CHAPTER SIX

America Is Number Two

BY 1860, THE UNITED STATES WAS HOME TO 31 MILLION PEOPLE, OR NEARLY as populous as Great Britain and France. Until the 1830s, population growth had been dominated by the rate of natural increase. Immigration accelerated in the 1830s, and from the 1840s until the 1920s consistently accounted for a quarter to a third of the total growth in population. As the country grew, its center of gravity also steadily moved west.

The country was urbanizing. At the turn of the century, three-quarters of employed Americans worked in agriculture, but by 1860, only 56 percent of workers toiled on a farm. Agricultural employment accounted for fewer than a third of jobs in the Northeast by 1860 but still more than 60 percent in the Midwest, and a nearly unchanging three-quarters in the South, which remained dependent on King Cotton.

1 The Northeast still commanded about half of the country’s total income, but average incomes in the Northeast and the Midwest had begun to converge and would be approaching parity by the end of the century.

2The Northeast’s large income advantage reflected both its lower reliance on agriculture and greater concentration of good-paying, white-collar, service employment—banking, insurance, accounting, wholesale and retail trade. The white-collar pay advantage was particularly strong in the nineteenth century. Edward Tailer was twenty in 1850, when he started work as an assistant clerk for a New York dry goods importer while complaining of his $50 annual salary. But within two years, and after two job changes, he was making $1,000—a solid middle-class income. He then went on the road as a traveling salesman at $1,200 and had his own business when he was twenty-five.

3

TABLE 6.1 Population by Region, 1790–1860a

Americans were the best-fed people in the world—already by the mid-eighteenth century their nutritional intake was about the same as that of 1960s Americans. They were taller by several inches than the average European and commensurately heavier. The average work output of Americans was plausibly larger than that of Europeans, an effect that was partly offset by the Europeans’ adaptive smaller stature.

ba4Oddly, although American incomes and dietary provision continued to rise, height and mortality data suggest a major decline in Americans’ health over about a thirty-year period starting in the 1840s. The causes have not been definitively pinned down. Rapid urbanization and the westward migrations are obvious culprits. The exploding population in the West was a feast for malarial mosquitoes, while runaway growth in coastal cities overwhelmed public water and sanitation infrastructure, triggering wave after wave of typhoid, cholera, tuberculosis, and other crowd diseases. The poor health of many arriving immigrants, especially the famine Irish who flooded the eastern cities in the 1840s, was undoubtedly also a factor.

Recent research points to cataclysmic health consequences from the Civil War, which “produced the largest biological crisis of the nineteenth century, claiming more soldiers’ lives and resulting in more casualties than battle or warfare, and wreaked havoc on the population of the newly freed.” Freedpeople were particularly vulnerable as they were crowded into refugee camps and poorly fed and sheltered. Smallpox, cholera, and other diseases were rampant. To make matters worse, the Freedmen’s Bureau spread epidemics by frequently moving its charges from camp to camp over large areas of the country. Similar consequences appear to have followed the forced Native American migrations of the 1870s. Whatever the reason, Americans were still slightly shorter than the English and Swedes in the 1880s, although they recovered their advantage in the twentieth century.

5Finally, ordinary Americans, at least outside the South, were better educated than Europeans. The New England public school movement was well underway by 1820 and rapidly spread through the Middle Atlantic states and then to the Midwest. A study of national census return figures shows a quintupling of the population’s average lifetime days of school instruction. By the 1830s, about 70 percent of the white population ages five to nineteen in New England and the Middle Atlantic states were enrolled in school, including more than half of the children of paupers. The Midwest made spectacular gains starting a decade or so later and reached equivalency of provision with the Northeast well before the Civil War. Southern states increased their spending sharply in the 1850s, but enrollments were far lower than in the rest of the country, so only favored groups benefited from the spending increases. The spending increases were concentrated on the common schools in the early days of the movement, but as states approached near-universal literacy and numeracy among school-age children, reformers shifted their attention to high schools. By 1860, Massachusetts had nearly 120 public high schools.

6 The great British industrialist Sir Joseph Whitworth suggested that the receptivity of American workers to productivity-enhancing machinery was a consequence of their comparatively high levels of education.

7Even with the slippage in health-related indicia, the overall favorable demographic and economic trends were such that the country was growing very rich. In 1800, the United States was a struggling ex-colony, wrestling crops and wood products from a resistant nature either for subsistence or to export to its erstwhile mother country. A half century later, it was the second biggest economy in the world, with output per worker virtually even with that in Great Britain. Isolating just manufacturing productivity, the United States was probably already ahead of Great Britain by the 1820s, and by 1850, according to a recent analysis, the average output of American manufacturing workers was plausibly 75 percent higher than that of the British.

bb8Economy-wide, Great Britain still had a small edge in output per worker, as a result of substantial advantages in services and agriculture. All of Great Britain’s commercial services industries—shipping, railroads, delivery services, banking, and finance—were far in advance of America’s, even as the very large share of agricultural workers in the American labor force—three times that of Britain—pulled down average worker output even further.

By 1860, there was already visible a rough map of American industry that would prevail into the 1930s and beyond, leaving aside developments in the far West. Both the Northeast and the Midwest were becoming industrial powerhouses, but each with its own development pattern. Industry in the Midwest was closely tied to its natural resources, while the eastern patterns of development were more the result of history and specific skill bases. We will look at each in turn.

The Queen City of the West

By the time of the Civil War, about a third of the free population lived in the nonslave states west of the Appalachians. For a couple of decades in mid-century, the region’s economy revolved around the city of Cincinnati. Its population was on an exponential curve that reflected the growth of commerce—2,500 in 1810 to 161,000 in 1860. By then it was the seventh largest city in the country, just a hair behind New Orleans, with fast-growing St. Louis and Chicago nipping at its heels.

For a vivid journalistic tour through Cincinnati in the 1850s, we are indebted to another Englishwoman, Isabella Lucy Bird, just twenty-four at the time but as intrepid as Trollope and as gifted a writer. She was the sickly daughter of a minister, visiting American relatives but traveling solo for much of the time. Although she was pious, the “sickliness” seemed to occur only when she was living in the parsonage or later with her spinster sister. She desperately longed to travel and finally convinced her father to allow her to go to America. He gave her £100 for her trip, with his permission to stay as long as the money lasted. She stretched it for nearly a year in 1854–1855, a journey she described in her first book,

The Englishwoman in America. For the rest of her life, the inevitable sickliness induced by sojourns in England was magically cured by travel—to the Rocky Mountains, Japan, Tibet, much of South Asia. Back in England, and turning fifty, she finally acquiesced to a pathetically long courtship by a respectable doctor some years her junior. Marriage greatly worsened her health, but her husband’s providential early death effected a complete cure. After training as a doctor to justify continued travel, she spent the rest of her life in the remotest parts of the world, mostly in Asia and the Near East. There were eighteen more books after her first American account, the last of which, on Morocco, she produced in 1901, when she was seventy.

9Lucy Bird on the road was nothing like the neurasthenic creature haunting the parsonage halls. For one thing, she liked men. Her first encounter with “prairie men” on a train from Cincinnati to the Mississippi, made her giddy:

Fine specimens of men they were: tall, handsome, broad-chested, and athletic, with aquiline noses, piercing gray eyes, and brown curling hair and beards. They wore leathern jackets, slashed and embroidered, leather smallclothes, large boots with embroidered tops, silver spurs, and caps of scarlet cloth, worked with somewhat tarnished gold thread, doubtless the gifts of some fair ones enamoured of the handsome physiognomies and reckless bearing of the hunters. Dulness fled from their presence.... Blithe, cheerful souls they were, telling racy stories of Western life, chivalrous in their manners, and free as the winds.

10We get a fuller picture of Lucy Bird from her second American trip eighteen years later, ostensibly to seek the curative air of the Colorado Rockies. By now, the twaddle about infirmities was a comic tic, for the trip was the last leg of a jaunt through Australia and Hawaii, where she had climbed Mauna Loa. Her “cure” over a long winter high in the Rockies, included serious climbing and eight hundred miles of horseback travel, some of it alone in mountain blizzards. She rode astride the saddle like a man and was strong enough on a “broncho” that she was drafted to work as a cowboy during a difficult, weeks-long, end-of-winter roundup of cattle scattered through snowed-in ravines. Her most reliable companion was her “dear desperado,” “Mountain Jim” Nugent, who was missing an eye from an encounter with a bear. He was a legendary trapper and formidable gunfighter, with a dark past as a Kansas-Nebraska War bushwhacker. She was out riding one morning and saw him standing by his cabin.

[He was] a broad, thickset man, about the middle height, with an old cap on his head, and wearing a grey hunting-suit much the worse for wear . . . a knife in his belt, and a “bosom friend,” a revolver, sticking out of the breast-pocket of his coat.... His face was remarkable. He is a man of about forty-five, and must have been strikingly handsome. He has large grey-blue eyes, deeply set, with well-marked eyebrows, a handsome aquiline nose, and a very handsome mouth. His face was smooth-shaven except for a dense moustache and imperial. Tawny hair, in thin uncared-for curls, fell from under his hunter’s cap and over his collar. One eye was entirely gone, and the loss made one side of his face repulsive, while the other might have been modelled in marble.

11Even better, her mountain man was well spoken and courtly; he wrote poetry and knew the classics, although nothing is known of his roots. While her account gives no direct hints, some suspect a serious romance. One hopes it’s true. But Nugent was also an episodic alcoholic, and whiskey could make him a monster—and she does record her pleading with him to swear off drink. “Too late,” he always replied.

12When she finally left for home, Nugent rode down the mountain with her to the stage. It arrived with an Englishman, a land speculator, whom she had met previously on her trip: “He was now dressed in the extreme of English dandyism, and when I introduced them, he put out a small hand cased in perfectly-fitting lemon-coloured kid gloves. As the trapper stood there in his grotesque rags and odds and ends of apparel, his gentlemanliness of deportment brought into relief the innate vulgarity of a rich

parvenu.”

bc13Bird’s youthful trip to Cincinnati occurred in the early fall of 1854, so she was able to travel from Boston entirely by rail. The trip covered about 1,000 miles in forty-two hours, with just a couple of train changes and a few brief stopovers to allow passengers to hurriedly purchase meals from station vendors. She recorded her arrival thus: “It was a glorious morning. The rosy light streamed over hills covered with gigantic trees, and park-like glades watered by the fair Ohio.... And before us, placed within a perfect amphitheatre of swelling hills, reposed a huge city, whose countless spires reflected the beams of the morning sun—the creation of yesterday—Cincinnati, the ‘Queen City of the West.’”

14The city reminded her of Glasgow, “the houses built substantially of red brick, six stories high—huge sign-boards outside each floor denoting the occupation of its owner or lessee—heavily laden drays rumbling along the streets . . . massive warehouses and rich stores—the side walks a perfect throng of foot passengers—the roadways crowded with light carriages.” And all of this “life, wealth, bustle, and progress” are on a “ground where sixty years ago an unarmed white man would have been tomahawked as he stood.”

15Cincinnati’s population had multiplied fourfold since Trollope’s visit, with about half the increase from newly immigrated Germans and Irish. But it was a crossroads city, and Bird saw “dark-browed Mexicans, in

som-breras and high slashed boots, dash about on small active horses with Mamelouk bits—rovers and adventurers from California and the Far West, with massive rings in their ears, swagger about . . . and females richly dressed . . . driving and walking about, from the fair-complexioned European to the negress or mulatto.”

16Trollope had been a generation too early with her dream of a department store featuring European luxuries, for Bird found that although store windows featured “articles of gaudy apparel and heavy jewelry, suitable to the barbaric tastes of many of their customers,” inside she found “the richest and most elegant manufactures of Paris and London,” while a bookstore, “an aggregate of two or three of our largest, indicated that the culture of the mind was not neglected.”

17Despite her hitherto sheltered life, Bird had a quick grasp of economics:

Cincinnati is the outpost of manufacturing civilization, though, large, important, but at present unfinished cities are rapidly springing up several hundred miles farther to the west. It has regular steam freighters to New Orleans, St. Louis, and other places on the Missouri and Mississippi; to Wheeling and Pittsburgh, and thence by railway to the great Atlantic cities, Philadelphia, and Baltimore, while it is connected with the Canadian lakes by railway and canal to Cleveland. Till I thoroughly understood that Cincinnati is the centre of a circle embracing the populous towns of the south, and the increasing populations of the lake countries and the western territories, with their ever-growing demand for the fruits of manufacturing industry, I could not understand [the basis for all the vast enterprise].

18Bird closes her descriptions of the beauty of Cincinnati’s streets and the “astonishing progress, and splendour of her shops” by divulging:

that the Queen City bears the less elegant name of Porkopolis; that swine, lean, gaunt, and vicious-looking, riot through her streets; and that, coming out of the most splendid stores, one stumbles over these disgusting intruders. Cincinnati is the city of pigs. As there is a railway system and hotel system, so there is also a

pig system, by which this place is marked out from any other. Huge quantities of these useful animals are reared after harvest in the corn-fields of Ohio, and on the beech-mast and acorns of its gigantic forests. And at a particular time of the year they arrive by thousands—brought in droves and steamers to the number of 500,000—to meet their doom, when it is said that the Ohio runs red with blood!

19

Porkopolis

Bird was correct about Cincinnati’s annual hog-processing volume, which had expanded by a factor of ten in just twenty years. “It was Cincinnati,” a wag said, “which originated and perfected the system which packs 15 bushels of corn into a pig, packs the pig into a barrel, and sends him over the mountains and over the ocean to feed mankind.”

20 Besides its favorable siting as an Ohio River entrepôt, Cincinnati was conveniently near the large salt deposits required for a packing center. During the antebellum period, western meatpacking was all about hogs. Beef cattle were easier to drive, and their meat harder to preserve, so they usually traveled to eastern markets on the hoof.

To ease the hog traffic in the city streets, local merchants and traders organized stockyards just upriver of the main city through the 1830s. Butchers who had doubled as hog slaughterers relocated around the stockyards and gradually consolidated into several dozen industrial-scale operations—“something on the plan of the abbatoirs of Paris,” Bird suggested.

21 Most of them were sited on the Miami-Erie Canal, so slaughtering waste could be dumped to float away on the once-blue Ohio. A last rationalizing step was the integration of slaughtering, packing, and by-products processing to create the first midwestern high-volume, continuous-flow factories.

22The scale of the industry was enormous. A contemporary survey showed 96 packing points throughout the Midwest during the 1843–1844 season, shipping the meat of 1.25 million hogs. A decade later 216 packing points processed 2.6 million hogs. Cincinnati was the highest-volume producer throughout the prewar era, although its volumes stabilized near the half million mark. Cincinnati’s efficiency and the competitive forces in the industry suggest that they were probably operating near an economic maximum.

Slaughtering was a manual process, so efficiencies were derived primarily from work rationalization and topped out at lower volumes than in, say, the Waltham-Lowell textile mills. The biggest antebellum hog packers packed around 20,000 animals a year. Since the point of maximum efficiency in postbellum beef packing plants has been estimated at 100 animals a day, hog packers were running their plants at a high level.

Transportation was the next critical factor. Cincinnati was well positioned for distributing the finished product to market, but its access to the live animals was limited to the number that could be raised within droving range. As local railroads proliferated through the Midwest, it became more economical to shorten droving times by building stockyards and Cincinnati-style slaughterhouses at interior rail depots, and then rail-shipping the processed meat to the closest Ohio River ports. The internal logic of the industry led to a broad decentralization of efficient but medium-sized packing plants.

bd23The rationalization of slaughtering evolved over more than a quarter century. In the late 1850s, an English traveler reported that it took hardly two hours “from the first hammerstroke until [the carcass] was singed, cleaned, cut up, placed in brine, and packed in a cask for exportation.”

24 A skilled team could separate a carcass into its constituent parts in less than a minute.

Since time immemorial, slaughtered animals had been hung upside down on hooks to drain and for most cutting and cleaning operations. In the early Cincinnati “disassembly line,” slaughterhouse workers lifted the animals from one worker’s station hook to the next. (Pregutting, a standard Cincinnati hog weighed about two hundred pounds.) In the 1840s, the hooks were attached to a wheeled chain to move carcasses from the slaughtering floor to cooling rooms. It took another twenty years to finally evolve the continuously moving hook array traversing all the slaughtering and trimming steps. Henry Ford later remarked that the meatpacking disassembly line had been one of the inspirations for his famous Model-T plant.

25The Cincinnati disassembly line was a signal achievement. It was not nearly as complex as a New England cotton mill, but rethinking the sequence and content of manual operations to fit the space-time units available to each worker was a big step toward the rational factory. A decade later, the beef disassembly lines in Chicago had up to seventy-eight processing steps. A knocker stunned a steer with a sledgehammer, and it was swept up on a hook and sped past gutters, slicers, splitters, skinners, rump sawyers, hide droppers, and trimmers. It was fast, hard, dangerous work, and the blur of wickedly sharp instruments exacted a fearful toll among the workers. The Chicago plants became a lurid wonder of the world, a tourist attraction that the famed actress Sarah Bernhardt pronounced “a horrible and magnificent spectacle.”

26As volumes expanded, Cincinnati’s packinghouses were regularly reengineered to keep pace. A favored design was a multistory packinghouse. The animals were driven up a ramp and slaughtered on the top floor, cut and dressed on the next, with hams, ribs, bacon, and other cuts dropped into chutes leading to their various curing and salting tanks in the cellar. Over time, rendering of the lard and other wastes became part of a seamless flow. As the scale of investment increased, the packers moved to year-round operations. Packinghouses were rebuilt with giant ice cellars: during the winter they were loaded with tons of river ice that was covered with layers of sawdust. As the weather warmed, fans circulated air over the ice and through vent systems to the operating floors.

By the 1830s, Cincinnati slaughterers were learning to harvest more and more of the valuable hog by-products—selling “all but the squeal,” as the slogan went. Hides went to tanners, bristles to brush makers, bones to eastern button factories, and newly arriving German butchers took the intestines for sausage casing. Packers began to pay drovers for the privilege of slaughtering, cutting their deals well in advance of the season. Rendering plants sprang up alongside the slaughtering and packing clusters around the stockyards. The variety and quality of marketable by-products grew steadily as processing innovations conferred better and better control over outcomes.

America’s First Chemical Industry

Hog lard is one of the most desirable animal fats. Gourmet pastry chefs still prefer it as shortening, and it’s actually healthier than butter or hydrogenated vegetable fats.

27 Lard contains multiple fats and oils that are important constituents of soap, candles, waxes, and lubricants.

28 The annual lard rendering for soap and candles was the most exhausting, dirty, and dangerous of the farmwife’s tasks, exposing her to caustic lyes. But rising American wealth and production efficiency gradually brought store-bought, scented, noncaustic soaps and long-lasting candles within the reach of the average home. Lard-based lubricating oils—odorless, nonexplosive, with excellent viscosity in cold weather—were ideal for finely meshing mechanical parts, while lard-oil illuminant was much cheaper than the ever-scarcer spermaceti oil, and its bright flame made it the first choice of lighthouse operators on foggy shores.

A signal invention came from a Cincinnati meatpacker, Ebenezer Wilson, in 1844. Industrial lard rendering had been just a larger-scale version of the farmwife’s lard boiling: the same open-flame cooking, but in 100-gallon kettles. Quality control was spotty at best, and the lard was easily scorched. Wilson reduced the lard with superheated steam in 1,200- to 1,500-gallon pressure cookers. With experience, he learned he could reduce virtually the entire carcass—offal and all—and still produce a highly purified lard with minimum residuum, as well as a variety of oils and glue. By 1847, he was operating four processing tanks in Cincinnati, was turning out 35,000 tons of prime lard annually, and had opened plants at meatpacking centers in Kentucky and Indiana.

Wilson may also have been the first to integrate slaughtering, disassembly, and rendering in a single plant. By 1851, the newest and largest integrated plant, in Covington, Kentucky, packed 23,500 hogs, more than all of Chicago’s packers. The entire operation, including nine curing cisterns and a Wilson rendering system, ran within a single building the size of a football field, sited on its own wharf so the packed meats went directly from the plant into riverboat holds.

New soap-boiling apparatuses developed by a Baltimore chemist combined the mixing and boiling steps while preserving the best qualities of the lard. Cincinnati soap makers naturally adopted the same kind of continuous-flow factory principles as the meatpackers. Steam-heated conduits piped the soap through each step in the manufacturing process. After cooling into blocks, wire machinery cut and shaped uniform soap bars; fancier soaps could be poured directly into molds.

A. Ebenezer Wilson greatly improved by-product recovery by treating the post-packing hog carasses with superheated steam in a rendering tank at pressures up to 100 pounds per square inch for up to fifteen hours. As in a petroleum refinery, the resulting fractions separeted by weight into lard, tallow and various iols, which were drained off by the petcocks to the left of the tank. The small amount of gelatinous residue was drained off at the bottom. B . To make quality soap the raw lard, which was easily burned, had to be heated and vigoriously stirred to create a smooth consistency. The apparatus shown used steam power to turn the tubular mixer at high speed, and a the same time super-heated the tubes with high-pressure steam

Mastery of the chemistry of lard facilitated the production of pure glycerine for a host of applications. It was important to tanners, a useful solvent, and widely used in the production of pharmaceuticals and food. Purified stearine, another lard derivative, was far superior to the farmwife’s tallow for candle making. It was odorless, maintained its shape much better under heat, and could be easily molded and dyed—clear “opal” candles were a Cincinnati specialty. From the mid-1840s to the mid-1850s, Cincinnati’s soap exports increased twentyfold, while candles, chemicals, lubricants, and other lardoil products jumped at comparable rates. As Cincinnati’s processing sophistication rose, the area sprouted a number of industrial chemical plants making inorganic acids, pigments, dyes, and other chemicals used in metal and food industries.

A major consumer company was born in Cincinnati when an English candle maker and an Irish soap maker, named William Procter and James Gamble respectively, married sisters, and their new father-in-law convinced them to go into business together in 1837. By 1859, their turnover passed the $1 million mark.

29 Their timing was perfect, for they were selling into a new middle-class gentility boom. About a century before, the English gentry had become interested in personal cleanliness. Regular bathing, though rarely with soap, became commonplace. Upper-class Americans, always eager for cultural clues from England, began to emulate the custom. When Boston’s elegant Tremont Hotel opened in 1829, it included “eight bathrooms” in the basement. America’s new and ever-alert middle class were quick to jump on the cleanliness bandwagon. Horatio Alger’s Ragged Dick, who “had no particular dislike of dirt” as a street urchin, was transformed by a good bath and clean clothes. Missionaries to more benighted lands began to insist that the natives wash.

30The processing of lard and its derivatives was America’s first true chemical industry. (New England textile makers generally bought their bleaches and dyes from the British.

31) Lard processing also offered a prototype for the postbellum oil-refining industry. In its early stages, oil refiners were an assemblage of mom-and-pop operations, not much different from whiskey distilling. But they rapidly morphed into the same kind of large-scale continuous-flow operation as lard processing, with the additional benefit of a good native base in academic chemistry.

32

. . . And Mass Production of Furniture

Lucy Bird spotted another Cincinnati specialty besides pigs when she stopped at a mass-production, machine-based furniture factory, which she recognized as something new under the sun:

There is a furniture establishment in Baker Street, London, which employs perhaps eighty hands, and we are rather inclined to boast of it, but we must keep silence when we hear of a factory as large as a Manchester cotton-mill, five stories high, where 260 hands are constantly employed in making chairs, tables and bedsteads.

At the factory of Mitchell and Rammelsberg common chairs are the principal manufacture, and are turned out at the rate of 2500 a week, worth from 1

l to 5

l a dozen. Rocking chairs, which are only made in perfection in the States, are fabricated here, also chests of drawers, of which 2000 are made annually. Baby rocking-cribs, in which the brains of the youth of America are early habituated to perpetual restlessness, are manufactured here in surprising quantity.

33Lumber and finished wood products were one of America’s leading industries in 1850, well behind textiles and cotton but in an approximate tie for second place with leather and its products, metal and its products, and transport equipment and machinery. From colonial days, there was industrialized logging in Massachusetts, Maine, New York, and Pennsylvania, both for coastal ship builders and for export to England.

34Commercial exploitation of the great forests of the Midwest was underway by the 1830s and, like all of the region’s industries, was heavily reliant on the high-pressure steam engine. A characteristic innovation was the development of large, portable circular saws packaged with a steam engine that could be trucked from one logging area to another.

Rough-sawing raw logs at the logging site greatly improved transportation efficiencies. Midwestern loggers developed steam-powered portable saws that could handle logs up to thirty feet long.

Rough sawing in the forest greatly reduced transport costs. A portable forest mill, with a crew of two or three men and a 40-horsepower engine, could process 15,000 to 20,000 board feet of timber a day. One such mill, manufactured by a Cincinnati company, Lane & Bodley, could handle logs up to thirty feet long and forty-eight inches in diameter.

A survey in an 1872 British text noted that such forest mills in the Midwest had become

a vast business; not less than two thousand workmen are, in the state of Ohio alone, engaged exclusively on portable circular-saw mills, with the steam engines to drive them. . . . At first sawyers who had, by observation and experience, mastered the circular-saw mill, were in great demand at high wages. In fact, it is a feat of no mean pretensions to keep a large circular saw at work on rough timber; yet experience has done much to overcome the mystery of “running” a circular mill. . . . Portable circular-saw mills have not yet been to any extent built in England. There is, however, a colonial demand springing up for them.

be35All Europeans criticized the wastefulness of American lumbering practice. Running big logging saws at high speeds and keeping them true required very heavy, thick saw blades, so the kerf, or width of the wood ground up by the blade, was as much as a half inch.

36 Big timber-producing states like Maine, Michigan, and Wisconsin each processed routinely 200 to 300 million board feet a year, so those half inches added up. To forest-deprived Britons, it was a continuing scandal.

From the earliest periods, Boston, New York, and Philadelphia were centers for fine furniture making, much of it exported to wealthy planters in the West Indies. Americans showed great imagination in chair making; the rocking chair is apparently an American invention. The Niles Weekly Register recorded a shipment of 12,000 chairs dispatched from Baltimore in 1827 for a trip around the Horn, with delivery points up and down both of the South American coasts.

Before the 1820s, furniture was a small-shop, mostly handcrafted product. Fine cabinetmaking was almost entirely a bespoke business. Some local carpenter shops might make modest quantities of workaday furniture for sale but would otherwise produce to order. By the 1830s, New York craftsmen were already complaining that machine-made product was driving down the price of common furniture, but the most intensive development of furniture factories was pursued in the Midwest after 1840. Whitworth also reported on the American furniture industry, but it was only in the eastern states. He does not report on any large factories but details several “interesting machines,” like an apparatus for shaping the arms and legs of chairs.

37The Mitchell and Rammelsberg plant memorialized by Bird offers a fine case study of the industry’s evolution. The company’s founders, Robert Mitchell and Frederick Rammelsberg, were two successful Cincinnati cabinetmakers who joined forces in 1847. The factory that Bird visited was steam-powered. Rough plankings were delivered and finished on the first floor; manufacturing processes took place on the middle floors, with finishing, varnishing, and drying on the top floor and roof.

38There is a surviving equipment list from a factory expansion in 1859. Two basement steam engines drove all the machinery, which included sixteen lathes, dovetail cutters (for joining the corners of drawers), planing machines, varieties of rip saws and crosscut saws, mortise and tenoning machines, routers, boring machines, and a variety of trimming equipment—scroll saws, friezing machines, and a molding machine.

A number of these machines, like the mortising machine, date from the Brunel-Bentham-Maudslay Portsmouth block factory a half century before. (The mortise is the female joint of the mortise-and-tenon system for joining wooden corners; the machine is a steam-powered chisel preset to the desired cut.) Most decorative machines, like the friezing machine and various carvers, are developments of the original Blanchard principle of a profiler/carver: an independently powered cutting tool directed by tracing a pattern of the finished product.

39The 1859 factory had thirty-six carvers for decorative work, working both by hand and with the aid of powered equipment. The scroll saw was a narrow reciprocating blade passing through a table and held in tension by a spring. A carver could draw a pattern on a workpiece and make a manually guided rough cut with the scroll saw before finishing it by hand. More advanced profiling carvers were developed after the Civil War, but precise effects usually required a dozen or more progressively finer cutting tools and tracing styluses, and the tool changes were time-consuming. Spindle carvers were small, fixed rotary cutters projecting horizontally from a base. The carver would hold a workpiece against the cutter and manipulate the piece to create decorative flourishes. The blade type determined the nature of the cut, but the carver free-handed the pattern.

The nineteenth-century American furniture industry is sometimes cited as an example of the armory tradition of manufacturing interchangeable precision parts with specialized machinery. But that seems a stretch. The Mitchell and Rammelsberg achievement is best understood as a brilliant product/marketing strategy—creating a cornucopia of styles and price points to suit both the newly well-to-do nonconnoisseur and the middle-class clerks, craftsmen, and hog farmers brightening their homes with a nice-looking table-and-chair set. In an age of heavy, ornately decorated furniture, different-size wooden orbs, flat squares, and cubes with beveled edges could be combined into a near-infinity of treatments of newel posts, leg bases, bed headboard posts, and other ornamentation. A variety of machine-molded edges added finish and style to flat shelving. Standard engravings, friezes, and carved crests were combined on beds and sideboys. Headboards could be flat with simple crests or have inset panels with contrasting veneers and more ornate flourishes. Veneers were widely substituted for expensive hardwoods, while stains turned oak into rosewood. Manufacturing tolerances were not highly demanding, but machinery construction was technically challenging since the machines typically ran much faster than metal-cutting machinery and had heavier blades, which stretched the limits of current ball-bearing technology.

40A Philadelphia architectural magazine sneered in 1861:

An immense trade has sprung up in the last few years in a cheap and showy class of furniture, of mongrel design and superficial construction. . . . [Demand in the South and West is such] that a number of large steam factories are engaged in this trade exclusively. They make furniture of a showy style, but with little labor in it, and most of that done with the scroll saw and turning lathe.... This furniture is easily detected by examination, as it consists mostly of broad, flat surfaces, cut with scroll-saws into all imaginable and unimaginable shapes, and then by a moulding machine the edges are taken off uniformly: this gives it a showy finish.

41The critic did not name any specific manufacturers, but the article’s descriptions of both furniture types and manufacturing processes, absent the sarcasm, was a dead-on portrait of Mitchell and Rammelsberg. By that time, the company seems to have been the trendsetter for the industry and had opened substantial stores throughout the major cities of the region.

An English observer had a better understanding of what was afoot, however, when he wrote in a catalogue of an American exhibition in London a decade earlier: “The absence in the United States of those vast accumulations of wealth which favour the expenditure of large sums on articles of mere luxury, and the general distribution of the means of procuring the more substantial conveniences of life . . . [directs American industry] to increasing the number or the quantity of articles suitable to the wants of a whole people, and adapted to promote the enjoyment of the modest competency which prevails among them.”

42

A. Dovetailing machinery was proliferating in mid-century, judging by a caustic reference in an 1872 textbook. They were a standard fixture even in modestly-sized furniture factories by the 1880s. B. Nineteenth-century furniture factories in the Mitchell and Rammelsberg tradition were quick to exploit Blanchard’s concept of duplicating profiler/carvers. For inscribing cuts like the one shown, up to a dozen cutters might be driven off a single pattern guide.

By 1860, the Midwest was a major manufacturing center in its own right, mostly centered around the big Ohio River cities like Cincinnati and Louisville. Chicago was gaining rapidly in population—110,000 to Cincinnati’s 161,000—but Cincinnati still had a nearly six-to-one edge in manufacturing employment. Food processing and its by-products were the largest single industry, but the Midwest was developing a large transport sector: steam engines, steam boats, and, increasingly, rails and rail cars.

In the first few decades of the Midwest’s rise as a manufacturing power, the east-west transportation barrier acted like a protective tariff. Trade between the eastern states and the Midwest was dominated by easy-to-transport goods: the West sold packed meat and lard products and bought shoes, clocks, and textiles. At the same time, improving riverine transit, the construction of nearly 1,000 miles of canals in the 1830s and 1840s, and the spectacular burst of 1850s railroad construction welded the Midwest into a large and more or less cohesive economic unit that could support its own substantial manufacturing base. By the time a national railroad network nearly eliminated transport barriers, Midwest manufacturers were able to hold their own, especially in piping, valves, steam engines, agricultural equipment, and other heavy machinery.

43The skill-based industries of the East, by contrast—shoes and textiles, brass clocks and fine instruments, the light machinery of the Connecticut River Valley—were there mostly by accidents of history. That deepening skill base created a regional advantage in newer industries like sewing machines, typewriters, and watches. But skill-based eastern manufacturing also included very heavy fabricated products—locomotives, large mill machinery, and large printing presses. We will look at those in the rest of this chapter, along with the one eastern industry that was driven purely by locational factors—open ocean–sailing vessels.

Steamships

The steamship industry may be the only instance in which the United States plausibly seized, or was in position to seize, leadership from Great Britain but quickly gave up its advantage and for all practical purposes exited the business.

Competition in the East Coast steamboat industry was ferocious. By the 1830s and 1840s, the boats were of oceanic proportions, roughly twice the size of Fulton’s

Clermont/Steamboat and far heavier and faster. Competing lines raced, and occasionally jostled, each other on the water, rather like NASCAR racers. There was no dominant owner, but the active presence of Cornelius Vanderbilt kept all the lines at a knife-sharp point of tension. His strategy was to move into and out of the trade opportunistically—launching price wars against complacent operators to gain control of their routes, then selling out at a profit. Vanderbilt had become by far the richest of the operators and the only one who could order and pay for major steamboats from his own resources—rich enough even to shrug off the loss of a major new boat,

The Atlantic, a 321-foot behemoth. (It was driven on rocks during a fierce storm in Long Island Sound, with the loss of fifty of the seventy passengers and crew.) Unlike many buyers and sellers of companies, Vanderbilt was also a superb manager and nearly always turned lackluster properties into profit machines.

44Since almost all the steamboats were built locally, the New York–New Jersey harbor was lined with massive foundries and engine and machine shops, as well as shipyards of the largest dimension. By 1850, they had produced thirty-eight major steamships, including two for foreign governments. William H. Brown was the biggest yard, accounting for about a quarter of the hulls. Other important yards included William H. Webb, Westervelt & Mackay, Simonson’s, and Jacob Bell. There were also multiple dry docks. Webb’s, built in 1854, was the biggest at 325 by 99 feet with a 38½ foot depth; it had twelve pumps and was operated by two large steam engines, one on each side, each with a locomotive boiler. About half of the steamboat engines were made by the Allaire Works on the East River, a pioneer of the marine compound engine,

bf with the Novelty Works likely in second place. (Vanderbilt gradually absorbed both the Allaire and Simonson businesses to improve his profit margins.

45)

Transatlantic shipping was largely the province of American sailing ships until two British steamships, the

Sirius and the

Great Western, arrived in New York Harbor within twelve hours of each other in the spring of 1838. The

Great Western was much the more formidable ship—it had twice the tonnage of its rival and was a third greater in length and much faster (it had left England three days later). It had been designed by Isambard K. Brunel with an engine from Maudslay Sons and Field—respectively the sons of Mark I. Brunel and Henry Maudslay, who created the great pulley-block factory at Portsmouth. As was the convention until well into the second half of the century, both ships were under steam power and sail the entire voyage to conserve fuel. A number of other British competitors jumped into the fray, and the Cunard Lines won the premier position by virtue of a coveted mail subsidy—a generously calculated payment for handling British-American mail.

46E. K. Collins of New York, scion of a generation-old transatlantic packet-boat and freight operator, responded by launching four steamships in 1849–1850, all of them built in New York harbor, buttressed by an even more lucrative mail subsidy from the American government, justified on “national interest” grounds. The first two, the

Atlantic and the

Arctic, had engines from the Novelty Works, while the engines of the

Pacific and the

Baltic were from Allaire. The engine cylinders were all ninety-five or ninety-six inches in diameter, while the pistons had nine- or ten-foot strokes. There were other steamship lines, but the Collins and Cunard ships were on the same routes and even used the same terminal in New York, so they were most visibly engaged in a head-to-head competition. On the early matchups, the Collins ships—besides being much bigger—proved much faster. Cunard commissioned two big new ships, the

Asia and the

Africa, which were a marked improvement. But they did not decisively trump the Americans until the launch of the very large and very fast

Persia in 1855.

47Cornelius Vanderbilt, in the meantime, had been gaining experience as an ocean steamship operator by running a lucrative Pacific line to take advantage of the California Gold Rush. The route went from New York to a port on the coast of Nicaragua. Passengers then embarked on a combined river-lake-transit road trip across the peninsula to meet steamships to San Francisco. His first ship commissioned for the East Coast leg was the

Prometheus, which in 1850 made the 5,600-mile run, including stops at Havana on the way down and at New Orleans on the way back, in the extraordinary time of nineteen days, while consuming about a third less coal than any comparably sized ship would have required.

48The secret of the

Prometheus’s performance was the engine. All of the oceanic steamships were side-wheelers. British design dogma, which had been adopted by Collins, required that oceanic ships have their engines located low in the hull for stability, so operating the side wheels required complex gearing with poorer operating efficiency. Vanderbilt insisted on a traditional walking beam engine, with the beams on the deck and the drive shafts connected directly to the side wheels, and proved the naval architects wrong. The walking-beam engine was much lighter and more efficient, and the ship, like most side-wheelers, was very stable.

49Vanderbilt launched the

North Star in 1853, and in a slow market, he adopted it as his personal yacht. At 2,500 tons, with 260 feet at the waterline, 34-foot side wheels, and two walking-beam engines, it was among the largest and most capacious, most lavishly outfitted, and fastest commercial-scale ships in the world. He took his family and retainers on a world tour, in part just to introduce himself to the international scene but also to advertise the capabilities of American shipping and to underscore his challenge to the Collins mail franchise, which Vanderbilt bragged, doubtless correctly, that he could operate at half the price.

50Vanderbilt returned from his tour, refitted the North Star as a passenger ship, and began work on the Vanderbilt, even bigger and faster than the North Star. Plausibly, the United States looked poised to seize shipping supremacy from the British. It didn’t happen. By the eve of the Civil War, the Collins line had collapsed, and Vanderbilt had sold off most of his steamship interests, turning over his larger ships to the government for war transport.

What happened? The immediate causes were economic. Congress decided to make drastic cuts in the Collins subsidy, just as the economic crisis of 1857 devastated freight and passenger revenues. More subtly, the British, acting on pure free-trade doctrine, had opened their registries to foreign shipping in 1849. As British shipping interests had predicted, the Americans, with their unmatchable clipper ships, quickly dominated international freight shipping, most especially the lucrative China and India trade.

But theory for once was triumphant. All sensible American investors plowed their money into the wooden sailing-ship industry. When the Crimean War ended and the British began a full-scale transition to iron ships

bg and propeller drives, Americans were simply not in the game. And at the end of the day, compared to the opportunities in the American West and in railroads, ocean steamships did not look like an especially attractive business, since it was so heavily dependent on subsidies.

51After the Civil War, the Pennsylvania Railroad attempted to re-create a steam-based merchant marine industry by building four creditable ships, but it finally merged them into a Belgian combine in 1884. In 1902, at the height of an American leveraged buyout boom, J. P. Morgan led a roll-up of two American and two British shipping lines. The new entity, International Mercantile Marine, was arguably insolvent on its first day of business, and as an investment, was an unmitigated disaster.

52

Baldwin Locomotive

Matthias Baldwin was a Philadelphia jeweler, a whitesmith—a metalworker in silver, pewter, and tin—and clearly a gifted mechanic. When he and his partner moved to a bigger shop in 1824, he built a stationery steam engine to power their machinery. Although it was his first engine, it was remarkably efficient and had enough useful innovations to attract a number of orders from other Philadelphia workshops. When the partnership broke up in 1829, Baldwin opened his own workshop as a jobbing machinist and specialist in steam engines.

53This was at the dawn of the railroad age, and in 1830 Baldwin was commissioned by the Franklin Institute to build a realistic working model of a steam-driven railroad. That led to contract from the new Philadelphia-Germantown Railroad to build a full-scale engine. A second contract with another line followed a few months later, and others after that; in the single year of 1835, he built fourteen locomotives.

From the time Baldwin entered the business, he pushed the product boundaries. The second engine he produced incorporated Jervis’s four-wheel swiveling truck at the front of the engine, which improved its performance on curves. Baldwin followed that up with a bigger three-axle engine, including the truck, and then added a power train to the truck. In both 1836 and 1837, Baldwin sold forty locomotives, employed some three hundred men, and became one of the wealthier Philadelphia manufacturers. An 1838 Treasury survey showed that there were 350 steam locomotives in the United States, 122 of them from Baldwin. Since 78 engines had been imported, Baldwin had 45 percent of domestic production, and had begun to win contracts on the European continent.

54 Among some twenty-two other American locomotive producers, Baldwin was clearly the dominant player.

When the 1837 Bank Panic shut down most railroad construction, Baldwin was exposed to the perils of big-ticket capital goods production. Since he supplied much of his customers’ financing, he found himself desperately squeezed for cash, scraping through by stonewalling suppliers and groveling to creditors. He preserved the company by working out an informal receivership with his creditors that allowed him to retain control until markets recovered, although he lost his position as industry leader. For Baldwin, a deeply religious man with high business principles, it was a time of terrible strain.

55 The half-century-long railroad boom that followed the Civil War finally put the company on a solid footing, and by the 1880s, it was the world’s largest locomotive maker.

Despite the financial headaches, between 1850 and 1870 Baldwin made extraordinary productivity gains, as shown in

Table 6.2.

That accomplishment is the more impressive if one considers the much greater complexity of the 1870 over the 1850-vintage locomotive, plus the fact that dominant railroads like the Pennsylvania and the Baltimore & Ohio were increasingly specifying highly customized designs.

How did they do it? The original Baldwin manufacturing strategy was, at heart, that of the classic machinist’s job shop. But superimposed on that was a prototype for the modern systems integrator, like Boeing. Boeing has great manufacturing skills and is arguably the world leader in mega-wing design and production, but the vast majority of the millions of components in one of its planes are sourced from outsiders, including many of the most critical, like the engines and the avionics. The ability to manage that complexity is the deep skill that makes Boeing such a successful company.

Baldwin’s challenge was similar. By the 1840s, standard locomotives weighed 40,000 tons and had some 4,000 parts, far more than Baldwin could make itself. Many of the components, moreover, like boiler plates, axles, wheel castings, and large flues, were beyond Baldwin’s shop capacities. From the earliest days, therefore, Baldwin formed strong relationships with key vendors. Each new contract produced a flood of parts orders that could usually be specified by the variations from a previous order. On a standard engine delivery schedule of sixty days, the first four to six weeks were devoted to making, or purchasing and finishing, the components, followed by two weeks of building the engine. Several engines could be worked on simultaneously, but each one, along with virtually all its components, was essentially built from scratch, and few of the engines were ever completely identical. Throughout the decade, depending on the market, Baldwin turned out a locomotive every ten days to two weeks.

Baldwin did that with almost no management to speak of. As the company entered the 1850s, Baldwin was the sole owner and chief executive. He had elevated a shop foreman, Matthew Baird, as the de facto number two, although Baird spent most of his time with customers. The rest of management consisted of a general superintendent, George Hufty, who oversaw day-to-day production, and one more executive, a shop floor veteran with a flair for numbers who took care of the accounts. Baldwin, besides managing day-to-day financing issues, was immersed in tooling strategies and product design, a major source of the company’s reputation. And that was it—four managers in a four-hundred-person company, two of them in sales and accounting rather than line positions, supported by a handful of clerks.

Operating management lay with the shop foremen. There were seven shops in 1850: foundry, boiler, smith, painting, and three machine shops. Each foreman was effectively the master of his house. Baldwin and Hufty would establish a production schedule, set the timelines for each of the shops, and order the required components and raw materials. From that point, the shop foremen were on their own. In effect, they were running sizeable businesses with about fifty workers each, and like Baldwin, they had mastered every detail of their shop work, hired and fired their workers, purchased their own shop supplies, and organized their internal work flow as they saw fit—with the major difference that they had only a single customer. The relation with major suppliers was somewhat similar. Over the years they must have developed high levels of trust, and Baldwin could not have met its schedules without top-priority treatment by all its vendors.

But as the 1850s opened with a surge of new sales, the company’s productivity could not keep pace. Locomotives were bigger, and part counts were rising—so were mistakes and missed deadlines. Baldwin and Baird began to rethink operations, and over the next twenty years the company became a model of a modern, World War I–vintage, capital goods manufacturer.

The first step was the installation of a piecework payment system. That wasn’t a matter of turning a switch, for there was no documentation on the discrete tasks performed in each shop or the value of each major process completed. It took a couple of years, but they worked it through. In general, the men liked it because they earned more. (Baldwin, unlike an Andrew Carnegie, did not use piece rates to reduce wages; if output was rising, he was happy to see the men earn more.) The foremen hated it because the implicit task standardization invaded the traditional independence of the shops.

The next challenge was the proliferation of locomotive designs.

bh Parts counts were becoming unmanageable, and the craft-shop manufacturing culture meant that standard parts were rarely identical anyway. So-called standard parts emerging from the machine shops couldn’t be fitted into standard boilers in the boiler shop without extensive reworking. To make matters worse, customers were complaining about the work required to make even the simplest repairs. Other shops had the same problems, but a high-volume producer like Baldwin

bi could strangle on them.

Solving the parts snarl took more than a decade and required a complete rethinking and upgrading of the production system. The first step was to identify all the parts used in production and eliminate any unnecessary variation. All boilers have multiple water taps, for instance; absence a specific justification for a variance, all such parts should be identical. But to achieve that, the company had to choose the default tap, carefully specify it in a set of dimensioned engineering drawings, and then repeat that exercise for a couple of thousand or so more standard parts. By the early 1870s, there were standard, dimensioned drawings covering all important standard parts, with a comprehensive parts catalog. When a job was being laid out, all standard parts were specified by their catalog number.

Bladwin Shop. After all parts had been anufactires or received from its vendors, baldwin typically devotes two weeks to assembling each engine. Since avery engine was different, the erecting shop workers had to embody a broad range of skills. Even standard parts that were nomilally "interchangeable" were likely to require fitting just as gun parts did. The workers by the windows are filing parts The erecting shop was expanded to accommodate multiple engines in the early 1850s, and was regularly further axpanded as volumes increased. There are at least seven engines being worked on in this picture from 1869, which suggests the complexity of the parts acquisition and tracking challenge.

The last step was to gradually adopt armory-style gauging. Baldwin had a large cadre of skilled machinists and had long made almost all of its own machines, so it’s likely that it made its own gauges as well. By the 1880s, locomotive makers were claiming that all their parts were “interchangeable,” although only subsets, like critical gears and power train parts, demanded the kind of high precision required by watchmakers or gun makers. All major railroads had sophisticated machine shops to manage repairs, and since replacement parts were typically installed in heavily used machinery, some fitting was almost always required.

The striking advances in productivity speak for themselves. But they had much more to do with management than with machines—simplifying designs, rationalizing the production and assembly process, and taking control of parts, specifications, and work sequences. Improved specification also allowed the company to experiment with “insourcing” the shops: bidding out contracts, usually to foremen, for delivering annual production according to a negotiated price schedule. On the whole, the experiment worked out well and was retained for many years, but the ground had been prepared by the years of work on standardization and work rationalization.

Baldwin offers yet another model of mass-production manufacturing. Like the Mitchell and Rammelsberg plant, it has a number of affinities with armory practice. But although it took full advantage of improvements in gauging, cutting tools, and materials quality, its operations were highly labor-intensive well into the twentieth century, with heavy reliance on general-purpose machinery in the hands of skilled workers.

The real story at Baldwin was not mechanization but its operations management—the product of an ultralean top management with deep experience on the shop floor. There were no outside “efficiency experts.” In the early twentieth century, indeed, Baldwin executives were extremely critical of Taylorism and the so-called scientific management movement. An 1879 visitor noted: “Owing to the magnitude of the establishment, a stranger would naturally suppose that it would require almost a regiment of Bosses and any amount of ‘bossing,’ but such is not the case by any means. There are very few lookers on to be seen in the shops.... The proprietors, superintendents, gang, and track bosses all work themselves so there are very few, if any, drones in the hive.”

56And it stayed lean for a long time. In 1910, when Baldwin had grown to 14,500 employees turning out 1,675 locomotives, most of enormous weight and complexity, the president, William Austin, normally spent half his working day in the drafting room checking drawings.

Corliss Engines

George H. Corliss was a dominant figure in steam-engine technology in the second half of the nineteenth century. The son of an upstate New York physician, he had no university or technical training and is said not to have seen the inside of a machine shop before he was eighteen. But Corliss had the gift. Bored as a clerk in a country store, he invented a machine for sewing leather and patented it in 1843, when he was twenty-six. Hoping to develop prototypes, he went to Providence, a machining center, in 1844 and took a job as an assistant in a machine shop. The partners appreciated his acumen and encouraged him to shift his interest to steam. Within two years he was a full partner. By then Corliss had already conceived the mechanisms that one of his rivals, who later became an industry historian, called “the most famous steam engine that has appeared since the time of Watt.”

57One of the machine-shop partners capitalized a new company to develop Corliss’s ideas. Corliss got one-third interest plus royalty payments on sales, in return for his patents and a small capital contribution. The first engine sold that same year for $8,600 without the boiler, and its success quickly led to several more sales. By the time of the final patent award in 1849, they were already building a new and expanded factory. The company was renamed the Corliss Steam Engine Company in 1857, and by 1864 Corliss had purchased full ownership.

The standard American high-pressure steam engine of the 1840s was based on the slide valve. There is a steam chest along one side of the cylinder: as the slide valve moves back and forth, it alternately admits and vents steam on both sides of the piston. After the success of the engine in river steamboats, it spread rapidly throughout industry, freeing mills and forges from the dependency on waterpower. Even in waterpower-rich New England, rising power demands and winter production losses forced the shift to steam. The Lowell Locks and Canals Company acquired its first steam engine in 1850 and had thirty-nine by 1870.

But as the stationary steam engine became the factory power source of choice, its gross deficiencies became the more apparent. For one thing, standard engines were prodigal consumers of coal. Fuel was usually the biggest factory expense after personnel. Just as important, the energy output from most engines was very irregular. In small shops, that was rarely an issue, but in a large textile mill, where high gearing often ran looms at extreme speeds, power variations were amplified to violent effect. Even with steady power, if several big looms went down at the same time, the drop in power load could cause the other looms to spin at destructive speeds. In a big iron rolling mill, the sheer weight of the machinery made variations in power especially damaging. A skilled operator could throttle steam up or down, but the inherent lag between the action and its full effect made it hard to prevent major plant disruptions.

Corliss’s first patent addressed both fuel consumption and speed regulation as related problems. The operations of a standard slide valve exposed each end of the steam chest to alternate doses of fresh and expanded steam. The temperature differentials were wide enough that much of the heat in the fresh steam was spent on rewarming the steam chest. Corliss’s first innovation was to completely separate the intake and exhaust operations to minimize the need to reheat the apparatus on each cycle.

The second innovation was to rethink the throttle. In the slide valve engine, the throttle limited the steam entering the piston cylinder from the steam chest while venting any excess—thus wasting good steam. Instead, Corliss regulated the engine with an automatic variable cutoff valve. To reduce or increase power, Corliss reduced or lengthened the period of the valve that admitted steam directly into the cylinder. Since just the right amount of steam was delivered, none had to be vented, so energy waste was greatly reduced. The regulation of the valve cycle was performed by the traditional spinning-ball governor. As the engine changed speeds, centrifugal force would change the plane of the balls’ rotation, and an apparatus connecting the governor to the valves would modify the valve settings proportionately. An important fillip was that as the balls approached horizontal, the valve connection was dropped—in the words of the patent, the valve was “liberated”—so it would shut almost instantaneously. (A clever latch arrangement automatically reconnected a closed liberated valve, while a shock absorber prevented any damage from too hard a closing.) The inventions, moreover, were adaptable to any type of steam engine.

Modern analyses show that Corliss’s valves and valve management systems improved fuel efficiency by about 30 percent. Since Corliss’s early sales were almost all to replace older engines, the savings were usually 50 percent or more. British observers were inclined to mock the awkward-looking rods on the outside of the machine

bj but were converted by its performance at the Paris Exposition of 1867, where it won the gold medal. A British engineer wrote of the Paris engine that it was “refined, elegant, most effective and judicious . . . spares steam to the utmost but develops what it uses to most effect.” The governor was “sensitive to the most delicate changes of speed, and feels the slightest demand upon the engine for more or less work and steady speed.” In sum, the review concluded, “everywhere tells of wise forethought, judicious proportion, sound execution, and exquisite contrivance.”

Corliss’s first innovation was to save steam by separating the entry and exhaust valves on each side of the piston. (A conventional slide valve both admitted and expelled steam leading to wide temperature variation both at the valve and within the steam chest, so steam was wasted on reheating engine parts.) The exterior drawings show how the Corliss wristplate and the valve rods manage the valve actions, while the interior drawings show the separation of the steam intake and expulsion actions. The second innovation was that the intake period could be precisely timed to accommodate shifting power requirements. Conventional engines tuned power through a throttle that slowed the rate of steam admission, necessarily wasting excess steam. The drawing on the next page illustrates the Corliss timing mechanism.

The power engineer could set a maximum speed for the engine rotation. Speed would be measured by the rotating flyball governor in the inset. When the governor reached the preset speed, it triggered the valve regulator, and a drop lever instantly shut the intake valve. If a number of looms went down in a large mill, the Corliss would instantly reduce power to the point where they continued to operate at a constant speed, and would make a comparable adjustment as the failed looms were brought back on line.

Corliss marketed his machine in the early days by offering customers an option of a fixed price or a sum geared to actual fuel savings. Customers who chose the contingent price always paid much more. Fuel savings were even higher than raw fuel consumption data suggest, because the intrinsic regularity of the operation allowed the use of lower-quality coals. Textile mill operators most valued the “extreme regularity” of the Corliss. The reductions in thread breakage made it almost a must-have in the industry. In its first fifteen years of operation, up to 1862, the company sold 480,000 horsepowers, or about 480 separate engines. (At the time, engines were only about 30 percent of its sales.) Sales over the next seven years more than doubled the installed horsepower, reflecting both sales growth and a trend toward larger engines. By the time his patents expired in 1870, Corliss had collected $213,000 just in royalties, mostly from his own company.

Corliss’s great success was marred by bitter and prolonged patent litigations. In truth, almost every important feature of his engine had been anticipated by previous patents, although none had presented a comprehensive, integrated, new plan for an engine the way Corliss had. In later patent filings, he acknowledged the priority of other designers for specific pieces, although the designs themselves were quite different. While he didn’t win every case—he bemoaned the unpredictability of lay jurors—he carried all the essential ones, and Congress granted him a seven-year extension to compensate for his loss of revenue while the litigations were underway.

Corliss’s most famous engine was produced as the showpiece for the 1876 centennial celebration in Philadelphia. It was an unreserved bash, attracting 10 million visitors from all over the world with some 30,000 exhibits spread over 236 acres in Fairmount Park. But the center of attraction was the goliath Corliss steam engine powering thirteen acres of machinery in Machinery Hall. It comprised two one-cylinder walking-beam engines. The beam centers were 30 feet off the floor; the beams themselves were 27 feet long and 8 feet deep at their center. The cylinder was more than 3 feet in diameter, and the great flywheel weighed fifty-six tons. Visitors were most impressed, however, by the machine’s near silence, which attests to the very high quality of manufacturing at Corliss. The power shaft driving the Hall’s machinery was 352 feet long, and its major distributing gears were all 6-foot-diameter bevel gears. The trueness of the drive shaft and the lack of chatter in the enormous gears exemplified the precision of Corliss’s products.

Unlike a Baldwin, Corliss usually made every part in his own factory, which had been constructed to build to monumental size. Besides his engines, he made a wide range of heavy machinery and parts, like heavy wheel and shaft castings. His plant could pour single castings of as much as thirty-two tons. There were also four in-plant locomotive turntables with two railroad spurs connecting to commercial lines. (A locomotive could enter the plant, take a load, and be turned around on the table.) A fair summary of the Corliss operation is that it was one of the world’s best British-style heavy manufacturing operations, working on a craft basis at every stage of production.

In the mid-1880s, Corliss closed down his plant with the thought of converting it to a more mechanized, assembly-line-type operation, but he died suddenly in 1888, at the age of seventy-two, and the plans were never implemented. The business declined after his death, for he had not provided for a successor. One of his great engineers, Edwin Reynolds, had joined the E. P. Allis Company of Milwaukee (later Allis Chalmers) in 1877, after serving as Corliss’s general superintendent for six years. With Corliss gone, Allis became the leader in innovation in very heavy machinery. By then, nearly the whole industrialized world had converted to Corliss-type machines for heavy steam plants, until they were superseded by the steam turbine and new valve configurations around the period of the First World War.

Hoe Printing

Robert Hoe, an apprentice carpenter, emigrated from England to the United States in 1803, when he was nineteen. In New York City, he and two brothers-in-law, a joiner and the inventor of a hand press, formed a company to make wooden presses and later saws. After his brothers-in-law died, Hoe continued the firm under the name of R. Hoe & Co. When he died in 1833, he was succeeded by his eldest son, Richard March Hoe, who became one of the great figures in nineteenth-century printing technology.

58Hand printing presses had changed little since the days of Gutenberg, and the conventional designs were maintained through the early generations of power-driven presses. A bed of type—the form—was inked, and then a piece of paper held tightly in a frame was forcefully pressed into the form by a flat metal or wood platen. Thus the first powered cylinder press, invented by a Saxon, Friederich Koenig, and installed at the London

Times in 1814, was something of a landmark event. In Koenig’s machine the set type lay flat and was moved back and forth. A cylinder held the paper sheet and had three positions: one for loading the sheet, one for the actual printing, and one for removing the sheet. Sheet loading and removal was by hand, but with skilled feeders the presses could produce up to four hundred pages an hour. The machine was widely adopted by the British, who made a number of improvements, especially in the paper handling.

59The Hoes learned about the cylinder press only in 1832, when the senior Hoe was already ill. Richard produced his own version in 1833 and sold them by the hundreds. By the 1840s, his double-cylinder press achieved speeds of 4,000 pages per hour on one side, with two feeders.

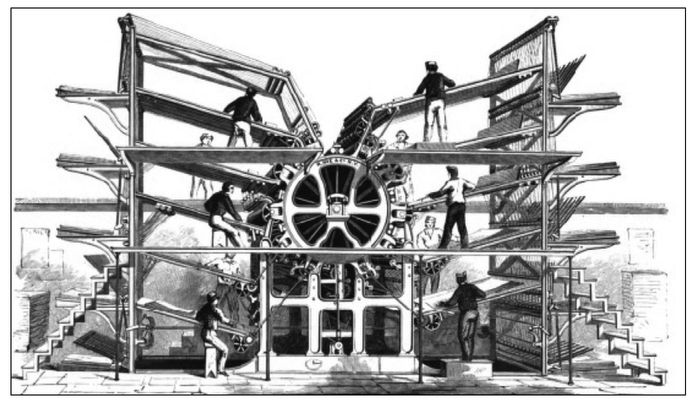

The cost of paper fell rapidly after the introduction of the Fourdrinier paper-making machinery from France. In the world’s most literate and information-hungry nation, cheap paper was like crack cocaine; the bottleneck was only the speed of the presses. Hoe’s response was the patented Hoe Type Revolving Machine. Instead of a flat bed of type with the paper turning on a cylinder, Hoe put the type on a large central cylinder, with the paper fed in flat and taken up by a stationary roller. The major technical challenge was learning how to fix the type securely in the form of a nearly perfect circle.

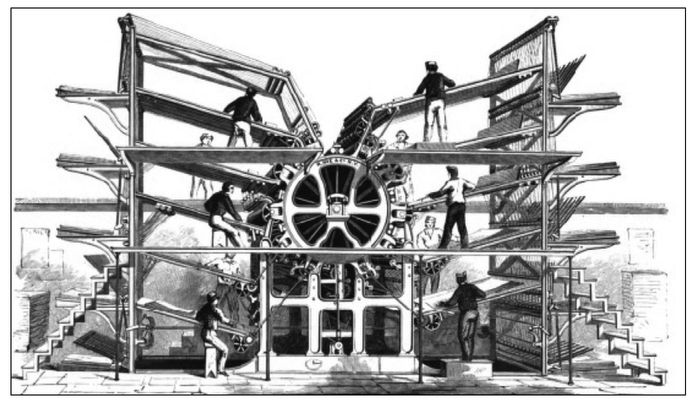

The new machine incorporated a number of important paper-handling improvements: the feeder simply slid the sheets down a ramp, and mechanical contrivances positioned them correctly on the roller, unloaded them after printing, and stacked them in the correct piles; the inking apparatus was built into the central cylinder. The beauty of the arrangement was that one could position a number of separate feeding slots and printing rollers around the central roller. The biggest, and fastest, model sold was the Ten Cylinder model shown on page 235, with feeders positioned on both sides.

The Ten Cylinder machine achieved output of 20,000 pages an hour and was an essential enabler of the vast proliferation of newspapers of all kinds in the mid-nineteenth century. Most of the large presses in the world adopted the Hoe revolving press. Great Britain was the sole holdout, until the London Times finally purchased two Ten Cylinder presses in 1856. That was an especially sweet victory for the Hoes, for in 1848, when the Times purchased a conventional press, it had pointedly editorialized on the absurdity of the Hoe claims: “No art of packing could make the type adhere to a cylinder revolving around a horizontal axis and thereby aggravating centrifugal impulse by the intrinsic weight of the metal.”

Hoe Ten-Cylinder Printer. Printing presses achieved very high speeds when Richard Hoe managed to create a cylindrical type holder that could retain the heavy type at a high rate of rotation. The inking apparatus was inside the cylinder, so fresh newsprint could be introduced at multiple points on the cylinder. Young boys could serve as feeders, since advanced paper-handling apparatus made the final paper placements. Note that six feeders are working on the near side of the machine and four on the other.

Not much is known of the details of Hoe’s manufacturing processes, but what is known suggests that they ran rather as Baldwin’s did. All makers of heavy equipment were necessarily major uses of power-assisted machinery, much of it made in their own factories, as it was with Baldwin and Corliss. Precision requirements were increasing in all branches of industry, and a machine like Hoe’s Ten Cylinder press included thousands of small parts and had to be exquisitely calibrated to maintain proper print registers at speed. Hoe also developed its own large-form depthing micrometer for precise manufacturing measurements, which put them in the forefront of the gauging movement.

60 Because of their scale and complexity, major products did not lend themselves to mass-production engineering. Like a locomotive, each big press would be custom-built, but with considerable standardization of key parts to simplify servicing and maintenance.

R. Hoe & Co. was a dominant player in large-scale printing through the rest of the century; among its many other innovations, it invented the first newspaper-folding presses. Almost weirdly, it never dropped the saw business that the senior Hoe and the Smiths had picked up in the company’s earliest days. Mocking any business-school notion of “focus,” Hoe was a major competitor in large industrial saws well into the twentieth century.

61

BUT THE NORTHEAST WAS HOME TO ANOTHER STREAM OF INDUSTRIAL development : the true armory practice tradition of mass production of complex, high-precision products, with special-purpose machinery and high-precision hand finishing to such a level of accuracy that parts can be freely interchanged from one unit to the other. In mid-century, the exemplar of armory practice was Samuel Colt’s great gun-making plant in Hartford. The British discovery of Colt and of armory practice manufacturing, and their decision to purchase American arms-making equipment for their own military, marked the first recognition by influential Britons that the United States was proceeding about its business in some quite original ways.