Appendix 1

HUMIDITY IN STRAWBALE WALLS

by Jakub Wihan

The doubts that generally come to mind in connection with strawbale walls are always related to fire, rodents and moisture. While worries about fire and animals can easily be dispelled by the application of good plaster on to the straw, the question of the vulnerability of straw to humidity is potentially more serious and is worth looking into in detail.

Even in the often-wet climate of the UK and Ireland, straw will become damp only in certain situations. When a farmer finds some old bale in a forgotten corner, it is likely to still be in very good shape after many years or even decades unless it sits on damp ground, is covered so that fresh air can’t get to it, or is exposed to leaks, condensation or direct rain. So, according to the experience of any farmer, a wall of stacked bales that is built on a tall and draining plinth and covered by a generous overhang will last for a very long time, even in a very humid climate such as that of the UK and Ireland.

Questions start to spring to mind when contemplating building a strawbale house on a site exposed to severe winds. For example: Will the render shield the straw enough from driving rain? And if the rendered straw gets wet for some reason, doesn’t the render then prevent the straw from drying? And, most importantly, doesn’t the cold weather cause condensation within a strawbale wall?

Research: where are problems most likely to occur?

Houses built out of straw and hay bales more than 100 years ago in the Nebraskan desert are failing to give us convincing answers to the above questions, because there is not much that can go wrong with a strawbale house in a desert climate. But since people in the late 1980s started building in a more humid environment, in the UK and Europe, the effect of moisture on strawbale walls has been the subject of numerous investigations. This has given an idea of:

• how different plasters and renders influence humidity levels within the straw

• the relationship between humidity and potential straw decomposition

• the most common causes of straw rot in walls.

A questionnaire* sent to professional strawbale builders all around the world in June 2004 was used to create a database of 174 moisture problems in strawbale walls that those builders had repaired during their careers. Almost a quarter of all the cases of serious moisture damage related to bad window or door detailing, where leaking windowsills were the most frequent causes. One in six reported moisture problems was related to a leaky roof, and only slightly more – 30 cases out of the 174 – had rotting straw in their walls due to wind-driven rain. The window detailing can’t ever be underestimated in strawbale building, because the window and door surfaces tend to collect large amounts of concentrated water during rain. This water is then usually driven by wind into the bottom corner of the recessed opening, where it is likely to find its way into the wall through any cracks between the render and the frame. Figure 1 shows window detailing designed for extra protection against water ingress.

The roof above strawbale walls needs to be finished with the utmost care, and the same applies to all external straw protection. The render quality, for example, can’t be compromised. For this reason, it is best practice to use traditional lime render (using wellgraded sharp sand and mature lime putty in the ratio 3:1 – see Chapter 11), applied when there is no risk of frost and to the best possible standard.

Figure 1. Extra corner protections embedded in window frames and generous (sometimes doubled) windowsills with drip edges will guarantee the owners of any strawbale building sound sleep at night. Picture: Carol Atkinson’s strawbale cabin in Howden, East Yorkshire. Photograph © Jakub Wihan

What we know about straw is that it gets wet quickly – but it also gets dry quickly! One case study that demonstrates serious moisture damage caused by the application of lime render too late in the year comes from the southern ocean front of Brittany, France. A pair of strawbale semi-detached houses had been built in a village only about 100 metres away from the cliff edge, where severe, long-lasting storms make local stone dwellings extremely wet during the winter. Insufficiently carbonated, vulnerable and soft lime plaster didn’t manage to protect the straw from heavy winter rain that had been driven by very strong coastal winds into the exposed wall constantly for two days. As a result, straw in the wall on one house got wet all the way through, so that wet patches appeared on the interior plaster of the building. Almost immediately after the incident the house started to smell of rot.

The owner of the house took a risk and, rather than trying to dry the walls, he decided to clad the entire house in timber to prevent any further damage. Wet straw, protected by cladding, although covered in soaked plaster, dried out to a satisfactory level in about four months. Decomposition stopped and, since the disastrous storm, the house has been used for its original purpose without any trace of bad smell or straw rot. This shows us that even saturated straw can dry out fairly quickly in the right conditions, resulting in no long-term problems. Timber-clad strawbale walls on this house are performing in this extreme climate, where outdoor humidity levels rarely drop under 75 per cent relative humidity (see box below), remarkably well.

According to the experience of building with straw in similar conditions in the UK and Ireland, properly made and executed traditional lime render, if carbonated enough (the finishing layer applied in mid-September at the latest), has proved able to protect straw from driving rain in most situations. However, in areas of extreme exposure (on gable walls, for example), it is recommended that the plastered strawbale walls are clad in timber, or at least that some trees are planted in the direction of prevailing winds to protect the walls.

Relative humidity

The amount of water vapour in the air at any given time is usually less than that required to saturate the air. The relative humidity is the percentage of saturation humidity, generally calculated in relation to saturated vapour density.

Relative humidity (RH) =

Moisture monitoring

In order to bring peace of mind to strawbale home owners, it is also recommended that they monitor humidity levels in any potentially questionable section of their strawbale walls. Generally, the area of interest is the bottom of the most exposed wall, as the moisture tends to gather at the baseplate. Good monitoring points are towards the bottom of the bottom bale, just above the baseplate, aligned with the sides of the windows. The data indicating the greatest values of relative humidity or moisture content generally come from the exterior side of the wall (see box below). The exterior monitor is usually buried in the straw, about an inch away from the inner surface of the exterior plaster. The central monitor, placed halfway through the wall, will collect other useful data. This way it is possible to check the depth of any moisture intrusion and thus assess the seriousness of a problem. The central and exterior monitors should never share the same hole in the wall, but they should be as close to each other as possible. It is reassuring for homeowners to know the pattern of moisture activity within a strawbale wall over the year; this way they can be sure that their straw protection is doing the job it’s supposed to do.

The humidity profile in a wall

The relative humidity (RH) profile through a wall changes gradually from the exterior humidity level to the interior humidity level over the thickness of the wall. The closer to the exterior we monitor inside the wall, the closer we get to the exterior values of RH. The gradient of the curve characterising the change of RH across the wall – its steepness – depends on the difference between the exterior and interior RH and on the property, individual to each different material, called the water vapour diffusion coefficient (WVDC). If the render is closed – not breathable (or vapour-permeable) – it has a high value for its WVDC and the curve over the thickness of the render tends to be steep. That is why we usually find quite different RH levels just behind the render compared with the exterior environment, although this difference gets smaller the more breathable a plaster we use.

Clay plaster generally has the lowest WVDC of all renders and plasters, followed by traditional lime render. Cement has the highest WVDC value, which might suggest that the cement render is the best in protecting the straw from any very humid environment. However, the opposite is in fact true. Cement render, because of its high WVDC, prevents straw from drying out. It has been proven by many years of experience in the USA, where cement renders had been used on strawbale buildings initially, that it fails to protect the straw from high humidity levels outside the wall despite a high WVDC, because of the shrinkage cracking of cement. Shrinkage cracking happens inevitably during the drying process of cement mortar. Shrinkage cracks are invisible capillaries leading the moisture deep into the cement, making it wet all the way through, and having a disastrous effect on straw, which is then left wet and unable to dry.

There are several options when choosing appropriate monitoring equipment. Depending on your budget and aim of your research, you can build a moisture probe of your own or buy a factory-manufactured data logger. These tools measure either moisture content or relative humidity – see page 133 for more about how these relate to each other.

Make your own moisture probe

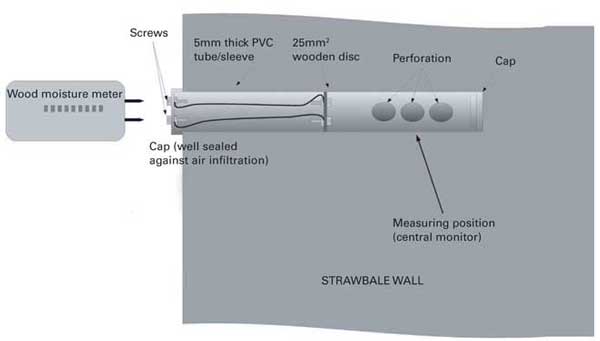

Canadian and UK research shows that home-made wood-disc moisture probes (see Figure 2), if built properly, are capable of giving the owner of a strawbale building fairly accurate readings of moisture content in a strawbale wall. They are cheap and easy to make. They require a discipline in regular data collection and any kind of cheap wood moisture meter to view the readings. One handheld wood moisture meter will serve all the probes installed.

Figure 2. The wood-disc moisture probe is like the moisture meter’s extended arm. It allows the moisture meter to extend its sensors towards the desired monitoring position within the wall (in this case towards its centre), where it measures the moisture content in a 5mm thick, 25mm wooden disc that always has the same moisture content as the surrounding straw in that particular location. The couple of screws and the cap sticking out of the wall need to be perfectly sealed against air infiltration, as do any cracks in the plaster around the protruding cap. Image by participants of the Humidity in Strawbale Wall course run by amazonails in France.

Or buy a data logger

While wood-disc moisture probes are capable of showing directly the moisture content of straw in a measured location, data loggers (see Figure 3) are generally calibrated to measure relative humidity in the air surrounding the straw.The advantage of a data logger is in automatic data collection – a data logger can be set up to store in its memory thousands of readings.The data are automatically collected at regular time intervals (from one minute up to an hour). However, the data logger doesn’t give an immediate picture of measured data, unless it is pulled out of the wall and plugged into a computer. Once displayed on a computer screen, readings show the development of humidity levels in a strawbale wall over time, in a colourful chart with satisfactory precision.

Home-made wood-disc moisture probes are the most convenient option, as they give the homeowner instantaneous readings and thus an early warning of any moisture problem. Data loggers, on the other hand, serve the best in providing consistent, reliable readings for more in-depth research into humidity development within strawbale walls.

Before deciding on the best monitoring approach for you, it is useful to have a clear understanding of the difference between moisture content and relative humidity.

Figure 3. A section through a strawbale wall with a data logger in the external monitor position.

Moisture content and relative humidity

Hygroscopic materials

Some materials, such as glass, are indifferent to changes of humidity that surround them. If we weigh a piece of glass that has been in an environment with very dry air (in a desert, for example), and then compare its weight after it has been rained on for a while, this will hardly change. Materials such as glass or steel are called ‘nonhygroscopic’, which means they are indifferent to moisture.

Most building materials, however, are hygroscopic, which means that their weight gradually increases if, for example, they are suddenly transferred from the Sahara to West Wales. The extra weight relates to the quantity of liquid water adsorbed (see box below) from the air into the porous structure of the hygroscopic material. Straw, wood, concrete, most renders and plasters are hygroscopic and porous, and the amount of adsorbed water – the moisture content – is closely related to the humidity of the air that surrounds them, the relative humidity. The more humid the air, the more the hygroscopic material will adsorb liquid water.

Relative humidity and moisture content in different materials

The exact amount of moisture adsorbed by a material depends on the material’s microscopic structure, particularly on the number of pores and their sizes. At the same level of atmospheric humidity, materials such as straw and wood will tend to adsorb more moisture than brick, for example, because straw and wood are more sponge-like in the sense of having much more microscopic pores.

Adsorption by hygroscopic materials

Hygroscopic material surrounded by water vapour in the air attracts water molecules

to its surface by tiny electromagnetic forces. The surface is often very rough, with – from the water molecule’s perspective – lots of caves and canyons. The tinier the crack, the more attraction, thus water molecules are trapped in very small capillaries,

where they tend to stick together to form miniature liquid drops in a process called adsorption. That is why the material gets wet when surrounded with humid air and that is why the weight of a hygrosopic material changes in these conditions – it is influenced by the presence of liquid water within it.

Adsorption is a different process from absorption. Adsorption is the accumulation of atoms or molecules on the surface of a substance. Absorption is where atoms or molecules actually penetrate into another substance.

The relationship between relative humidity and moisture content is unique for each material, and can be determined by a simple test. A sample of a material is placed in a room with stable relative humidity for a couple of days. This will allow enough time for the sample’s weight to settle. Once the weight is stable, the material’s moisture content is in equilibrium with the room’s relative humidity, and the sample can be thoroughly dried in an oven. The completely dried sample is weighed at intervals until the weight stabilises, and the difference between the weight of the sample before and after drying will reveal the exact mass of moisture adsorbed by the material in the room with that particular relative humidity. Moisture content can be calculated on a wet-weight basis or a dry-weight basis.

Example 1

A 1.11kg bunch of straw that has been in an environment with 50% relative humidity for a couple of days weighs 1kg after thorough drying in the oven. This means that the sample had adsorbed 0.11kg of water at 50% relative humidity.

The percentage of dry-basis moisture content refers to the weight of water divided by the weight of dry material.

Dry-basis straw moisture content @ 50% relative humidity = 0.11/1 = 11%.

The percentage of wet-basis moisture content refers to the weight of water divided by the weight of wet material.

Wet-basis straw moisture content @ 50% relative humidity = 0.11/1.11 = 10%.

Example 2

The same sample of straw has been placed for a couple of days in an environment with 80% relative humidity. It gained 0.2kg of water, hence:

Dry-basis straw moisture content @ 80% relative humidity = 0.2/1 = 20%.

Wet-basis straw moisture content @ 80% relative humidity = 0.2/1.2 = 17%.

Researchers carrying out tests on the same sample of straw repeatedly, each time in an environment with different relative humidities, plot the results of their investigation as a curve, known as a sorption curve or sorption isotherm (see Figure 4).

Straw decomposition

An important investigation* on samples of straw has shown that there is a certain borderline at which straw starts to significantly decompose. And, as UK and Irish farmers might expect, this borderline relates to an environment with very high relative humidity. Even in very humid air, with relative humidity up to 95 per cent, straw decomposes at an unnoticeable rate, but once relative humidity gets higher than about 98 per cent, straw starts to rot.

What does an environment with 98 per cent relative humidity look like? Air with 100 per cent relative humidity is saturated with water vapour, which starts to show on all material surfaces as liquid water. 100 per cent relative humidity in nature refers to dew, fog or rain. It is not surprising that straw at 100 per cent relative humidity – at this point practically covered all over with liquid water – starts to rot. What is reassuring, however, is that according to the research it doesn’t significantly decompose until almost at that very point.

The same investigation has shown that very slow straw decomposition, although unnoticeable, can be recorded by very sensitive

Figure 4. The sorption curve, or sorption isotherm, is different for each material and can be usually found among basic building material characteristics, provided by the manufacturer. Sorption isotherms of different straw samples are well known as a result of agricultural research. The thick dotted curve shows levels of safe moisture content and relative humidity. The dashed portion of curve shows the danger zone, with potential moisture problems, and the continuous thick black line refers to levels of relative humidity and moisture content that cause significant decomposition of the straw.

laboratory equipment in an environment with 84 per cent relative humidity. Strawbale builders have taken this value as a limit for a healthy condition within a strawbale wall. It has been generally agreed that data loggers showing relative humidity readings above 84 per cent in a strawbale wall are usually referring to a potential moisture hazard.

Measurements of relative humidity have one great advantage. A data logger measuring relative humidity in the air shows clearly how close the environment is to creating a moisture problem. This level is 98 per cent relative humidity, or, to be on the safe side, a benchmark of 84 per cent relative humidity.

In order to assess the danger of a potential moisture problem with measuring equipment showing moisture content values, rather than relative humidity values (using a home-made moisture probe, for example) one needs to have the relevant sorption isotherm handy. The straw sorption isotherm shows that a hand-held wood moisture meter referring to a dry-basis moisture content above 25 per cent, or a wet-basis moisture content above 20 per cent, shows readings in the danger zone, because it can be seen from the sorption isotherm that the level of relative humidity in the air surrounding straw with this moisture content is above 84 per cent. The sorption isotherm also reveals that significant decomposition starts when straw has adsorbed as much moisture as is equivalent to 39 per cent dry-basis moisture content, or 28 per cent wet-basis moisture content, which relates to 98 per cent relative humidity.

Note: The building industry prefers to use the dry-basis moisture content, which is what the handheld moisture meter would probably be showing. However, most of the moisture meters used by the food industry and agriculture will give wet-basis moisture content readings, although this isn’t a rule. Before using any moisture meter data it is crucial to find out which moisture content the meter had been calibrated for.

When moisture conditions change quickly

Although the difference in meaning between moisture content and relative humidity is that the former relates to the weight of water contained within the material structure and the latter refers to the saturation level of water vapour in the air, the most important difference for practical purposes, i.e. when monitoring moisture, is in the speed of reaction of the material to changing conditions.

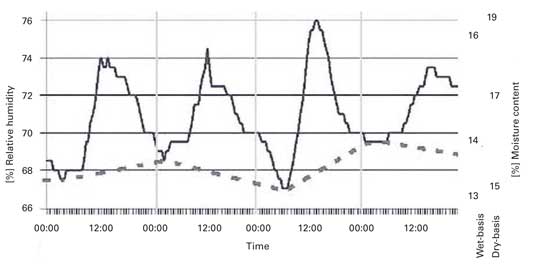

A data logger measuring relative humidity will respond to sudden changes in humidity levels within the environment quickly with great accuracy, while it can take hours or sometimes even days for straw to settle to its final weight with a relative humidity change. In fact, the perfect balance between relative humidity and moisture content can never be fully established, because the percentages of relative humidity in a wall change all the time on a daily basis. In reality, monitors of straw moisture content just can’t react so quickly. Moisture content might almost seem like relative humidity’s slower sibling. Observations show that in an environment with changing humidity levels, the straw moisture content always tends to rather lazily correspond to lower levels of relative humidity, while ignoring its peaks (see Figure 5).

Figure 5. Data logger readings (solid line) in an external position (in straw, a few inches away from the outdoor environment) reflect the pronounced daily fluctuations of outdoor relative humidity. At the same time, measured straw moisture content in the same location (dotted line) keeps relatively stable, corresponding to lower values of relative humidity.

This fact needs to be fully understood when measuring relative humidity by data logger. Even though the data will peak daily at a certain level, it is actually the troughs that are giving us a picture of the true amount of moisture adsorbed by straw in given fluctuating conditions.

What we know about humidity in straw

• Mould growth and rot occur only when relative humidity levels are at 98 per cent or above (where 100 per cent = rain, fog or dew).

• Even when relative humidity around straw reaches this level, it has to remain there for a considerable time (two days) for it to affect the straw bale, because straw adsorbs moisture quite slowly from the air. This level of moisture in the air remains at 98 per cent for as long as two days only in a rainforest.

• Strawbale builders generally take a level of up to 84 per cent relative humidity to be a safe threshold.

• A dry-basis moisture content of 25 per cent, or a wet-basis moisture content of 20 per cent, is equivalent to a relative humidity reading of 84 per cent.

• Straw will adsorb moisture quickly if it is in direct contact with water, for example if it sits in a puddle, if wind drives rain through unprotected straw, or there is a hole in the building’s roof.

• Straw will dry quickly once the source of water has been removed and good ventilation is applied.

• Even if mould growth has occurred, it will stop and the straw will become healthy again once the straw has dried out.

Guidelines for healthy straw houses

To keep straw houses healthy and free from mould growth or rot they need to have:

• good ventilation – all plasters, renders and surface finishes should be vapourpermeable, and there should be at least 500mm (20”) of clear space around each exterior wall

• protection from the damp of the earth and rain splashback – straw should be raised up at least 300mm (12”) and preferably 450mm (18”) from the ground on self-draining non-porous foundations

• protection from leaks – a good overhang of at least 450mm (18”) on the roof and all maintenance carried out when necessary

• protection from driving rain – fully carbonated lime render, timber cladding and rain screens in areas of extreme exposure

• protection from condensation – use of vapour-permeable plasters and finishes with good ventilation.

There are some circumstances in which it is good common sense to adapt the best practice guidelines above to suit particular conditions. For example, it is sensible to tile bathrooms and kitchens to protect plastered straw walls from direct water contact. Similarly, timber cladding may be required in areas of extreme exposure outside. However, all these areas will benefit from having as much vapour-permeable material around them as possible, as straw needs good ventilation to remain healthy, so keep tiling to a minimum and use clay or lime plasters in the rest of the room.

If you want to have a truth window with a glass front, or to show off your straw walls through a perspex cover, as long as you have enough ventilation around nearby this should not present a problem.

Intuition

None of the studies conducted to date has made any groundbreaking discovery. The results support the common knowledge of natural materials that had been, until recently, carried through generations by handing down experience. Straw, like wood or other plant materials, consists mainly of cellulose and lignin and that is why it is vulnerable to decomposition. It is our common sense and our basic intuition that have advised us for millennia with regard to how to keep organic materials, such as wood, when used in construction, away from water. Nothing can go wrong if we apply the same knowledge to straw.

* Detailed analysis of this questionnaire is included in: Wihan, J. (2007) Humidity in Straw Bale Walls and its Effect on the Decomposition of Straw, MSc Architecture thesis written for the University of East London. Available at www.jakubwihan.com/ pdf/thesis.pdf.

* Summers, M. D., Blunk S. L. and Jenkins, B. M. (2003) How Straw Decomposes, EBNet Straw Bale Test Program, DRAFT 12/8/2003. Available from EBNet database: www.ecobuildnetwork.org/pdfs/How_Straw_Decomposes.pdf.