1). With the panels on their edges, attach two of the corner posts to the bottom panel. Flip the assembly right-side up and attach one of the top rails to the top of the corner posts and center panel post. Attach the other two corner posts and top rail (photo 2). Attach the bottom supports to the bottom panel with 11/4" screws.

Attach the bottom panel to the posts. Drive 21/2" screws through the underside of the bottom panel and into the ends of the center panel posts.

Install corner posts and top rails. Each top rail should be attached to a corner post and a center panel post with 21/2" screws. Drive one screw into each post.

NSTALL THE CORNERS, TRIM & SIDING

Cut the corner stiles to length and width. Attach the corner stiles to the corner posts with four 11/4" screws. Drill a countersunk, 1/8"-diameter pilot hole for each screw (photo 3). Cut the front-bottom rail to length and width and attach it to the front-bottom support with four 11/4" screws and decorative finish washers. Cut the side siding and back siding pieces to length. Drill two countersunk pilot holes in each end of each siding board. Space the holes 1" in from the ends and 3/4" in from the edges. Attach the siding boards to the corner posts with 11/4" screws, spacing the boards 1/4" apart (photo 4). Drill a 11/4"-diameter hole near the bottom of the back of the refrigerator section for the power cord to fit through.

Install cornerboards. Attach the corner stiles to the corner posts with 11/4" screws. Align the inside edges of the stiles and posts.

Add siding. Drill two countersunk pilot holes through each end of each siding board. Locate the holes 1" from the ends and 3/4" from the top and bottom edges. Attach the siding boards with 11/4" screws, spaced with a 1/4" gap between boards.

INSTALL THE SHELVES

The shelves for this outdoor cart are optional. As shown, they’re spaced to allow storage of items of varying height, such as plates and cups. But if you want to store taller items, such as bags of charcoal or a turkey fryer, eliminate the shelves from the plan.

Measure and mark the shelf heights on the inside faces of the left side siding and center divider. Here, the shelves are spaced so the lowest shelf opening is 15" high. The middle opening is 10" high and the top opening is 8" high. The shelf supports are sized so the shelves will not interfere with the front corner posts. Attach the shelf supports with 11/4" screws driven through countersunk pilot holes in the supports and into the cabinet walls. Cut the shelves from 3/4"-thick plywood (preferably cedar plywood). Cut 11/2 × 31/2" notches in the left corners of each shelf board to fit around the posts. Drive a few brads down through the shelves and into the supports to secure them (photo 5).

Install the shelves. Attach the shelf supports with screws and then tack the shelves into position with 11/4" brads.

BUILD THE DOOR

Cut the door stiles to length. Cut the door siding to length and the top door siding board to length and width. Drill two countersunk pilot holes in each end of each full-width door siding board. Space the holes 1" in from the ends and 3/4" in from the edges. Drill one countersunk pilot hole in each end of the top door siding board. Attach the siding boards to the door stiles with 11/4" screws (photo 6).

Attach the door siding boards to the door stiles. The top door siding board is attached with only one screw in each end.

ATTACH THE WHEELS & HARDWARE

Tip the cabinet upside down and place one caster in each corner (here, 21/2" casters are being installed). Mark the caster screw holes and drill 3/16" pilot holes for each screw. Fasten the casters with 1/4 × 11/2" hot-dipped lag screws (photo 7). To hang the door, attach zinc-plated or brass hinges (a pair of 3" butt hinges will do) to the door and the left corner post and corner stile (photo 8). Also add a handle (an aluminum door pull installed vertically is used here) as well as a latch and strikeplate to hold the door closed.

Attach the casters. Position each caster and drill pilot holes for each caster screw. Attach the casters with 1/4 × 11/4" lag screws.

Hang the door and install hardware. Fasten the door hinges to the door (or doors if you choose to cover each opening) and then attach the door to the cart frame. Use a 1/4" spacer under the door to position it.

BUILD & ATTACH THE TOP

The top for this cart features a 3/4"-thick plywood subbase that supports a cementboard backer for the tiles (here, eight 12 × 12" porcelain tiles). Cut the plywood subbase to size from exterior plywood and attach it to the top rails with 11/4" deck screws. Cut a piece of tile backer board (here, 1/2"-thick cementboard) to 24 × 48". Attach the backer board to the subbase with construction adhesive and 1" screws (make sure the screwheads are recessed below the cementboard surface). Attach the tiles to the backer board with construction adhesive (photo 9).

Install the tile work surface. Instead of traditional thinset mortar, exterior construction adhesive is being used because it better withstands temperature and humidity changes.

Cut the top sides, front, and back edging pieces to length from cedar 1 × 2. Drill countersunk, 1/8"-diameter pilot holes in the edging pieces and attach them to the subbase edges with construction adhesive and brads (photo 10). Fill gaps around tile with caulk. Apply a clear, UV-protectant finish to the wood surface and seal the tiles.

Attach countertop edging. Made from strips of 1 × 2 cedar, the edging hides the countertop edges and protects the tile. Fill the gaps around the edge tiles and between tiles with caulk.

Pitmaster’s Locker

Pitmaster’s Locker

Supplies and accessories for your outdoor grilling and barbecuing have special storage requirements. Some, such as charcoal starter fluid and propane tanks and bottles, are hazardous, flammable chemicals that should be locked safely away outside of the house or garage. Other supplies, such as big bags of charcoal briquettes, turkey fryers, or starter chimneys, are bulky and often dirty or dusty. Additional tools, like grill brushes, thermometers, rib racks, and Texas-size kitchen utensils, are best kept together in a neat area close to your grill. This Pitmaster’s Locker addresses all of these concerns in a rugged-looking package that fits in well with today’s popular grilling equipment.

The frame for this grill locker is made with solid aluminum angle iron, sold at most building centers. Aluminum is rigid, sturdy, and withstands exposure to the elements very well. It is also relatively easy to drill, which you will appreciate. Because the metals market is fairly volatile, costs for aluminum can run on the high side. But if you buy in volume you can usually save a little money. Our eight pieces of 72" aluminum angle cost us $130 from an Internet seller (this is at a time of high metal costs). If you like this design but want to save some money, you can substitute paintable hardwood, such as poplar, for the frame parts. This requires recalculating the shelf and panel dimensions, however.

The lower shelf of this locker has 24" of height capacity. If you plan to store a 20-pound propane tank on this shelf, you can lower the supports for the middle shelf by 6" and still have enough room for the 171/2" tall standard tanks. This creates a middle shelf that has 30" of height capacity (or two shorter shelves).

For the serious grill cook (a Pitmaster in barbecuer’s parlance), a lockable, dedicated storage locker is the best place to keep tools, fuel, and other supplies organized and safe.

Pitmaster’s Locker

Pitmaster’s Locker

MAKE THE METAL FRAME

The framework for this locker is built from solid aluminum angle (1/16" thick × 11/2" wide each direction). Although aluminum is very rigid, it is also relatively soft and very workable for cutting and drilling. You can easily cut the metal parts for this project with a hacksaw, though keeping the cuts straight can be tricky. If you have access to a metal cutoff saw, it will save a lot of time—you might consider renting one. Do not install an abrasive blade in a power miter saw. You can also use a reciprocating saw or a jigsaw with a bimetal blade, as seen here (photo 1). Whichever saw you use, clean up and deburr the cut edges with a bench grinder.

Cut the aluminum angle for the frame parts (above) and then deburr the cut ends on a bench grinder (below). Don’t overdo it on the grinder or use a file.

Lay out shelf locations on the frame legs with a wax crayon or pencil (avoid permanent markers, as they work but the marks cannot be erased). Install shelf supports between pairs of legs at selected heights. Clamp each support to each leg with a locking pliers. Drill one 1/4" guide hole in the middle of each joint (photo 2). Use a carbide-tipped twist bit. TIP: Lubricate the drilling point with a drop of cutting oil before drilling. Add more oil if the metal begins to smoke. Once the guide hole is drilled, insert a 1/4 × 3/4" bolt and add a locknut on the interior side (photo 3). Hand-tighten the nut, but wait until the entire frame is assembled and squared before tightening nuts all the way.

Drill guide holes for bolts. Clamp the part for each joint together with locking pliers and then drill for one 1/4" bolt per joint.

Assemble the frame. Secure each frame joint with a 1/4 × 3/4" bolt and lock nut. If you’re able to locate aluminum fasteners use them, otherwise use stainless steel or hot-dipped fasteners.

After all of the joints are secured with hand-tightened bolts, check the assembly with a framing square and adjust as needed. Begin fully tightening the locknuts. Grasp each nut with a locking pliers and tighten the bolt head with a socket and ratchet or cordless impact driver (photo 4).

Assemble the frame by tightening the locknuts onto the bolts. Hand-tighten all nuts first and then check the frame to make sure it is square. Tighten the nuts with a cordless impact driver or a ratcheting socket set.

ADD THE PLYWOOD PANELS & SHELVES

Cut the shelves to size from 3/4" thick plywood (use quality plywood such as AB or BC as opposed to sheathing or CDX). Cut the panels from rough-textured cedar siding panels (these come in 4 × 8-foot sheets, usually around 3/8" thick). Sand and stain both faces and the edges of the panels and shelves with exterior stain before installing them.

Attach the back panel, top panel, and side panels in the correct locations with 3/4" pop rivets (photo 5). Clamp each panel in place and drill guide holes for the rivets through the frames and the panels. Install the pop rivets from the exterior side of the cabinet. Install the back panel first because it helps to square up the cabinet.

Attach the panels using aluminum pop rivets driven through guide holes in the frame and the panels.

HANG THE DOOR & INSTALL HARDWARE

The locker door is sized to fit in between the metal frame members, and it closes against the slightly recessed shelf edges. It is made from 3/8"-thick siding and framed with 1 × 2 trim. Install three butt hinges to the left leg with bolts and lock nuts. You will probably need to enlarge the screw holes in the hinge plates to accept the 1/4"-diameter bolts. After installing all three butt hinges, attach the edge of the door to the free hinge plates (photo 6). Test the door. If it works properly, attach the locking hasp. Use exterior-rated wood glue and 1" brass brads to attach 1/4"-thick × 3/4"-wide wood shelf edge to the front edges of the shelves (photo 7).

Hang the door. Attach the hinges to the metal frame first and then attach the other plates to the back of the door on the edge with no shelf edge molding.

Make the panels and shelves. Cut the shelves and door to size from exterior plywood and attach wood shelf edge molding to select edges as instructed. Cut the side, back, and top panels from cedar plywood (siding). Stain the parts before installing them in the frame.

Timberframe Sandbox

Timberframe Sandbox

Building this sandbox requires a good deal more effort than if you simply nailed four boards together and dumped a pile of sand in the middle. The timber construction is both charming and solid. A storage box at one end gives kids a convenient place to keep their toys. The opposite end has built-in seats, allowing children to sit above the sand as they play.

The gravel bed and plastic sheathing provide a nice base for the sandbox, allowing water to drain while keeping weeds from sprouting in the sand. The gravel and liner also keep sand from migrating out of the box. The structure is set into the ground for stability and to keep the top of the pavers at ground level so you can easily mow around them. When your children outgrow the sandbox, turn it into a garden bed.

If you have small children, a backyard just isn’t complete without a sandbox. This version is nicely sized, sturdy, and designed for ease of cleaning.

Timberframe Sandbox

Timberframe Sandbox

PREPARE THE SITE

Outline a 48 × 96" area using stakes and strings. Use a shovel to remove all of the grass inside the area. Dig a flat trench that’s 2" deep × 4" wide around the perimeter of the area, just inside the stakes and string (photo 1).

Remove the grass in the sandbox location with a flat-end spade, and then dig a trench for the first row of timbers.

LAY THE FIRST ROW OF TIMBERS

Cut the side, end, and storage box wall timbers using a reciprocating saw or a power miter saw. Coat the timbers with a wood sealer and let them dry completely. Place the first tier of sides and ends in the trench so the corners on successive rows will overlap one another. Place a level across a corner, then add or remove soil to level it. Level the other three corners the same way. Drill two 3/16" pilot holes through the timber sides, then drive 6" barn nails through the pilot holes.

Measuring from the inside of one end, mark for the inside edge of the storage box at 18" on both sides. Align the storage box wall with the marks, making sure the corners are square, and then score the soil on either side of it. Remove the timber and dig a 3" deep trench at the score marks.

Replace the storage box timber in the trench. Its top edge must be 3/4" lower than the top edge of the first tier of the sandbox wall. Add or remove dirt until the storage box timber is at the proper height. Drill 3/16"-diameter pilot holes through the sandbox sides into the ends of the storage box timber, then drive 6" barn nails through the pilot holes.

Pour 2" of coarse gravel into the sandbox section. Compact the gravel with a hand tamper or simply by stomping on it for a while. Cover the gravel bed section with heavy-duty plastic sheet (photo 2). Pierce the plastic with an awl or screwdriver at 12" intervals for drainage.

Prepare the base. Lay the first row of timbers, including the wall for the storage box. Fill the sandbox area with a 2" layer of gravel, and cover with plastic sheet or weed blocker.

BUILD THE SANDBOX FRAME

Set the second tier of timbers in place over the first tier and over the plastic, staggering the joints with the joint pattern in the first tier. Starting at the ends of the timbers, drill 3/16"-diameter pilot holes every 24", then drive 6" galvanized barn nails through the pilot holes. Repeat for the remaining tiers of timbers, staggering the joints.

Stack the remaining storage box timbers over the first one. Drill 3/16"-diameter pilot holes through the sandbox sides into the ends of the storage box timbers, and then drive 6" barn nails into the pilot holes (photo 3). Cut the excess plastic from around the outside of the sandbox timbers using a utility knife.

Build the rest of the sandbox frame, staggering the corner joints. Drill holes and drive barn nails through the holes.

BUILD THE STORAGE BOX FLOOR & LID

Cut the floor cleats and position one against each side wall along the bottom of the storage box. Attach them using 2" galvanized screws. Cut the floorboards and place them over the cleats with 1/2" gaps between boards to allow for drainage. Fasten the floorboards to the cleats using 2" screws.

Cut the lid boards and lay them out side-by-side, with the ends flush. Cut the lid cleats and place across the lid, one at each end and one in the middle, making sure the end of each cleat is flush with the back edge of the lid. Drill pilot holes and attach the cleats using 2" galvanized screws. Attach the lid to the sandbox frame using heavy-duty child-safe friction hinges (photo 4).

Attach the bench lid using heavy-duty hinges. Install a child-safe lid support to prevent the lid from falling shut.

BUILD CORNER BENCHES

Cut the bench cleats. Mark 3/4" down from the top edge of the sandbox at two corners. Align the top edges of the bench cleats with the marks and fasten them using 2" deck screws.

Cut the corner bench boards to length with a 45° angle at each end. Place it in the corner and attach it to the cleats using 2" screws (photo 5). Cut the bench boards to length with a 45° angle at each end. Butt one against the corner bench board, and then attach it to the cleats. Repeat this step to install the second corner bench.

Install 2 × 2 cleats 3/4" from the top of the sandbox to support the seats in the corners. Attach the corner bench boards using galvanized screws.

FILL SANDBOX & INSTALL BORDER

Fill the sandbox with play sand to within 4 to 6" of the top. Mark an area the width of your pavers around the perimeter of the sandbox. Remove the grass and soil in the paver area to the depth of your pavers, plus another 2", using a spade. Spread a 2" layer of sand into the paver trench. Smooth the sand level using a flat board. Place the pavers on top of the sand base, beginning at a corner of the sandbox (photo 6). Use a level or a straightedge to make sure the pavers are even and flush with the surrounding soil. If necessary, add or remove sand to level the pavers. Set the pavers in the sand by tapping them with a rubber mallet. Fill the gaps between the pavers with sand. Wet the sand lightly to help it settle. Add new sand as necessary until the gaps are filled.

Place the pavers into the sand base. Use a rubber mallet to set them in place.