WHAT IS A STRAW BALE HOUSE? Why are bales a good choice in a cold climate? Can bale walls be designed to withstand the vagaries of weather in the snow belt? These are questions we’ve been asking of ourselves for a good many years, and they have now become the guiding questions behind this book. To begin at the beginning, however, we must ponder this question of why. The idea of building a wall of bales seems to entice people’s imaginations. Why bales? We have come to believe that people are searching for alternatives to the plywood palace, to the modular mentality that has come to dominate the mainstream construction industry. Most new houses today are made of the same materials: machined sticks and sheets of wood, plastic, metal, and gypsum. They are usually assembled according to the same set of principles, so that once you’ve built a few, they get pretty boring. Except for that small percentage in which a designer, owner, or builder puts some real thought into creating a form and finish that suits the owner and the site, these houses somehow feel the same.

There are three main reasons that straw bale construction is different. First of all, bale walls look very different from sheetrock walls. They look like the product of a human, rather than the product of a machine. Though bales are a new material (which makes design work challenging and fun), the feel of the finished wall harkens back to the preindustrial era. It seems that as our lives become increasingly technological, more and more people want to surround themselves with spaces that feel handmade and timeless.

Process is the second reason. Conventional construction is mathematical and precise, while bales and plaster are sloppy and intuitive. These characteristics are inviting to amateur builders, not only because they make bale construction easy to learn, but because they stand in contrast to the obsessive efficiency that most of us have had to accept as a part of the industrial economy. People see bale construction as a chance to cut loose.

Third, bale construction feels like an alternative to ecological waste. It’s akin to recycling. Recycling enjoys broad support across the political spectrum, because it’s obvious, it’s easy, and it gives people a sense that they can at least do something that is not harmful to the planet. While our agriculture is far from perfect, it does produce a lot of straw, so using some of it for construction makes intuitive sense.

Bruce Millard, a thoughtful architect from Sandpoint, Idaho, has developed this idea about building with bales a bit further. “Once people try this type of construction, they absorb it and agree with it, and begin to recognize it as a concept, as a psychological departure from the idea that industry is somehow more sophisticated than nature. It brings the left and the right together; it functions as a stepping block into an ecological way of building and living. People begin to ask, ‘How can I put this to work in the rest of my life?’”

Bruce sees the bale itself as a short-lived material. “We will soon realize that straw is very valuable—it will start going into particleboard and panelized materials, and it might be mixed with wood fiber for paper production.” Bruce uses the bale as an introduction to a whole array of recycled-content panels and blocks.

Bales also tend to serve as an introduction to traditional natural building techniques from around the world, all of which have much longer track records than the bale itself. Loose straw has been used for millennia in combination with clay and sand, for everything from plasters to load-bearing walls. Five-hundred-year-old examples of straw and clay infill are still in use in Germany, and this material has actually been rewetted and put back into wall cavities during restoration. Thatch makes a beautiful, durable, insulative roof. These and other techniques must be explored and developed if we are to continue to create decent housing for future generations on this planet. (See chapter 15, “Beyond the Bale.”)

Straw can provide thermal and sound insulation or even serve as a load-bearing wall, all in the form of a compact, portable, nontoxic, and recyclable bale.

Why Build a House of

Straw Bales?

“Didn’t you learn anything from the first little pig?”

A mouthful of oatmeal and an earful of propaganda against building with straw; many of us were spoon-fed this breakfast throughout our childhoods. How is it, then, that perfectly sane people can consider living in a house whose walls are bales of straw? Maybe urbanization, suburbanization, and the decrease in the North American wolf population has lulled them into a sense of complacency about this domestic predator. Or maybe bales make such unusual walls that many of us are just willing to take the risk.

Beauty

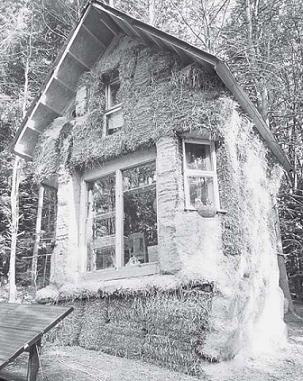

The most compelling among many reasons to build with bales is the quiet beauty of bale walls. Unlike walls of panelized materials, which require layers of ornamentation to bring life to their unnaturally uniform surfaces, bale walls look and feel as if they were made by hand. Their deep windowsills and gentle undulations lend a comfortably safe, quiet feeling to the interior of a home, while the plaster finish softly gathers and reflects light, changing in subtle ways as the sun shifts through each day and season. The effect is a heightened connection between indoor and outdoor worlds, an especially important relationship in climates where people spend a good part of the year inside buildings.

“We fell in love with the deep windowsills and rounded corners.”

“I like the massive feel, and the flexibility, of the bales; you can do anything with them, curvy or straight.”

“The house has a solid, embracing feeling, like it has its arms wrapped around me.”

Paul often describes bale walls as “plastered stone for the person of moderate means.” This is not to imply that bale walls don’t have a character of their own, which they certainly do; the point is that the massive, rounded feel of the bale wall is reminiscent of the old-world solidity of stone. (Bale walls also offer far more insulation value than stone walls, but we’ll get to that later.) Part of the appeal of bale buildings is that they just feel safe. Storms can be howling outside, or cars roaring along a nearby highway at twice the reasonable rate, and after the (good-quality) door clicks shut on a straw bale house, you will find yourself in near total silence. This sort of quiet allows the home to act as a refuge for the psyche; a place where the senses can escape the busy din of the postindustrial world.

Insulation Value

Straw bale houses may look and feel like plastered stone or earth houses, but they are in a different thermal category, entirely. Old stone houses are cold. New stone houses are typically built with foam insulation, either sandwiched between two independent stone walls, or blown onto the inside face of the stone. Both of these methods are quite expensive. Plastered bales, on the other hand, provide a highly insulative wall at a price that is competitive with quality conventional construction.

Paul’s

Very

Subjective

Discourse

on Walls

Not all that long ago in Western societies, and in some societies still, most people spent most of their waking hours outside, in the unfiltered presence of fresh air, warm (and sometimes hot) sun, cooling (and sometimes downright cold) breezes, and the visual, aural, mental, and spiritual stimulation of the ever changing natural world. Now that most of our society seems to have moved indoors, exchanging fresh air and physical work for office partitions, stress, and air heated, cooled, and otherwise denatured by a central delivery system, it has become quite necessary for the home to serve not only as a refuge, but also as a vehicle of connection to the natural world, a world whose subtleties are easily overlooked when your senses have been trodden by the glaring images of the TV and computer screen.

A person building with bales can bring the outside in by playing subtly with light, texture, and form. This requires a certain sensitivity on the part of the bale layer and the plasterer. On the one hand, it is possible to allow the short sight of the trowel too much control over the plastering process; the result is a flat, rather dead surface that speaks only of the mechanical ability of the hand that applied the plaster. It is also possible to get so carried away with lumpy textures and wild paints that the subtlety of the space disappears into a gawky argument between elements. A quietly beautiful wall lies between these two extremes.

What do I mean by this? The relationship between windows and views serves as a parallel example. Let’s say you come to a site. It’s a nice spot for a house, and it has this incredible view of a range of mountains. You sit there, maybe eat a picnic lunch and drink a glass of wine, and you look at the view. The sun is warm, and maybe you’re just a touch sleepy, but you’re also excited and so you’re talking with your partner about this great spot that you’ve found, about how beautiful it is, and about the future. You do this a few times, maybe a whole bunch of times, and you’re designing a house in your mind, and of course this view must be the central feature of the living room, because it’s been the central feature of your experience of this place. So you build the house, and you spend quite a sum of money on a big picture window, or maybe on a whole gable end of the house filled with glass, so that you can bring those mountains in.

For a while, maybe during the construction process and for a few months after you move in, you spend a few minutes after supper looking out at the mountains, and you feel good. One day, a year later, you’re stopped in front of the window; maybe you’re cleaning the glass, and you pause for a minute, realizing that you haven’t actually looked at those mountains for some time. You’ve glanced at them in passing (how could you not, they’re right there, staring you in the face), but you haven’t really stopped to look in detail at the change in color with the change of seasons, or at the movement of the snowline, or at individual trees and boulders. For all of your effort and expense, you haven’t succeeded in bringing the mountains in, at all. The wall of glass has come, as walls inevitably do, to simply define the perimeter of your living space. (Meanwhile you’re cold whenever you sit near that wall in winter, and your heating bills are quite a bit higher than they ought to be.)

Why has this happened? There are two reasons. First, an unmoving scene is not really all that interesting when viewed through a pane of glass. Birds at feeders, trees blowing in the wind, fire trucks racing by, these things work because motion attracts the eye, causes you to look through and beyond the window. If you attempt to fix your attention upon an unmoving object, however, a pane becomes a lens, a psychological obstruction between you and the thing you are trying to see.

Second, anything becomes commonplace when it is constantly staring you in the face, precisely because you soon stop taking the time to look at it closely. Instant gratification is incompatible with visual richness—nothing in this world is truly interesting to look at more than once or twice, until you learn to pause, even for only a few seconds at a time, and look closely.

The most beautiful bale walls I have seen have a quiet feeling; they invite a person to slow down, look longer, look closer. They make utmost use of the light that strikes them, which is to say that they look different at different times of the day, and through the seasons. They also change as you look closer, or back away. My favorite bale walls tend to be light in color, with a flat, typically unpainted finish, so that light can reflect from them without creating an unpleasant glare. Their surfaces are less lumpy than what Matts Myhrman describes as “softly irregular.” Flecks of mica or finely chopped straw, or subtle variations in color, keep the wall interesting right up to the point where you fairly well have your nose pressed against it. I prefer curved window wells to those that are flat or beveled, because they react with far greater variety to changes in angle and intensity of light.

All of this surface irregularity and general curvaceousness creates a wall whose outstanding features are the small pools of light and shadow that move across its surface as the sun makes its way up and down the sky. Not surprisingly, this effect is most pronounced in rooms with access to early-morning and late-afternoon light.

Buildings consume roughly one-third of the energy used annually in the United States. Superinsulated buildings (bales provide a super-insulated wall) keep their occupants more comfortable than their conventional counterparts, while pumping far less carbon dioxide and pollutants into the atmosphere. In other words, they cost less to heat and cool, to you and to the planet.

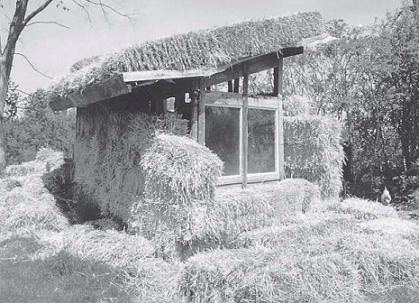

In 1998 tests at Oak Ridge National Laboratory in Tennessee found that the Rvalue of a bale wall laid flat measured at 1.45 per inch, while tests by the California Energy Commission found a bale wall laid on edge to measure at 2.06 per inch. (This translates to R-26 for a two-string bale laid flat; R-29 for a two-string bale on edge; R-33.5 for a three-string bale laid flat; and R-33 for a three-string bale on edge.)

The insulation in a bale wall is continuous; it is not interrupted by less insulative wooden members, as is the case with conventional construction. A 2-by-6 and fiberglass wall, rated at R-19, will really only achieve this value in the insulation cavities. In designs that do not specify advanced framing techniques to reduce wood use in corners, around windows, and in other detailing, the decrease in overall wall Rvalue due to thermal bridging through the studs can be substantial. Imperfections in the installation of insulation materials can also reduce the performance of conventional walls, to the point where their effective Rvalue is not much more than half that of a bale wall.

Basic bale nomenclature.

The actual performance of a bale wall system is also influenced by the thermal mass of both the bales and the plaster. This factor has a significant effect on the wall’s ability to store heat, and thus to maintain a constant temperature. It also appears to affect the rate at which heat flows through the wall. In the Oak Ridge tests, one side of the wall was heated to 70°F (21°C) and the other chilled to 0°F (–18°C). It took most of two weeks at this temperature difference before the wall began to lose heat at a steady rate. This means that as heat moved through the wall, some portion of it was being stored within the mass of the wall. Presumably, it was only after the wall temperature had stabilized that heat began to flow through at a consistent rate. David Eisenberg points out that in real world conditions in most cold climates, two straight weeks at a 70°F temperature difference would be quite an unusual event. Temperatures typically swing up in the daytime and down at night. The combination of mass and uninterrupted insulation in a plastered bale wall flattens these swings, providing even greater comfort and energy savings than the wall system’s rated Rvalue would imply.

Veteran solar architect Ken Haggard, of San Luis Obispo, California, points out a further benefit of the bale and plaster combination: “The thermal mass is integral to the wall finish.” Good passive solar design, of course, relies on a combination of southerly glazing, superinsulation, and internal mass. In conventional buildings (1/2-inch drywall, wood floors) the amount of glazing that can be added for solar gain is limited by the heat storage capacity of the building’s interior. Since adding mass to the interior is often viewed as an extra expense, many houses with good solar orientation end up with a disappointingly small proportion of their heat provided by the sun. Or (and this might be more common), lots of windows are shoved into the south wall, with little thought given to where the heat will be stored. The result is excessive heat buildup on sunny afternoons, coupled with excessive heat loss at night.

Guest room. Wisbaum home, Charlotte, Vermont.

In a bale building, there is no practical way around the application of one inch or so of plaster on the interior of the walls. This adds up to quite a lot of thermal mass, which translates into opportunity (and room for error) in the passive solar components of the design. It also means that a well-designed solar bale house cannot be spoiled in the construction phase by a foolish decision to eliminate the mass, in order to save a few dollars.

Nontoxic

Bales are a natural material. Unlike many manufactured building products, they contain no toxic ingredients, and are chemically stable. They will release no unhealthy chemicals into your home, and will not emit poisonous fumes in case of a fire. A relatively small amount of fossil fuel energy is consumed in the production of straw bales, and no toxins are released during the production or installation processes. Straw can eventually be composted back into the soil.

Use of Resources

A great deal of straw is grown around the world every year, enough for millions of houses. Some percentage of this straw (depending on soil type and the fertility program of any given farm) should be going back into the soil, ideally mixed with animal manure, which provides the nitrogen necessary for its decomposition. (This scenario bears no relationship to current agricultural practices in the industrialized world, but it is a worthy ideal, nonetheless.) Much of this straw is now burned in the field. By incorporating straw into buildings, we reduce particulate pollution and lock up carbon in a solid state, rather than releasing it as carbon dioxide, the most important greenhouse gas. We might also reduce the pressure on forests (the most important carbon sinks and oxygen producers on the planet) and the demand for relatively energy- and pollution-intensive industrial insulation materials.

Pliny Fisk III, of the Center for Maximum Potential Building Systems in Austin, Texas, points out that a better idea than using the straw from annual grains is baling the stems of native perennial grasses (as the original bale builders did) and invasive exotic species. GreenSpace (Paul’s company) has begun to experiment with the mixed stems of old field succession plants: goldenrod, milkweed, mixed native grasses, various woody perennials, small saplings. These are the plants that move in when pastures or hay fields in our region are allowed to fall out of agricultural use. New England hill farmers are often happy to part with these bales for half the price of good straw or hay, as the inputs are less, and part of their payment comes in preventing their land from growing up to brush.

A further development, suggested by biologist and landscape architect Ruth Parnall, of Conway, Massachusetts, would be a baler that could wade into marshes, to harvest phragmites (Phragmites communis). This European reed (used for thatch) has overrun much of the wetlands of the Mid-Atlantic and Northeast regions of the United States Consistent, aggressive bal-ing of phragmites could become a useful tool in containing its spread.

Whether the labor is volunteer or professional, almost every project is a custom project, with details and techniques invented during the design and construction phases.

Economical

“Plastered stone for the person of reasonable means.” Have you priced out a stone building lately? Or calculated the time to build one yourself? Most traditional earth and stone building systems have become quite expensive nowadays, because human labor has become expensive, compared with efficient assembly of machine-produced building components. The reason bales have risen to such prominence in Santa Fe is that the building code there requires that everything (including strip malls) look as if it is made of adobe. Bale houses are substantially less expensive than real adobes, and look and perform a whole lot better than stick frames mas-querading as earth.

In the industrialized world, bale construction is getting to be cost-competitive with good-quality stick-framed construction, assuming a tight design that doesn’t drive labor costs through the roof. Mechanical or volunteer application of plasters and hands-on experience with a few bale projects help substan-tially, here. Availability of bales is also impor-tant. It is not really fair, however, to compare bale walls with 2-by-6 walls. They look more like stone or earth, and they perform more like double-stud, 10-inch-deep walls, blown full of cellulose.

Because bale construction is still maturing, it is also reasonable to assume that the cost of walls will continue to drop. Whether the labor is volunteer or professional, almost every project is still a custom project, with details and techniques invented during the design and construction phases. We are all constantly refining our methods, hunting down those details that make for an efficient construction process. This is part of the fun, of course.

A small pile of recyclable materials is often all that is left over after construction of a straw bale house.

In areas of the world where machined materials are expensive or unavailable, and straw and labor are cheap, bales will compare favorably with any other type of construction. Bale houses tend to be more durable and comfortable than either government houses (typified by the random and horribly expensive application of industrial techniques), or scabbed-together houses (usually built of whatever cast-off materials happen to be lying around). Bales offer a route back toward the sensible, owner-built, locally adapted housing that could be found everywhere on this planet, before the Industrial and Green Revolutions swelled our population and our egos.

Owner-Builder Friendly

At the time of this writing, most of the bale buildings in the world have been owner-built. This ratio is sure to change over time, as bale buildings develop a longer track record, as more mainstream home buyers and financers begin to recognize the strengths of walls built with bales, and as more contractors develop expertise in and enthusiasm for this type of construction.

Bales will remain a choice material of owner-builders, however, because they are so well suited to a “gang of friends” method of construction. (See below, under “Fun.”) Novices are also attracted to the apparent simplicity of the wall system. Even people who have no experience with construction can wrap their minds around the idea of stacking bales. On many occasions, this initial sense that “I can do this!” leads an otherwise intimidated nonbuilder out of his or her shell, toward a willingness to take on framing, plaster, finish work, and so forth.

With a good design, careful organization, and the guidance of a few skilled people, it is possible to keep dozens of volunteers engaged in various stages of bale and plaster work.

Fun

Many aspects of construction can be great fun. Framing is enjoyable unless you are stuck doing it every day, because it goes so quickly that structures seem to appear out of thin air. Some people love the attention to detail required by finish work. Hard as it is to believe, many drywall contractors seem not to mind hanging and taping wallboard.

Bale construction is fun for two reasons. The first is because its two main components— stacking bales and smearing plaster— lend themselves to work parties. With a good design, careful organization, and the guidance of a few skilled people, it is possible to keep dozens of volunteers engaged in various stages of bale and plaster work. Because the process can be broken down into many distinct tasks, people are free to try different jobs and learn various skills. There are niches to be filled by persons of all levels of physical ability and experience. The synergy of this group effort (not to mention the sheer volume of work possible in a day) is one of the greatest thrills of straw bale construction.

The second reason is that laying bales and applying plaster are essentially right-brain activities. Stacking bales is much more like playing with blocks than it is like any mainstream construction practice. This is especially true when the structure is framed in advance, because in this case plumb and level have already been determined by the framing crew. Clay plaster work is reminiscent of making mud pies. You can smear the stuff on the wall with the heel of your hand. You can throw it at the person working next to you. If you are so inclined, you can get yourself completely coated in earth.

Durable

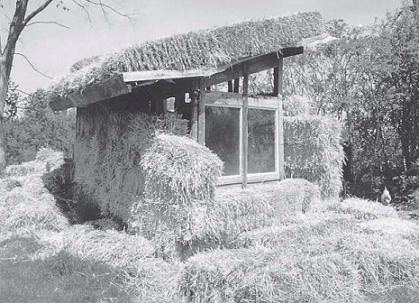

The oldest bale structures in Nebraska date back nearly one hundred years, to the invention of the baler. The oldest bale house in New England has kept its occupants warm and dry through twenty-five wet, coastal winters, and is still in excellent condition. (See the profile of the Hay House, following this chapter.) Bale walls appear to last indefinitely, if kept dry.

Combinations of straw and clay have been used for millennia all around the world, and five hundred-year-old houses with straw-clay walls are still inhabited in Germany. (See chapter 15, Beyond the Bale.)

FIRE RESISTANCE

Plastered bale-wall systems have outperformed wood-framed walls in fire tests. In a trial performed by SHB Agra Engineering and Environmental Services Laboratory in Albuquerque, New Mexico, in 1993, walls built of two-string, wheat-straw bales were examined both bare and with plaster skins.

In the first case, on an uncoated wall, the fire took 34 minutes to work its way through, at a seam between two bales. The maximum applied temperature was 1,691°F (921°C).

The second test, on a wall finished with gypsum plaster on the heated side and cement stucco on the unheated side, was even more impressive. The heated side of the wall reached 1,942°F (1,060°C), while the highest rise in temperature on the unheated side, after two hours of exposure, was only 21°F. Behind cracks in the gypsum plaster on the heated side of the wall, charring in the straw was only 2 inches deep.

Unfortunately, the final report on this test has never been produced, because of a lack of funding. The U.S. and Canadian national code bodies, therefore, have yet to issue a fire rating for plastered bale construction. Nonetheless, the results of this test have been very influential in convincing local and state code officials that plastered bale walls pose no unusual threats to their occupants, in the case of fire. At the Sivananda Lodge (see profile following chapter 8) bales were easily accepted for a one-hour fire rating. The case has also been made that plastered bale walls, because of their density, are more fire resistant than the ubiquitous studs and drywall.

RODENTS AND INSECTS

When detailed correctly, bale walls are highly resistant to damage from insects or rodents. Tiny bugs (springtails, most often) have sometimes been present on the interior surface of plaster while it is drying, or in houses that have experienced high moisture levels within the bales. Under normal circumstances, they seem to depart once the plaster has cured fully. The best defense against insects seems to be to keep your walls dry.

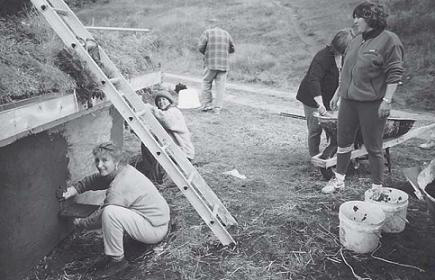

Happy crew at work during a straw bale workshop.

The same set of details that protect your bales from damage by moisture should also be sufficient to keep out rodents, for at least as long a period as in conventional construction. We will not claim that mice will never get in: Rare is the building that has stood for fifty years without these little monsters finding a way into the walls. Typical plaster finishes (or appropriate screening, in the case of a sided building) should provide reasonable protection against their entry.

Even if mice do eventually sneak in, it is distinctly possible that they will matter less than in a conventional cavity wall. Rodents rarely bore into bales; they favor the slightly less dense horizontal runs between courses. Their movement throughout the wall is, therefore, limited. Also, without a large cavity to scratch around in, the occasional mouse should not be very much of a nuisance to the occupants of a bale building.

The first of Paul’s two favorite stories about rodents and straw comes from the Hay House, in Connecticut, the oldest bale house in New England. Over the past twenty-five years, squirrels have, at times, taken up residence in the rafter cavities. David Brown, who owns the Hay House, explains that at one point the squirrels could even get into the living space; they apparently enjoyed standing on top of a bookshelf and watching him dress in the morning. Never, in all of this time, has there been any evidence of squirrels moving into the bale walls, even though the top of the north wall has never been plastered.

The best defense against insects is to keep your walls dry.

Marc Rosenbaum, P.E., of Energysmiths, in Plainfield, New Hampshire, relates another story: At one point he had some bales stacked under a porch roof, near his front door. They were to be incorporated into the walls of an entryway addition. In preparation for the work, he had an electrician disconnect an electrical box that was cut into the foam-core, stressed-skin panel wall of his house. Within weeks, he found evidence of mice chewing into the newly exposed foam, and tacked a board over the hole. Come spring, and upon removing the board, he found an entire family of dehydrated mice within the foam panel; when he then moved the straw bales, mouse signs were nowhere in evidence.

Such anecdotes do not necessarily add up to the assumption that rodents are not an issue in bale houses. The fact is, however, that we have yet to come across a well-detailed building that has had any problems with these unwelcome guests.

EARTHQUAKES

The solid, unshakable feeling of bale walls turns out to be based in physics. In 1998 tests by David Riley and his students at the University of Wash-ington found that bale walls finished with gypsum plaster on one face and cement stucco on the other (both reinforced by wire) showed an unusual ability to absorb the sort of push-pull shear forces (no, that’s not the official engineering term) that are typical of seismic events. “Only under substantial displacement (e.g., an earthquake) would bales in a wall be subjected to the movement applied in this test; however, the test results show that the bale walls were capable of absorbing a significant amount of energy on repeated cycles. For this reason, a bale structure should behave favorably under seismic loads.”1

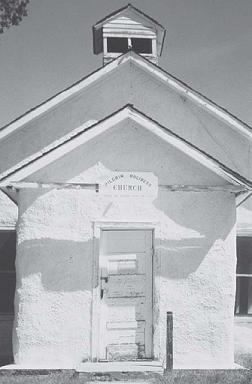

The Pilgrim Holiness Church in Arthur, Nebraska, built by the congregation with donated rye-straw bales.

Another revealing test was performed in Berkeley, California, in the spring of 1998, on a straw bale arch. The arch and test were designed by Skillful Means and structural engineer David Mar, with input from other experienced members of the California straw bale community. The arch was built of three-string bales, finished with meshreinforced cement stucco, inside and out. The inner and outer curtains of mesh were fastened together by wire ties run through the bale core of the structure. A specially calibrated hydraulic jack simulated earthquake forces by simultaneously pushing in and pulling out on the arch.

The arch performed extremely well. Its elastic limit (the point at which the stucco began to crack) was not reached until the out-of-plane load totaled 55 percent of its weight—nearly double the seismic code requirement of 30 percent. The test rig was incapable of causing the arch to fail. The maximum load was 115 percent of the weight of the structure; this is the equivalent of turning it on its edge and applying a further 15 percent of its weight.

David Mar thinks that bales will turn out to be an unusually appropriate material for earthquake-prone regions. He believes that bale walls designed according to the seismic principles that govern masonry walls offer the advantages of lighter weight, greater ductility, and, most important of all, the ability to absorb significant quantities of energy without failing catastrophically.

Historical Background to

Modern Bale Building

Straw bale construction began with the invention of the baler, at the tail end of the 19th century, in the Sand Hills region of Nebraska. The Sand Hills are a vast tract of grass-covered dunes, formerly the margin of a sea that filled up the Mississippi Basin. As water receded, the shoreline sands drifted into the Sand Hills formation.

When homesteaders began to move into this country in the 1880s, they found that wood for construction was available only in the river bottoms. Since most farms had no access to this resource, lumber for building quickly became an expensive commodity. By this time, using wide strips of turf to build up the walls of a house was a common method of conserving wood in homestead construction. Because the primary work in the early years of a farm was breaking the dense plains sod to plant crops, it made good sense to incorporate this material into buildings. In areas where the soil was appropriate, these “soddies” were excellent houses. Many still stand today.

Unfortunately for some Sand Hills homesteaders (but fortunately, for the rest of us), the loose Sand Hills soil produced a turf of poor quality for construction. Nobody knows how many Sand Hills sod houses collapsed before some ingenious farmer came up with the idea of stacking bales of grass—a product of the newly invented baler— into the walls of a house. Stories about early bale houses inevitably involve imminent winter and a large group of neighbors gathering to move a roof, wholesale, off a crumbling sod house and onto a freshly stacked set of bale walls. Oral history also indicates that many of the early houses were originally plastered only on their interiors; the owners intended, before long, to build a “real house.” Within five or so years, they typically came to realize that they possessed a house that was not only real, but comfortably warm in the winter and cool in the summer; at this point the exterior plaster would be applied.

While some of the details may be apocryphal, there is no question that this type of story captures the spirit of early bale construction. The original bale builders were eminently practical people doing what needed doing in order to carve a life out of a raw and difficult land. If creating shelter for winter meant carrying a roof through knee-deep snow, there is little doubt that they would have been up to the task. And if it took five years to accept the idea that bales and plaster could make the walls of a real house, that is a blip compared to the hundred years it has taken for this same idea to begin to reach a wider audience.

It seems no coincidence that bale construction was revived among another generation of homesteaders. The technique may have died out completely, were it not for an article by Roger Welsch in Shelter, a compendium of indigenous and offbeat building styles from around the world, written for a 1970s back-to-the-land audience. This article inspired a few practical and independentminded people, including Jon Hammond in California, Jorg Ostrowski in Alberta, Louis Gagné, Francois Tanguay, Clément Doyer, and Michel Bergeron in Quebec, Ben Gleason in Connecticut, and a handful of others, to begin experimenting with this technique. An article on Hammond’s straw bale studio, published in 1983 in Fine Homebulding, led others in the mid-1980s, Steve and Nena MacDonald among them, to give a try at stacking simple, inexpensive walls of bales. By the late 1980s, Matts Myhrman and Judy Knox, Athena and Bill Steen, David Bain-bridge, and Pliny Fisk III began to have a close look at the wider implications of bale construction for grassland regions.

Like the Sand Hills homesteaders, the early rediscoverers of this technique usually had rather immediate reasons for choosing bales: they needed a place to live, and needed to make do with what they had lying around. Ben Gleason put it best: “We knew that we’d only be farming a few more years in Connecticut, then we were moving to Vermont. I built this place for $500 in materials, and figured if it lasted five years, that would be good enough.” Ten years later and in a drier climate, the MacDonalds had greater hopes for the longevity of their building, but they, too, were primarily concerned with getting up a habitable shelter on a very tight budget. Luckily, the MacDonalds decided to share what they had learned. With the 1991 publication of Steve’s Straw Bale Primer (illustrated by his son, Orien) straw bale construction became available to a much wider audience.

Straw bale construction has come a long way since these early pioneering efforts. Several excellent books, videos, and hundreds of articles have been produced on the subject. The indefatigable David Eisenberg has brought awareness of bale construction to the highest echelons of the international building code hierarchy, while thousands of people, by patiently working with their local officials, have received project approval in jurisdictions around the world. Bales have been incorporated into homes of many different styles, which cross a very wide range of expense. As our understanding of how a bale wall works has become more sophisticated, new options have emerged for meshing bales with other materials. What hasn’t changed, however, is the simple beauty of these early bale houses.

The Past Meets the Present

Nebraska-style straw bale houses built in the early part of the 20th century can be compared to any other type of vernacular architecture. They were all built with the same set of materials and according to a common system by people who shared both cultural background and physical environment. Today’s examples of straw bale houses, even those that were directly inspired by the Nebraska dwellings, have departed from the characteristics of vernacular houses; they are designed and built by individuals of all imaginable cultural backgrounds, with access to very different material and economic resources, responding to an endless variety of site and lifestyle conditions. As these buildings have spread around the world, they have been influenced by practitioners of many different trades, bearing a great diversity of local construction wisdom, many of whom got interested because of the creative challenge of working with an odd new material. The original system has traveled as far in new ideas and concepts as it has across continents. Intuitively or deliberately, modern bale pioneers have done their utmost to adapt the system to different environmental conditions.

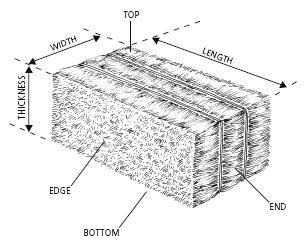

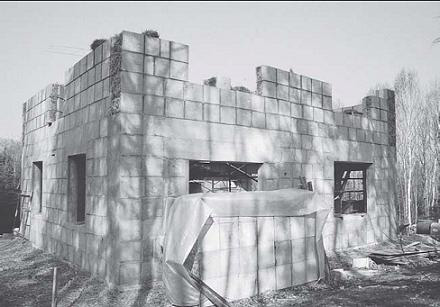

Stud frame house with straw-clay walls. Lauzon, Quebec.

What straw bale builders share around the world is access to the basic information and their attraction to a material that has been used in vernacular architecture since the beginning of humanity: straw.

Straw bale house under construction, using a preplastered, load-bearing system. Saint-Faustin, Quebec.

Straw in its modern baled form seems to have reconnected many of us to our roots. The growing popularity of straw bale houses is likely akin to an increasing interest in other techniques that use straw in its loose form. Cob and straw-clay walls, plasters, and blocks are gaining repute as alternatives to modern industrialized materials and techniques. As designers look further back at the history of straw in construction, they have become increasingly likely to blend these methods into their straw bale houses.

As straw bale construction has bloomed in the 1990s, so has electronic communications. (If only the humble bale were to receive as much media attention as the Internet!) Bale building designers have made extensive use of these technolo-gies to keep each other appraised of the latest experimentation, sometimes on a day-to-day level. This has been generally useful and occasionally hazardous: there is a natural temptation to copy at home what seems to work well at the other end of the planet. As straw bale houses pop up all over, many inexperienced builders have fortified their frenzy of excitement over the well-adapted simplicity of the early Nebraska buildings with incomplete contemporary information, without ever stopping to think critically about how to adjust these prototype designs to their own environment.

Much experimentation, field testing, and monitoring remains to be carried out, across many geographical regions, before local cultures establish their own standards for bale construction. But with time and with investment by local communities in this research, straw bales may yet become a key material in the definition of new vernacular architectures in parts of the world where the originals have been replaced by anonymous, industrialized dwellings.

A Straw Bale Reality Check

Though this might come as a surprise to some enthusiasts, we are quite sure that bales are not a perfect construction material. Their bulky and uneven size, their unwillingness to hold nails, and their need to be kept dry forever make for a substantial set of design limitations. Similarly, the fact that straw bale construction is still in an evolving state means that when labor is paid, straw can actually turn out to be more expensive than conventional alternatives.

The

Owner-

Builder:

Eyes

Wide Open

When we hear about extremely inexpensive bale houses, we have discovered the product of an equation: labor x money. It is possible, up to a point, to substitute labor for money in a building. For a patient and talented person, this is where the real savings can happen.

What does this mean? Trees, especially standing trees, are far less expensive than milled lumber. Cut and peel timbers, from your land or a neighbor’s. Bring in a mill to saw dimensional lumber on-site. Better yet, salvage an old building. Salvage good-quality, doublepaned windows. Salvage slate or metal roofing materials. Do your own site work, with rented equipment, or by hand. Minimize trim. Buy used appliances and plumbing fixtures (if you live in a jurisdiction where you are allowed to install them yourself). Build small Build small. Build small. Expect to realize very little return, on a dollars saved per hour spent basis, for the time you spend in salvage and handwork. The reason why most people in the industrialized world don’t do these things is because they can work for money and buy materials (and, to some degree, skilled labor time) more efficiently than they can throw their relatively unskilled hours at salvage and building projects.

There is no such thing as a cheap house of good quality, except maybe in depressed areas where the real-estate market has been deflated. Quality costs a combination of time and money. This combination can be varied somewhat, but the bottom line is the same: House construction boils down to a skillful reorganization of a massive quantity of raw materials into an absolutely necessary end product. This end product should be expensive, especially if the owner insists on its being unnecessarily large, as is the norm in North America. The idea that enduring, comfortable, and even elegant shelter can be had for a minimal amount of work is an illusion of our stock market and lottery-oriented society, and shows a complete disrespect for all of human history. If you only care about cheap, then you should save up $1,000 and buy an old trailer.

We are not advocating a huge mortgage and a turnkey house. We are firm believers in the pay-as-you-go, owner-built house. The point is that this method entails a lot of hard work, both physically and mentally. Using bales for your walls won’t really change that fact, so you had better be prepared for it.

At GreenSpace, we ritually explain to potential clients that we are 90 percent sure that straw bale construction is a good idea, in our cold and wet climate. This is based on the fact that, while we employ a set of details that seem as if they should work, straw (at least in baled form, and as a component in an overall strategy for superinsulation) does not have a long track record, in our climate. It is crucial that modern straw builders proceed with humility and an open mind, and with the assumption that many of the true strengths and weaknesses of this technique have yet to be defined. We are in the business of experion, and only a fool treats an experiment as a sure thing.

Cost, Labor, and the Strange

Values of Western Society

The greatest myth about bale buildings is that they are cheap. Bale construction can be less expensive than its thin-walled cousins, if the raw materials are locally abundant and human hours spent fiddling with bales and applying plasters by hand do not count as costs. Walls typically account for between 10 and 15 percent of the price of a house in the industrialized world, however— so if someone tells you that you can build a very inexpensive house on account of using bales in your walls, you should probably look elsewhere for advice.

Good-quality, relatively inexpensive bale houses have been built in cold climates. At least in North America, they have not been built for the 10 or 20 U.S. dollars per square foot that is sometimes possible in climates that require a minimal investment in foundation, roof, windows, or heating system.

The fact remains that a large percentage of people first get interested in straw bale construction because they think a bale house is going to be less expensive than its conventional counterpart. Whether this turns out to be the case has less to do with the bales than with the character of the homeowner. Buildings are complicated enough that no one material choice can have all that great an effect on their total cost. We have seen simple bale-walled utility buildings constructed of salvaged materials and basically for free; we have also seen bale-walled houses that finished out at $200 plus per square foot. What really affects the cost of these buildings is how the bales and the many other components fit into the larger issues of budget and lifestyle choices.

Houses are built by one of three processes. The first, and by far the most common method in the industrialized world, is by contracted crews of professional tradespeople working with purchased materials. The second method is by the owner, probably with some paid help and subcontracted phases, and with mostly purchased materials. Most owner-built houses in the Western world fall into this category. The third method is by the owner, with the help of whatever free or cheap labor can be scrounged up, and with as few purchased materials as possible. This is the model that is typical in the developing world.

Bales will save no money in process number one. In fact, it is only with a careful design and efficient on-site organization that the bales can even compete with mainstream materials. Compared with dimensional lumber, plywood, drywall, concrete blocks, and the many other premachined components available today, bales are relatively imprecise and cumbersome to handle. They soak up time, and time, in this scenario, is expensive. (And appropriately so. Wading to their elbows through a swamp of overpaid office workers, tradespeople, the providers of shelter, can still usually afford some simple privi-leges—such as owning the place where they live. Unlike other basic service providers, such as farmers and garment industry workers, they have not yet been mechanized into poverty.)

So, bales will not save any money if your house is built by professional tradespeople; at this early stage of their development they will often cost more to install than the conventional materials familar to contractors. All of the other reasons to use them still apply, of course. And here is a unique reason: The bales and plaster offer an ideal opportunity for the homeowner and his or her friends to become involved in the construction process. Owner labor during these phases can keep the cost of the building down to (or slightly below) conventional standards. More significantly, it helps the owner balance the stress of constant financial and aesthetic decisions with some good old-fashioned hard work. Most people (and especially those whose careers re-quire nothing of their hands) get a real kick out of pitching in on their own house. They have fun, and they feel a sense of competence and ownership. Regardless of what the realtors may tell you, when it comes time for the final accounting of satisfaction gained per dollar spent, all of this is at least as valuable as the number of square feet under roof, and whether or not the countertops are made of Corian.

The fact remains that a large percentage of people first get interested in straw bale construction because they think a bale house is going to be less expensive than its conventional counterpart.

In process number two, what we might call the conventionally organized owner-built house, bales and plaster can save some money. Plaster materials (especially if clay is used as the binder) are relatively inexpensive; bales can also be less expensive than conventional insulation materi-als, though this varies tremendously by region and season. The plaster component will add sub-stantial labor time over the cost of drywall and cladding, so bales will only save money if the owner-builder is skilled at gathering and coor-dinating large work parties, or if the project progresses on a relaxed schedule. The danger with owner-built houses that are on a tight schedule (especially when the owner is not an experienced contractor) is that time will begin to press in on the process, and labor will have to be hired in to speed up the finish. Such unplanned outlays can quickly wipe out the economic benefits of in-expensve, labor-intensive materials choices.

All of the benefits of bales that apply in the first case apply in the second scenario, also. Additionally, we have met many owner-builders for whom bales (the idea of bales, really) made the self-build route psychologically possible. Most of these owner-builders also say they wish they knew in advance how much work would ulti-mately go into the bale and plaster walls. We have yet to come across one, however, who was not ultimately happy about their decision to use bales, or about the quality of the space they were able to create.

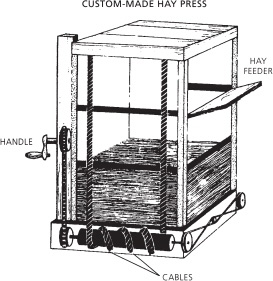

In the third scenario, the true low-income, self-help housing model, bales can be a godsend. They might not cost any less than other salvageable options, but their use will almost always lead to a better building. The straw, in this case, will certainly be grown locally, and might be hauled directly from the field, by the builder. He might even do the baling himself, with a handpress. Plaster will be composed primarily of materials that are free for the taking. Interior finishes will be simple and integral to the structure. Foundation, roof, windows, and heating system will likely be the elements that consume what limited funds are available to the owner. If a large percentage of the materials are to be salvaged, the building will usually be a small one, because salvage is a lot of work. This type of house will almost always grow over time, in a pay-as-you-go fashion. Sometimes, it will possess more elegance and humanity than buildings that cost 100 times as much.

Grass Cellulose and Wood-Pulp Cellulose

If there is one point to this discourse, it is that straw bales are not a panacea. They are one of many excellent materials that, when used in intelligent combination, can provide a beautiful, durable, and unusually functional house. One obvious comparison is with a close cousin of straw—blown cellulose insulation. Cellulose is recycled newspaper. Skilled installers can pack it dense enough that it functions as an air barrier; it also has a tremendous ability to diffuse moisture out of wall and ceiling cavities. It blows around obstructions such as pipes, wires, and ducts. It is much lighter than baled straw.

Straw has a very low embodied energy; so does cellulose. (“Embodied” energy is the amount of energy used to produce, transport, and install a unit of material.) Extrapolating from Ann Ed-minster’s Investigation of Environmental Impacts of Straw Bale Construction, one can reasonably assume that a 45-pound, two-string straw bale will embody 250 Btus of energy per square foot of wall surface. Blown cellulose embodies 600 Btus per square foot, installed at a density appropriate to achieve R-20 in a 51/2 inch wall.2 The bales come in quite a bit lower than the cellulose (especially if you increase the cellulose numbers by 50 percent to create a more direct insulation comparison with a bale wall), but both the cellulose and the bales embody far less energy than fiberglass (4,550 Btus per square foot, R-20) or EPS foam (18,000 Btus per square foot, R-20).

A handpress can make longer or shorter bales. From LaVie Paysanne, 1860–1900.

In GreenSpace projects, we generally use blown cellulose in ceilings, in floors when necessary, and in any sections of wall where bales do not make sense. On more than one occasion we have suggested to potential bale builders who wanted flat walls that they were probably better off with doublestud construction, drywall, and cellulose. That’s basically how we see it, from the perspective of the eastern woodlands: if you want wavy walls, use bales and plaster. If you want flat walls, use cellulose and drywall.

The issues of land use, biodiversity, and soil conservation are also significant. Logging practices in old-growth forests have finally begun to receive the attention that they deserve, and just in time. But when did you last hear someone squawk about the demise of old-growth grasslands? Aldo Leopold had a thing or two to say about it, but fifty years ago; he was already too late.

It is economically feasible to manage a woodland for biodiversity, and soil conservation, and log production. Under our current agricultural system, the same can rarely be said for cropland. Putting sentimentality aside for a moment, we might recognize the “amber waves of grain” for what they are, in biological terms: a vast monoculture that exists for the sole purpose of maximizing production of food for humans. The high percentage of the North American continent that has been converted from prairie and woodland to grain production loses millions of tons of top-soil every year, while absorbing equally stupendous quantities of petroleum-derived fertilizers, herbicides, and (to a lesser degree) pesticides. Millions of gallons of fuel are consumed in driving over this land, several times per year, in order to plant, maintain, and harvest this monoculture. The great majority of straw used in construction, quite unfortunately, is a by-product of an industrial agriculture whose patterns are no less ecologically destructive than those of industry in general.

The major issue in a bale building, as in a wood building, is control of rainwater; the secondary issue is control of condensed interior moisture.

We could, as Pliny Fisk points out, be building with the baled stems of native perennial grasses; we might also practice baling as a tech-nique to control the spread of invasive exotic species. We could harvest straw from smaller, more diverse farms that employ crop rotations and animals in an overall fertility program. Sadly, the new orthodoxy of The Economy seems not to preach an interest in such approaches. Until a new Luther arises to correct the gross overindulgences of this all-powerful cult, we must proceed with a humble recognition of how imperfect a material our lovely straw really is.

Moisture

Moisture, of course, is the major issue facing straw bale construction in cold climates. Bales need to be kept dry once they are in the building, but they also need to be kept dry during construction. No other non-ground-contact insulation material is installed until after the building is dried in—which is to say the roof and exterior walls (including sheathing and windows) are in place. Because bales are typically the substrate for the exterior skin, and are also, in the case of Nebraska-style methods, the support system for the roof, keeping them dry during construction becomes a major design issue.

Damage from moisture can be a problem throughout the life of the building, of course. Luckily, this is also the case with wood, and bale buildings can borrow many details from traditional wood buildings. The major issue in a bale building, as in a wood building, is control of rainwater; the secondary issue is control (or dissipation) of condensed interior moisture. The key to success in cold-climate straw bale design is to think obsessively about where and how water may enter the wall, by either of these processes, and to design a forgiving system with a high potential to dry any moisture that gets past your initial defenses. Strategies for dealing with these issues will be detailed in the following chapters.

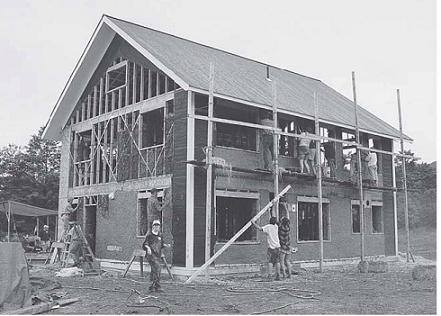

A pay-as-yougo project. Bellow’s Falls, Vermont.

MOLD

Only under one circumstance are bales known to be dangerous: if a specific mold, Stachybotrys atra, is allowed to grow in very wet straw. This mold can also live in many other common building materials, including water-soaked wood, ceiling tiles, wall paneling, unpainted plasterboard surfaces, cotton items, cardboard boxes, and stacks of newspaper, though it prefers straw over almost anything else, according to Canadian mold and fungal specialist, Dr. David Miller.3Stachybotrys has recently received attention as a health risk in conventional buildings, as well. According to the November 1999 issue of Environmental Building News, “One Canadian study found evidence of the mold in 2 percent to 3 percent of the homes surveyed, and Dorr Dearborn of Case Western Reserve University . . . was quoted as saying that he has found evidence of the mold in more than half of inner-city homes surveyed.” Stachybotrys seems primarily to be a danger to infants.

The point here is that bales need to be kept dry. If your walls get so wet that Stachybotrys begins to grow, then you have other problems beyond mold.

1 . David Riley, Gregory MacRaw, and Juan Carlo Ramirez, “Strength Testing of Stucco and Plaster Veneered Straw Bale Walls,” The Last Straw, 24 (winter 1998): 8–9.

2 . Alex Wilson, “Insulation Materials: Environmental Comparisons,” Environmental Building News (January/February 1995): 15.

3 . Don Fugler and Habib Gonzales, “Mold Warning: Stachybotrys Atra,” The Last Straw 22 (spring 1998): 11.