A typical large calorifier ready for fitting.

Hot water

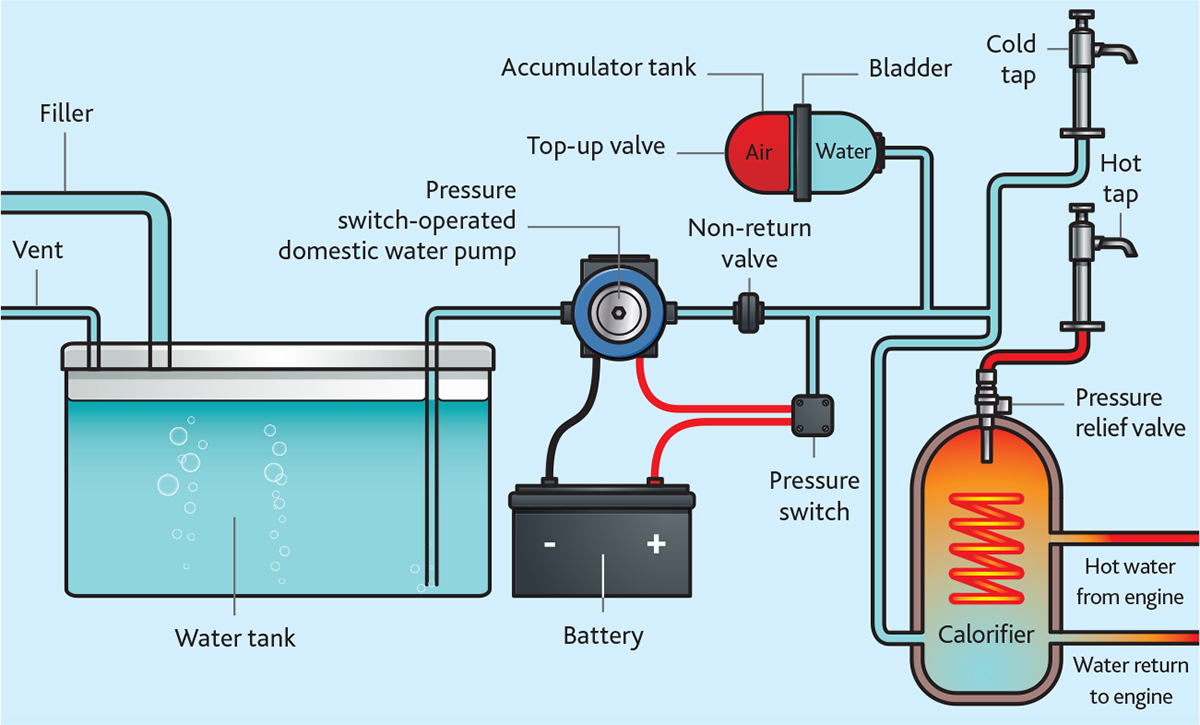

Today most boatowners require both hot and cold water aboard. A calorifier is often the method chosen for heating water and it makes use of the heat generated by running the engine. This means there is no reason not to enjoy free hot water while under way, or from the built-in immersion element while connected to shore power.

A calorifier is similar in appearance to the standard household domestic indirect cylinder and works in the same way. A coil of copper tube inside the cylinder is connected to the engine cooling water system.

Water at engine running temperature is fed into the upper end of the coil. It passes down through the coil and is cooled during the process of heating the water in the cylinder. It is then returned to the engine where it is again heated and passed through the calorifier tube. A full cylinder of hot water will be available after about 30 minutes of running the engine from cold!

While calorifiers are generally run from fresh water (heat exchanger) cooled engines, they can also be run from raw water (direct) cooled engines. The heat of the water will be less than that from a fresh-water cooled system as the normal engine running temperature is around 50ºC (122ºF) for raw water-cooled-engines compared to 80ºC (176ºF) for fresh-water-cooled engines.

The high temperature of the fresh-water engines means that a much smaller calorifier can be fitted as the amount of hot water required for any particular use is lower. More cold water is mixed with it at the basin or shower to bring it to a usable temperature. Hot water from a raw water-cooled engine is already at a usable temperature, but still quite hot enough for a nice comfortable shower and general washing-up on board.

A pressure relief valve is an essential fitting on the calorifier and is set above the working pressure of the system, otherwise it would constantly be opening and preventing the pump pressure switch from stopping the pump.

Even better is a combined temperature and pressure relief valve, which will open in the event of excess temperature as well as over-pressure. This vents the system before the water reaches boiling point.

A typical large calorifier ready for fitting.

Although a luxury, it is becoming increasingly commonplace to have hot water on board a smaller boat.

A combined pressure and temperature relief valve offers the greatest safety.

A marine-grade immersion element being installed into a calorifier.

A shore power isolating switch should be fitted to allow shore power to be cut off without the need to pull out the plug.

Dual power

A marine grade double-insulated immersion element to allow the water to be heated when connected to shore power is generally a standard fitting. Cheap domestic elements will work, but are likely to cause earthing problems with marina electrical supplies. Similarly, using lower wattage units will avoid overpowering the electrical systems in many marinas.

If shore power is being installed for the first time, a standard domestic consumer unit will do the job perfectly as long as it is inside and well protected from the elements. Select a unit with room for using circuit breakers as well as for a residual current device to protect against current leakage. A shore power isolating switch should also be fitted as a safety measure. The mains system should only be installed by a qualified or suitably experienced person.

Expansion tank

An expansion tank needs to be included within the system to allow for expansion of the water within the cylinder as it heats up. Without this, the pressure relief valve would again be constantly opening, causing the pump to run. However, systems that include an accumulator tank do not require an additional expansion tank as the accumulator tank will happily perform both tasks.

A basic cold water system incorporating an accumulator tank, making the installation of an expansion tank unnecessary.