FROM THE ASHES OF THE OLD

![]()

THE DECISION TO REBUILD

To rebuild the bridge across the Tay had been one of the first decisions taken by John Stirling after the initial disaster in 1879. It is not difficult to see why. The enormous success of the first bridge in bringing about an increase in the carriage of passengers and freight, and therefore of income to the North British, was too great to be dispensed with. To the loss of income caused by the destruction of the bridge should be added the capital loss in share values. When trading began on the Monday following the accident, shares in the company opened at almost ten per cent below their previous value, representing according to one account a loss in one day equivalent to the whole cost of constructing the bridge, though it is true that within a year the value of the shares had been restored. And of course the bridge itself had gone – a huge capital asset which before it fell had become the property of the North British, the company having agreed to take it over from the shareholders in the Undertaking on payment of a premium of £30 per share in lieu of accrued interest. Then there was the capital value of Taybridge Station and all its connecting lines, which would remain worthless until such time as the bridge came to be rebuilt.165

The decision to rebuild must have met with the approval of the majority of Dundonians, and not only those with business interests to serve. The people of the city, not to mention the inhabitants of Fife, had become accustomed in the few months of its operation to the great convenience which the bridge had afforded them of easy access to the opposite shore of the river, and they were unwilling to go back to the inconvenience of the ferry. The loss of the bridge would have been felt particularly in Newport, whose main water supply had been cut off when the collapse of the bridge severed the pipe line, and where as a consequence of the new rail connection with the northern shore a great number of houses had been built for Dundee’s prospering middle class.

Rather less enthusiastic about the rebuilding of the bridge, to be sure, were the tradesmen and Town Councillors of Perth. Resigned to the replacement of the bridge with a new but similar structure, they were extremely angry to learn of a move by the Town Council of Dundee to try to get the height of the bridge reduced to a mere 40 feet above the level of the water. All the old arguments and jealousies of the previous decade resurfaced, as the men of Perth accused ‘these sapient and supreme gentlemen of Dundee’ of seeking ‘to decree the complete extinction of the Tay as a navigable river’. Perthshire newspapers painted extravagant pictures of the future of their town as a potential rival to Glasgow, if only they were allowed to develop the navigation of the river unhindered by the Tay Bridge. Sympathy for their plight came indeed from a correspondent in Glasgow, who described the people of Perth as

the victims of a cruel set of circumstances. Perth, as the most ancient town on the Tay, possessing since the twelfth century the right to levy dues on the river, might be supposed to have a prescriptive right to all the advantages the river can give. Yet the rights of Perth are to be put on one side by the upstart Dundee, which never had a royal charter, and which was a howling wilderness when Perth was a Royal residence.

In the end the matter was resolved in exactly the same way as it had been resolved in 1870 – by cash. Under the 1870 arrangement, the Company had agreed to pay to the Perth Corporation an annual sum of £25 for every foot of reduction in height from the original 100 feet. This arrangement was now extended to cover further reductions in height, at the same rate per foot.166

As we have seen, once the report of the Court of Inquiry had been published, the North British had lost no time in filing a new application to Parliament for a bill to repair and restore the original bridge. This proposal was remitted to a Special Committee, which was given very specific instructions to report

as to whether the Tay Bridge should be rebuilt in its present position, or whether there is any situation more suitable, having regard to the safety of the travelling public and the convenience of the locality. That their special attention be directed to the interests of the navigation, and that the height of the bridge shall be so fixed as not injuriously to interfere with the river navigation. That they shall consider generally in what way any bridge that may be authorised should be constructed so as to secure its permanent safety.

This Committee came unanimously to the view that the application according to the plans submitted to Parliament should not be granted, but recommended nevertheless that the bridge should be reconstructed on its present site, with its spans over the navigational channel lowered from 88 to 77 feet.167

W.H. BARLOW

Faced with this outcome, the directors decided to call on the services of W.H. Barlow, one of the members of the Court of Inquiry and an engineer of the highest reputation, to advise them on how they should now proceed with reconstruction, on the basis of a double-line bridge. Barlow was determined to take no chances, and before he produced his report he carried out a number of investigations and experiments. The first step was to take a series of soundings along the line of the bridge to find out what had been the effect of the scouring action of the river, and then to take borings at 500 foot intervals on a line parallel to the centre line of the old bridge. What these investigations showed was that the construction of the old bridge had caused a deepening of the river, especially in the area where the ebb tide was strongest. The total area of the waterway occupied by the piers was equivalent to about one tenth of the total waterway of the river, and it was found that the effect of the scour was to restore to the river about the same area as was taken up by the piers. The result of the borings was to show that close to the shore on either side the river bed was of whinstone, and from the southern shore as far as pier no. 12 of the old bridge was sandstone. From the rock on both sides for about 900 feet towards the centre of the river there extended a strip of tough boulder clay, but the remainder of the river bed consisted of silty sand, in which there were beds of gravel of varying thickness.

Two experiments were now carried out to test the load-bearing capacity of the river bed. First, two of the piers of the old bridge were loaded with 1,500 tons of rails, producing a pressure of a little over 3.5 tons per square foot. One of these piers, situated in clean sand, sank a mere quarter of an inch, while the other, in micaceous sand, sank two inches. Next a trial cylinder was sunk to a depth of 20 feet in the area showing the worst silty sand, filled with concrete, and loaded to a gross weight of 7 tons per square foot. This produced a settlement of five and a quarter inches, but it then sank no further, even after the weights had been left in place for three-and-a-half months.

Barlow and his team now produced four separate designs and estimates for the construction of a double-line bridge. Only one of these was for an entirely new structure. The other three would all have involved keeping the old bridge intact, and either widening it on one or both sides, or constructing an additional single line bridge alongside, and bracing the two structures together. There were serious difficulties in all three schemes, despite the cost savings which would arise from making use of the original structure. The main problems had to do with the insecurity of the old foundations, which it was found had not been sunk deep enough to protect them from the effect of scour, and would require reinforcement. To do this was made more difficult by the fact that Grothe and his team had produced so many different forms of foundations – some single cylinders, some double, some elliptical, some on piles, and some partly square and partly round.

There were two other important considerations: first that the Board of Trade had by now specifically prohibited the use of supports consisting of cast iron braced with wrought-iron ties, and second that the standing parts of the old bridge were ideally placed to bring up men and materials to build the new one, provided the new one was built alongside the old. The plans which involved incorporating the structure of the old bridge with the new were therefore discarded; Barlow recommended to the directors that they build a new bridge, and his advice was accepted.168

In designing his replacement of the old Tay Bridge, Barlow was clearly going to take special care to avoid the mistakes of his predecessor. Thorough calculations were carried out to make allowance for the effects of wind pressure on the structure, and these calculations were based on a pressure of 56 lbs per square foot. Moreover, as Barlow’s son explained to fellow members of the Institution of Civil Engineers in March 1888, his father had erred heavily on the side of caution, and ‘in estimating the overturning effect produced by this force, the parapet and train were treated as presenting a plane surface of resistance; the girder as a surface one and a half times its actual area, and the octagonal side of the pier as a square surface; with these conditions the balance of effects was largely in favour of gravity.’169

In many ways, however, the design of the new bridge was similar to that of the old. 10,711 feet in length, with eighty-five piers, and sited 60 feet upstream from the old bridge, it followed much the same line across the estuary, the two centre lines running parallel for the whole of the straight central section of 8,396 feet. In outline, seen from the side, the two would have been hard to tell apart, were it not for the difference in height. The piers of the new bridge were placed exactly in line with the old ones, whose bases now formed the cutwaters for their new counterparts. Moreover, the lattice girders from the surviving spans of the old bridge were found to be perfectly suitable for re-use as the outward parapet girders of the new. All that was needed to provide the width necessary for a double-line bridge was to install two new girders between each pair of old ones.170

The overall similarity in the design of the two bridges conceals some important differences in both design and construction. At the southern end of the bridge, where branch lines were led off to the west across Fife and to the east towards Newport, the old arrangement had been for the branches to be carried by two separate viaducts, joining the bridge at some distance from the shore, and with the waters of the river clearly visible between them. In order to comply with the conditions laid down by the Parliamentary Committee in 1880, the branch lines to the new bridge joined it at a point much nearer to the shore, and were supported on brick arching wide enough to carry both of them. At the northern end, the great eastward curve of the rails of the new bridge was made gradually to approach the line of the original as it drew into Taybridge Station. Out in the middle of the river there were once again to be thirteen high girders over the navigable channel, but their height above high-water level was reduced from 88 to 77 feet.

No less important than these changes to the original design were substantial changes to the construction of the bridge, beginning with the foundations. These were now to be in the form of twin wroughtiron cylinders, 16½ feet in diameter, but widened out at the base to 23 feet, and filled with concrete and brickwork. One and a half feet above high-water level these were joined together with a horizontal member of concrete and brickwork seven feet deep, resting on cast-iron supports, and across the whole was fixed a strong wrought-iron frame, which was to provide the base for the wrought ironwork of the piers above. The frame itself was secured to the foundations with sixteen wrought-iron tie bolts, anchored to cast-iron plates set in concrete. Above these came the piers themselves, constructed neither of brickwork, as in the original Bouch design, nor of the now discredited cast-iron columns, but of plates of wrought iron riveted together. These piers took the forms of two hollow octagonal columns joined by a connecting arch, supporting the superstructure which, although it was to be constructed of the same kind of lattice girders as the original, was now to be supplied with a deck of corrugated steel, instead of wood.171

WILLIAM ARROL AND CO

The Parliamentary Bill for the construction of the new Tay Viaduct received the Royal Assent in July 1881, and by October the firm of William Arrol and Co. of Glasgow had been appointed as contractors. Arrol was one of the great bridge engineers of his day, and among his successes to date had been the iron bridges for the Glasgow, Hamilton and Bothwell Railway, including a large bridge carrying the rails at a considerable height over the Clyde near Bothwell. He was both methodical and innovative, and amongst other ingenious inventions he had designed a hydraulic riveting machine which was soon in general use in bridge and ship building. Arrol had originally been engaged by the North British to build Bouch’s bridge over the Forth, and when that scheme was abandoned he was given the contract to reconstruct the bridge over the South Esk at Montrose. It was Arrol of course, who built the present bridge over the Forth.172

Arrol and Co. had intended to make a start on the replacement bridge at the end of 1880, but they were prevented from doing so by legal wrangles over the terms of the bill which, in its final form, had included a clause requiring the company to ‘remove the ruins and debris of the old bridge and all obstructions interfering with the navigation caused by the old bridge, to the satisfaction of the Board of Trade.’ The interpretation put upon this clause by the Board was that the process of clearing away the remains of the old bridge must precede any work on the new, and as the estimate for the new bridge had been based on the use of the old lines to carry men and materials out to the new bridge in the course of construction, as well as the re-use of girders from the low sections of the old bridge, the position adopted by the Board caused serious difficulties. The dispute was eventually resolved, but only after the loss of several months, with the result that work on the bridge did not begin until June 1882, and the first foundation was not laid until early in the following year.173

BUILDING THE NEW BRIDGE

Once started, however, the work under Arrol’s expert supervision progressed smoothly and swiftly. The method of construction was similar to that used on the old bridge, but with some significant improvements, most notably in the design of the pontoons for sinking the foundation cylinders, and in the extensive use of steam-driven and hydraulic machinery in place of manual labour. As with the old bridge, the cylinders for the foundations were built on shore and floated out to their positions by pontoons. But Arrol’s pontoons, unlike Gilkes’, were fitted with four large cylindrical legs which could be raised or lowered by hydraulic power. With the legs standing firmly on the river bed, the height of the pontoon itself could by adjusted up or down hydraulically. As a result, the pontoons were extremely steady, even in rough weather, and the operation of sinking the cylinders could be carried out with unusual accuracy. A visitor to the site described the operation of these great pontoons or ‘quadrupeds’:

Though the water was very rough, it made no impression on the vessel, for the simple reason that the hydraulic power on board had been applied, and the quadruped, unlike most quadrupeds, had lengthened its legs until the water was some 6 feet below its bottom. It matters not how stormy the weather might be, operations can always be carried on on board.

These pontoons also carried a good deal of steam-powered equipment – steam engines for powering the excavating equipment and concrete mixing machinery as well as steam cranes. It was therefore possible to do more of the construction of the cylinders on site than before – only the metal work was fabricated before the cylinders were floated out to their final positions, and the construction of the brick lining inside each cylinder was completed on board the pontoon. As before, the cylinders were fitted with a flange or internal ledge on which brickwork was built up before the whole was lowered into position on the river bed. The inside of the cylinder was excavated by steam digger, until it had been sunk to the required depth, and the whole was then filled with concrete.174

In December 1885 the site was visited by David Carr, a reporter for the Pall Mall Gazette, who recorded a graphic description of the scene:

Clouds of steam and the noise of rattling chains fill the air as we leave the deck of the launch that has brought us from the shore and ascend, with the cautious steps of unpractical feet, the encircling staging of the huge caissons which, in a double line, are being sunk across the broad estuary of the Tay. Clambering over a mass of beams and planks, we reach the platform at the summit, and watch the steam excavators at their work as they hang suspended, like the drawn fangs of some mighty giant, over the gaping mouth of each iron cylinder. With a sudden movement they sink from sight and plunging downwards are lost in the sandy bottom of the river. The laboured snorting of the engine marks the tightened strain upon the chains which, by their upward action, close the sharp pointed blades, and bring to light a mass of stones and mud. As the load nears the surface and rises clear above the iron edge, the long arm of the crane, obedient to a touch, swings round, and sends the dripping gravel out into the turbid waters of the stream below. Slowly the massive column descends, and length is added upon length till it will sink no further, even when weighted with a load far greater than it will ever have to carry. This point once reached, the excavation ceases, and the hollow core is lined with brickwork and filled with a solid mass of concrete.175

In his evidence to Parliament in support of the bill to build a new bridge, W.H. Barlow had undertaken to test the foundation of every single pier with a weight equal to one third more than that produced by the weight of the structure added to the rolling load of the traffic on both set of rails. This undertaking was included in the bill, and faithfully adhered to. After each pair of cylinders had been filled with concrete, iron girders were placed across them, and loaded with weights until all subsidence ceased. A careful check on the process was kept by Major Marindin for the Board of Trade, who became a frequent visitor to the site.

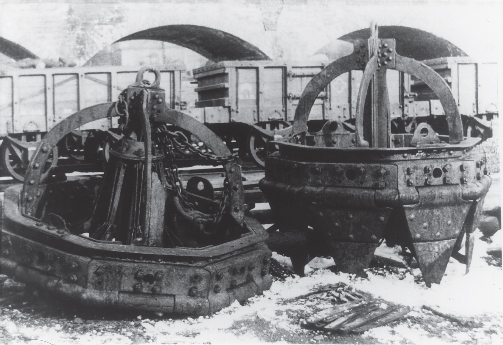

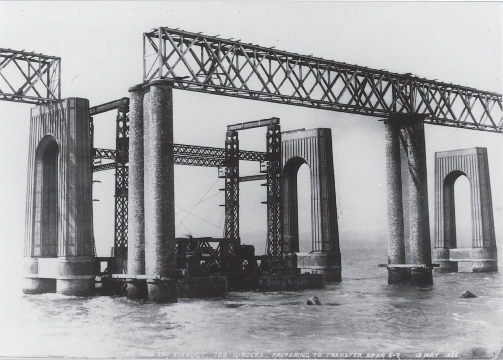

Once the testing had been completed, the wrought-iron piers were built up on their bases. Each pier was in the form of a pair of octagonal hollow legs, joined at the top by an arch, and was initially built up and fitted together at the Arrol works in Glasgow, before being dismantled and transported to the site of the bridge. The same process was followed with the new girders, though these were reassembled on shore, as with the old bridge, and floated out to the piers in much the same way as before – on pontoons hauled out by steam tugs. Once in position they were lifted by hydraulic presses, and the plates of the piers progressively riveted in place beneath them. In the case of the old girders salvaged from the surviving sections of the old bridge, these were transferred across to the new ones on pontoons which once again were specially designed by Arrol for the purpose. The girders were supported on telescopic legs which could be raised or lowered to allow for the state of the tide. With the pontoon stationed underneath a girder, the rise of the tide was sufficient to raise it from its bed plate, from where it could be floated the 60 feet across to its new home.176 It was a remarkable record that the entire process of floating out and lifting the girders was accomplished without either failure or accident.

After the initial delays caused by the dispute over the removal of the remains of the old bridge, work had begun in earnest in the early spring of 1882. In less than eighteen months substantial progress was reported in sinking the foundations of the piers, which by this stage were being constructed at the rate of one a week. Work was also far advanced on building the first three piers from the north end, for the construction of which huge coffer dams were being built, the first of them out of great logs 11 inches square, and between 24 and 40 feet long, to suit variations in the river bed. The caissons took the form of two concentric rings with a gap of two feet between them, the gap being filled with quantities of clay supplied by the Glencarse Pottery. By the end of September 1883, The Times reported, nineteen piers had been completed, and it was expected that the whole bridge would be finished by the late summer of 1885.177

This was perhaps over-optimistic, and would have meant that the new bridge would have been completed in less than half the time taken to build the old. But the man from The Times was not alone in his admiration for the great skill and efficiency of Arrol and Co., and the effective use they were making of modern steam-powered machinery. ‘A visitor to the works,’ commented one such in February 1884,

is very much impressed by the quiet, methodical manner in which the operations are being carried on. The large number of powerful and intricate machines employed in preparing the material for the structure turns out enormous quantities of work, which not long ago was done by manual labour, and is striking evidence of the advance made in recent years by mechanical engineering.178

By May of the same year, another visitor was able to report that

all the foundations from pier 54 to pier 85 have been laid, and the cylinders are all more or less advanced. Pilasters have been put into the face of pier 86 (the easternmost column of the first brick arch) to make the old and new brickwork join better together. Piers 84 and 85, which carry the bowstring girder over the footway of the Esplanade [this was before the roadway on the Esplanade had been extended to its present length] have been finished, and a wooden staging has been erected for the building of the girders. The skew brick pillars which have been built in anticipation of the extension of the Esplanade are now in an advanced state. It is the intention of the contractors to erect the girders of the new bridge at the north end as soon as the piers are ready. Cast-iron connecting bases have been placed on the cylinders of two of the piers (54 and 55) which are now ready for the brickwork from which will spring the malleable iron superstructure. The piers are being systematically tested by the Board of Trade, and the results have proved eminently satisfactory to all concerned.179

By the beginning of January 1885, all but a handful of the pier foundations had been sunk, while the superstructure of all the piers on the south side as far as pier 13 was ready to receive their girders. At the north end, all 43 foundations stretching from the northernmost of the high girders to the Esplanade had been laid. On 32 out of the 43 the superstructure was also complete, while 23 of them had also been fitted with their girders, ready for the rails. On the Dundee shore the bridge was by now joined to the brick viaduct carrying the rails into Taybridge Station, so that most of the work still to be done was on the water. By now the workforce had been increased from 200 to 630, and the work of construction was carried on by night as well as by day, through the use of powerful Lucigen electric floodlights.

Not only was the construction of the bridge proceeding at a much faster pace than had been the case with the first bridge, but the structure exhibited a welcome appearance of stability and solidity lacking in its predecessor. To an observer of the almost finished structure in the autumn of 1885 to overall effect was reassuring.

The increased basal area of the cylinders, and the breadth and solidity of the superstructure will give stability to the bridge and will no doubt inspire the public with confidence in its permanence. The girders, being doubled in number, have, as compared with the old Bridge, a much more substantial appearance, and the screens with which they are surmounted on either side give a different aspect to the new Bridge and impart to the visitor when walking along the permanent way a feeling of security. In their design the Messrs Barlow have discarded all new or tentative methods in bridge architecture. They have evidently striven to model a strong and durable bridge, and to attain those qualities they have proceeded on well-known and fully recognised principles.180

TWO INSPECTIONS

In June 1886 the directors of the North British decided on an inspection not only of the new Tay Bridge, but also of the great bridge over the estuary of the Forth, now under construction. Unlike previous such inspections, this was no carefree jaunt, but a hard day’s work taken seriously by all those involved. ‘Time was,’ commented the Advertiser with a certain nostalgia,

when such an inspection by the North British directorate implied for the most part a pleasant holiday. Ten years ago, to go no further back, one might count upon pleasant companionship and blithe talk, into which politics and commerce entered hardly at all, and a minimum of inspection, and an elegant dinner at the residence of one or other of the merchant princes of Dundee – shall we say the late Provost Cox of that busy manufacturing town? But many things have happened since then, and the directors of railway companies, in the interest of their shareholders, must now take things more seriously, and live laborious days, inspecting two concerns, either of which is enough at a time, and shun the wholesome delights of an early dinner . . . The inspection by the directors, it may be said, was no mere general look around. Practical men accompanied them, answering questions, and offering explanations. Not contented with what they had seen on the bridge, the directors, after a hurried luncheon at the offices on the Dundee shore, sailed round the piers, and were able to say generally that the work has made great progress since their last visit, and that the end is now within measurable distance.181

On 16, 17, and 18 June 1887, the Board of Trade inspectors, (including amongst them our old friend Major General Hutchinson) came to Dundee to carry out their inspection. They ran eight coupled engines on each track, and tested for vibration and deflection of the structure – the effect was negligible. They took soundings in the river to measure the effect of scour on the foundations – they were wholly satisfied with the result. They spoke ‘in very high terms of the substantial and skilful manner in which the bridge had been constructed’, and sent a telegram to the Board in London to record their complete satisfaction with the structure. A mere three and a half hours later the first train to cross the bridge set off on its short journey carrying, as the Advertiser recorded, ‘the Provost, Magistrates, and Town Council of Dundee, along with their lady friends, numbering in all 200, and it is to be hoped that the pleasure experienced by the passengers in that train will be the experience of all those who will cross the viaduct in all time coming.’ On its return to Taybridge Station the train was met with a salute of 21 fog signals, before the passengers alighted to partake of cakes and wine in the station dining room. A mere two days later the bridge was opened for passenger traffic, and without further ceremony the first scheduled train left Dundee for Fife at 5.05 a.m. on Monday 20 June, 1887.182

It had taken five more years of construction work, and an aggregate expenditure for the two bridges of almost £1 million, but the North British now had their permanent bridge across the river Tay. Let William McGonagall have the last word, even if his knowledge of engineering was even less sure than his skill as a poet:

Beautiful new railway bridge of the Silvery Tay,

With your strong brick piers and buttresses in so grand array,

And your thirteen central girders which seem to my eye,

Strong enough all windy storms to defy.183