Plant By-Products and Food Industry Waste: A Source of Nutraceuticals and Biopolymers

Abstract

Processing of plant materials for food and feed production leads to a significant amount of by-products and biowastes, which are potential sources of nutraceuticals, biopolymers, and biofuels. The waste produced during processing can be rich in oil, carbohydrates, proteins, and other nutritional components. Researchers are increasingly exploring the utilization of by-products, to prevent pollution and related adversities. In past decades, plant by-products have been established as a source of nutraceutical components, including dietary fibers, phenolics, and many other compounds. Scientists have also explored plant by-products and the wastewaters of the food industry as the cheap feedstocks of a variety of biopolymers. This chapter summarizes the different plant by-products and food industry wastes explored for nutraceutical and bioplastic production, with the diverse technologies applied for that purpose, which in the future can decrease pollution and generate employment opportunities.

Keywords

1. Introduction

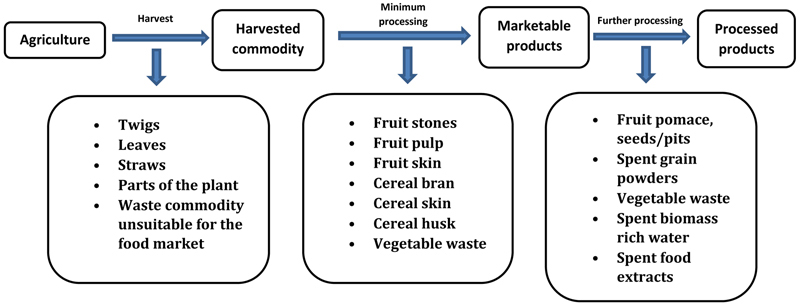

2. By-products and Wastes

3. Nutraceutical

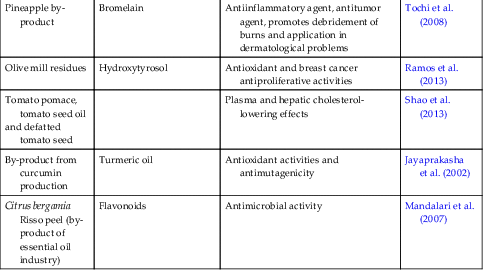

Table 8.1

Various by-products, with nutraceutical components and corresponding beneficial effects.

| By-Products | Nutraceuticals | Beneficial Effects | References |

| Wheat bran | Dietary fibers | Protection against colon cancer | Alabaster et al. (1997) |

| Oat bran | Dietary fibers | Reduce serum cholesterol due to its capacity to bind bile acid; constipation management; increased bioavailability of Vit B12 | Drzikova et al. (2005); Sturtzel et al. (2010) |

| Citrus peel | Dietary fibers | Reduction of both serum total and high density lipoprotein-cholesterol levels | Wisker et al. (1994) |

| Mango and peach juice industry by-products | Soluble and insoluble dietary fibers, polyphenols, carotenoids, phytosterols, saponins | Reduced hyperglycemia; reduction of hepatic steosis; decrease the activity of α-amylase | Amaya-Cruz et al. (2015) |

| Guava juice industry by-products | Insoluble dietary fibers, phytosterols, saponins | Decreased the rate of body weight gain; reduction of hepatic steosis | Amaya-Cruz et al. (2015) |

| Apple juice industry by-product | Soluble dietary fiber, pectin | Lower cholesterol, delay gastric emptying; increase fecal excretion of steroids in rats | Leontowicz et al. (2001); Sembries et al. (2004) |

| Sugar beet pulp | Dietary fiber | Improve lipid metabolism | Leontowicz et al. (2001) |

| Cocoa powder | Phenolic compounds | Inhibit low density lipoprotein oxidation and atherogenesis | Baba et al. (2007) |

| Brassiaceae | Glucosinolates | Decrease in the occurrence of tumors in the reproductive organs and retardation of the growth of cancer cells | Jahangir et al. (2009) |

| Onion by-product | Fiber content | Decrease in serum lipid and total cholesterol increment, generally caused by high fat diet | Benítez et al. (2012) |

| Tomato peel, seeds, by-products | Phenols | Antioxidant and antimutagenic activities | Valdez-Morales et al. (2014) |

| Cherry by-product | Perillyl alcohol | Inhibit growth of mammary tumors; increased the apoptotic index approximately 10-fold in liver tumor cells | Mills et al. (1995) |

| Rice bran | Phytic acid | Suppression of colon carcinogenesis | Norazalina et al. (2010) |

| Rice bran | γ-Oryzanol | significantly lower mass of tumor | Kim et al. (2012) |

| Rice bran, palm oil | Tocotrienol rich fraction of oil | Hypoglycemic and nephroprotective effects | Siddiqui et al. (2010) |

| Corn wet milling by-products | Low molecular weight peptides | Antihypertensive effects in vivo and in vitro | Lin et al. (2011) |

| Soymilk industry by-product | Bioactive peptide | Angiotensin-converting enzyme inhibition and multifunctional antioxidant activities |

Jiménez-Escrig et al. (2010) |

| Pineapple by-product | Bromelain | Antiinflammatory agent, antitumor agent, promotes debridement of burns and application in dermatological problems | Tochi et al. (2008) |

| Olive mill residues | Hydroxytyrosol | Antioxidant and breast cancer antiproliferative activities | Ramos et al. (2013) |

Tomato pomace, tomato seed oil and defatted tomato seed |

Plasma and hepatic cholesterol-lowering effects | Shao et al. (2013) | |

| By-product from curcumin production | Turmeric oil | Antioxidant activities and antimutagenicity | Jayaprakasha et al. (2002) |

| Citrus bergamia Risso peel (by-product of essential oil industry) | Flavonoids | Antimicrobial activity | Mandalari et al. (2007) |

Table 8.2

Different by-products and corresponding beneficial components.

| By-Products | Beneficial Components | References |

| Cereal by-products | Dietary fibers | Elleuch et al. (2011) |

| Apple by-products (peel, pomace, seeds) | Pectin, polyphenolic compounds, dietary fiber powder | Kolodziejczyk et al. (2007); Schieber et al. (2003); Vasantha Rupasinghe et al. (2009) |

| Grape by-products (peel, seed, stem) | Grape seed oil, citric acid, methanol, ethanol and xanthan gum, polyphenolic compounds, dietary fibers | Chidambara Murthy et al. (2002); Deng (2011); Harsha et al. (2014); Krishnaswamy et al. (2013); Llobera and Cañellas (2007); Pinelo et al. (2005) |

| Lemon by-product (peel, seed, fruit pulp) | Dietary fiber, iron, phenolic compounds (Hesperedin), carotenoids | Gorinstein et al. (2001a); O’Shea et al. (2012) |

| Mango by-product (Kemel, Peel) | Dietary fiber, polyphenols, carotenoids, vitamin C and E, lipids, protein, enzymes, and pectin | Ajila et al. (2007, 2008, 2010); Sogi et al. (2013) |

| Orange by-product (seed, peel, fiber) | Dietary fiber, pectin, cellulose | Chau and Huang (2003); Maran et al. (2013) |

| Peach by-product (peel, kernel, stone) | Dietary fiber, phenolic content, carotenoids, peptides | Vásquez-Villanueva et al. (2015); Zhang (2014) |

| Apricot by-products (peel, kernel) | Dietary fiber, fat, protein, carotenoid | He and Liu (2013); Seker et al. (2010) |

| Carrot by-products (peels, pomace obtained after juice extraction) | Carotenoid, phenolics, dietary fiber | Roohinejad et al. (2014) |

| Cauliflower (floret, stem, leaves) | Nonstarch polysaccharides, phenolics (kaempferol and quercetin), glucosinolate (sinigrin) | Abul-Fadl (2012); Cabello-Hurtado et al. (2012); O’Shea et al. (2012) |

| Onion (skins, roots, two outer fleshy scales) | Dietary fiber, quercetin, biosugar | Benítez et al. (2012); Choi et al. (2015) |

| Potato by-product (peel, pulp, downstream waste) | Dietary fiber, Phenolic acids (Chlorogenic acid), water soluble polysaccharides | Schieber and Saldana (2009); Al-Weshahy et al. (2013); Jeddou et al. (2016); Wu et al. (2012) |

| Tomato by products (peel) | Dietary fiber, carotenoid (lycopene), phenolic compounds, umami taste amino acids, tocopherols, sitosterols | Herrera et al. (2010); Luengo et al. (2014); Perretti et al. (2013); Valdez-Morales et al. (2014); Zhang et al. (2015) |

| Banana by-products (peel) | Polyunsaturated fatty acid, carotenoid (β-carotene), starch, crude protein, crude fat, dietary fiber, essential amino acid, micronutrients, banana oil, phenolics | Anal et al. (2014); Mohapatra et al. (2010) |

| Brocolli by-products (leaves, stalks) | Glucosinolates, phenols, vitamin C, minerals, trace elements | Domínguez-Perles et al. (2010) |

| Camellia oleifera (fruit hull) | Phenols | Zhang et al. (2011) |

| Date by-products (syrup, press cakes, seed) | Carbohydrate, fat, protein, phenolics, dietary fiber | Al-Farsi et al. (2007) |

| Pomegranate by-product (seeds) | Tocopherol, aliphatic alcohol (including policosanol), squalene, phytosterols, and triterpene contents, linolenic acid |

Caligiani et al. (2010); Verardo et al. (2014) |

| Kenaf by-product (seed, leaf) | Protein, carbohydrate, Mg, K, P, phenolic content | Chan et al. (2013) |

| Pineapple, acerola, cashew apple, guava, papaya, passion fruit, Surinam cherry | Carotenoid, phenolics | Da Silva et al. (2014) |

| wheat by-product | Wheat bran oil, vitamin E, carotenoids, quinones, lipids, and fatty acids |

Durante et al. (2012) |

| Cherry by-product | perillyl alcohol | Duarte et al. (2008) |

| Olive leaves | Secoiridoid oleuropein, secoiridoids, flavonoids, triterpenes | El Sedef and Karakaya (2009) |

| Olive oil processing by-product (alperujo) | Hydroxytyrosol, monosaccharides, oligosaccharides | Fernández-Bolaños et al. (2004); Ramos et al. (2013) |

| Rice by-product (husk, bran fiber, straw) | Cellulose, hemicellulose, lignin, phenolics, tocopherol, γ-oryzanol, peptide | Patel and Naik (2004) |

| Almond by-products (Shell, hull, skin) | Phenolics, xylo-oligosaccharides | Esfahlan et al. (2010) |

| Vigna mungo L. by-products | Dietary fiber, phenolic acids, proteins, carotenoids | Girish et al. (2012) |

| Barley by-products | Dietary fiber, protein, minerals, vitamins, amino acids | Gupta et al. (2010) |

| Flax processing waste (cuticle fragments, flax shives, processing dust) | Wax esters, long-chain fatty alcohols or policosanols | Buranov and Mazza (2010); Holser and Akin (2008) |

| Eggplant by-product | Anthocyanins | Todaro et al. (2009) |

| Peanut (skin) | Phenolics | Ballard et al. (2010) |

| Ipomoea batatas by-product (leaves) | Phenolics | Song et al. (2011) |

| Corn starch industrial waste | Carbohydrate | Yoshida et al. (2010) |

| Corn wet milling by-products | Low molecular weight peptides | Lin et al. (2011) |

| Plum by-products (Seed) | Bioactive peptides | González-García et al. (2014) |

| Soymilk industry by-products | Bioactive peptides | Jiménez-Escrig et al. (2010); Stanojevic et al. (2013) |

| Canned bamboo shoots by-products | Bioactive peptides | Liu et al. (2013) |

| Hempseed protein | Bioactive peptides | Lu et al. (2010) |

| Pineapple latex and peel | Bromelain | Ketnawa et al. (2010, 2012) |

| Oil palm wastes | Carotenoids, phenolic compounds, sterols, tocols | Ofori-Boateng and Lee (2013) |

| Raspberry seeds | Tocopherols, fatty acids | Oomah et al. (2000) |

| Blueberry leaves | Polyphenols | Piljac-Žegarac et al. (2009) |

3.1. Classification of Various Nutraceutical Compounds

3.1.1. Dietary fibers

3.1.2. Protein, peptides, amino acids, and protein hydrolysates

3.1.3. Enzymes

3.1.4. Oils/essential oils/fatty acids

3.1.5. Polyphenols

3.1.6. Other components

3.2. Major Processing Methods for the Preparation of Nutraceuticals

3.2.1. Pretreatment steps

3.2.2. Extraction

Table 8.3

Various extraction methods applied for nutraceutical with respective benefits and drawbacks.

| Extraction Methods | Advantages | Drawbacks | References |

| Pressurized liquid extraction |

• Efficient as compared to solvent extraction

• Consumes less solvent

• Water and generally recognized as safe solvents can be efficiently applied

|

• Thermolabile compounds can be damaged due to high temperature

|

Gil-Chávez et al. (2013) |

| Subcritical water extraction |

• Water is under subcritical conditions

• Efficient method for both polar and nonpolar compounds

|

• Nature of the different target compounds might change due to the exposure to high temperature water

|

Gil-Chávez et al. (2013) |

| Super critical CO2extraction |

• CO2 is nontoxic, nonflammable, noncorrosive, cheap, recyclable

• Highly efficient

• Efficient for extraction of nonpolar compounds

• With addition of polar solvents, polar compounds can also be extracted

• Ideal for thermosensitive molecules

• Inactivates microorganism.

• Rancidity development is prevented, due to no oxygen contact

• Gives solvent free extracts

|

• Needs dry samples as water content of the samples can adversely affect the efficiency

• Is not efficient for the extraction of very polar compounds

|

Durante et al. (2012); Routray and Orsat (2012) |

| Pulsed electric field extraction |

• Effective nonthermal method of extraction

|

Azmir et al. (2013) | |

| Microwave extraction |

• Efficient method of extraction

• Less solvent consumption

• Less time consumption

• Better quality of extracts

|

• Further research required for pilot-scale production

|

Routray and Orsat (2012) |

3.2.3. Separation/purification

3.2.4. Encapsulation

4. Biopolymer-Based Products

4.1. Processing Techniques to Manufacture Biopolymer-Based Products

4.2. Different Biopolymers and Their Sources

4.2.1. Biofibers and polysaccharides

4.2.2. Proteins

4.2.3. Oils

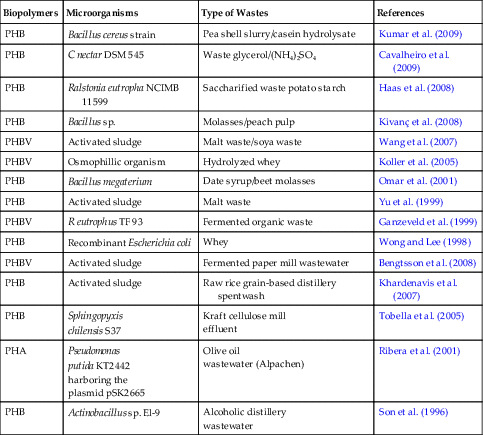

4.2.4. Microbial resources and waste

Table 8.4

Various biopolymers with respective source of nutrient (type of waste) and the source of microorganisms.

| Biopolymers | Microorganisms | Type of Wastes | References |

| PHB | Bacillus cereus strain | Pea shell slurry/casein hydrolysate | Kumar et al. (2009) |

| PHB | C nectar DSM 545 | Waste glycerol/(NH4)2SO4 | Cavalheiro et al. (2009) |

| PHB | Ralstonia eutropha NCIMB 11599 | Saccharified waste potato starch | Haas et al. (2008) |

| PHB | Bacillus sp. | Molasses/peach pulp | Kivanç et al. (2008) |

| PHBV | Activated sludge | Malt waste/soya waste | Wang et al. (2007) |

| PHBV | Osmophillic organism | Hydrolyzed whey | Koller et al. (2005) |

| PHB | Bacillus megaterium | Date syrup/beet molasses | Omar et al. (2001) |

| PHB | Activated sludge | Malt waste | Yu et al. (1999) |

| PHBV | R eutrophus TF 93 | Fermented organic waste | Ganzeveld et al. (1999) |

| PHB | Recombinant Escherichia coli | Whey | Wong and Lee (1998) |

| PHBV | Activated sludge | Fermented paper mill wastewater | Bengtsson et al. (2008) |

| PHB | Activated sludge | Raw rice grain-based distillery spentwash | Khardenavis et al. (2007) |

| PHB | Sphingopyxis chilensis S37 |

Kraft cellulose mill effluent |

Tobella et al. (2005) |

| PHA | Pseudomonas putida KT2442 harboring the plasmid pSK2665 |

Olive oil wastewater (Alpachen) |

Ribera et al. (2001) |

| PHB | Actinobacillus sp. El-9 | Alcoholic distillery wastewater |

Son et al. (1996) |

Source: From Mumtaz, T., Yahaya, N.A., Abd-Aziz, S., Yee, P.L., Shirai, Y., Hassan, M.A., 2010. Turning waste to wealth-biodegradable plastics polyhydroxyalkanoates from palm oil mill effluent: a Malaysian perspective. J. Clean. Prod. 18, 1393–1402.

PHA, Polyhydroxyalkanoate, PHB, polyhydroxybutyrate; PHBV: poly(3-hydroxybutyrate-co-3-hydroxyvalerate).

5. Biorefinery

6. Conclusions

Abbreviations

ACE Angiotensin-converting Enzyme

GC Gas chromatography

HPLC High-performance liquid chromatography

LDL Low-density lipoprotein

PHA Polyhydroxyalkanoate

PHB Polyhydroxybutyrate

PHBV Poly(3-hydroxybutyrate-co-3-hydroxyvalerate)

PLA Polylactic acid

PUFA Polyunsaturated fatty acid

UV Ultraviolet