CHAPTER 6

The Simple Case

Pat Lancaster of Louisville, Kentucky, is a heroic American type, the stand-alone inventor-industrialist often found at the heart of capitalist lore. He grew up tinkering in the family workshop, convinced from an early age that he could be an inventor. After college, he tried the family business of selling packaging materials to industrial firms and then life in the product development group of a large chemical company. “But it just wasn’t satisfying. From my earliest memories I wanted to be an independent inventor, manufacturer, and entrepreneur.” When he was twenty-nine (in 1972), he had his big idea, a new way for manufacturers to wrap their products for shipment. He and his brother invested $300 in simple metalworking tools to build their first machine, rented a small warehouse, and went to work under the corporate name of Lantech, a contraction of Lancaster Technologies.

Lancaster’s big idea was for a device to “stretch-wrap” pallets of goods (for example, the cases of cola we examined in

Chapter 2

) with plastic film so they could be shipped easily from plant to plant within a manufacturing system and then onward, as finished products, to the wholesaler and retailer. Traditional “shrink-wrapping” was then in wide use by manufacturers and distributors who laid plastic bags loosely around large pallet loads of goods that were then run through an oven to shrink the plastic and give a tight fit.

Stretch-wrapping, by contrast, pulled the plastic wrap tightly around the pallet load as it rotated on a turntable. As the plastic was stretched taut, it rebounded slightly to give a snug fit while eliminating the energy, equipment, effort, and time required for heat treating. In addition, stretching the wrap practically halved the amount of plastic required to secure a pallet load for shipment.

Lancaster’s next invention was the key complement to his fundamental insight that the plastic should be stretched rather than shrunk. He discovered that a complex set of precision rollers (collectively termed the roll carriage) could exert a smooth force on the plastic to stretch it dramatically

before it was wound around the pallet. Eventually, he found ways to decrease the amount of plastic needed to hold a pallet load together by a factor of 7.5 compared with shrink-wrapping.

When Lancaster obtained patents for his concepts at the beginning of the 1970s, they were so general and broad that he could easily fend off competitors for years. All he needed was a market. This was supplied by the world energy crisis of 1973, which unfolded just as he completed his first, hand-made stretch-wrapping machine. As energy prices zoomed, the amount of process energy and plastic (made from natural gas) which his new technique could save created an overwhelming advantage for stretch-wrapping in the contest with traditional shrink-wrapping.

Suddenly he had a real business and needed to think about how to make his product in volume. He had created his initial design and his first machine in a continuous flow of activities, so Lantech, like most start-up businesses, was born lean. However, it didn’t seem plausible to run an established business this way.

In reconstructing his thought process during the transition from start-up to established firm, Lancaster recollects that “I had no production experience—remember, I was an inventor—so I decided I should get myself an experienced operations manager. What’s more, I knew I would need to engineer a variety of configurations of my basic concept for different wrapping tasks, so I got an engineering manager. Finally, I had a complex product which needed explanation to the customer, so I got a sales manager. I knew instinctively about the division of labor and returns to scale, so it seemed natural that my operations, sales, and engineering managers should organize my rapidly growing firm into a series of departments, each with a specialized task, and each operating in batch mode.”

The operations manager created a series of departments in the manufacturing plant, one for each of the basic steps in building a Lantech stretch-wrapper. The Sawing Department used metal saws to fashion frame members from steel beams. The Machining Department drilled and punched holes in the steel to create attachment points for component systems. The Welding Department welded the frame members together to form the completed frame for the machine. The Painting Department applied a corrosion-inhibiting base coat and a cosmetic finish coat to the completed frame. Component systems—notably the roll carriage, the turn-table, and the control module—were assembled in the Sub-Assembly Department from parts purchased from suppliers. These were attached to the frame in the Final Assembly Department.

Final Assembly was not the end of the line for products making their way from department to department and storage area to storage area. Because it was thought to be efficient, Lantech built its four basic types of machines in

batches. Ten or fifteen machines of a type would be fabricated and assembled at a go. The nature of the product, however, meant that individual customers usually bought only one. Therefore, it was necessary to store many machines in a finished goods area for some time before they could be matched up with customers.

When it was time for shipment, it was often necessary to remove grime and to paint over nicks caused by moving machines from department to department. This meant a journey to a Touch-Up Department. Often the machine had to be sent back to Final Assembly as well to change its mix of optional features in order to accommodate changing customer desires. Finally, the machine was sent to the Crating Department for actual shipment.

The progression of a stretch-wrapper through Lantech is shown in

Figure 6.1

, often called a “Spaghetti Chart” by firms who have mastered lean thinking.

F

IGURE

6.1: P

HYSICAL

P

RODUCTION AT

L

ANTECH

Physical production of the machine was not the only process to manage. The real complexity in volume production began to emerge as Lantech tried to move the orders gathered by the sales force (a group of about fifty independent firms distributing industrial machinery) through the office and into the plant.

Because the machines were often customized and cost from $10,000 to $50,000 apiece, it was decided that a standard price list would not work.

Instead the sales force contacted Lantech for authorization before quoting a price on any machine with special features. The proposal was sent to the Engineering Applications Department within Sales for cost analysis. After analysis, the “right number” was sent back to the sales force. Then, once the offer was accepted (with the distributor negotiating a final price with the customer which included the distributor’s margin), the order was sent back to Lantech for production scheduling.

Upon arriving back at Lantech, the order proceeded from the Order Entry Department to the Credit Checking Department to the Engineering Applications Department (for its second visit). There, a Bill of Materials (BOM) was generated for the order. This was the precise list of every part which would be needed to manufacture a specific machine. Because every department had a waiting list of orders, there were usually delays. Typically, an order took twelve to fourteen working days to travel from the Entry Department to the Scheduling Department, while the actual processing time—what we will call “continuous flow time”—was less than two days.

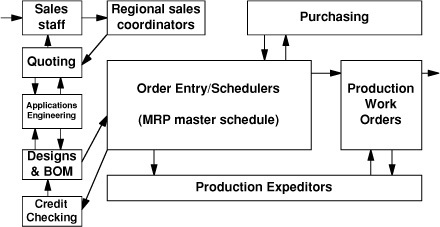

The order with the BOM was then taken to the Scheduling Department inside Production Operations to work into the master schedule. Because it became apparent immediately that the flow of production through the plant would be very erratic, a separate Order Management Department was created in Sales to maintain liaison between the independent sales force and the plant on just where the machine was in the production process and to initiate expediting (using a technique we will examine in a moment) if the customer was getting restless. Information progressed through the system as shown in

Figure 6.2

.

F

IGURE

6.2: L

ANTECH

O

RDER

F

LOW

The master schedule itself resided in the Scheduling Department inside Production Operations in the form of a computerized Material Requirements Planning system. The MRP melded a long-term forecast for orders with actual orders as they were received to create a daily production schedule assigning tasks to each department in the plant. Each morning, workers in each department—sawing, machining, welding, paint, sub-assemblies, final assembly, touch-up, and crating—would pick up a printout with their tasks for the day. At the end of each day, each department would report its progress back to the computerized Scheduling Department.

This system was fine in plan, but always a mess in practice because of the conflict between changing customer desires and the logic driving the production system. In order to gain scale economies, Pat Lancaster and his operations manager decided from the beginning that each department should do its work in batches: ten frames welded for the E model, then twenty frames welded for the T, then twenty-five welded for the V. This minimized the time Lantech’s machinery was idle during the changeover to a new part. In addition, running long batches was thought to improve quality by minimizing opportunities to misset machines and by keeping operators focused on the operation itself rather than changeovers.

Separate departments for each production step, batches of parts run through the departments, and waiting time at the entrance to each department inherently meant long lead times. Typically, it took sixteen weeks to turn the incoming steel for the frame into a completed machine on the shipping dock. Most of this time was spent waiting as batches of parts were built in each department and then sent to storage to await the next fabrication step in the next department. The actual amount of time needed to complete the physical transformation of raw materials into a stretch-wrapper—the “continuous flow time”—was only three days.

Long lead times meant in turn that the sales force distributing Lantech’s machines to the end user tried to figure out how to beat the system. A favorite approach was to order machines on speculation and then, as a real customer was found, to alter the options requested (or even the base model) very late in the production process. This tactic created the need either to rework the machine initially ordered or to slip the delivery date and build a properly configured machine from scratch.

Soon the factory was being pulled in opposite directions by two conflicting planning systems—the master schedule worked out by the Scheduling Department based mostly on sales forecasts, and the ever-changing demands from the Sales Group intent on pleasing actual customers.

These latter demands were met by a team of expediters moving through the plant with a “hot list.” These were orders which were either long overdue for shipment or in which the sale would be lost if the product was not

reconfigured to the new specification. The expediters visited departments in sequence and ordered the workforce to make just one item of a batch—a “partial”—so they could take that part immediately to the next department and move it to the head of the line in that department. In an extreme situation, when Pat Lancaster agreed that an order absolutely had to be expedited all the way through the company, it was possible to get a machine built in less than four weeks. However, when this was done, the schedule of every other machine in the plant slipped, creating the need for more expediting.

This system of order-taking and production sounds chaotic—and it was. But it was and is the standard method in most of the industrial world for making products when there is considerable product variety, long lead times, and a complex production process. To make matters worse, the production and sales technique of batch-and-queue soon had an exact analog in product development in Lantech’s departmentalized engineering process.

To create a new design, it was necessary for the marketing staff, engineers skilled in several specialties, the purchasing staff, and operations planners to work together. The marketing group determined what the customer wanted. (“A machine able to wrap forty four-thousand-pound pallet loads per hour in a fifteen-by-fifteen-foot work area at a cost of fifty cents per pallet.”) The chief engineer then translated these desires into engineering specifications. (“A turntable able to support a four-thousand-pound pallet load, a turntable motor of x

horsepower capable of y

rotation speed, a control system able to direct the wrapping procedure automatically, etcetera.”)

Next, a mechanical engineer designed the moving mechanical parts, notably the roll carriage and the turntable. Another mechanical engineer then designed the frame and an electrical engineer designed the control system to meet the engineering specification. The manufacturing engineer then designed the fabrication tools. Once the product design and tools were finalized, an industrial engineer from the Production Department figured out how to get the product to progress by steps through the plant.

The Engineering Department was initially quite small, with only a half dozen engineers, but even then the communication barriers between the one-person “departments” were substantial as the design was moved from marketing group to chief engineer to mechanical engineer to electrical engineer to industrial engineer. A considerable amount of rework and backtracking was required to get from the initial concept to a complete, production-ready design. (The prime cause of the backtracking was that the design didn’t fit the needs of the next specialist in the line—“there’s not enough room for my control panel,” etcetera—and was sent back for modification. A frequently employed alternative to sending the design back was

to secretly redesign it.) As Lantech grew and more engineers were added, these communication problems got worse.

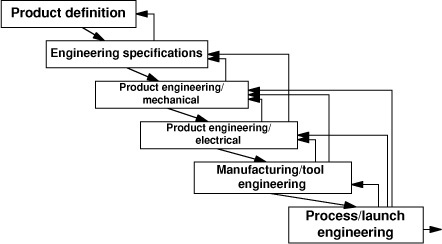

What was more, each engineer typically had a stack of projects on her or his desk, so that expediters soon appeared in engineering as well as in the plant to get “rush” projects through the system. In practice, it typically took a year to introduce a minor improvement in a family of machines and three or four years to introduce a new family suited to a different task, such as wrapping small bundles. The “continuous flow time,” by contrast, was only a few weeks for minor improvements and six months for a new family of machines. The progression of a design through the design and engineering system is shown in

Figure 6.3

.

F

IGURE

6.3: L

ANTECH

P

RODUCT

D

EVELOPMENT

S

YSTEM

The three major activities undertaken in Pat Lancaster’s new company—development of new designs, management of information on what to make, and physical production of the machines—were all conducted in a classic batch-and-queue manner. And they were conducted with great success.

Looking back, Pat Lancaster summarized his dream of becoming a highly successful inventor, manufacturer, and entrepreneur. “After 1973, we were selling a top-priced product which had major performance advantages over competitor products due to my patent position. Over the next fifteen years Lantech grew to 266 employees and $43 million in sales. We could and did deliver late because of conflicting demands for efficiency versus speed within the production process. We offered so-so quality in terms of manufacturing

defects in machines delivered to customers. We took more than a year to develop ‘new’ machines which differed only in very minor ways from previous models. But we were way ahead of the competition and we made tons of money. For fifteen years my dream came true.”

Then, on June 26, 1989, Lantech lost a patent infringement suit against a competitor offering lower-priced clones of Lantech machines. (The suit concerned a new generation of patents Lantech had obtained in the mid-1980s as follow-ons to its original patents obtained in the early 1970s.) This threw open the market to every packaging machinery firm. “By the end of 1989, clones with roughly comparable performance started to appear everywhere and the bottom fell out of my pricing. I was still turning a small profit but I knew worse was coming as soon as the business cycle turned down. In my heart I knew that Lantech was ‘walking dead.’”

Pat Lancaster is by nature a highly dynamic individual. So he had plenty of ideas on what to do. In fact, he tried many of the remedies popular in the American business community at that time. His first approach was to reorganize the firm into profit centers for “standard products” and “specials” (those requiring extensive customization). This was to increase accountability and to move the highly customized products out of the path of easier-to-make “mass-production” machines. Then, as sales flattened, he considered laying off employees and shrinking Lantech—what we now call “downsizing.” However, Lancaster was convinced that no firm had ever been saved by cost cutting and retrenchment alone.

He needed a new way to think about his business and sought it in the Total Quality Management (TQM) movement. After a visit to Milliken, the South Carolina textile giant, he came back to Louisville with plans for putting the voice of the customer first and foremost. The old “good enough” standard for delivered defects and customer service was quickly replaced with talk about perfection.

Over the next few years this focus was supplemented with a process of “value-driven culture change” to create an empowered organization, build trust, and knock down departmental barriers. The original senior management team, which had been composed of hierarchical personalities accustomed to a top-down, command-control style, was replaced by a new group of managers willing to work in a team-based organization. (Lancaster is the only senior manager remaining from the 1970s.) In addition, extensive training was conducted in team processes, team leadership, and individual interaction.

These programs were an essential start, but they lacked a direct link to Lantech’s core activities. As Bob Underwood, a longtime production worker, put it in retrospect: “We learned to respect each other and wanted to work together in teams, but we were all revved up with nowhere to go.” The

factory was still a mess. Product development was still too slow. The sales force was still playing games to beat the lead-time problem.

The third approach to the crisis was a new production method called “Max-Flex.” The idea was to dramatically reduce lead times by building inventories of major components—machine frames, roll carriages, turntables, control modules—far in advance and then mixing and matching the components to build complete machines to customer specification very quickly once orders were confirmed. The objective was to overcome Lantech’s pricing disadvantage by promising more rapid delivery of machines with customer-specified features.

On one level the performance of the new Max-Flex concept was impressive—lead times fell from sixteen weeks to four. But the costs were enormous. Engineering change orders were frequent in Lantech’s business now that it had become highly competitive. These changes were both to add product features to keep up with the competition and to rectify defects discovered in service. Therefore, it was often necessary to work backwards, “retrofitting” changes into the mountain of components built in advance. Obviously, the cost of carrying this mountain of “just in case” components was substantial, and Lantech began looking for a new warehouse to store components as storage space in its plant was exhausted. But most exasperating, despite Lantech’s best efforts at planning production, cases quickly arose where one critical component needed to complete a machine was lacking. (Taiichi Ohno noted long ago that the more inventory you have, the less likely you are to have the one part you actually need.) The solution was a new team of expediters to move the missing component through the production system.

Yet a fourth approach to the crisis was better technology. A new scheduling system, based on the next generation of MRP, was installed in 1990. It permitted every worker to have direct access to the status of every machine in production and to input their own data as they moved a part or a whole machine ahead. This permitted every worker to get work orders from a terminal at his workstation and, in theory, to feel full “control” over his activities. (As Pat Lancaster noted: “It seemed to be a wonderful marriage of technology and democracy. Everyone could look into the computer to see what was going on all over the plant and get their work orders immediately. Our slogan was ‘Data to the people.’”)

The new system required a new computer, a new Management Information System Department with four people on the day shift and three more on the night shift to keep all of the data current, and direct inputting of every work task by workers on the plant floor as they completed it. As Jose

Zabaneh, Lantech’s manufacturing director, noted, “Pretty soon workers were fully in ‘control,’ yet the system was wildly inaccurate because many items simply never got entered and there was no means of catching errors. The old MRP system was slow but 99 percent accurate. Our new ‘democratic’ MRP system was a complete catastrophe; instead of information we had given muda

to the people.” To compound the situation, the magnitude of inputs and changes was causing the computer to run very slowly. Lantech’s information technology consultant recommended that the best solution would be a much more powerful and expensive computer.

By the end of 1991, Lantech’s orders began to fall for the first time, despite price reductions, and the factory was finding it nearly impossible to respond to continuous shifts in demand. As Pat Lancaster summarized the situation later, “We began losing money for the first time and our fundamental ideas on how to run the business were in a meltdown.” Then he discovered lean thinking.

The Lean Revolution

Ron Hicks does not look like a revolutionary. He looks like an accountant (although he was trained as an industrial engineer) and talks in dispassionate tones. But he brought a revolution when he came to work at Lantech as vice president of operations in March of 1992.

He had learned how to be a revolutionary while working at the Danaher Corporation, a collection of fifteen manufacturing companies collected by Steve and Mitchell Rales in the 1980s. Quite improbably, these two youthful entrepreneurs from Washington, D.C., had become acquainted with the lean concepts pioneered by Taiichi Ohno, and the firm had convinced some of Ohno’s Japanese disciples to establish operations in the United States in 1987 to support Danaher’s conversion effort. They grasped that lean thinking could revolutionize their firms, which had initially been bought because they were attractively priced, as part of their effort to diversify out of their core real estate business. One of these firms was Hennessy Industries of Nashville, Tennessee, a manufacturer of automotive repair tools and garage lifts. Ron Hicks was working there as vice president of operations.

Ron Hicks remembers the day in 1989 when “the light went on.” “I went to visit the Jacobs Brake Company in Bloomfield, Connecticut, another Danaher company, and discovered they had followed Ohno’s advice by completely eliminating their traditional production departments. They had installed work cells in which all of their machines were realigned into the actual processing sequence needed to make specific product families of truck engine components. Each part was then manufactured in a continuous flow

with absolutely no buffer stocks between steps using a concept they called ‘single-piece flow.’

“What really amazed me was that on the day of my visit they were conducting an improvement exercise and had decided that the work flow for a particular item would be much smoother if they moved a massive machine from one position to another. They decided to do it early in the morning, got the moving team together almost instantly, moved the machine, and were back in production in a few hours.

“In my fourteen years as an operations manager at the General Electric Company, where I worked before moving to Hennessy, it would have taken an act of Congress to move such a large machine. But these guys just did it, and it worked. I suddenly realized I was living in a different world.”

By March 1992, when Hicks received a phone call from Pat Lancaster, he had transformed himself from a “concrete head” into a lean thinker and was ready for a new challenge. Lancaster had screened hundreds of applicants in his search for a new operations vice president and was sure that Ron Hicks had the ability to transform a manufacturing operation. The question was exactly how and how fast.

In the newly empowered spirit of Lantech, Ron was invited to Louisville and interviewed by those he would manage. His simple proposal came as a revelation: Lantech would immediately form teams to rethink the value stream and flow of value for every product in the plant, and then every step in order-taking and product development. Lantech would line up the essential activities required to design, order, and manufacture a stretch-wrapping machine and perform them in sequence, one machine, one design, one order at a time. Batches, queues, backflows, and waste—muda

of all sorts—would be banished. The value stream

—the irreducible minimum set of activities needed to design, order, and make a stretch-wrapper—would flow smoothly, continuously, and rapidly.

Ron Hicks was hired and immediately went to work with a simple plan: Disaggregate the four basic types of machines flowing through Lantech’s departmentalized, batch-and-queue production system; eliminate all of the production departments; create a production cell—four in total—for each type of machine; and then line up all of the activities required to make each machine within a cell and perform them in a continuous flow. This was the kaikaku

phase in the Lantech plant, the time to completely tear things apart and recombine them in a totally different way.

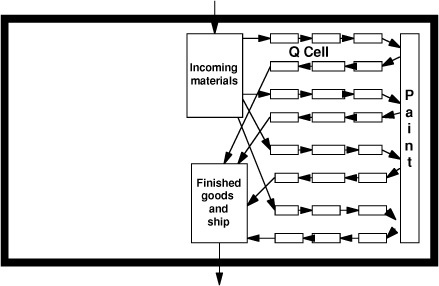

The T/V model, which was soon replaced by the new Q model, was the acid test. A team of Lantech’s best workers was selected to rethink the flow and quickly, in only one week, devise and put into production the plan—shown in

Figure 6.4

.

The sawing operation was located immediately adjacent to the machining

operation, which was only a few steps from the welding operation. Although it was still necessary for all four models to share a massive, centralized paint booth, continuous flow picked up again with sub-assembly and final assembly. Testing and crating were placed at the end of the line and conducted by the work team. Even though only eight machines were made each day—one per hour—an imperceptibly moving track was installed in final assembly as a pacing device.

F

IGURE

6.4: F

LOW OF

Q L

INE

Each morning the saw operator would start production of a new machine on the hour. A kit of all the frame parts required for the machine was prepared by the saw operator by the end of the hour and rolled about three feet to the machining station. From there it would proceed about four feet to welding. Fourteen hours later—about half of this due to the curing time required by the paint booth—a completed machine was ready for shipping.

To make this simple system work, Lantech had to change a generation of industrial thinking about how to do work and how to work together. Because all of the jobs were directly linked, with no buffers, it was necessary that everyone think about standard work,

which is to say the best way to get the job done in the amount of time available and how to get the job done right the first time, every time. (By design, either the whole cell is working or nothing is working.) Every step of every job was soon charted by the work team and posted for everyone to see.

Similarly, because in this new system machines are only made when

ordered—remember that production lead time has fallen from sixteen weeks

to fourteen hours

so there is no need to build machines ahead of time on speculation in order to permit rapid deliveries—it was important to introduce the concept of takt

time. This is the number of machines to be made each day to meet the orders in hand divided into the number of hours in the day. (With production at eight machines per eight-hour day, takt

time is one hour.) The important point about takt

time was that when orders did not require the full utilization of equipment and workers, takt

time was increased. The machinery was slowed down and each of the multiskilled workers in the Q cell performed several of the jobs in the cell while excess workers were put on other tasks around Lantech. This reversed the age-old tendency to work ahead and build inventories if no orders were immediately on hand.

Two other concepts were needed as well. Lantech had to right-size

many of its tools and devise a number of new tools so that smaller saws and machining tools could be fitted in the work cells. (As it turned out, the excess workers freed up by rethinking production flow were able to make most of the tools needed.) Finally, Lantech had to learn how to perform quick changeovers

on all of its tools so it could make all of the parts for each machine and a variety of product options for successive machines with very little downtime.

When the new cell concept was proposed, many of the production workers were baffled or dismayed. As Bob Underwood, one of the most skilled workers on the floor, noted: “We were used to a system in which each of us had a set of hard-earned skills—welding, machining, and, in my case, the ability to adjust nonconforming parts so they would fit. We were used to doing our own work as we saw fit at our own pace in our own department. As long as we met our daily production quota we were left alone. What’s more, the real kick in the work was ‘fire fighting,’ in which the Lantech Volunteer Fire Department went into crisis mode to get an emergency order through the system or eliminate a sudden production bottleneck. I was one of the best fire fighters at Lantech and I loved it.”

Ron Hicks was proposing a new system of standard work and takt

time that sounded like oversight by the industrial engineer, which every skilled tradesman hates. (The difference, of course, was that the work team would standardize its own work.) What was more, he was proposing making complete machines one at a time. Finally, he claimed that if the work was standardized by the work team, the machines were realigned to permit single-piece flow, and takt

time was adhered to with no working ahead, there would be no more fires to fight. As Underwood remembers, “It didn’t sound like much fun and I thought it would never work.”

When the conversion week was completed and the new cell was ready to

go … it didn’t work. All kinds of problems, long submerged in Lantech’s massive inventories and closely held work practices, suddenly emerged. Some steps had not been included in the standard work charts. Poor tool maintenance—easily tolerated in the old batch system—repeatedly stopped the whole cell. The supply of components to the cell was not dependable. The widespread feeling was that Ron Hicks was pushing a novel concept that would never work at Lantech.

At this point Jose Zabaneh, the production manager, played the key role: “I was so fed up with our failures and so taken with the logic of the new system that I threw my heart into it. I called a meeting of the workforce and announced that I would stay all night and all weekend to work hands-on on fixes to the problems we were encountering with the new cell, but that I would not spend one second discussing the possibility of going back to the old batch-and-queue system.”

Pat Lancaster gave unfaltering support to the new system, Ron Hicks (along with his consultant, Anand Sharma, who had advised him earlier on the conversion of Hennessey) had the technical skills to work the bugs out, and Jose Zabaneh was “our spark plug.” Gradually, it all began to come together.

(We’ll see that these three attributes—taking the long view, technical virtuosity, and a passionate will to succeed—are essential for any organization making the lean transition. Sometimes they are possessed by a single individual, sometimes, as at Lantech, they are shared by a group of leaders. However initially distributed, they are all necessary and eventually they must be shared by the whole organization.)

By the fall of 1992, the whole Lantech production system had been converted from batches to single-piece flow, including the cell for the largest Lantech machine—the $50,000 H model—made at the rate of only one per week. The plant now looked as shown in

Figure 6.5

.

The consequences for performance were truly staggering. Although Lantech’s headcount stayed constant at three hundred, the number of machines shipped doubled between 1991 and 1995. (The sales growth was due to a general recovery in the market, aggressive pricing by Lantech to capture share, and a host of new products, to be described in a moment.) The plant, which had been bulging at the seams with inventory, now had 30 percent excess space despite the doubling of output. The number of defects reported by customers fell from 8 per machine in 1991 to .8 per machine in 1995. Production throughput time, as we have noted, fell from sixteen weeks to fourteen hours. The percentage of machines shipped on the date agreed with the customer went from 20 to 90 percent.

To speed this remarkable transition, Pat Lancaster made two promises to his workforce. These seemed almost quixotic in 1992, given the financial

condition of the firm, but have proved critical to success. First, he promised that no one would be let go because of the lean conversion. Instead, a kaizen

team was created from freed-up workers who were deployed to plan the improvement of other activities. Bob Underwood, the original skeptic and chief “fireman,” was made head of this team. After every improvement, the best (not the worst) workers in the revamped process are transferred to the kaizen

team, making clear that this is a promotion, not a punishment. The steady growth in output of the newly competitive Lantech has meant that within a short period these workers have been needed again for production work.

F

IGURE

6.5: N

EW

L

ANTECH

P

RODUCTION

F

LOW

At the same time, Lancaster reviewed Lantech’s wage policy and adjusted the base wage upward from about $7.00 to about $8.50 per hour. As Ron Hicks noted, “We had been running unskilled employees through like McDonald’s, with a sharp premium for our small core of skilled workers. It quickly became apparent that all workers in the new Lantech would be skilled workers, but with a very different type of skills. So we had to pay all of them a better wage. As a result, turnover quickly fell to just about zero.” (Note that because each machine is now being made with one half of the formerly needed hours of human effort, a 25 percent wage increase is easily affordable.)

• •

•

As the lean revolution gained momentum in the plant, it was time to turn to the office and in particular the order-taking process. As Pat Lancaster put it, “We wanted the goodness of the plant to suck the badness out of the office. If we could make a machine in fourteen hours, how could we live with an order-taking process which required three weeks?” In one notable case, Lantech made and delivered a machine in four days—long before the credit check could be completed—only to discover that the buyer was insolvent.

The technique employed to transform the office was exactly the same. Lantech set up a kaizen

team to collectively rethink the process. It included all the workers involved in a specific process, the firm’s technical experts—including production workers from the plant kaizen

team and one outside consultant (Sharma). The group mapped the entire value flow and looked for wasted time and effort. As each process was rethought and turned from batch-and-queue into flow, the best of the workforce was assigned to the kaizen

team to lay the groundwork for the next process review. No one was laid off and the move to the kaizen

team was clearly an acknowledgment of superior performance.

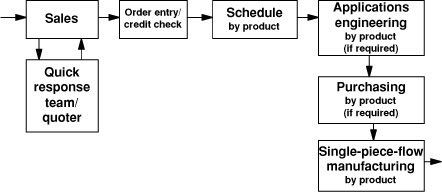

When these techniques were applied to the entire order-taking and plant-scheduling system, the results were truly astounding. Because Lantech now understood its costs much better, it was possible to publish fixed prices on all but truly custom-built machines and to eliminate the haggling step between Lantech and the distributor. The order itself, once at Lantech, could be inserted into the production schedule in only two days.

Perhaps most remarkably, most of the computerized scheduling system was no longer needed. MRP was retained for long-term materials ordering from suppliers, but day-to-day scheduling is now run off a large white board in the sales office. The production day is divided into slots by takt

times and orders are written on the board as they are confirmed. At the times we have visited Lantech, the white board slots have been filled anywhere from three days to two weeks ahead of the current date and no machine will be made except in response to a confirmed order.

A large white board easily visible to everyone in the firm has proved to be a remarkable spur to the sales force, particularly as the amount of filled space gets smaller and the amount of empty space gets larger. This is an excellent example of yet another lean technique, visual control,

in which the status of an activity is displayed so every employee can see it and take appropriate action.

The final step in this process is to copy down each evening the roster of machines to be made the next day and to take this list to the four production cells. For each machine, the cell is given the name of the actual customer and the promised delivery date, typically two days from the start of the build

sequence for high-volume machines and ten days for the lowest-volume, large machine. The former Management Information System Department with its seven full-time workers has been eliminated because the parts within the plant are pulled along to the next workstation automatically. Information flows that had been automated have now been completely eliminated because product and information have been combined into one. The full results, as shown in

Figure 6.6

, can be contrasted with the labyrinthine order process shown in

Figure 6.2

.

F

IGURE

6.6: N

EW

L

ANTECH

O

RDER

F

LOW

The main transitional problem has been that the distributors and buyers of industrial equipment are unaccustomed to getting rapid and on-schedule deliveries. Orders have often been “guesstimated” on the presumption that many weeks were available to firm up the precise specification, notify the manufacturer of changes, and plan for the machine’s installation. In one notable case, Lantech made and delivered a machine within one week of the order, just as promised, to find the customer quite upset: “You’ve sent us our machine before we’ve given any thought to how to use it. We thought we were placing an order simply to guarantee ourselves a place in the production line, that we would have time to respecify the options, and that you would deliver late as usual. Now, you’ve gone and made it already!”

The final step in transforming Lantech has been to rethink the product development process. Pat Lancaster knew from the early days of the plant conversion that he would need to grow his business dramatically in order to keep everyone busy, as he promised, while productivity zoomed. This meant turning strategic thinking on its head: “I didn’t have time to find a brandnew

business to go into and I didn’t have the money to buy out any of my major competitors. Instead, I needed to revitalize and expand my product range so I could sell more in an established market I knew well. At the same time, I knew that a total redesign of my products to make manufacturability a key consideration would slash my costs even further and dramatically improve quality and flexibility for the customer.”

He also knew that his batch-and-queue product development system would take years to come up with market-expanding products if not given the same treatment as the plant and the office. He wanted to put new product designs into single-piece flow, just like orders and machines. “We needed the design to move continuously from the initial concept to the launch of production. This meant no stopping due to the bureaucratic needs of our organization, no backflows to correct mistakes, and no hitches during production ramp-up.”

Lantech had experimented with development teams in the late 1980s and early 1990s but without much success. A few “bet the company” projects were pushed through by a designated “dictator” who was effectively a new type of expediter (slowing down all other projects to get his project through). Otherwise, weak “team leaders” tried to coordinate the activities of the numerous technical specialists needed to develop a complete product, each with their own priority list. In no case was the team leader—dictator or weak coordinator—responsible for the end results of the project: Did the product please the customer and make money for Lantech during its production life? No one was really in charge and not much had changed despite the new “team” terminology.

In 1993, Lantech went to a new system of dedicated teams led by a Directly Responsible Individual (DRI) clearly charged with the success of the product during its lifetime. The corporate annual planning process identified the major projects to be developed that year and ranked them. A team of dedicated specialists was designated for the two top-ranking projects. This consisted of marketing, mechanical engineering, electrical engineering, manufacturing engineering, purchasing, and production (including hourly workers from the plant kaizen

team who would actually build the machine once launched). These teams were co-located and told to work nonstop on the designated project and to do nothing else until it was done. The welter of minor projects which formerly cluttered up the Engineering Department were simply dropped (or “deselected” in Lantech-speak). As the engineering director noted, “We never would have finished them anyway!”

A kaizen

of Lantech’s prototyping process showed that if all of the needed skills were available, a working prototype for the top-ranked project could be put together in a week, a process which formerly would have taken three months. And the presence of the actual production staff on the team quickly

identified manufacturing problems which the mechanical and electrical engineers had never imagined.

The major objections to dedicated teams—that work flow is uneven, so some team members will be underutilized some of the time and teams will be in conflict for scarce skills needed at specific points in development—were overcome in two ways. First, it developed that team members actually had much broader skills than they had ever been asked to use. (After all, they had been reengineering each other’s designs in secret for years!) They could quickly develop additional, narrow skills to address specific problems. Mechanical engineers could actually help manufacturing engineers with their work and the reverse. This meant that the uneven work flow problem could be largely corrected within the team.

Second, it turned out that a bit of careful scheduling could identify conflicts in requirements for skilled personnel far ahead of time. Moving a few specialists from one team to the other and back, as needed, could solve the problem.

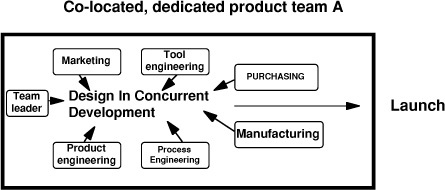

Under the new Lantech product development system, the progression of the design looks as shown in

Figure 6.7

, in contrast with the maze shown in

Figure 6.3

:

F

IGURE

6.7: N

EW

L

ANTECH

P

RODUCT

D

ESIGN

F

LOW

The first product to come through the new system showed its dramatic potential. The new S series, launched in mid-1994, was developed in one year (compared with four years for its predecessor) with about half the effort previously thought to be required. (Remember: There were no delays for lack of personnel or queue time, no backtracking, and no secret rework.) Then, the launch was much smoother than in the past and the number of

defects reported by customers was a tiny fraction of the rate experienced with previous new products.

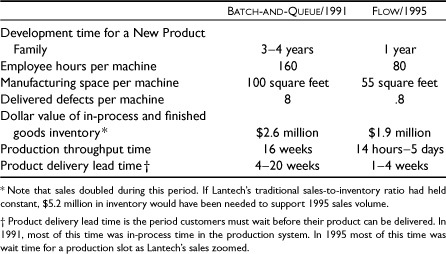

The Bottom Line

The conversion of Lantech from classic batch-and-queue to lean thinking has produced a dramatic box score of performance improvements (see

Table 6.1

).

T

ABLE

6.1: T

HE

L

EAN

T

RANSFORMATION AT

L

ANTECH

However, the result by which any business in a market economy must be measured is the ability to make enough profit to renew itself. If the transition at Lantech cost a fortune in new investment or disrupted the firm’s ability to satisfy customers it would be an interesting technical exercise rather than a revolution in business practice.

In fact, the amount of investment required was substantially zero. The tools were moved and reconfigured, for the most part, by workers freed up from inefficient production tasks. The reconfiguration of the office and the development process were performed much the same way. Fewer computers, less space, and less expensive tooling were needed at every step. And the effect on customers was dramatic: Lantech’s share of the stretch-wrapping market zoomed from 38 percent in 1991 to 50 percent in 1994. As a result, the large operating losses of 1991 were turned into solid profits by 1993 and an industry-leading financial performance by 1994

.

Work as “Flow”

As noted in

Chapter 3

, the rethinking of work in accord with lean principles produces the potential for greatly expanded experiences of psychological “flow.” Workers in the Lantech manufacturing cells can now see the entire work flow from raw materials to completed machine.

Takt

time, standard work, and visual control (including posted work charts for all tasks) give an immediate sense of how the work is proceeding. Multiskilling and job rotation make full use of each worker’s skills and the frequent repetition of

kaizen

events (as described in

Chapter 5

on perfection) gives an opportunity to participate actively in work design. The constant elimination of

muda

and the movement of workers out of work cells as more efficient methods are discovered mean that the work is a constant challenge. Finally, there are few interruptions in the form of line stoppages and sudden demands to shift to a completely different task to deal with a crisis.

The situation in the office is very similar. Visual control in order-taking makes it clear to everyone where Lantech stands and the new order entry system in which one employee can perform the whole task makes it possible to get immediate results. The kaizen

process in the office melds thinking and doing, planning and acting, just as it does in the plant.

Finally, the rethinking of development work gives a true sense of feedback as everyone involved in a project works in the same space and projects move rapidly to completion. (Formerly, the majority of Lantech’s development activities were never

completed because market conditions changed before the cumbersome development process could be concluded. We have found this same phenomenon in a wide range of firms over many years.) Employees respond positively to gaining new skills and being encouraged to use all the skills they’ve always had. The lack of interruptions and conflict over which task to work on next has come as a great relief.

As Bob Underwood characterizes the situation now compared to the recent past, “We were living in darkness and now we have come into the light.”

Yet it would be inaccurate to characterize Lantech as some sort of paradise. Indeed, coming out into the light can be painful to your eyes. The reorganization of work tasks into a continuous flow seems to have produced widespread psychological satisfaction in daily tasks, but it is also producing the need for constant change. “We just get something working smoothly when it’s time to improve it again” is a common refrain, and it’s clear that each change, at least subliminally, carries risks: “Will Lantech really honor its commitment to retain excess workers? Will my contribution to improvement activities be recognized and rewarded?” Perhaps most important,

many employees ask, “What will change mean for my career? Am I going anywhere or just flying a holding pattern while Lantech prospers?”

These are all important questions which firms must face once they make the initial leap to lean thinking. We will return to them in

Part III

on the challenge of building a lean enterprise.

The Last Step

One last step in the conversion of Lantech from a batch-and-queue to a flow organization remains to be discussed. In April 1995, Pat Lancaster promoted himself to the new position of chairman (at age fifty-two) and stepped down from day-to-day operations, turning the CEO job over to his son, Jim. Now he is starting a new creative process by thinking again about the value of his products to the customer.

As it happened, the lean transformation at Lantech was easy in one important respect because customers were quite satisfied with current-generation stretch-wrapping equipment in terms of its performance, price, and service support. That is, its

value

to them was not in question, and Lantech could safely skip the first step of lean thinking described in

Chapter 1

.

However, in a supremely ironic twist, Lantech has revitalized itself by banishing batches and their associated muda

from the design and production of a product whose sole use is to wrap. … batches! Stretch-wrapping machinery exists for the purpose of quickly and efficiently packaging large pallet loads of goods which are shipped from firm to firm within complex production and distribution chains.

Pat Lancaster has therefore embarked on a new strategic exercise to think through the nature of packaging his customers will need in the emerging world of small-lot production, single-piece flow, and right-located facilities. Lantech needs to be ready with the right-sized, right-tasked process machinery likely to be needed in the future in order to provide the desired value for the customer.

Beyond the Simple Case

Lantech is a striking example of what happens when a small American firm makes the value stream flow smoothly as pulled by the customer in pursuit of perfection. What’s more, there is absolutely no magic involved. Any small firm can follow the conversion steps just described

.

However, Lantech is a simple case. Pat Lancaster is a patient investor, not beholden to the impatient stock market. He had the authority as a change agent to “make it happen.” Lantech has only one plant, and it is still possible for senior management to know everyone’s name. The product range is relatively simple, really just four variants of one basic concept. The work-force is relatively young and has never shown an interest in joining a union to square off against management.

While the world is full of small firms like Lantech (which can make excellent investments for an individual or small group with the skills and energy to make the lean conversion), the majority of industrial activity in almost all countries is accounted for by much larger firms with much more complexity. What does it take to carry through a lean revolution in a larger and more traditional company?