15

Understanding Malted Barley and Adjuncts

What is Barley and Why Do We Malt It?

Barley (Hordeum vulgare) is a member of the grass family Poaceae, and the fourth-largest cultivated cereal crop in the world. It was domesticated around the same time as wheat, meaning it has been cultivated for about 12,000 years. There are three types of barley, two-row, four-row, and six-row, the terms referring to the arrangement of the kernels around the shaft of the ear. Only two- and six-row barley are used for brewing. The kernels of six-row barley are usually physically smaller than those of two-row barley, but higher in protein. Two-row is considered to be superior to six-row for malting and brewing, but modern malting varieties of six-row barley still make excellent beer.

Barley is harvested, sorted, dried, cleaned, and stored before it is malted. The purpose of malting is to make the barley starch more accessible to the brewer.

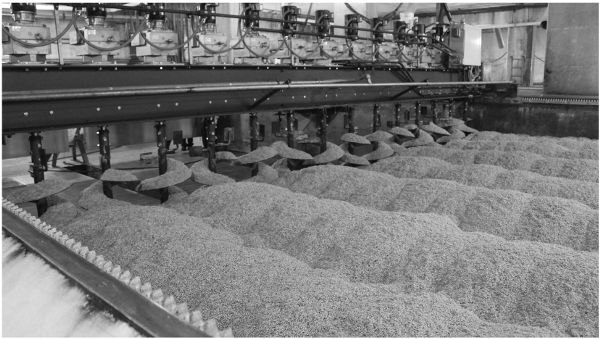

The malting process begins when the highest-grade barley—brewing grade—is steeped in water (fig. 15.1) until it has absorbed almost 50% of its initial weight in water and rootlets, or “chits,” begin to appear at the base of each barley grain (fig. 15.2). The barley is then drained and moved to a germination room where the actual malting process occurs. The barley is held at a controlled humidity level and periodically turned and moved to keep the temperature in the grain bed uniform (fig. 15.3). At this stage, it is referred to as green malt. After germination, the green malt is moved to a kiln where it is carefully dried at temperatures between 122°F and 158°F (50–70°C) to about 4% moisture. This malt is typically referred to as base malt or lager malt.

Figure 15.1. The barley is steeped for a total of 38–46 hours. (Photos on page 220 and 222 courtesy of Briess Malt & Ingredients Co.)

Figure 15.2. The end of steeping is signaled by the emergence of the rootlets, or “chits.” Once the barley has chitted, it must be moved to the germination tank where it will have more oxygen. (Photo courtesy of Briess Malting & Ingredients Co.)

Figure 15.3. After steeping, the malt is moved to a germination tank where it is aerated and turned over for several days to obtain uniform growth. The malt spends about four days in the germination tank before it is dried in a kiln room. (Photo courtesy of Briess Malting & Ingredients Co.)

The malting process allows each barley grain to partially germinate, making the seed’s resources available to the growing shoot (acrospire). During germination, enzymes in the aleurone layer (fig. 15.4) are released that break down the endosperm’s protein-carbohydrate matrix into smaller carbohydrates, amino acids, and lipids, and free the seed’s starch reserves.

The endosperm contains large and small starch granules that are packed in layers, like bags of mixed jellybeans and hard candy separated by cardboard in a box. The cell walls (bags and cardboard) within the matrix that contain the large and small starch granules (jellybeans and hard candy, respectively) are primarily composed of beta-glucans (a type of cellulose), some pentosans (gummy polysaccharides), and some protein. The box in this metaphor is the outer husk. The point is that there are several barriers that the maltster and brewer have to overcome to get to the candy.

Malt “modification” is the degree to which the enzymes tear open the bags and start unpacking the starch granules (i.e., break down the endosperm) for use by the growing plant, or, in our case, the brewer. One visual indicator that a maltster uses to judge the degree of modification is the length of the acrospire, which grows underneath the husk. The length of the acrospire in a fully modified malt will typically be 75%–100% of the grain length. More often, maltsters judge modification by squeezing the moist kernel between their fingers; they can judge whether some areas of the kernel are not softened, and are able to feel if the kernel is too soft as well.

Figure 15.4. A simplified diagram of a barley kernel during malting, showing a progressive picture of how the acrospire (the plant shoot) grows along one side of the kernel. The aleurone layer releases pre-existing and newly created enzymes that “modify” the endosperm (the protein-carbohydrate matrix starch reserve) for the acrospire to use as it grows.

If the seed were allowed to continue to germinate, a plant would grow, and all of the starches that the brewer hoped to use would be used by the plant. So, the maltster gauges the germination carefully and judges when the proper balance between resources made available for the acrospire and resources consumed by the acrospire has been reached. At this point, the maltster stops the process by drying.

After modification, the grain is dried and the rootlets are knocked off by tumbling. The kiln drying of the new malt denatures (destroys) a lot of the enzymes activated during germination, but several types of enzyme remain, including the ones necessary for starch conversion. The amount of enzymatic starch conversion potential that a malt has is referred to as its diastatic power. A malt that contains sufficient diastatic power to convert itself in the mash is called a base malt. Base malts can be made from barley, wheat, rye, and oats, although barley and wheat are by far the most common. Mashing is the hot water soaking process that provides the right conditions for the enzymes to convert the grain starches into fermentable sugars.

Malted barley is the principal source of the sugars (principally maltose) that will be fermented into beer. From a brewer’s point of view, there are basically two kinds of malts: base malts and specialty malts. Base malts make up the bulk of the wort’s fermentable sugars. Some base malts, such as Vienna and Munich malt, are kilned at higher temperatures to create warmer, breadier flavors. The higher temperatures denature some of the enzymes that contribute to the diastatic power of these malts.

The diastatic power of a particular base malt will also vary with the type of barley it is made from. Two-row barley varieties are the preferred type for all-malt beers (i.e., no adjuncts), having a slightly higher yield per pound, lower protein levels, and, it is claimed, a more refined flavor than six row. However, six-row barley has a slightly higher diastatic power than two-row. Historically, in the US, the higher protein level of six-row barley (which can produce a very heavy bodied and hazy beer) led brewers to thin the wort with low-protein grains like corn and rice. Brewers were able to take advantage of six-row barley’s higher diastatic power to achieve full conversion of the mash in spite of these non-enzymatic starch sources. As explained below, these non-enzymatic starches are called adjuncts.

Specialty malts are non-enzymatic malts that have been kilned and/or roasted to higher temperatures to generate a variety of flavors to enhance the beer. There are three types of specialty malts. The first are the highly-kilned malts, which are essentially toasted base malts, such as biscuit and amber malt. These specialty malts have flavors ranging from toasted bread, to cookie or biscuit, to graham cracker and pie crust.

The second type of specialty malts are the caramel or crystal malts, which are not dried after malting but kilned while still wet, converting the starches to sugars right inside the hull. Afterward, these sugary malts are roasted at higher temperatures to generate a variety of unfermentable sugars and flavors, from honey to caramel to toasted marshmallow. These crystal malts are available in different colors (the color denoted by the unit Lovibond [°L]), each having a different degree of fermentability and characteristic sweetness. These malts are typically called crystal malts in the UK and caramel malts in the US, and referred to casually as, for example, C40, C60, or C120. (i.e., crystal 40°L, caramel 60°L, or crystal 120°L).

The third type of specialty malts are the roasted malts. These malts are produced by roasting dry base malt at high temperatures, giving them a deep red-brown or black color, flavors ranging from heavily toasted bread to cocoa to coffee. The color of roasted malts is also denoted in °L, for example, chocolate malt 350°L.

Specialty malts generally don’t need to be mashed, they can simply be steeped in hot water to release most of their character. These grains are very useful to the extract brewer, making it easy to increase the color and complexity of the wort without much effort.

Lastly, there are fermentables not derived from malted barley—the adjuncts. Adjuncts are defined as being unmalted, and include raw or refined sugars, corn, rice, and flaked rye, wheat, and barley. Adjuncts should not to be scorned. Some, like unmalted wheat and roasted barley, are essential to certain beer styles. Some classic beer styles, such as Belgian wit, American lager, and Irish stout, depend on the use of adjuncts. Adjuncts made from unmalted grains must be mashed with enzymatic malts (i.e., malts that possess diastatic power) to convert their starches to fermentable sugars. Roasted barley is an exception to this rule, because its starches have been converted by high roasting, and it can simply be steeped.

Malt Flavor Development

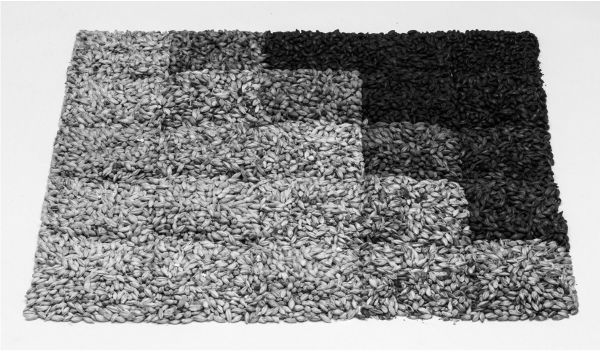

Maltsters usually divide the malt world into four types: base malts, kilned malts (including highly kilned), stewed malts, and roasted malts. Varying the moisture level, time, and temperature develops the characteristic flavors and colors of each specialty malt (fig. 15.5). Caramelization and Maillard reactions both play an important role in the wide variety of flavors that develop in these malts and in the beers made from them.

Table 15.1—Sugar Caramelization Temperatures

| Sugar | Minimum temperature |

|---|---|

|

Fructose |

230°F (110°C) |

|

Galactose |

320°F (160°C) |

|

Glucose |

320°F (160°C) |

|

Maltose |

356°F (180°C) |

|

Sucrose |

320°F (160°C) |

Figure 15.5. A mosaic of malts, produced by different kilning and roasting conditions.

Figure 15.6. After kilning, specialty malts like caramel and chocolate are roasted at high temperatures to produce caramelization and Maillard reactions for distinctive flavors. (Photo courtesy of Briess Malt & Ingredients Co.)

Caramelization is the thermal decomposition and chemical reaction of sugars that occurs via pyrolysis (see table 15.1). Caramelization is a non-enzymatic browning reaction that requires high temperatures and low moisture to occur. Maillard reactions, on the other hand, are reactions between amino acids and sugars, and can occur across a wide range of temperatures and moisture conditions, starting as low as 120°F and occurring up through 450°F (49–232°C). Maillard reactions produce a wide range of volatile, low molecular weight heterocyclic flavor compounds, and higher molecular weight compounds, like reductones and melanoidins. Reductones can oxidize and bind oxygen to improve flavor stability. Melanoidins are the color aspect of the Maillard reaction.

Both Maillard reactions and caramelization can generate some of the same flavors, like toffee, molasses and raisin, but generally caramelization reactions are responsible for the toffee-sweet caramel flavors in malt, while Maillard reactions are responsible for the malty, toasty, biscuit flavors associated with baking. The low-temperature, high-moisture Maillard reactions produce malty and fresh bread flavors, and the high-temperature, low-moisture Maillard reactions produce the toasty and biscuit flavors.

After drying, lightly-kilned base malts like pale ale malt are kilned at low temperatures (120–160°F [49–71°C]) to retain their diastatic power. The flavors expressed are lightly grainy with hints of warm bread and toast. Vienna malt is dried to about 5%–10% moisture and then lightly kilned at 194°F (90°C) to develop its color and flavor while retaining most of its diastatic power. More highly-kilned base malts like Munich, and aromatic malts are dried to relatively higher moisture levels (15%–25%), and treated to a schedule of higher temperatures (195–220°F, [90–105°C]), to produce rich, malty and bready flavors. Only Maillard reactions are involved at these temperatures.

Stewed malts, such as caramel 60°L and caramel 120°L, are produced by roasting green malt, that is, malt that was not dried by kilning after germination. These malts are put into a roaster and heated to the starch conversion range of 150–158°F (66–70°C). The converted sugars are in a semi-liquid state inside the kernel. After conversion, these malts are roasted at higher temperatures of 220–320°F (105–160°C), depending on the degree of color wanted.

Roasting at these temperatures causes the sugars inside the grains to caramelize, breaking them down and recombining them into less-fermentable forms. Maillard reactions also occur, causing further browning. The lighter caramel malts have a light honey and caramel flavor, while the darker caramel malts have a richer caramel and toffee flavor, with hints of burnt sugar and raisin at the darkest roasts.

The roasted malts include amber, brown, chocolate, and black malt. These malts are dried to a low moisture content (4%–6%) before roasting (fig. 15.6). Amber malts are produced by roasting fully kilned pale ale malt at temperatures up to 335°F (168°C). These high temperatures give amber malt its characteristic toasty, nutty, and biscuit flavors. Brown malts are roasted longer than amber malts and achieve a very dry dark toasted flavor, with color equal to that of the caramel malts.

The roasting process for chocolate malt begins at about 165°F (74°C) and is steadily increased to over 325°F (163°C), at which point the malt begins fuming. As the temperature is raised further to 420°F (216°C), the fumes turn blue and the malt develops chocolatey flavors. Some degree of caramelization occurs, but the majority of the flavors are from Maillard reactions. Black malts are roasted to slightly higher temperatures of 428–437°F (220–225°C), producing coffeelike flavors. The malt will actually burn at temperatures exceeding 480°F (249°C), so the trick is to spray the roasted malt with water at the critical point in time, and this was the basis of the invention of black “patent” malt. Roast barley is produced in a similar manner, but the difference is that it is never malted to begin with.

To summarize, kilning produces breadlike flavors from the low-temperature Maillard reactions. Roasting dry malts increases the Maillard reactions and accentuates the malt flavors of biscuit and toast. Roasting green malt causes both Maillard and caramelization reactions that produce toffee-sweet flavors. Kilning and roasting of dry malt at high temperatures produces the chocolate and coffeelike flavors.

Common Malt Types and Usages

Note: there are a few trademarked products in the following malts listed. I have listed these products because they best represent a particular style of malt that is commonly used for a particular flavor or purpose. Please note that this is an incomplete list—every malting house has its own specialties and I don’t come close to listing every malt here. Typical Lovibond color values are listed as °L.

In addition, it is important to understand that every batch of malt is unique, in the same way that every batch of beer is unique, and that the same type of malt (like the same style of beer), will be different between different maltsters (and brewers). Read the maltster’s websites for the best description about a particular malt type and product.

Base Malts

(The following base malts should be mashed.)

Lager or Pilsner malt (1–2°L). This type of base malt is the palest of the pale. The name comes from the fact that pale lagers are the most common style of beer and this is the type of malt used to produce them. Lager malt can be used as the base malt for brewing nearly every other style as well. After germination, lager malt is carefully heated in a kiln to 90°F (32°C) for the first day, withered at 120–140°F (49–60°C) for 12–20 hours, and then cured at 175–185°F (79–85°C) for 4–48 hours, depending on the maltster. This produces a malt with fine, mild flavor and excellent diastatic power.

The names lager malt and Pilsner malt should be synonymous, and either one can be produced from most any barley variety and on any continent, but the moniker “Pilsner malt” is generally associated with low-protein European varieties or indicates a premium lager malt. The “Pilsner” label may also be used to indicate a malt with lower modification compared to other base malt products from the same maltster.

Pale malt (a.k.a. two-row base malt) (2–3°L). There is a subtle difference between European and North American base malts; pale malt is essentially North America’s version of lager malt, generally made with North American barley varieties. It has slightly higher protein levels and diastatic power than European Pilsner malt, but can be used for any beer style.

Pale ale malt (3–4°L). Pale ale malt is kilned at higher temperatures than pale malt, giving a warmer, toastier malt flavor well suited to English style pale ale and will produce a golden to pale amber beer. Pale ale malt can be mimicked by using a combination of Pilsner or pale malt and Munich 10°L, but pale ale malt is often preferred for its own unique flavors, such as the pale ale malt produced using Maris Otter two-row barley.

Wheat malt (3°L). Wheat has been used for brewing beer nearly as long as barley has, and it has equal diastatic power. Malted wheat is used for 5%–70% of the grain bill, depending on the style. Wheat has no outer husk and therefore has fewer tannins than barley. Wheat kernels are generally smaller than barley kernels and contribute more protein by weight to the beer, aiding in head retention. But this higher protein content and lack of a husk causes wheat mashes to be stickier than barley mashes, which may cause lautering problems. A protein rest during the mash or adding rice hulls to the mash (or both) can help with lautering when using a high proportion of wheat.

Rye malt (3°L). Malted rye is not common, but is gaining in popularity. It can be used as 5%–10% of the grain bill for a “spicy” rye note. Rye is even stickier in the mash than wheat and should be handled accordingly.

Smoked malt (2-6°L). Smoked malts are a family of two-row base malts that have been cured over wood during the kilning process or have been smoked afterwards. Smoked malt can be used as 100% of the grain bill for a traditional rauchbier, or in smaller amounts (e.g., 20%) to add accent. Various woods, such as apple, beech, cherry, or mesquite, can be used for the smoking to give distinct characters.

Acidulated malt (2°L). Acidulated malt is a specialty product from Weyermann Malting and is prepared by spraying base malt with lactic acid produced from a soured wort. It is an all-natural product that complies with the Reinheitsgebot and allows German brewers to lower their mash pH without using brewing salts or commercial acid. It is reported to lower the mash pH by 0.1 for every 1% by weight used in the grain bill.

Kilned Base Malts

(Should be mashed.)

Kilned base malts are commonly produced by increasing the moisture content and curing temperatures used for base malt production.

Vienna malt (4°L). Vienna malt has a lighter flavor than Munich malt and is a principal ingredient of light amber beers. Retains more than enough diastatic power to convert itself, but is often used with a base malt in the mash. Typically used as 10%–40% of the grain bill, depending on beer style, although it can be used at 100% for Vienna style lagers. Contributes a warm malt flavor without excessive sweetness or bread crust flavor.

Munich malt (10°L). Munich malt has an amber color and gives a very malty flavor. This malt has just enough diastatic power to convert itself, but is usually used in conjunction with a base malt in the mash. Munich malt is used as 10%–60% of the grain bill for Oktoberfests, bocks, and many others, including pale ales. It can be used at 100% for Munich dunkles. Munich malt is the primary tool for imparting rich maltiness to many styles. Its flavor is like toasted bread crust.

Aromatic malt (15–25°L). Aromatic malt (a.k.a. melanoidin malt) is similar to a dark Munich 20°L, and in some cases probably is literally that. It has a very low diastatic power, but gives wonderful rich malt flavor and aromas, like dark bread crust. Aromatic malt contributes a deep amber or walnut-brown color to beer. Use as 5%–10% of the grain bill for accent.

Amber malt (20–40°L). Amber malt, a.k.a. biscuit or Victory malt, is a fully toasted, lightly roasted malt used to give the beer a warm flavor like fresh baked cookies (biscuits in the UK). It is typically used as 10% of the grain bill. Gives a deep amber color to the beer. No diastatic power.

Brown malt (60°L). Brown malt is getting hard to find, because it is only used in a couple of styles, such as old ale, porter, and stout. It has a very dry, bitter roasted character that falls somewhere between amber and chocolate malt, and it is not sweet. Kind of like concentrated bread crust. Use as 5%–10% of the grain bill, depending on style. No diastatic power.

Stewed Malts

(May be steeped or mashed.)

Caramel malts. Caramel malts (a.k.a. crystal malts) have undergone a special heat process that “stews” the malt, converting the starch and liquefying the sugar inside the kernels. These malts are roasted at various temperatures to caramelize the sugars to different degrees, which yields a range of flavors, from honey sweet to toffee to dark caramel. The same color rating from different maltsters can have different flavors due to individual techniques; malting is as much an art as brewing. Caramel malts are used to some degree in most beer styles. They are ideal for adding aroma and body to extract beers by steeping, but it is possible to overdo it and make the beer cloyingly sweet. Caramel malts are typically added as 5%–15% of the total grain bill.

Dextrin malt (3°L). Dextrin malt is typically used as 1%–5% of the grain bill, and enhances the body, mouthfeel, and foam stability of the beer without affecting the color or flavor. This glassy malt is very hard and difficult to crush. Consequently, dextrin malt does not give a good yield from steeping even though it is fully converted the same as other caramel malts. Two examples are Carapils® from Briess Malt & Ingredients Co. and Carafoam® from Weyermann.

Caramel 10 malt (10°L). Caramel 10 malt adds a light honeylike sweetness and some body to the finished beer.

Honey malt (25°L). Also known as brumalt, honey malt has a rich honey flavor that is very versatile.

Caramel 40 malt (40°L). The additional color and light caramel sweetness of caramel 40 malt is perfect for pale ales and amber lagers.

Caramel 60 malt (60°L). Caramel 60 malt is the most commonly used caramel malt, and is also known as medium crystal malt. It is well suited for pale ales, English-style bitters, porters, and stouts. Caramel 60 malt adds a full caramel taste and body to the beer. However, this malt is reported to oxidize (go stale) more quickly than other caramel malts, and some brewers opt to use a combination of 40°L and 80°L caramel malts instead.

Caramel 80 malt (80°L). Caramel 80 malt is used for making reddish-colored beers and gives a lightly bittersweet caramel flavor.

Caramel 120 malt (120°L). Caramel 120 malt adds a lot of color. It has a toasted, bittersweet caramel flavor, with hints of burnt sugar and raisin. Caramel 120 malt is useful in small amounts to add complexity, or in greater amounts for old ales, barleywines, and doppelbocks.

Special “B” malt (150°L) (Castle Malting). Special “B” is a unique Belgian malt that has a definite roasty or toasty flavor consisting of dark caramel, toasted marshmallow, and raisin. Used in moderation in the grain bill (1%–5%), it is very good in brown ales, porter, and doppelbocks. Larger amounts, >5% of the grain bill, will lend a prune-like flavor to abbey ale styles like dubbel. Several other maltsters make a similar 150°L–180°L product under various names, but Special “B” was the original.

Roasted Malts

(May be steeped or mashed.)

This class of highly roasted malts contribute bitter chocolate, coffee, or burnt toast flavors, to brown ales, porters, and stouts. Obviously, these malts should be used in moderation, typically 1%–5% of the grain bill (e.g., this equates to 0.25–0.5 lb./5 gal., or 115–225 g/19 L). Some brewers recommend that they be added toward the end of the mash to reduce the acrid bite that these malts can contribute. This practice will produce a smoother beer for people brewing with naturally “soft” or low-bicarbonate water. Roasted malts are typically used in small amounts and may be finely ground to achieve a better color contribution with a smaller addition.

Pale chocolate (200–250°L). Pale chocolate malt is used in small amounts (0.5 lb./5 gal., or 225 g/19 L) for brown ale, porter, and stout. This malt has a medium roast coffee flavor and contributes a rich ruby-brown color. Using too much will dominate the character of the beer.

Chocolate malt (300–400°L). Chocolate malt is used in small amounts (0.5 lb./5 gal., or 225 g/19 L) for brown ale, but used extensively (1 lb./5 gal., or 450 g/19 L) in porter and stout. This malt has a bittersweet chocolate-coffee flavor, pleasant roast character, and contributes a deep ruby-black color. Using a lot of chocolate malt will not make the beer taste like chocolate! I recommend not exceeding 1 lb. in 5 gal. (450 g/19 L). Too much will give the beer an unpleasant inky aftertaste.

De-bittered black malt (500°L). This special roast malt has had the husk removed prior to malting, creating a much smoother roasted character in the beer. This malt is often used for color adjustment, but only in small amounts (roughly 1.5–3 oz. in 5 gal., or 50–80 g in 19 L). It can be used in larger amounts, such as 5% of the grain bill, to contribute the roast character for porters and stouts without as much bite as a traditional black malt.

Black wheat malt (500–550°L). These are, obviously, black malts made from wheat instead of barley. Wheat doesn’t have a husk, so these malts can be highly roasted to give a smoother coffee-like flavor with less bitterness, like the de-bittered black malts. They can be used interchangeably with black malt for all styles.

Roast barley (500°L). Roast barley is not actually a malt, but highly roasted plain barley. It has a dry, distinct coffee taste and is the signature flavor of Irish and dry stouts. Use about 0.5–1 lb. per 5 gal. (230–450 g/19 L) for stout.

Black (“patent”) malt (500–600°L). Black “patent” malt is the blackest of the black and is mainly used for color. It should be used sparingly, generally less than 0.5 lb. per 5 gal. (225 g/19 L). As well as contributing color, black malt is useful for setting a “limit” on the sweetness of other beer styles that use a lot of caramel malt; 1–2 oz./5 gal. (30–60 g/19 L) is useful for this purpose.

Figure 15.7. Some of the common flaked adjuncts. Clockwise from top, flaked corn, flaked wheat, flaked rye, and flaked oats.

Other Grains and Adjuncts

Note: If you intend to use more than 10% of any of the following adjuncts in your recipe, you may want to conduct a cereal mash to better utilize them and achieve better flavors. Mashing of adjuncts is described in chapter 17. Adjuncts are frequently rolled and flaked (fig. 15.7).

Oatmeal. Oats are wonderful in a porter or stout. Oatmeal lends a smooth, silky mouthfeel and a creaminess to a stout that must be tasted to be understood. Oats are available whole, steel-cut (i.e., grits, or pinhead), rolled, and flaked. Rolled and flaked oats have had their starches gelatinized (made soluble) by heat and pressure, and are usually readily available as “instant oatmeal” in the grocery store. Whole oats, steel-cut oats, and “old-fashioned rolled oats” have not had the degree of gelatinization that instant oatmeal has had, so these must be cooked before adding to the mash. “Quick cooking” oatmeal has had more gelatinization than “old fashioned” oatmeal, but still benefits from being cooked before adding to the mash.

Cook the oatmeal according to the directions on the box (but add more water) to ensure that the starches will be fully utilized. Use 0.5–1.5 lb. per 5 gal. batch (225–680 g/19 L). Oats need to be mashed with barley malt (and its enzymes) for conversion. Oat malt is available as well, including Golden Naked Oats®, which is a caramel-type malt from Simpsons Malt.

Flaked corn (maize). Flaked corn (maize) is a common adjunct in British bitters and milds, and was also used extensively in American light lager in the past (although today corn grits are more common). Properly used, corn will lighten the color and body of the beer without overpowering the flavor. Use 0.5–2 lb. per 5 gal. batch (225–910 g/19 L). Corn must be mashed with base malt.

Flaked barley. Unmalted flaked barley is often used in stout to provide protein for head retention and body. It can also be used in other strong ale styles. Use 0.5–1 lb. per 5 gal. batch (225–450 g/19 L). Flaked barley must be mashed with base malt.

Flaked wheat. Unmalted flaked wheat is a common ingredient in wheat beers, and is essential to styles like Belgian lambic and wit. It can add starch haze and higher levels of protein than malted wheat. Flaked wheat also imparts more wheat flavor “sharpness” and a thicker mouthfeel than malted wheat. Use 0.5–2 lb. per 5 gal. batch (225–910 g/19 L), or up to 50% of the grain bill in classic witbier or lambic recipes. Flaked wheat must be mashed with base malt.

Flaked rice. Rice is the other principal adjunct used in American and Japanese light lagers. Rice has very little flavor and makes for a drier tasting beer than corn. Use 0.5–2 lb. per 5 gal. batch (225–910 g/19 L). Flaked rice must be mashed with base malt. Whole rice needs to be cooked in a cereal mash to effectively utilize it in the mash.

Oat and rice hulls. Not an adjunct per se, the hulls of oats and rice are not fermentable, but they can be useful in the mash. The hulls provide bulk and help prevent the mash from settling and becoming stuck during the sparge. This can be very helpful when making wheat or rye beers with a low percentage of barley malt and barley husks. Use 2–4 qt. (~2–4 L) of oat or rice hulls for 6–10 lbs. (~3–5 kg) of wheat, if doing an all-wheat beer. The barley hull is 5% of the kernel weight, so 5% of the adjunct weight is a good place to start. Do not exceed 3% by weight of the total grain bill or you will start tasting them as astringency in the beer.

How to Read a Malt Analysis Sheet

Every batch of malt is unique, so every lot is tested, sometimes multiple times to check the consistency of large batches. The requirements differ across the various types of malt, depending on primary usage and individual customer needs. At a minimum, each lot is tested for color, soluble extract yield, and percentage moisture (these are usually listed as Color, Yield, and % Moisture). There are two ways of measuring the soluble extract yield, either percent extract (%Extract) or hot water extract (HWE).

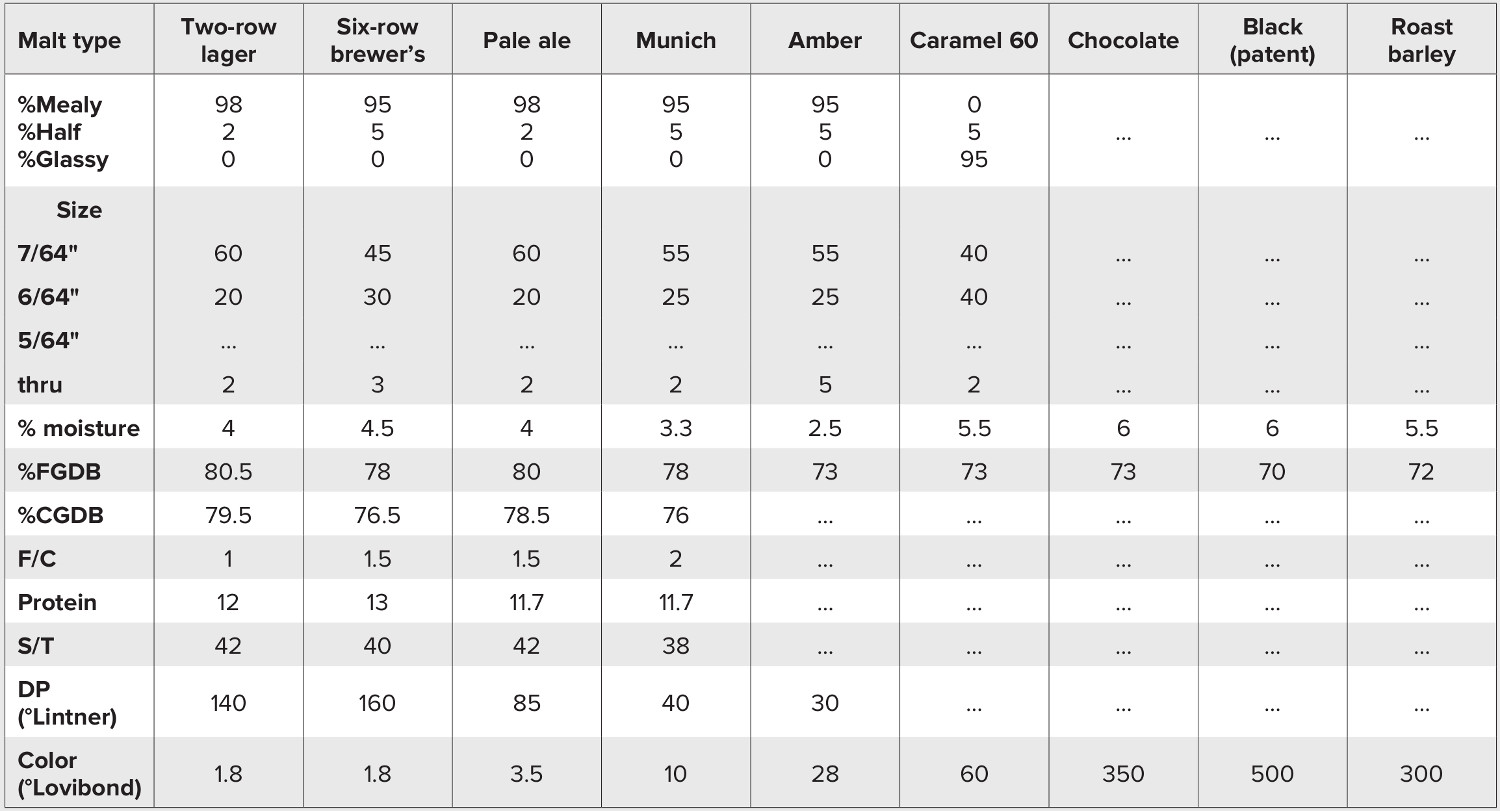

The other parameters typically tested for malt lots are: size characterization, protein levels, modification, and diastatic power. Example values for various malt types are given at the end of this chapter in table 15.2 for comparison.

Percent Extract–Fine Grind, Dry Basis

A typical malt analysis sheet does not give the malt’s yield in gravity points per pound per gallon (PPG) or liter degrees per kilogram equivalent to PKL—see explanation below. What you will most likely see instead for North American and European malts is a value called “% Extract–Fine Grind, Dry Basis” (FGDB). This percentage is the maximum soluble extract by weight that the malt will yield when mashed, and is typically 80% for base malt. This soluble extract percentage equates to 37 PPG, or 309 PKL.

When a malting house analyzes a malt sample to determine its extract yield, it conducts a “Congress mash,” named for the European Brewery Convention (EBC) of 1975 that standardized the procedure. A Congress mash (see sidebar) consists of a multistep infusion mash using a standard weight of finely ground malt (i.e., flour). The mash is continually stirred over a two-hour period and then drained for another hour. These times may not seem remarkable until you consider that the malt test sample is only 50 grams! This procedure yields the maximum soluble extract as a percentage of the original sample weight.

This yield is known as the percent extract–fine grind, as-is (FGAI). It is called “as-is” because properly kilned malt contains about 4% moisture by weight. To compare different lots of malt with different moisture levels, this weight needs to be accounted for in the extract calculation. Therefore, the basis of comparison, and the number you will most consistently see on an analysis, is the “%FGDB,” the fine grind, dry basis value corresponding to a malt sample that has been oven-dried to zero percent moisture. Extract yield will be discussed further in chapter 18.

The moisture content for the lot will be listed on the certificate of analysis, and should be 2%–4% for base and kilned malts. Caramel and roast malts typically have more moisture at 5%–6%, but the moisture level should always be less than 6%.

Percent Extract–Coarse Grind, As-Is and Dry Basis

The same Congress mash method is also used to determine the percent extract–coarse grind, as-is (%CGAI), and the moisture is measured to calculate the percent extract–coarse grind, dry basis value (%CGDB). Coarse grind represents a mill setting that is closer to what many professional breweries would use. The %CGAI is a slightly more realistic number for gauging the extract potential of a malt, but it’s still a maximum that few professional breweries attain.

Percent extract–coarse grind is not measured for most specialty malts due to the extra time and effort it takes. Professional brewers are not as concerned about the yield of specialty malts because they usually only represent a small percentage of the grain bill. Thus, the standard parameter of %FGDB is usually the only value determined for specialty malts, like caramel, chocolate, and roast malts.

Fine/Coarse Difference

The fine/coarse (F/C) difference value is simply the difference between the fine and coarse grind percentages (both as-is and dry basis—same difference, respectively). The F/C difference value allows the brewer to quickly convert between the two parameters. For example, looking at the numbers for Munich malt in table 15.2, the %CGDB is 2% less than the %FGDB, and this is indicated by the F/C value given in the next row. The F/C difference also serves as an indicator of the degree of modification, although the soluble-to-total protein ratio is most often used (see section further below). An F/C difference of 1% is typical for highly modified base malts. An F/C difference of 2% indicates a less modified malt, and a value of less than 1% would be over-modified.

Hot Water Extract

The hot water extract (HWE) parameter may be seen on malt analyses from the UK and Australia, where maltsters utilize a single temperature infusion mash method that differs from the ASBC and EBC Congress mash methods. The main difference is that the malt sample is mashed at 149°F (65°C) for 1 hour. The HWE is “as-is” and is measured as liter degrees per kilogram (L·°/kg).

Note the units for HWE, where a liter degree is a unit of extract yield, abbreviated to L·° or simply L°, and should not be confused with degrees Lovibond (°L). The degree in L° refers to the number of degrees, or points, of specific gravity. You may realize at this stage that a value in L°/kg can also be expressed as gravity points/kg/L—in other words, PKL (e.g., 300 L°/kg = 300 PKL). Therefore, HWE expressed as PKL is equivalent to PPG when the metric conversion factors for volume and weight are applied. (Also note: gravity points/lb./gal. = gal.°/lb.). The conversion factor is PKL = 8.345 × PPG.

Color

Degrees Lovibond (°L) was a unit created in 1883 by J.W. Lovibond to denote the color of beer and brewing malts. His system consisted of glass slides of various shades that could be combined to produce a range of colors and compared against samples of wort or beer. In 1950, the American Society of Brewing Chemists (ASBC) set a standard using optical spectrophotometers to measure the absorbance of a specific blue wavelength of light (430 nanometers) through a standard-sized sample, and this was called the Standard Reference Method (SRM). The SRM aligned nicely with the Lovibond scale and the two can be considered nearly identical for most of their range. However, the resolution of a spectrophotometer diminishes greatly with darker worts, when very little light can penetrate the sample to reach the detector.

For this reason, the Lovibond scale is still in use today, in the form of precision visual comparators. The use of comparators is most prevalent in the malting industry, particularly for roast specialty malts, and thus the color of malts is given as °L, while beer color is given as SRM, though the reference standard (absorbance at 430 nm) is the same. See the SRM color samples on the inside front cover of this book.

Prior to 1990, the EBC used a different wavelength for measuring absorbance, and conversion between the SRM and EBC scales was an approximation. Today, the EBC scale uses the same 430 nm wavelength for measurement, but uses a smaller sample glass. Color measurements using the current EBC scale work out to be about twice the SRM rating (actually, EBC = SRM × 1.97). See appendix B for more information on beer color.

Size

The average size of the kernels and the size distribution is important to the brewer, because it affects how well the malt is crushed by the roller mills. If a significant proportion of the kernels are small, then those kernels will not be crushed well and the extract from the mash and lauter will decrease. Kernel size and distribution are measured by sieving. The ASBC method uses standard sieves with mesh sizes of 7/64", 6/64", and 5/64". Kernels that pass through the 5/64" sieve are caught in a pan and classified as “thru” on the analysis sheet. The sum of the percentages captured by the 7/64" and 6/64" sieves is often described on the malt analysis sheet as “% plump.” Typically, malt is required to have 80% or 90% of the batch be plump. The percentage that passes through the 5/64" sieve is often labeled “% thin.” The requirement for malt is typically a maximum 2% of the batch be thin.

In Europe and the UK, the sieve sizes are very slightly larger, being 2.8 mm, 2.5 mm, and 2.2 mm.

Protein

The protein measurement in malt is actually an approximation, based on chemical analysis of the total amount of nitrogen in a malt sample. Every 1% of nitrogen is assumed to represent 6.25% of protein. You may see “total nitrogen” on an analysis instead of “total protein.”

American barley varieties are usually higher in protein than European varieties. The range of protein for two-row varieties is 11%–13% for North American barley, whereas European and Australian two-row is usually 9.5%–12%. Six-row varieties average a little higher at 12%–13.5%. Barley with total protein measuring over 13.5% is not used for malting.

Soluble-to-Total Protein Ratio

The soluble-to-total protein (S/T) ratio, also known as the Kolbach Index, is the most commonly used indicator of malt modification. During the malting process, the proteolytic enzymes in barley cleave the large insoluble proteins into smaller soluble proteins. About 38%–45% of the malt protein (as measured by nitrogen as total protein above) is converted to soluble protein, including enzymes, foam-positive proteins (i.e., proteins that form foam in the wort and beer), haze-forming proteins, and amino acids. The S/T ratio for the malt describes the extent of modification of the endosperm. To generalize, an S/T ratio of 36%–40% is a less-modified malt, 40%–44% is a well-modified malt, and 44%–48% is a highly modified malt. Soluble protein levels below 35% can result in low extraction due to the starches in the protein-carbohydrate matrix still being relatively inaccessible, and difficulty in lautering due to higher beta-glucan levels. Soluble protein levels exceeding 55% will lead to excessive darkening during wort boiling, beer haze, and loss of body in the beer.

Diastatic Power

The diastatic power of a malt is a measure of the starch conversion capability in degrees Lintner (°Lintner).1 Diastatic power is measured by evaluating the effects of all the diastatic enzymes in the malt, that is, those enzymes that can convert starch. The diastatic enzymes in malt are degraded by kilning, and thus the diastatic power of highly kilned malts, like Munich and Vienna, is less than that of lager malt. Malts with diastatic power of 40°Lintner or greater are able to convert themselves. Munich malt is typically 40–50°Lintner, pale ale malt is about 80°Lintner. Lager malt is generally 100–140°Lintner, and wheat malt and six-row brewer’s malt can be as high as 165°Lintner. High diastatic power is most useful when brewing with starch adjuncts. You can determine the conversion potential of an adjunct mash by calculating the dilution of the enzymatic malts and their diastatic power. In other words, a six-row brewer’s malt could be part of a grain bill that is two-thirds adjuncts and still have an equivalent diastatic power of 55°Lintner for the mash. The only caveat is that low-diastatic power mashes will take longer to convert, and there is the risk that all of the beta-amylase will be denatured by the mashing temperature before conversion is finished.

Summary

The malting process allows the barley grain to partially germinate, making the seed’s resources available to the brewer. Malted barley is the principal source of the sugars that are fermented into beer. From a homebrewer’s point of view, there are basically two kinds of malts, those that need to be mashed and those that don’t. Mashing is the hot water soaking process that provides the right conditions for the enzymes within the grain to convert the grain starches into fermentable sugars. The base malts, such as Pilsner, pale ale, Vienna, and Munich malts, have sufficient diastatic power to convert their starches into fermentable sugars.

Specialty malts are non-enzymatic malts, that is, they have no diastatic power whatsoever following heat treatment. Specialty malts are used for flavor and coloring, and can be divided into three groups, kilned, stewed, and roasted. The kilned malts, such amber and brown malts, do not have significant diastatic power and need to be mashed with base malts. Caramel malts have had their starches converted to sugars by heat and moisture right inside the hull, and can be steeped or mashed to release their character. The sugars in caramel malts have a pleasant caramel-like sweetness. The starches in roasted malts have been converted by high heat into soluble melanoidin compounds that have bitter chocolate and coffeelike flavors. These malts can also be steeped or mashed.

Lastly, there are non-enzymatic fermentables that are not derived from malted barley, which are called adjuncts. Adjuncts include refined sugars, corn (maize), rice, unmalted rye and wheat, and unmalted barley. Adjuncts made from grains must be mashed with enzymatic malts to convert their starches to fermentable sugars.

Table 15.2—Representative Malt Analysis Numbers

CGDB, coarse grind, dry basis; DP, distatic power; F/C, fine/coarse (difference); FGDB, fine grind, dry basis. %Mealy/%Half/%Glassy describes the friability of the malt, i.e., how it crushes.

1 Probably named after Carl Lintner (1828–1900), a director of the brewing school at Weihenstephan. Although °Lintner can also be represented as °L, I have not used this abbreviation here to avoid confusion with degrees Lovibond.